Semi-active shock absorber

A semi-active shock absorber and main valve core technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the high machining accuracy requirements of proportional electromagnets and the difficulty of localization of semi-active shock absorbers , damping characteristics can not be adjusted and other problems, to achieve the effect of reducing the processing accuracy requirements, continuous adjustment and control, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

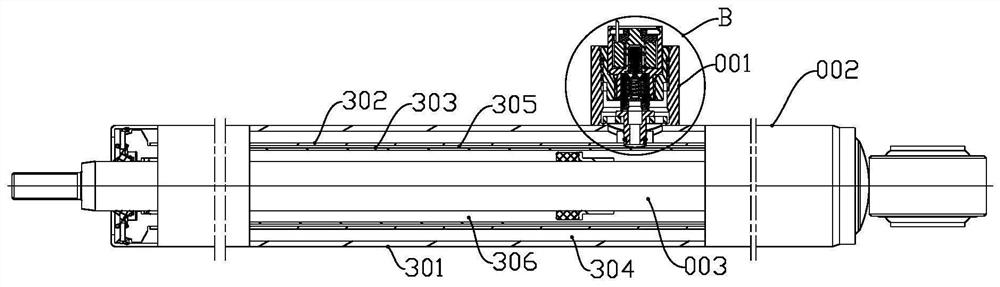

[0039] refer to figure 1 , the semi-active shock absorber in this embodiment includes an oil cylinder assembly 002, a connecting rod piston assembly 003, a bottom valve assembly and a digital proportional valve 001; wherein, the oil cylinder assembly includes an outer cylinder 301, an inner cylinder 302 and working cylinder 303, an oil storage cavity 304 is formed between the inner cylinder 302 and the outer cylinder 301, an intermediate cavity 305 is formed between the inner cylinder 302 and the working cylinder 303, and a working cylinder 303 is formed cavity 306 . The connecting rod piston assembly 003 is arranged in the working cylinder 303 , and the bottom valve assembly is arranged at one end of the inner cylinder 302 .

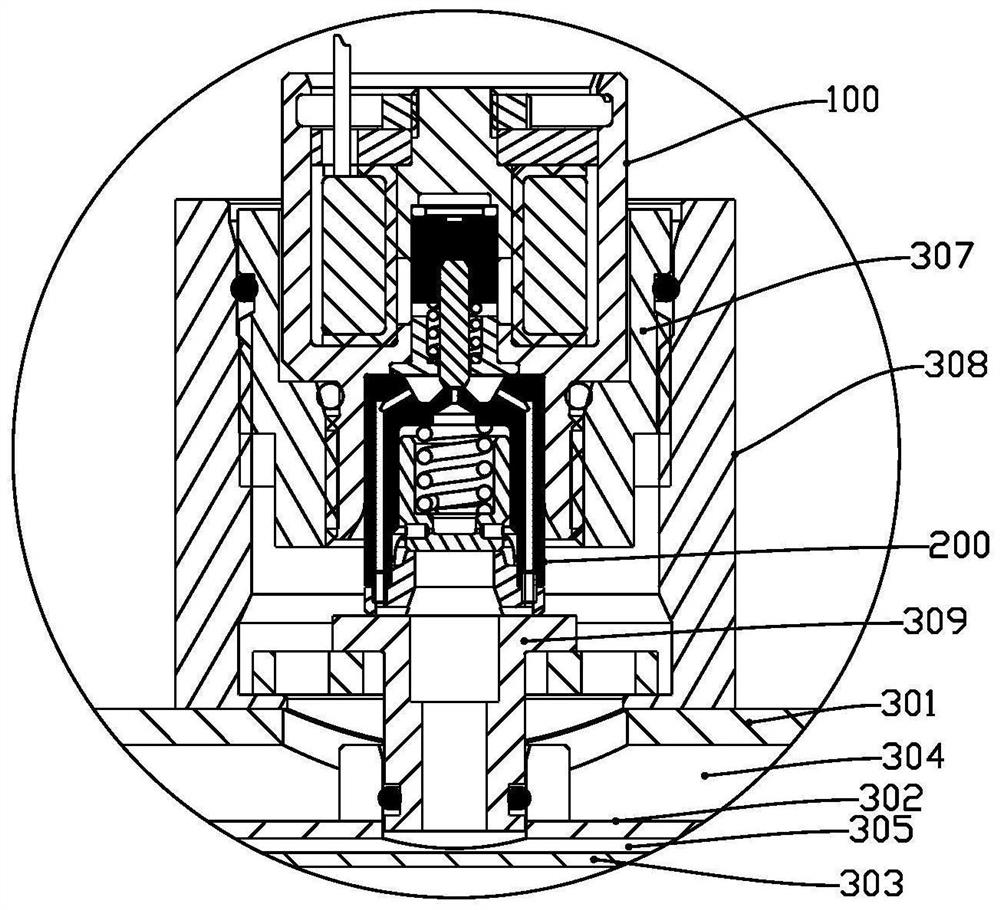

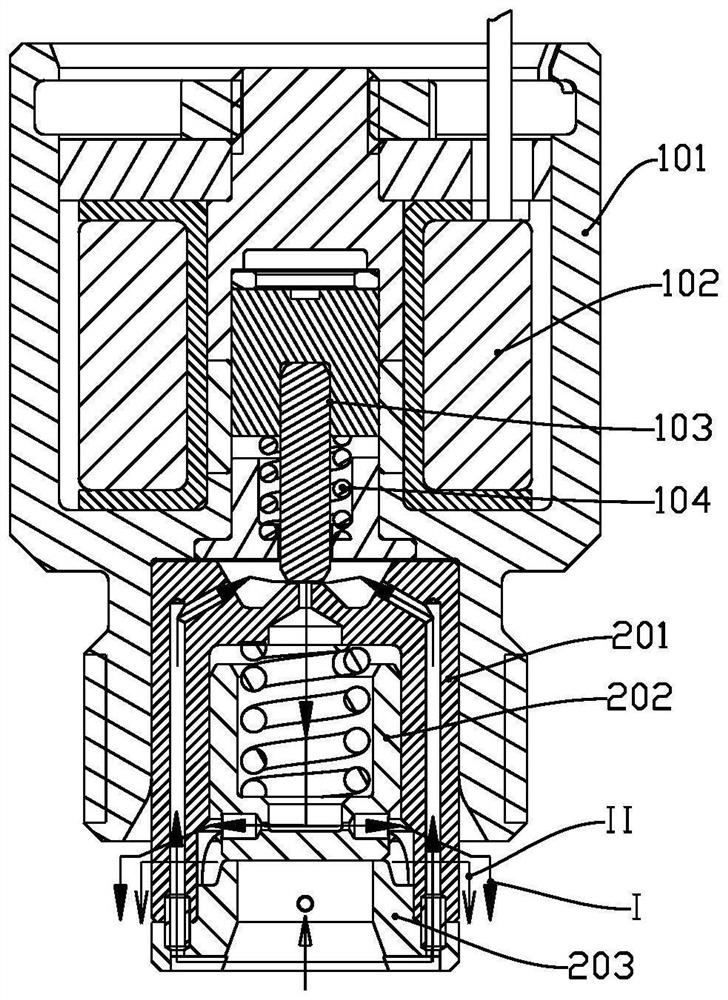

[0040] Such as figure 2 , 3 As shown in and 4, the digital proportional valve in this embodiment includes a switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com