Super high pressure booster centrifugal pump

A centrifugal pump, ultra-high pressure technology, applied in the direction of pumps, pump components, pump control, etc., can solve the problem that the pump cannot be used effectively as a series booster pump, to achieve enhanced rigidity, improved sealing effect, and reduced axial length effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

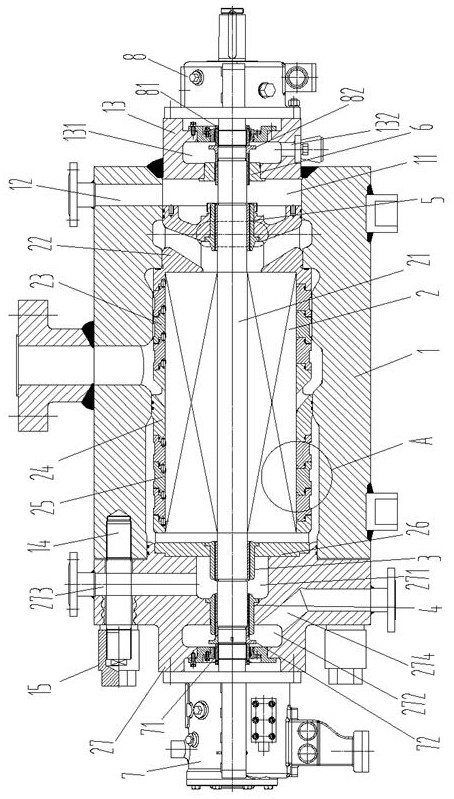

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

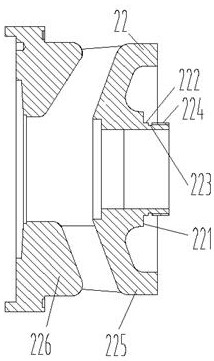

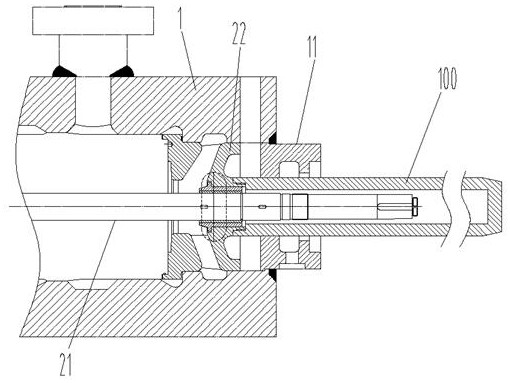

[0030] See figure 1, the ultra-high pressure booster centrifugal pump of the specific embodiment, the ultra-high pressure booster centrifugal pump, comprises a sleeve-shaped pump body 1, and an inner core assembly 2 is installed in the pump body 1 along its axial direction, and the inner core assembly 2 Including the pump shaft 21, the pump shaft 21 is provided with an impeller part and a pump cover 27, the impeller part is located in the pump body 1, and the impeller part includes a water inlet section 22 arranged in sequence along the axial direction of the pump shaft 21, a primary guide The flow section 23, the water outlet section 24, the secondary diversion section 25 and the high-pressure water inlet section 26, the pump cover 27 is fastened on one end of the pump body 1 and is located outside the high-pressure wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com