A comprehensive treatment method for smelting smoke and dust containing miscellaneous gold concentrate

A technology for comprehensive treatment of gold concentrates, applied in chemical instruments and methods, iron compounds, process efficiency improvement, etc., can solve problems such as pollution, waste of valuable element resources and the environment, and achieve the promotion of hydrolysis reaction, improvement of recovery, process efficiency short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

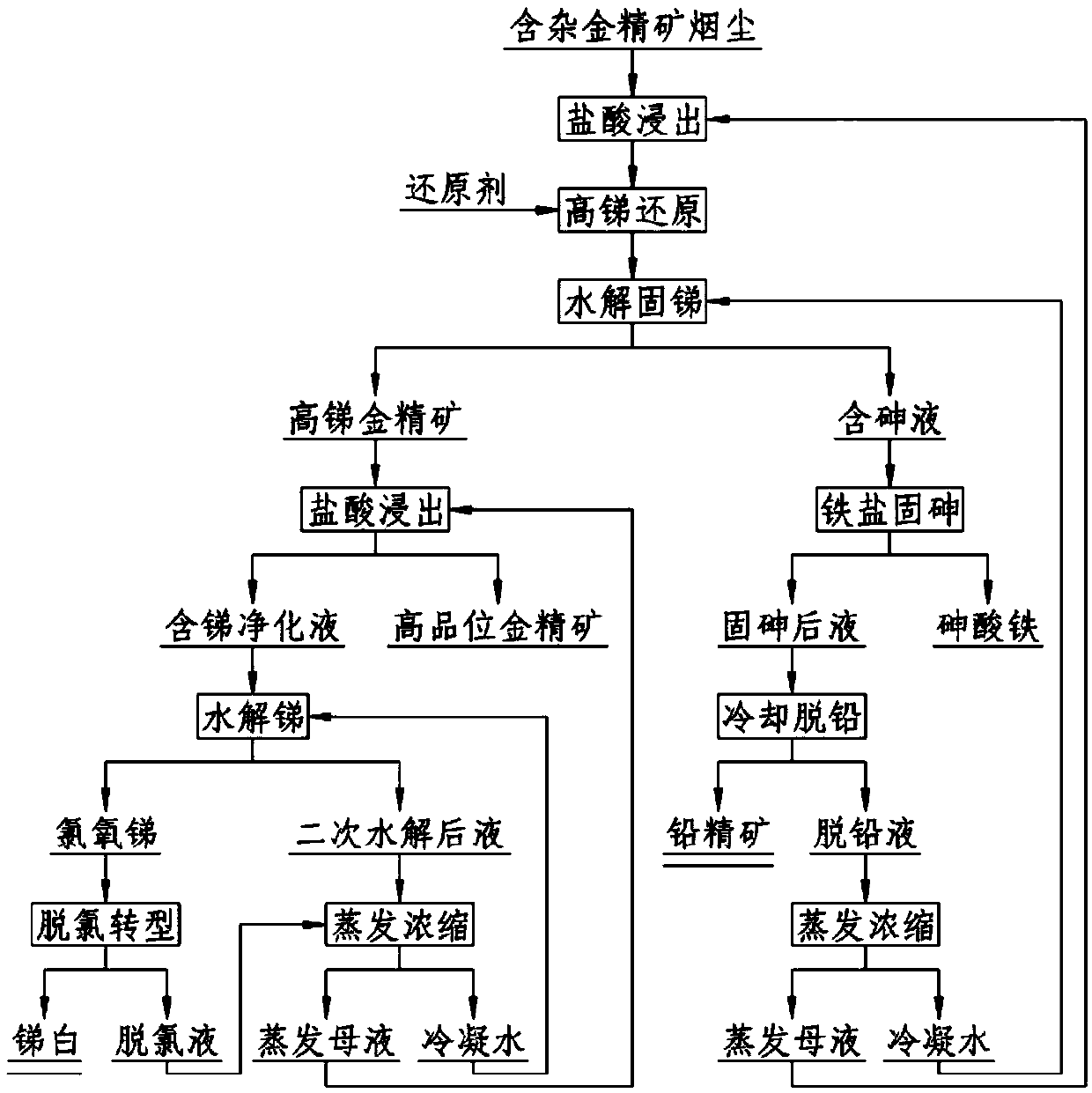

Method used

Image

Examples

Embodiment 1

[0062] The comprehensive processing method of the miscellaneous gold concentrate smelting dust of the present embodiment comprises the following steps:

[0063] Step 1. Enhanced leaching of smelting dust

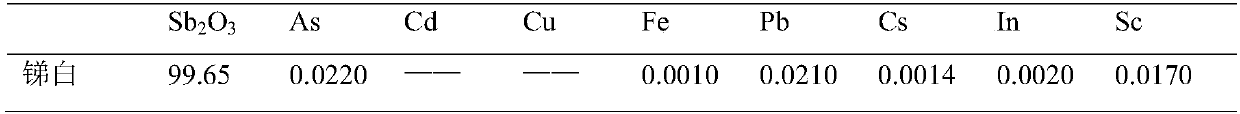

[0064] Add 500ml of 4mol / L hydrochloric acid into a 1L beaker, put it in a water bath to fix it and turn on the stirring, control the temperature of the water bath to 60°C, accurately weigh 100.00g of smelting dust containing gold concentrate and slowly add it to the beaker, stir and leaching for 1h, smelting The analysis results of the soot components are shown in Table 1. It can be seen from the table that the contents of antimony and arsenic in the soot to be treated are relatively high.

[0065] Step 2. Reduction of high-valent antimony in leaching pulp and hydrolysis of antimony

[0066] After the above reaction is completed, maintain the leached pulp temperature of 60°C and the mass ratio of leached liquid to solid, add 1.0g antimony powder and react for 0.5h, transfe...

Embodiment 2

[0080] The comprehensive treatment method for pyro-smelting dust of miscellaneous gold-containing concentrates of the present embodiment comprises the following steps:

[0081] Step 1. Enhanced leaching of smelting dust

[0082] Add 500ml of 8mol / L hydrochloric acid into an acid-resistant reaction vessel with a heating and stirring device, then accurately weigh complex gold concentrate smelting fume and slowly add it to the reaction vessel according to the liquid-solid mass ratio of 8:1, control the leaching temperature to 40°C, and stir Leach for 2h.

[0083] Step 2. Reduction of high-valent antimony in leaching pulp and hydrolysis of antimony

[0084] After the above reaction, maintain the leach pulp temperature and leach liquid-solid mass ratio, add antimony which is 1.2 times the stoichiometric number of pentavalent antimony to the leach pulp and react for 0.5h, then transfer the above pulp to a beaker, slowly add the total volume of leached pulp 4.0 Water at 25°C, hydro...

Embodiment 3

[0093] The comprehensive treatment method for pyro-smelting dust of miscellaneous gold-containing concentrates of the present embodiment comprises the following steps:

[0094] Step 1. Enhanced leaching of smelting dust

[0095] Add 500ml of 2mol / L hydrochloric acid into an acid-resistant reaction vessel with a heating and stirring device, then accurately weigh complex gold concentrate smelting fumes according to the liquid-solid mass ratio of 3:1 and slowly add them to the reaction vessel, control the leaching temperature to 85°C, and stir Leach for 0.5h.

[0096] Step 2. Reduction of high-valent antimony in leaching pulp and hydrolysis of antimony

[0097] After the above reaction, maintain the leach pulp temperature and leach liquid-solid mass ratio, add antimony with 1.1 times the stoichiometric number of pentavalent antimony to the leach pulp and react for 1.5h, then transfer the above pulp to a beaker, and slowly add the leach pulp with a total volume of 3.0 Water at 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com