Method for measuring movable pulley positioning precision in ship lifting system

A lifting system and positioning accuracy technology, which is applied in the field of measurement of the positioning accuracy of the moving pulley in the ship lifting system, can solve problems such as the inability to accurately measure the parallelism and symmetry of the moving pulley, achieve stable take-off and landing, simple operation, and ensure installation and positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, the method for measuring the positioning accuracy of the movable pulley in the ship lifting system of the present invention specifically includes the following steps:

[0041] S1, install a three-dimensional steel wire debugging device 24 on the bulkhead near the hydraulic press plunger 18, and place a temporary bracket 20 on the ground at the other opposite side.

[0042] Specifically, a support plate 19 is welded on the bulkhead near the plunger 18 of the hydraulic press, and the three-dimensional steel wire debugging device is fixed on the support plate 19 .

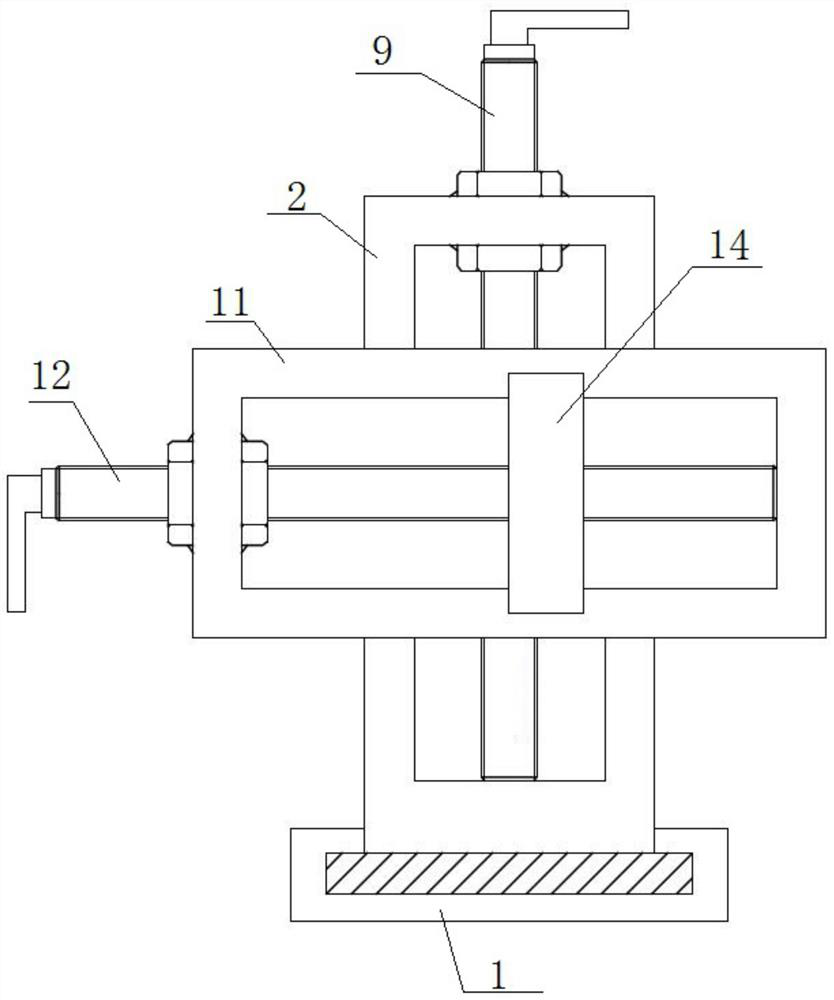

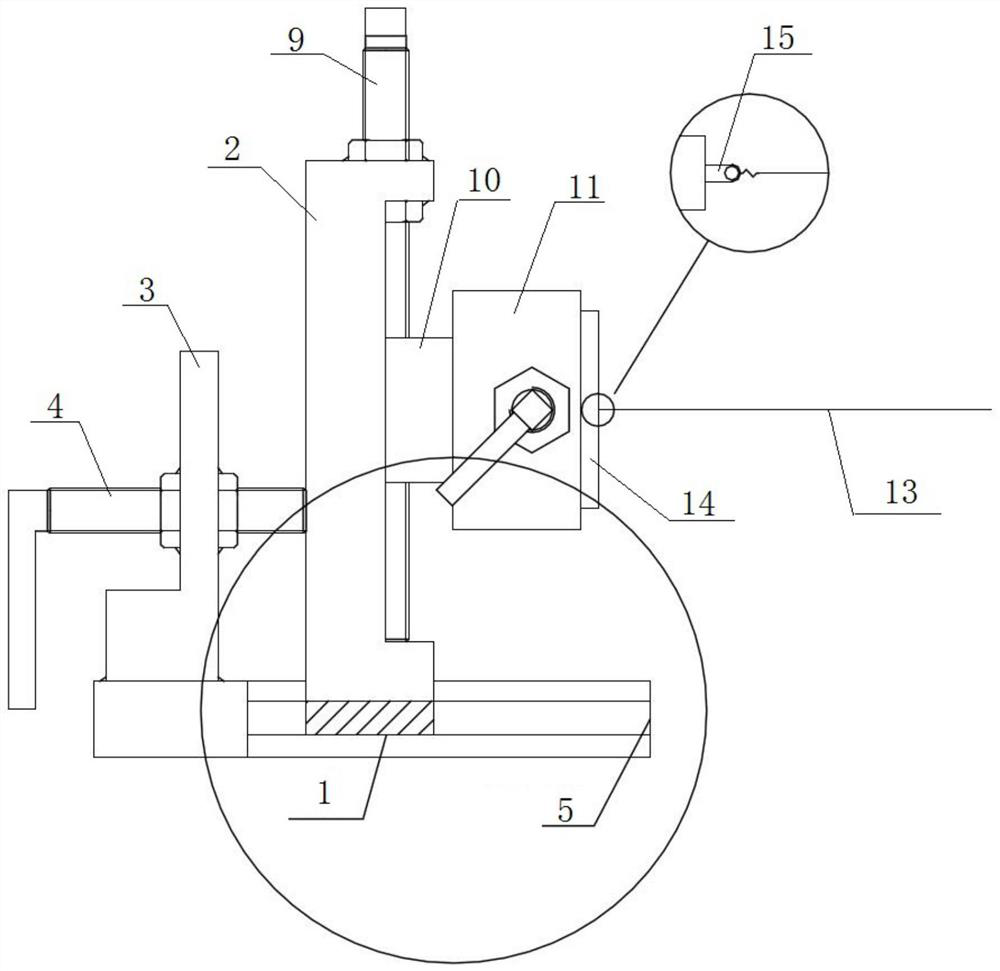

[0043] The three-dimensional steel wire debugging device includes a base 1, a longitudinal frame 2 movably arranged in the base 1, a support seat 3 fixed on the upper end surface of the base 1, and a support seat 3 arranged on the support seat 3 to adjust the longitudinal frame 2 on the base 1. The first adjustment mechanism 4 that moves in the length direction.

[0044] A rail groove 5 is opened...

Embodiment 2

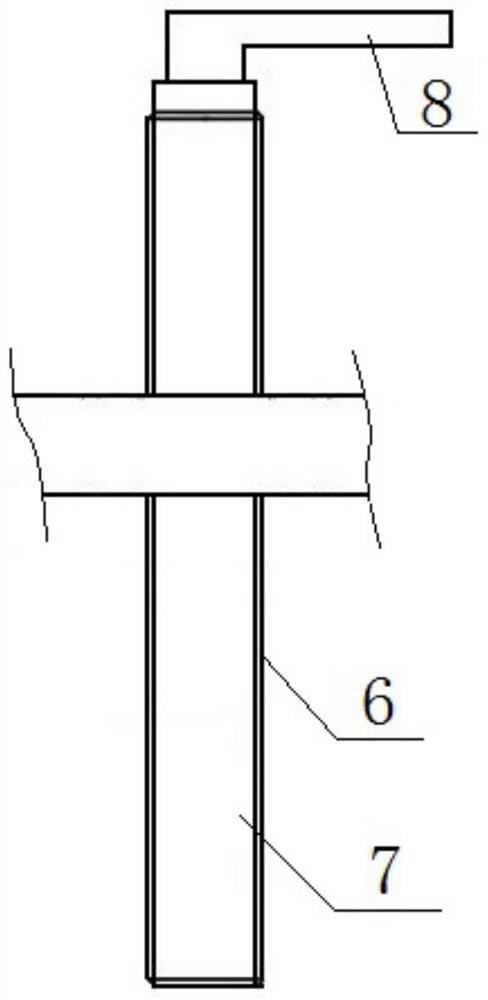

[0057] Embodiment 2, this embodiment is basically the same as Embodiment 1, the specific difference is that the first adjustment structure 4, the second adjustment mechanism 9 and the third adjustment mechanism 12 of the three-dimensional steel wire debugging device have the same structure, and all include nuts 23 , the screw rod 7 threadedly fixed with the nut 23, and the handle 8 fixed at the end of the screw rod 7.

[0058] Specifically, the nut 23 of the first adjustment mechanism 4 is welded and fixed on the front and rear end faces of the support base 19, and its screw rod 7 passes through the support base 3 and is threaded in the nut 23. By rotating the handle of the first adjustment mechanism 4, The screw rod of the first adjustment mechanism 4 can push the longitudinal frame 2 to slide in the guide rail groove 5 .

[0059] The nut of the second adjustment mechanism 9 is welded and fixed on the upper and lower end surfaces of the upper beam of the longitudinal frame 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com