Rail-changing wagon upper side bearing and rail changing method for standard-gauge rail and narrow-gauge rail

A railway freight car and standard rail technology, applied in the field of rail transportation, can solve the problems of time-consuming and laborious replacement, increase costs, etc., and achieve the effect of cost saving and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

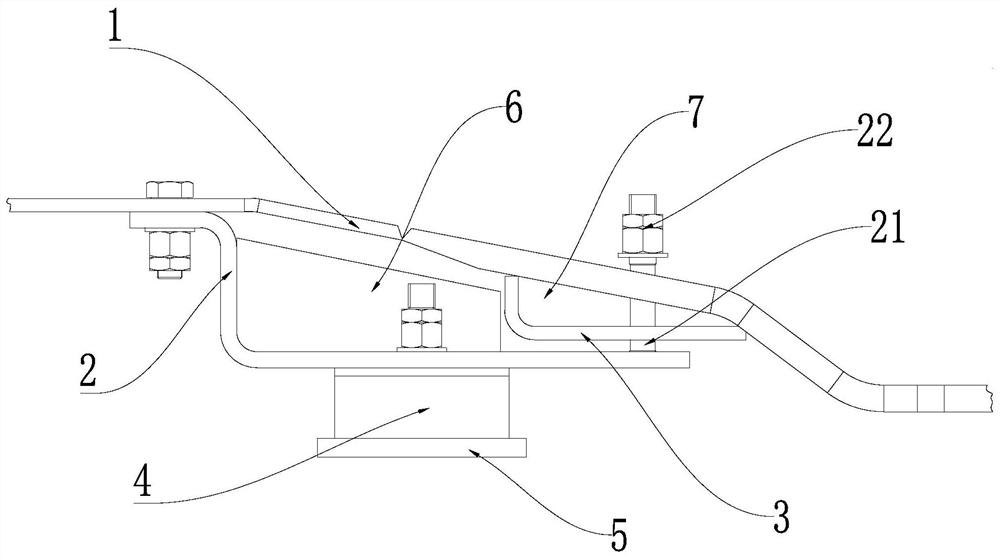

[0026] Example 1: See Figure 1 to Figure 3 , the upper side bearing of a kind of interchangeable railway freight car of the present embodiment, comprises the side bearing body 2 on the standard rail, the side bearing body 3 on the narrow rail, the adjustment backing plate 4 and the wearing plate 5; The side bearing body on the standard rail 2 is set under the lower corbel cover 1, the corbel lower cover 1 is used to receive the car body, the corbel lower cover 1 is a fixed part of the car body, and the side support body 2 on the standard rail One end is fixed on the corbel lower cover plate 1, and the other end is provided with the narrow rail upper side support body 3 and fixed under the corbel lower cover plate 1; the adjusting backing plate 4 is fixed on the quasi-rail Below the side support body 2 on the rail, the adjustment backing plate 4 is used to adjust the height of the side support body 2 on the quasi-rail, and the wear plate 5 is arranged at the bottom of the adju...

Embodiment 2

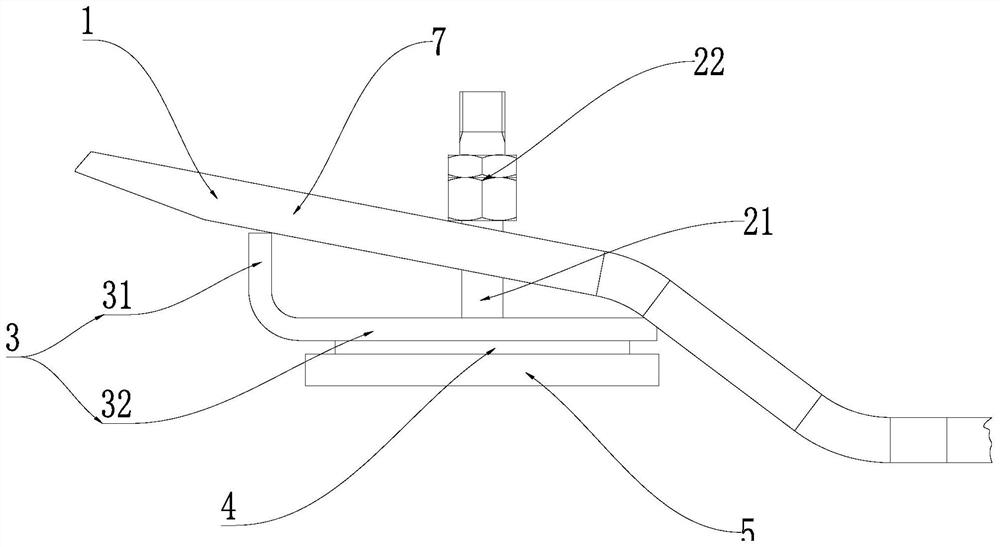

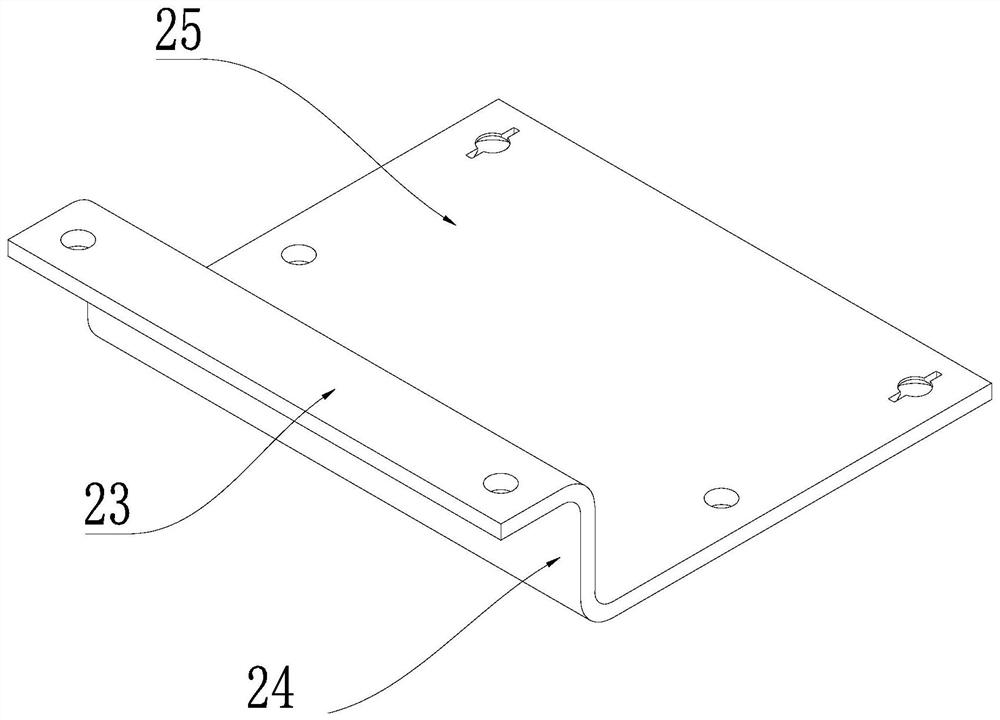

[0027] Example 2: see figure 1 , the side support body 2 on the quasi-rail of the present embodiment includes a first fixed plate 23, a first support plate 24 and a second fixed plate 25 connected in sequence, and the first fixed plate 23 and the second fixed plate 25 are respectively fixed on the corbel On the lower cover plate 1, the upper side support body 3 on the narrow rail is fixed between the second fixing plate 25 and the lower cover plate 1 of the corbel. The first fixing plate 23 of this embodiment and the lower cover plate 1 of the corbel are connected by bolts, the second fixing plate 25 is provided with studs 21 , the side support body 3 on the narrow rail is provided with the first screw hole, and the lower corbel The cover plate 1 is provided with a second screw hole, the stud 21 passes through the first screw hole and the second screw hole in turn, and the nut 22 is screwed into the stud 21, and then the side support body 3 on the narrow rail and the lower cov...

Embodiment 3

[0028] Example 3: See figure 1 , the side support body 3 on the narrow rail of this embodiment includes a third fixing plate 32 and a second supporting plate 31, the first screw hole is arranged on the third fixing plate 32, and one end of the third fixing plate 32 is connected to the second supporting plate 31 , the other end is used to resist the corbel lower cover 1 , and the end of the second support plate 31 away from the third fixing plate 32 is also resisted to the corbel lower cover 11 . In this embodiment, the third fixing plate 32 and the second supporting plate 31 are perpendicular to each other and have an integrated structure. The third fixing plate 32 is perpendicular to the second supporting plate 31, so that the bearing capacity of the third fixing plate 32 is stronger, and the stability of the overall structure of the side support body 3 on the narrow rail is ensured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com