Photoresist coating method and photoresist coating device

A coating device and coating method technology, applied in the field of photoresist coating method and device, can solve the problems of large wafer stress, uneven distribution of photoresist coating, poor coating of wafer edge, etc., to achieve Improved coating uniformity, reduced defects in edge distribution, and increased rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

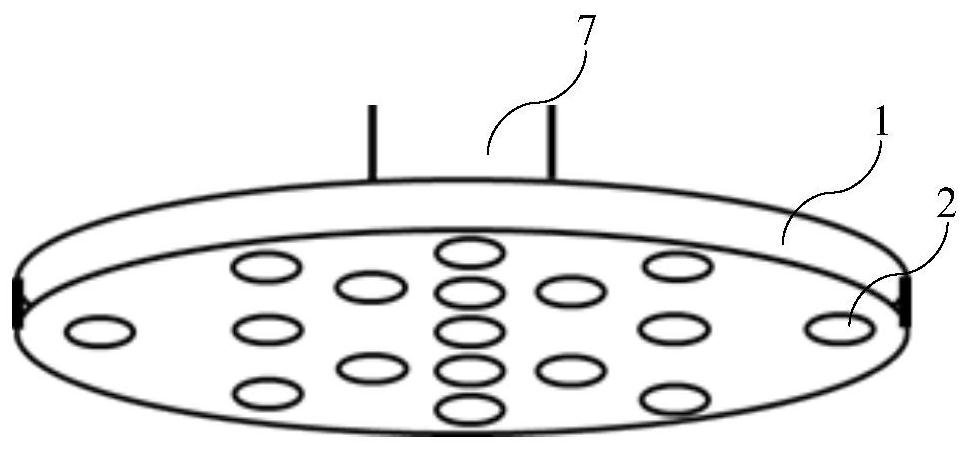

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

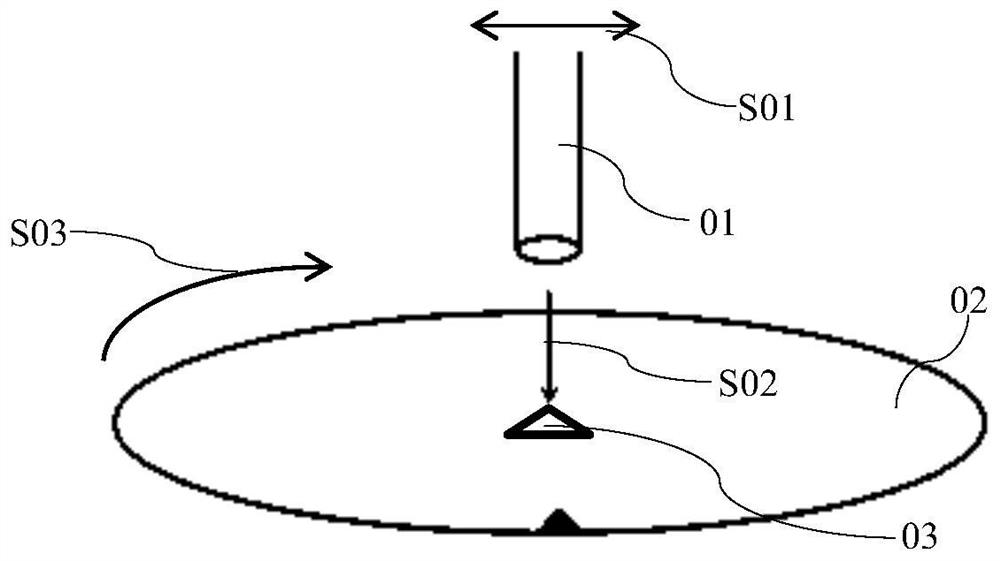

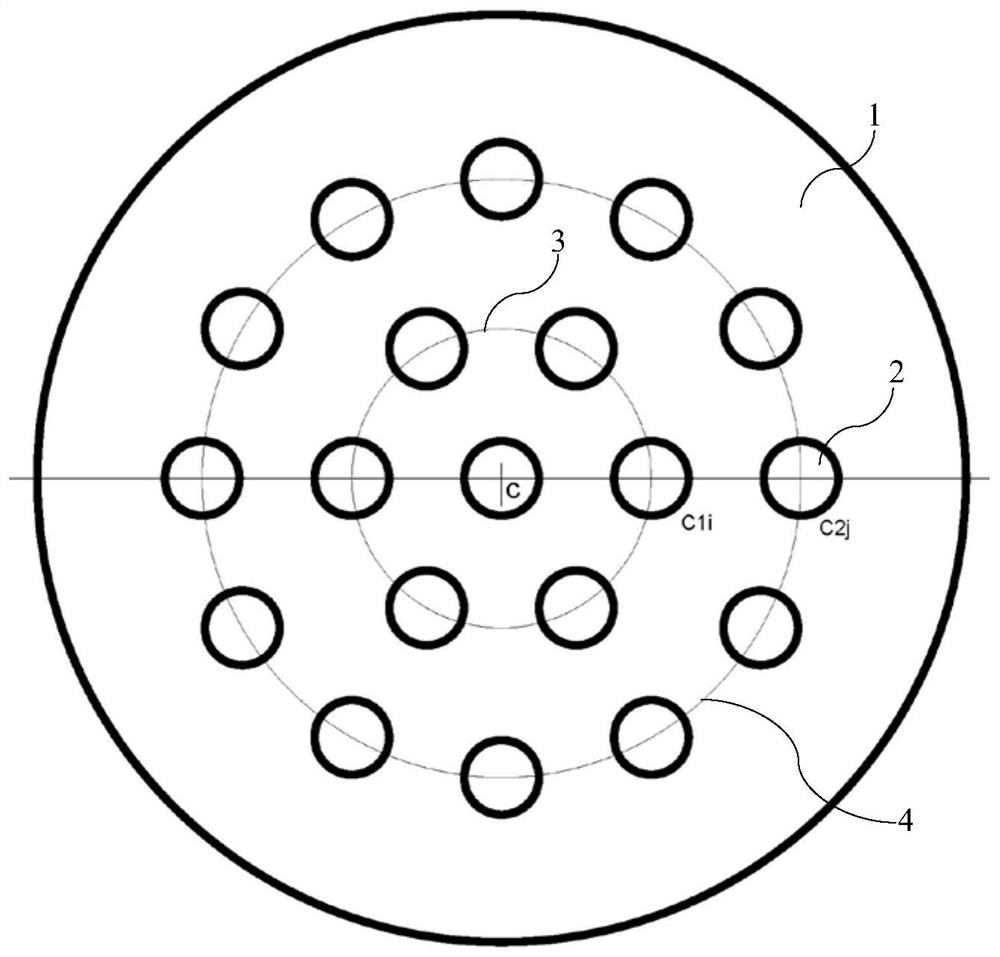

[0040] The photoresist coating method provided by the present invention includes: spraying photoresist at least two points above the wafer. According to the amount of photoresist ejected by each nozzle and the area that can be covered, a set number of photoresist ejection points are arranged above the wafer to cover the entire area of the wafer. Moreover, the controllable arrangement of these points can improve the uniformity of the film thickness of the photoresist.

[0041] Furthermore, in the photoresist coating method provided by the present invention, points for spraying photoresist are provided at different radii in the center of the wafer. Accordingly, the requirement of uniformly spraying photoresist for wafer radii of different sizes can be met.

[0042] Further, the photoresist coating method provided by the present invention con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com