Pipeline reconstruction sealing protective cover structure

A protective cover and pipeline technology, applied in the direction of engine seals, pipe components, pipes/pipe joints/fittings, etc., can solve problems such as leakage and achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

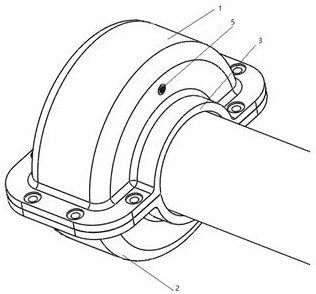

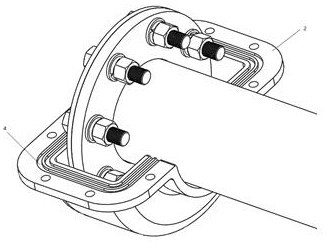

[0025]Such asfigure 1 figure 2 Shown: a pipeline reconstruction sealing protection cover structure, the pipeline reconstruction sealing protection cover is arranged at the end connection of a single pipe; it includes two shell structures, and the two shell structures are the pipeline reconstruction sealing protection cover The casing 1 and the pipeline are reconstructed with the lower casing 2 of the sealed protective cover.

[0026]The upper shell 1 of the pipeline reconstruction sealing protection cover and the lower shell 2 of the pipeline reconstruction sealing protection cover are both provided with a cavity structure for accommodating the connection of the pipeline, and the flange of the pipeline connection can be placed in the cavity structure; the pipeline reconstruction sealing protection A semi-cylindrical notch is opened on one end of the upper casing 1 and the lower casing 2 of the pipeline reconstruction sealing protection cover, and the upper casing 1 of the pipeline reco...

Embodiment 2

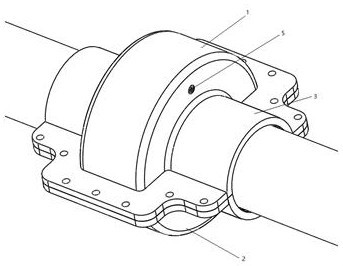

[0033]Such asimage 3 Figure 4Shown: a pipeline reconstruction sealing protection cover structure, the pipeline reconstruction sealing protection cover is set at the junction of two pipeline flanges; including two shell structures, and the two shell structures are the pipeline reconstruction sealing protection cover The casing 1 and the pipeline are reconstructed with the lower casing 2 of the sealed protective cover.

[0034]The upper shell 1 of the pipeline reconstruction sealing protection cover and the lower shell 2 of the pipeline reconstruction sealing protection cover are both provided with a cavity structure for accommodating the connection of the pipeline, and the flange of the pipeline connection can be placed in the cavity structure; the pipeline reconstruction sealing protection The upper shell 1 and the lower shell 2 of the pipeline reconstruction seal protection cover are provided with semi-cylindrical notches on both end faces, and the upper shell 1 of the pipeline recons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com