Steel plate bending device for building

A bending device and construction technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of reducing work efficiency, difficult to control the bending angle, wasting materials, etc., and achieve high work efficiency, fast and efficient The effect of bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

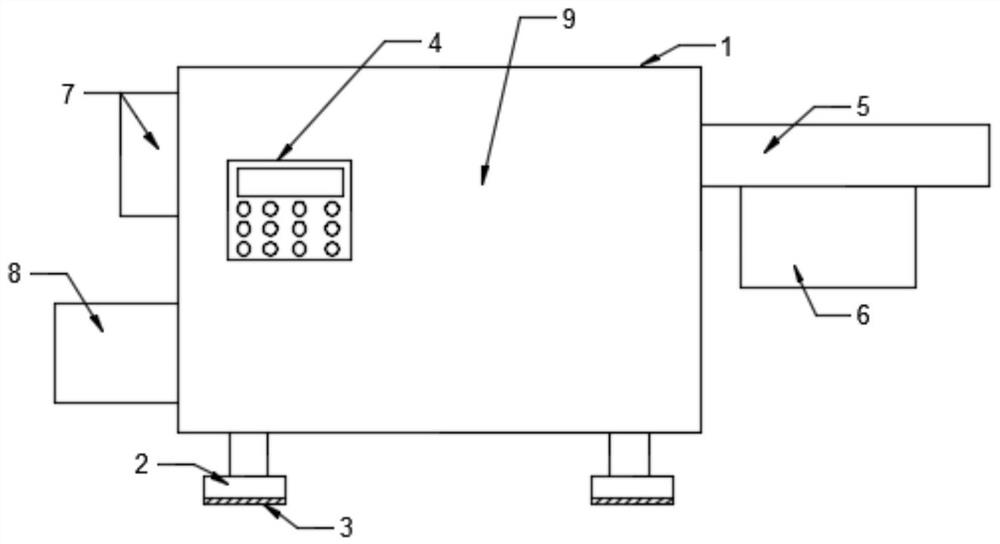

[0026] see Figure 1-6 , in an embodiment of the present invention, a steel plate bending device for construction, comprising: a box body 1, a leg 2 is fixedly installed at the bottom of the box body 1, and a power control box is arranged on a panel on one side of the box body 1 4. A stock plate 5 is fixed on one side of the box body 1, and a steel plate conveying mechanism 6 is fixed on the lower part of the stock plate 5; a steel plate cutting mechanism 7 is fixed on the other side of the box body 1, and the steel plate A material storage box 8 is fixed on the box body 1 at the lower part of the cutting mechanism 7 , and a steel plate bending mechanism 9 is arranged inside the box body 1 .

[0027] In this embodiment, the bottom of the legs 2 is provided with an anti-skid shock absorbing pad 3, which helps to reduce the vibration amplitude during the use of the device, and prevents excessive vibration amplitude from causing greater damage to the working process. influences....

Embodiment 2

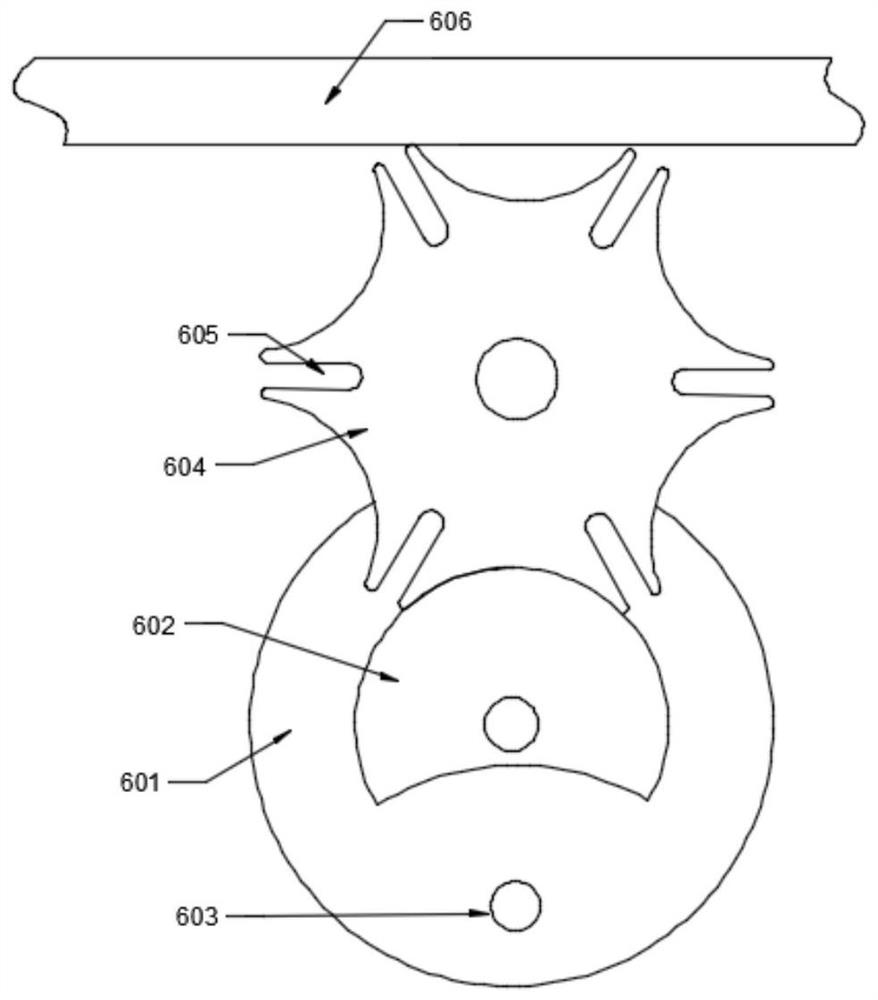

[0029] see Figure 1-6 , in this embodiment, the steel plate conveying mechanism 6 includes: a first wheel 601, an incomplete disc 602 is fixedly mounted on the first wheel 601, and a groove wheel is arranged on the upper side of the incomplete disc 602 604, the said sheave 604 is provided with a toggle groove 605, and the top of said sheave 604 is provided with a steel plate 606.

[0030] In this embodiment, a lever 603 is fixed on the first wheel 601 corresponding to the notch on the incomplete disc 602 , so that the lever 603 can move the sheave 604 conveniently.

[0031] In this embodiment, the diameter of the driving rod 603 is not larger than the groove width of the driving groove 605 , which is convenient for the driving rod 603 to enter the driving groove 605 to move the sheave 604 .

Embodiment 3

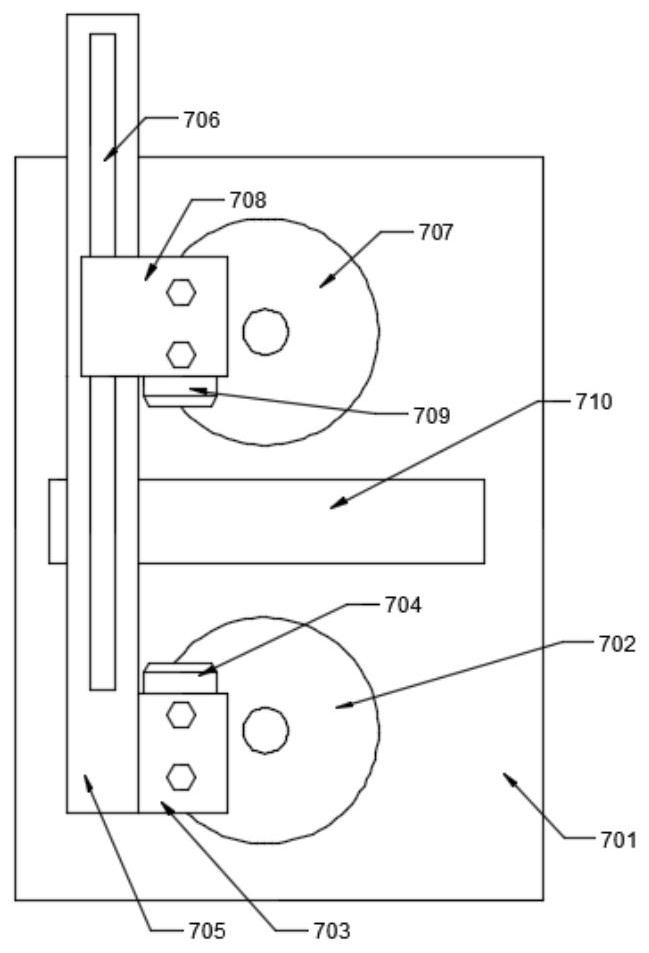

[0033] see Figure 1-6 , in this embodiment, the steel plate cutting mechanism 7 includes: a cutting bottom plate 701, a second wheel 702 is fixedly mounted on the cutting bottom 701, a first fixed block 703 is rotatably mounted on the second wheel 702, The upper part of the first fixed block 703 is fixedly equipped with a first cutter 704, and a connecting plate 705 is fixed on one side of the first fixed block 701, and a slide rail 706 is arranged on the connecting plate 705, and a slide rail 706 is arranged on the slide rail 706. A second fixed block 708 is slidably installed, and a second cutter 709 is fixed on the underside of the second fixed block 708, and a third wheel disc 707 is arranged on the rear side of the second fixed block 708 while the second fixed block 708 is rotated. A material outlet 710 is provided on the bottom plate 701 between the wheel 702 and the third wheel 707 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com