Single-screw extruder

A single-screw extruder and screw technology, applied in the field of extruders, can solve the problems of easy adhesion of powder in the screw groove, poor mixing effect of powder, long residence time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

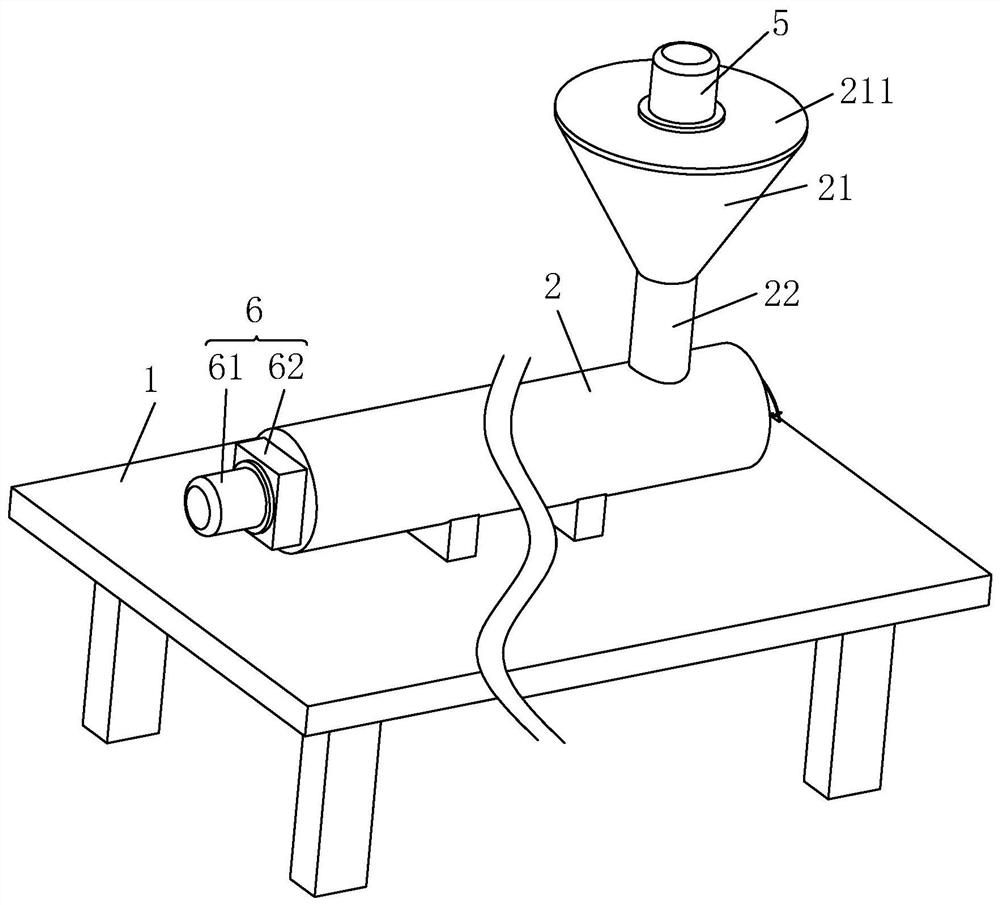

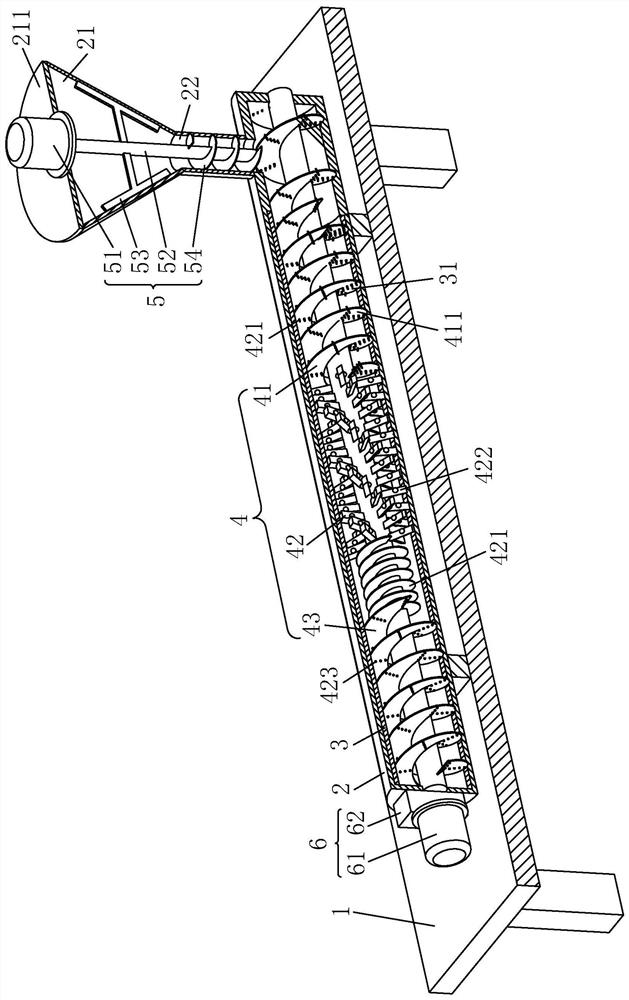

[0031] The following is attached Figure 1-2 The application is described in further detail.

[0032] The embodiment of the present application discloses a single-screw extruder. refer to figure 1 and figure 2 , a single-screw extruder includes a body 1, a horizontal barrel 2 is arranged on the body 1, a driving device 6 is arranged on one side of the barrel 2, a rotating cylinder 3 is arranged to rotate in the barrel 2, and a rotating cylinder 3 is fixed inside A screw 4 is provided, and the screw 4 is rotationally connected with the machine barrel 2 , and one end of the screw 4 is connected with the driving device 6 , and a feed hopper 21 is fixedly arranged on the machine barrel 2 , and the feed hopper 21 communicates with the inside of the rotating barrel 3 .

[0033] refer to figure 2 , the driving device 6 includes a driving motor 61 and a reduction box 62, the driving motor 61 and the reduction box 62 are fixedly arranged on the body 1, the output shaft of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com