Passive cutting type bamboo chip wire drawing system

A cutting-type, bamboo-chip technology, applied in the direction of grinding drives, grinding machines, mechanical equipment, etc., to prevent cracks, reduce impact, and reduce power burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

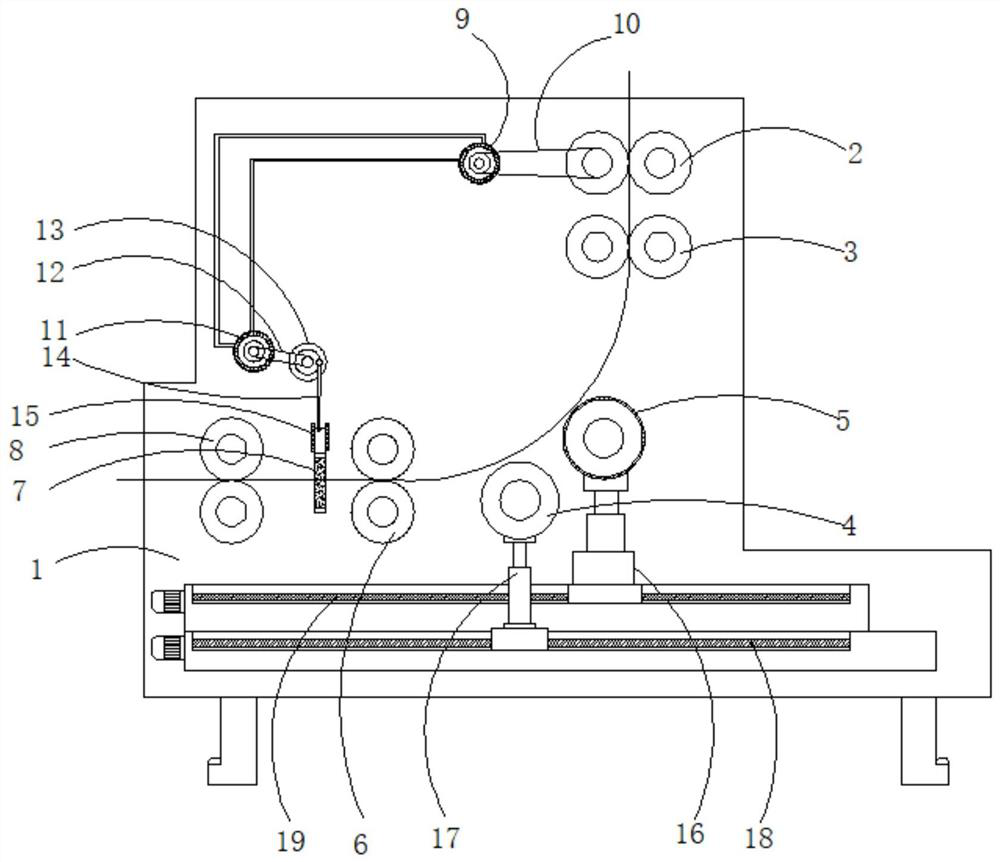

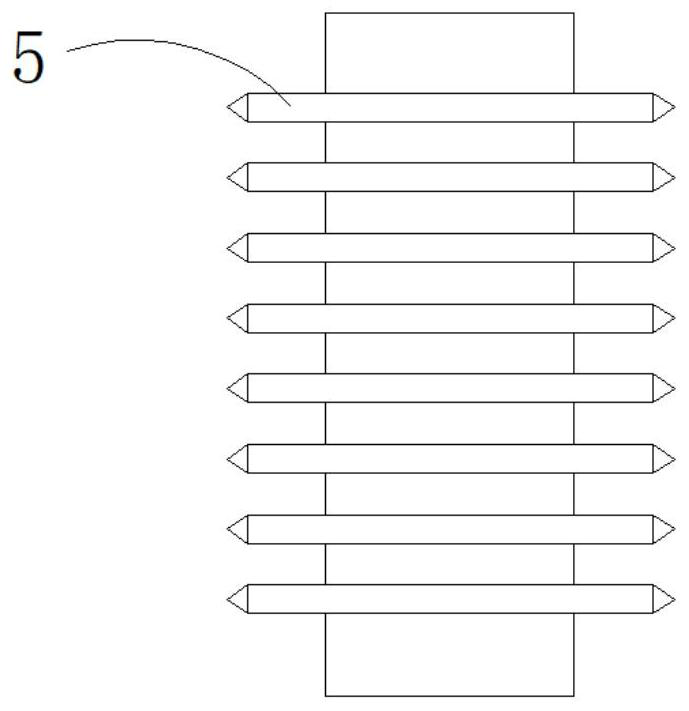

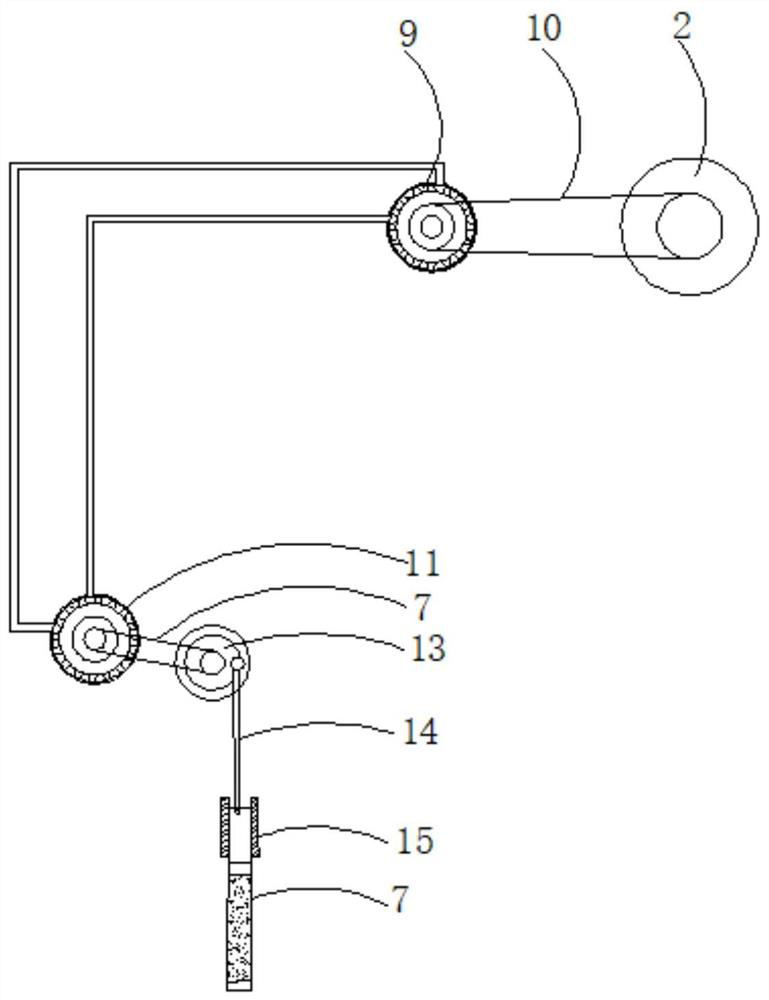

[0030] refer to figure 1 , the passive cutting bamboo chip wire drawing system includes a frame 1, a driving feed roller 2 for feeding bamboo chips and a fixed position, a guide roller 3 for introducing bamboo chips and a fixed position, and controlling the feeding direction of bamboo chips. Guiding roller 6 with movable position, positioning roller 4 for positioning the reasonable cutting position of bamboo slices, blade 5 for shredding bamboo slices and movable position, grinding sheet for grinding the edge of bamboo shreds and sliding position 7 and the discharge guide roller 8 that is used for bamboo chip discharging, described bamboo chip passes through driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com