Cooling ventilation simulation device and control method for high-altitude airborne equipment testing

A technology for cooling ventilation and airborne equipment, applied in aircraft component testing, control/regulation systems, non-electric variable control, etc., can solve problems such as uncontrollable temperature and flow, affecting test results, and failing to meet simulation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make those skilled in the art better understand the technical solutions of the present invention, the present application is described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present application. .

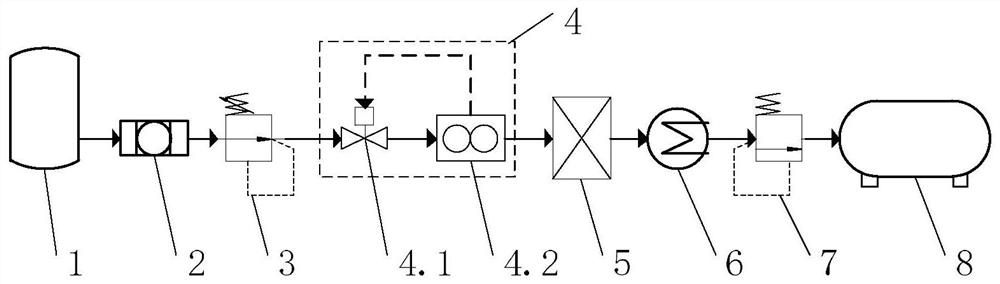

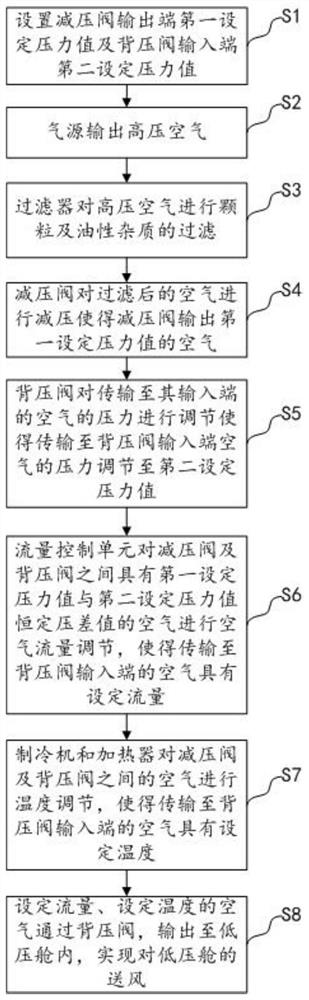

[0029] like figure 1 Shown is a schematic diagram of the first embodiment of the application. In this embodiment, the high-altitude airborne equipment is tested in the low pressure chamber 8. The ventilation device of the application includes: an air source 1, a filter 2, a The pressure valve 3 , the flow control unit 4 , the refrigerator 5 , the heater 6 and the back pressure valve 7 , the output end of the back pressure valve 7 is connected to the low pressure chamber 8 .

[0030] The air source 1 is used to output high-pressure air, the filter 2 is used to filter out particles and oily impurities in the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com