Prediction method of seam penetration of underwater wet welding based on grey relational analysis

A grey relational analysis and wet welding technology, applied in the field of arc welding, can solve complex, time-consuming and cost-intensive problems, and achieve the effect of improving the welding process and saving manpower and material resources

Active Publication Date: 2022-07-15

HOHAI UNIV CHANGZHOU

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the underwater welding process involves more complex physical and chemical changes, and the factors affecting the welding process are also more complicated. Direct research will take a lot of time and cost. Therefore, a method is needed to simplify the underwater wet welding parameters. Establish a prediction model for underwater wet welding weld penetration to optimize welding process parameters and guide the formulation of underwater welding process parameters

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

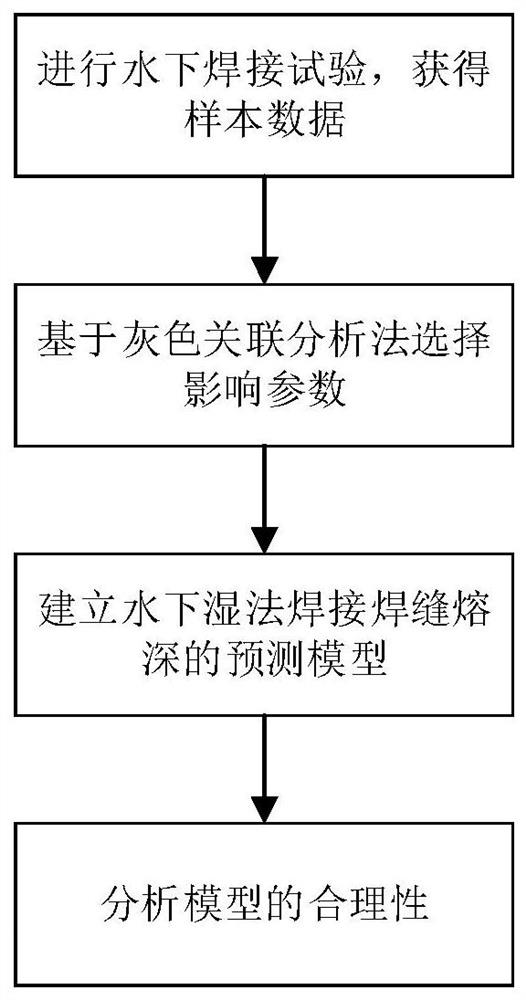

[0032] Example 1: as figure 1 As shown, the prediction method of weld penetration of underwater wet welding based on grey relational analysis includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

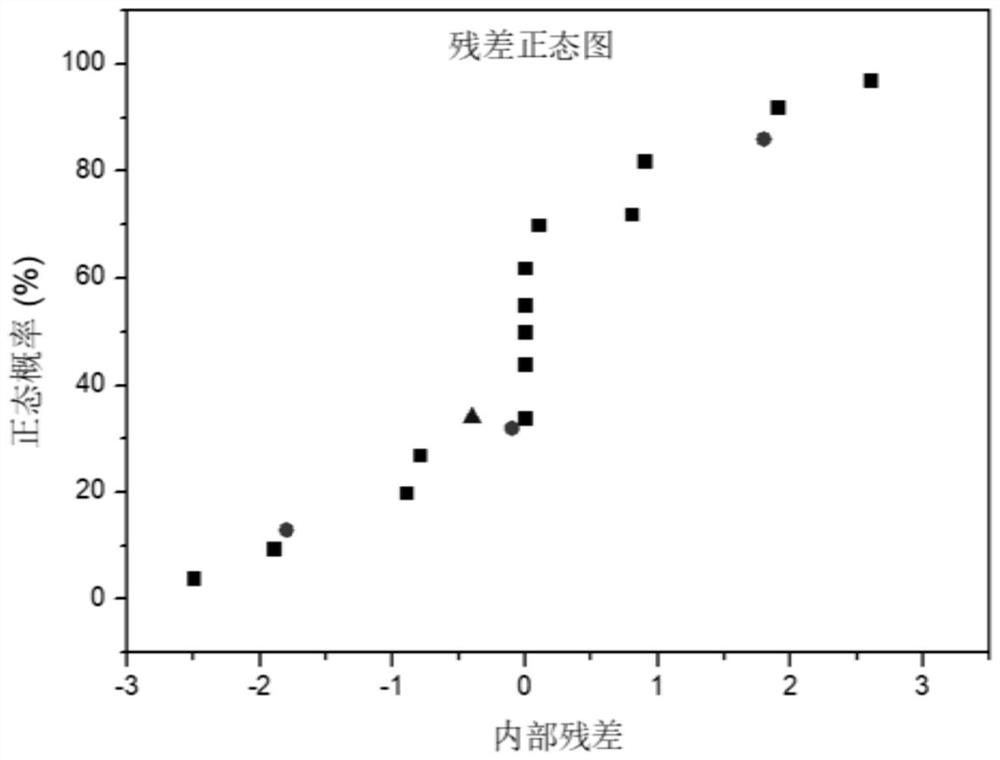

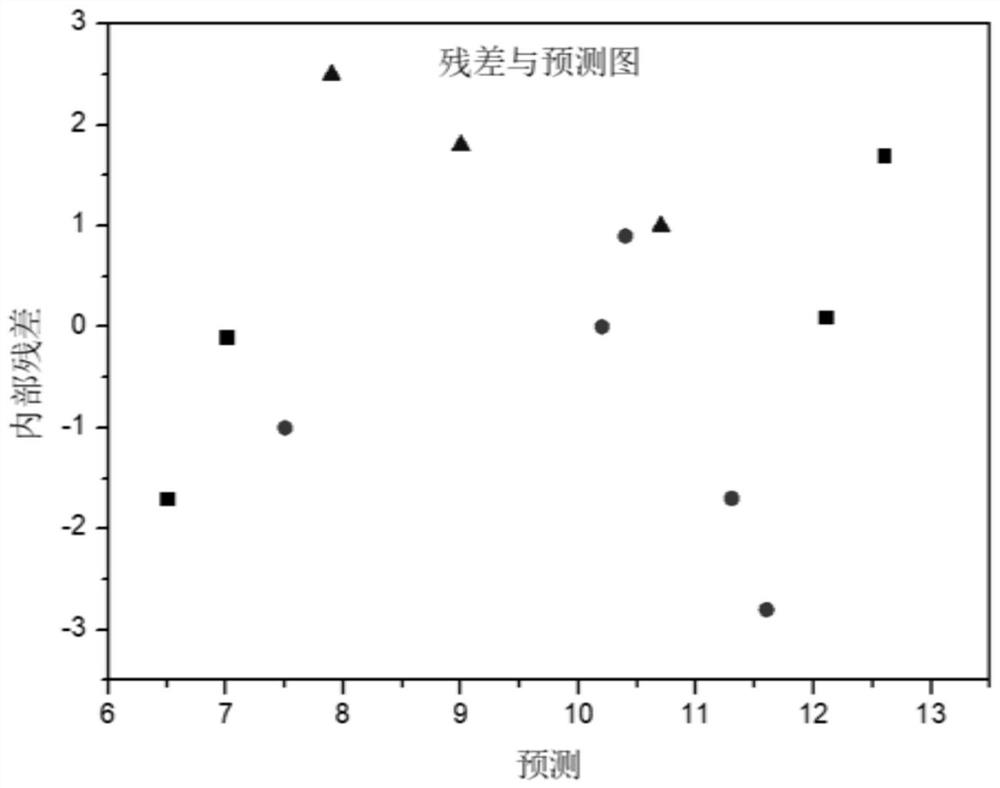

The invention provides a method for predicting the weld depth of underwater wet welding based on grey relational analysis. Measure to obtain sample data; Step 2: Select welding parameters with a high degree of influence on the penetration depth of underwater wet welding based on the grey relational analysis method; Step 3: Perform regression analysis on the sample data to establish the underwater wet welding seam Prediction model of penetration; Step 4: Analyze the established prediction model to verify the rationality of the model. According to the predicted penetration depth, the present invention obtains suitable welding parameters, thereby improving the welding process, saving manpower and material resources, and can effectively guide the actual underwater welding process.

Description

technical field [0001] The invention relates to a method for predicting the penetration depth of underwater wet welding seam based on grey relational analysis, and belongs to the field of arc welding. Background technique [0002] At present, underwater wet welding has obvious advantages in underwater engineering construction due to its wide application range and low cost. The geometric dimensions of underwater wet welding have a great impact on the mechanical properties of underwater welded structures. Predicting the geometric dimensions of underwater wet welding can guide the formulation of underwater welding process parameters. However, the underwater welding process involves more complex physical and chemical changes, and the factors affecting the welding process are also more complicated. Direct research will take a lot of time and cost. Therefore, a method is needed to simplify the parameters of underwater wet welding. The prediction model of the weld penetration of u...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K37/00B23K31/02

CPCB23K37/00B23K31/02

Inventor 严春妍易思张浩张可召姜心怡侯佳兵

Owner HOHAI UNIV CHANGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com