A method for resourceful treatment of waste water produced by Bic

A technology for producing wastewater and a treatment method, applied in the field of wastewater treatment, can solve problems such as uncontrollable synthesis and poor product quality, and achieve the effects of good universality, improved performance, and superior thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A 呔k produces wastewater resource processing method, including the following steps:

[0046] S1: Tempened the useful amount of wastewater containing the by-product of the 呔k production process to 50 ° C, distilled under -0.09 MPa, concentrated to the thick liquid viscosity of 800 MPa.s at 25 ° C, and cool down to 30 ° C ;

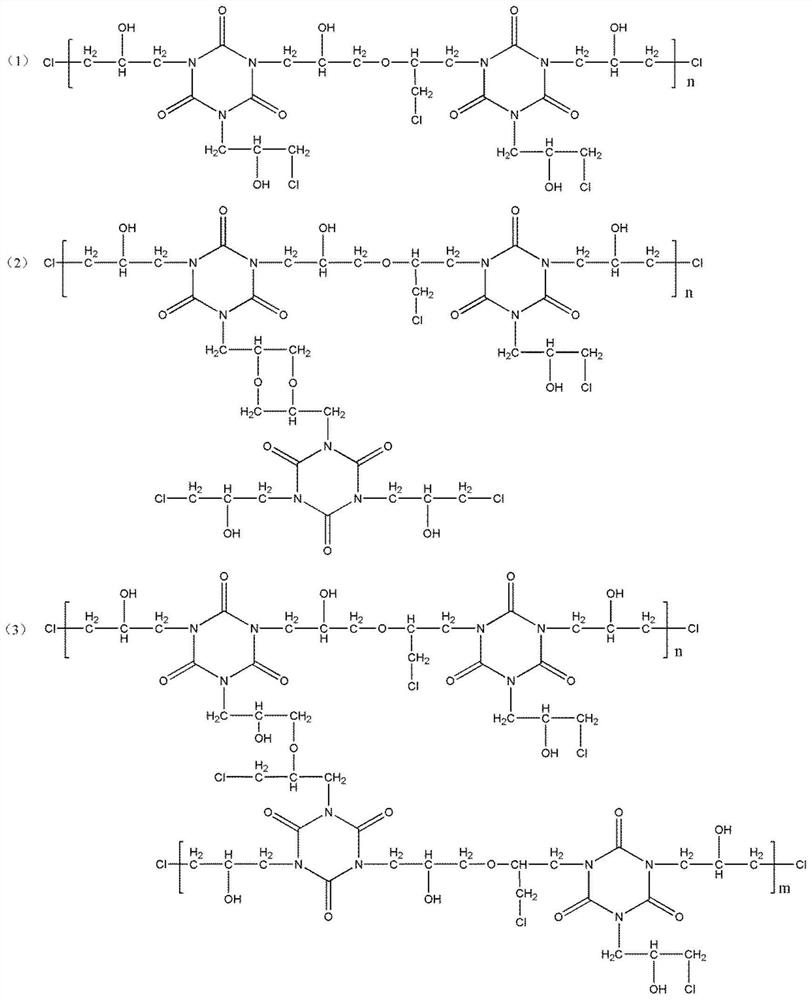

[0047] S2: Centrifugation of the thick liquid obtained in the S1 step, remove salt substances such as NaCl to obtain a pale yellow viscous polymer, spare, such as figure 1 The description, but is not limited to, various structural forms of Figure;

[0048] S3: Add 30g pale yellow viscous polymer, 60 g of polyether polyol 4100, 10 g of polyether polyols, 0.5 g of dietholamine, 0.02 g of triethylamine, 0.02 g of triamiacin, 0.05 g of acetate Potassium, 2G water, mix evenly gave component a;

[0049] S4: Add a certain amount of curing agent PM200 to the component a: The addition of the curing agent is 1: 1, immediately mechanically stirred 240s, stir evenly, ...

Embodiment 2

[0051] A 呔k produces wastewater resource processing method, including the following steps:

[0052] S1: The wastewater containing a by-product produced by the chick production process was heated to 50 ° C, distilled under -0.09 mPa, concentrated to a thick liquid viscosity at 25 ° C for 800 MPa.s, and cooled to 30 ° C;

[0053] S2: Centrifugation of the thick liquid obtained in the S1 step to remove salt substances such as NaCl to obtain a pale yellow viscous polymer, spare;

[0054] S3: 20g pale yellow viscous polymer, 70 g of polyether polyol 450, 10 g of polyether polyol PPG-2000, 0.5 g of polyether polyol PPG-2000, 0.5 g of polyether polyol, 0.02 g of ethylene glycol, 0.02 g of othiol , 1.5 g of triamia diamine, 2G water, mix evenly gave component a;

[0055] S4: Add a certain amount of curing agent to the component A, component A: The addition mass ratio of the curing agent is 1: 1, immediately mechanically stirred 240 s, stir uniform, immediately pour the mold to start foam,...

Embodiment 3

[0057] A 呔k produces wastewater resource processing method, including the following steps:

[0058] S1: The wastewater containing the by-product produced by the chick production process was heated to 50 ° C, distilled under -0.09 MPa, concentrated to a thick liquid viscosity at 25 ° C for 500 MPa.s, and cooled to 30 ° C;

[0059] S2: Centrifugation of the thick liquid obtained in the S1 step to remove salt substances such as NaCl to obtain a pale yellow viscous polymer, spare;

[0060] S3: Add 30g pale yellow viscous polymer, 60 g of polyether polyol 450, 10 g of polyether polyol 4110, 10.5 g of polyether polyol 4110, 10.5 g of ethylene glycol, 0.02 g of octoctate, 1.5 G trioxide diamine, 2G water, mix evenly gave component a;

[0061] S4: Add a certain amount of curing agent to the component a, component A: The addition of the curing agent is 1: 0.2, immediately mechanically stirred 180s, stir uniform, immediately poured into the mold to start foam, and finally obtained polyureth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com