A bumper bracket and a bumper assembly having the same

A bumper bracket and bumper technology, which is applied in the field of bumpers, can solve the problems of a wide range of areas, large joint areas, bumper impact, etc., and achieve the effects of strong rigidity, improved driving safety, and avoiding damage to tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

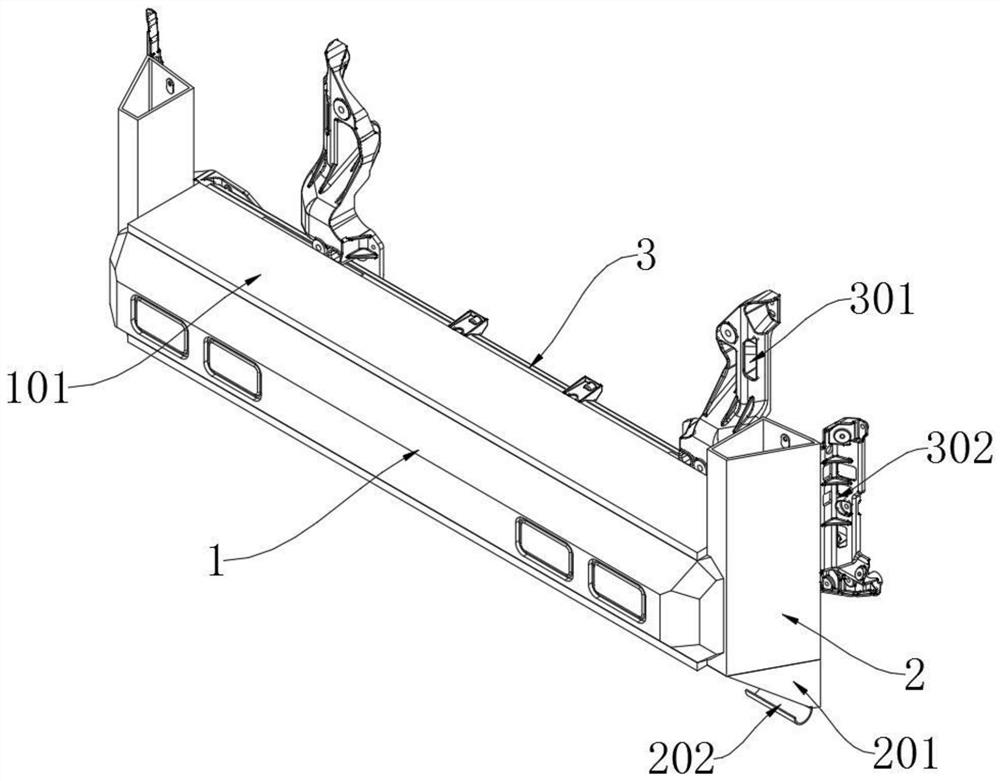

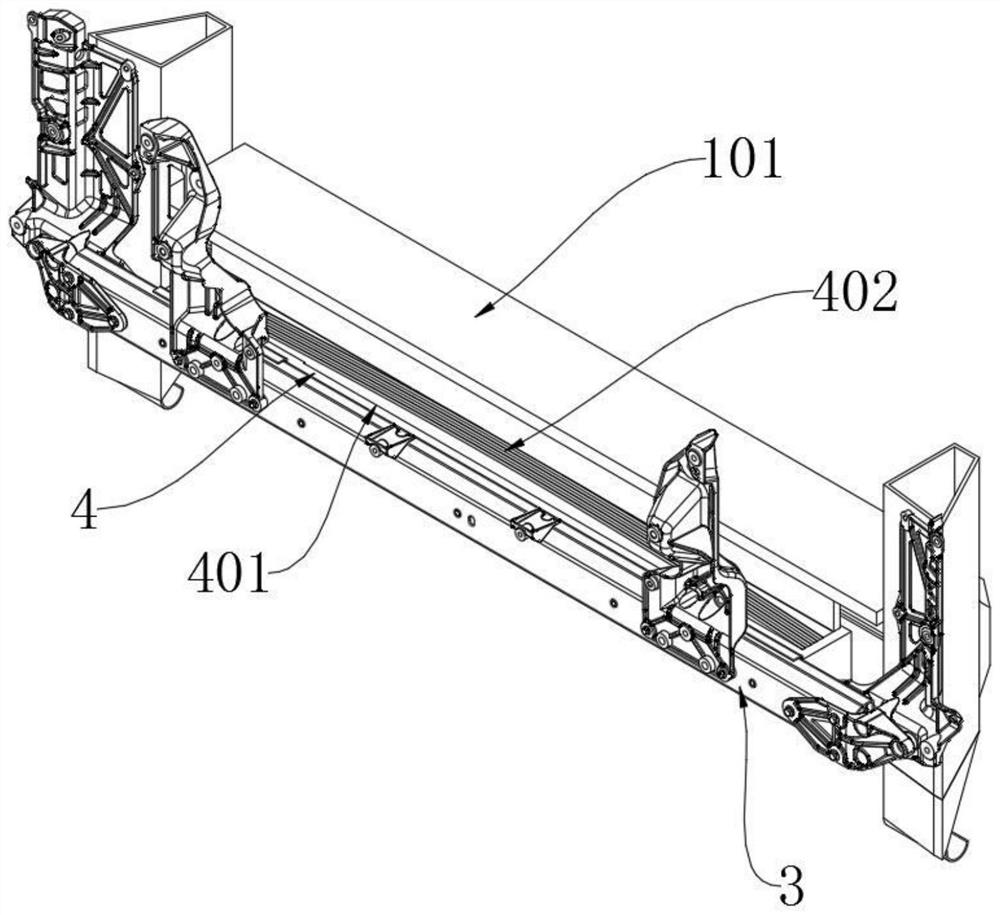

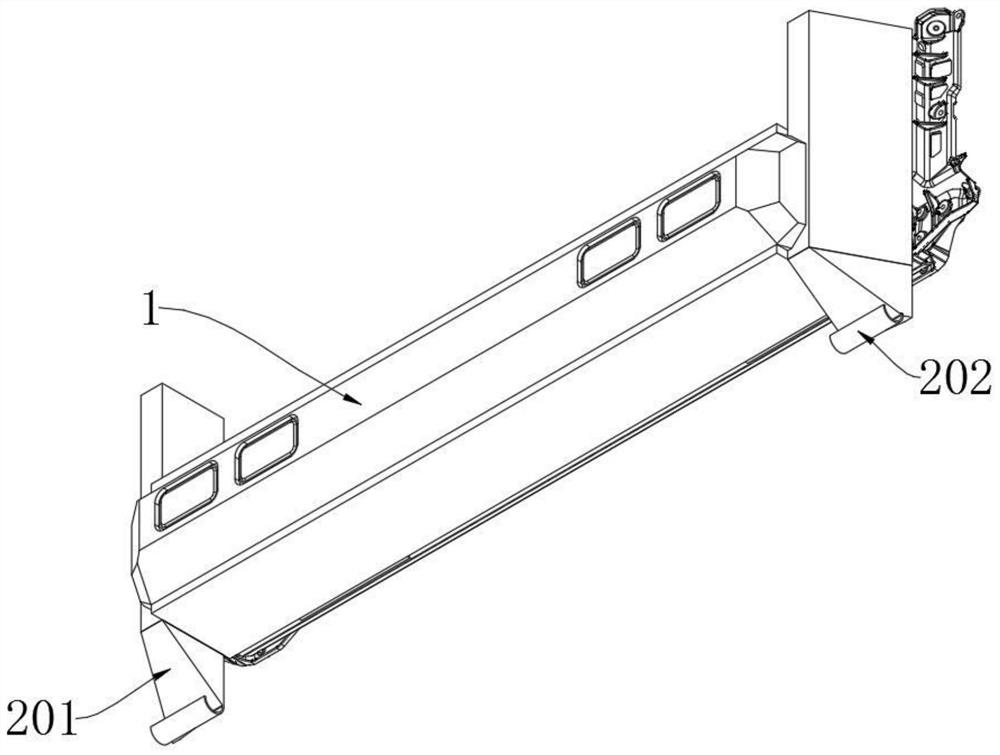

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036] The invention provides a bumper bracket and a bumper assembly thereof, including an energy-absorbing shell 1; the left and right ends of the energy-absorbing shell 1 are respectively fixed with vertical corner guards 2 by bolts; the corner guards The rear end of 2 is fixedly connected with the corresponding end of bumper bracket main body 3 by bolts; the front side wall of bumper bracket main body 3 is fixed with horizontal anti-collision mechanism 4 by bolts, and the anti-collision mechanism 4 The upper end and the lower end are clamped with the upper and lower inner walls of the energy-absorbing shell 1 respectively; the anti-collision mechanism 4 includes a mounting hole 401, an arched steel 402 and a clamping plate 403, and the middle part of the anti-collision mechanism 4 is provided with a rectangular mounting plate that penetrates up and down. Hole 401, in its mounting hole 401, arc-shaped arched steel 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com