A method of metal conductive material combined with sludge pretreatment to promote methane production by anaerobic digestion of excess sludge

A technology of excess sludge and metal conductivity, applied in biological sludge treatment, waste fuel, etc., can solve problems such as low hydrolysis rate and low methane yield, achieve strong mechanical strength, high unit methane production rate, and promote residual pollution. The effect of anaerobic digestion of mud for methane production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

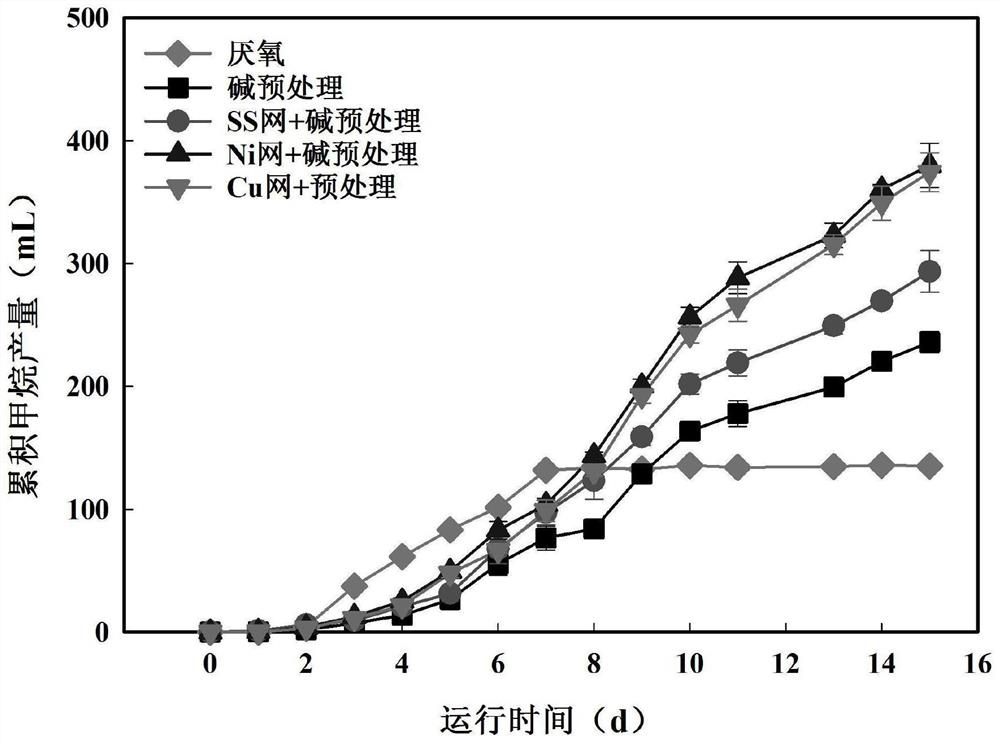

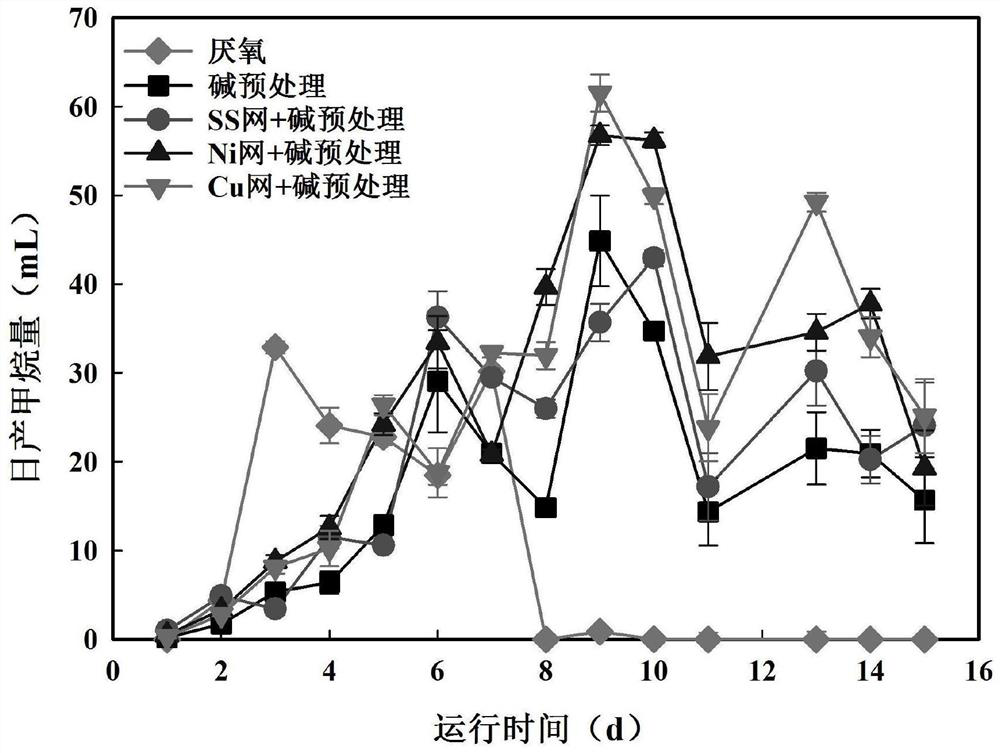

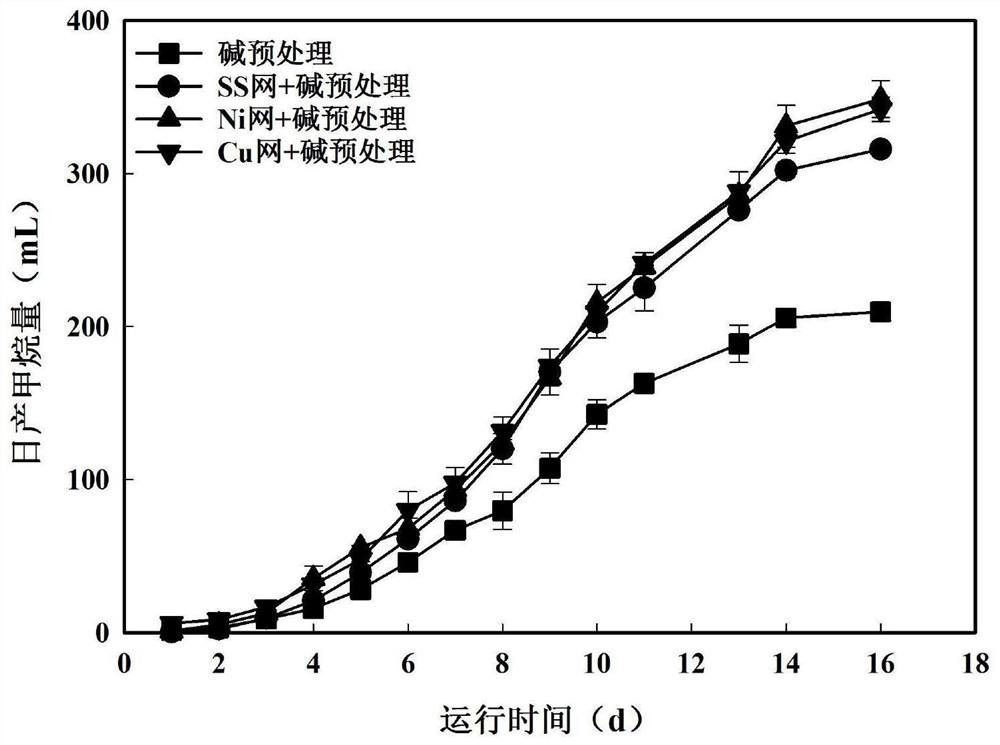

[0027] Example 1: In this example, the metal conductive material combined with the sludge pretreatment to promote the anaerobic digestion of excess sludge to produce methane is carried out according to the following steps:

[0028] Step 1. Pre-treatment of metal mesh: Take 200 mesh stainless steel mesh (SS-M), cut SS-M into 6.25mm×6.25mm pieces, and take the total area of 200cm 2 The SS-M fragments were soaked in HCl solution with a concentration of 5 mol / L for 24 h to remove the surface oxide film, washed with distilled water until neutral, and dried at 40 °C in a vacuum drying oven for use.

[0029] Step 2: Pretreatment of excess sludge: the excess sludge in the secondary sedimentation tank is naturally settled for 12 hours, the sludge concentration is adjusted to 12g / L after removing the supernatant, and the pH value is adjusted to 10-11 with 4mol / L NaOH solution. Adjust once every 10min for a total of 3 times, refrigerate at 4°C for use;

[0030] Step 3: Mix the SS-M tr...

Embodiment 2

[0034] Embodiment 2: The method for promoting methane production by anaerobic digestion of excess sludge by metal conductive material combined with sludge pretreatment in this embodiment is carried out according to the following steps:

[0035] Step 1. Pre-treatment of metal mesh: Take 200 mesh nickel mesh (Ni-M), cut the Ni-M into 6.25×6.25mm pieces, and take the total area of 200cm 2 The nickel mesh fragments were soaked in HCl solution with a concentration of 6 mol / L for 24 hours to remove the surface oxide film, washed with distilled water until neutral, and dried in a vacuum drying box at 40 °C for use.

[0036] Step 2. Pretreatment of excess sludge: the excess sludge in the secondary sedimentation tank is naturally settled for 24 hours, the sludge concentration is adjusted to 14g / L after removing the supernatant, and the pH value is adjusted to 10 with 6mol / L NaOH solution, every 10min Adjust once, adjust 3 times in total, and refrigerate at 4°C for later use;

[0037...

Embodiment 3

[0039] Embodiment 3: The method for promoting methane production by anaerobic digestion of excess sludge by metal conductive material combined with sludge pretreatment in this embodiment is carried out according to the following steps:

[0040] Step 1. Pre-treatment of metal mesh: Take 200 mesh copper mesh (Cu-M), cut the Cu-M into 6.25mm×6.25mm pieces, and take the total area of 200cm 2The nickel mesh fragments were soaked in HCl solution with a concentration of 6 mol / L for 24 hours to remove the surface oxide film, washed with distilled water until neutral, and dried in a vacuum drying box at 40 °C for use.

[0041] Step 2. Pretreatment of excess sludge: the excess sludge in the secondary sedimentation tank is naturally settled for 24 hours, the sludge concentration is adjusted to 14g / L after removing the supernatant, and the pH value is adjusted to 10 with 6mol / L NaOH solution, every 10min Adjust once, adjust 3 times in total, and refrigerate at 4°C for later use;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com