Extrusion device for machining mechanical parts

A technology of mechanical parts and extrusion devices, which is applied in the field of mechanical parts processing, can solve problems such as parts not meeting predetermined requirements, part performance and size not meeting requirements, affecting material properties, etc., to achieve easy deformation, improve processing efficiency and finished products The effect of the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

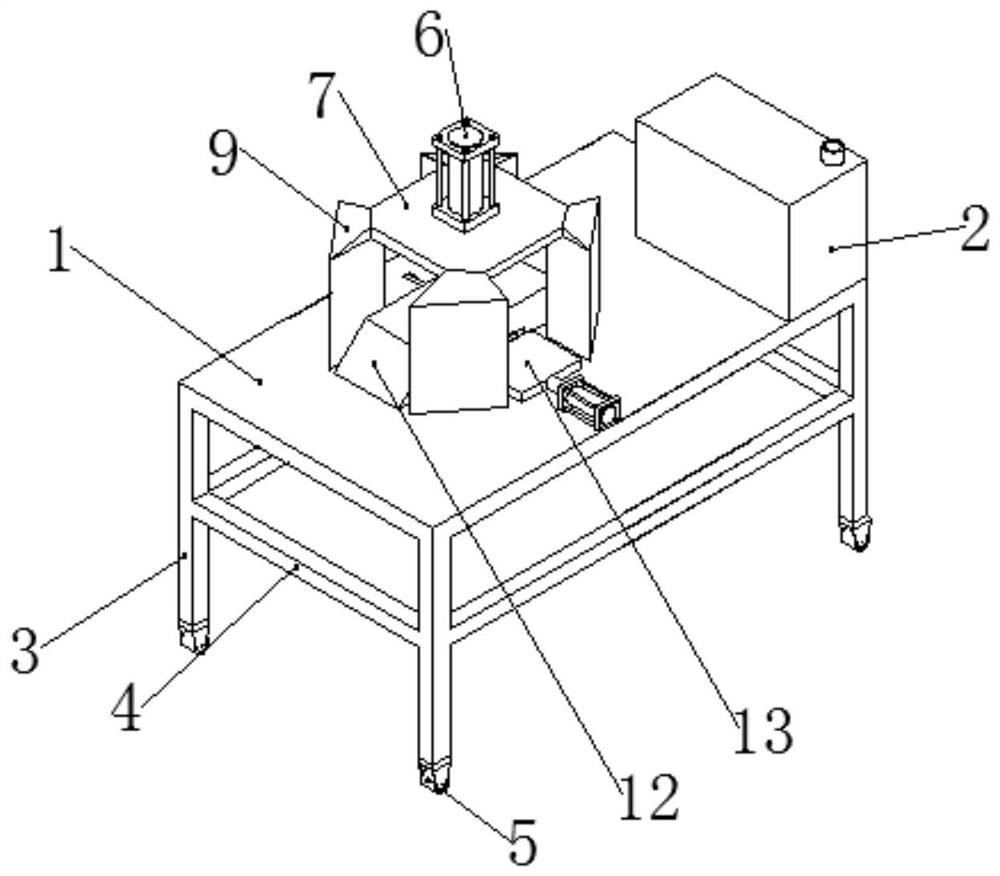

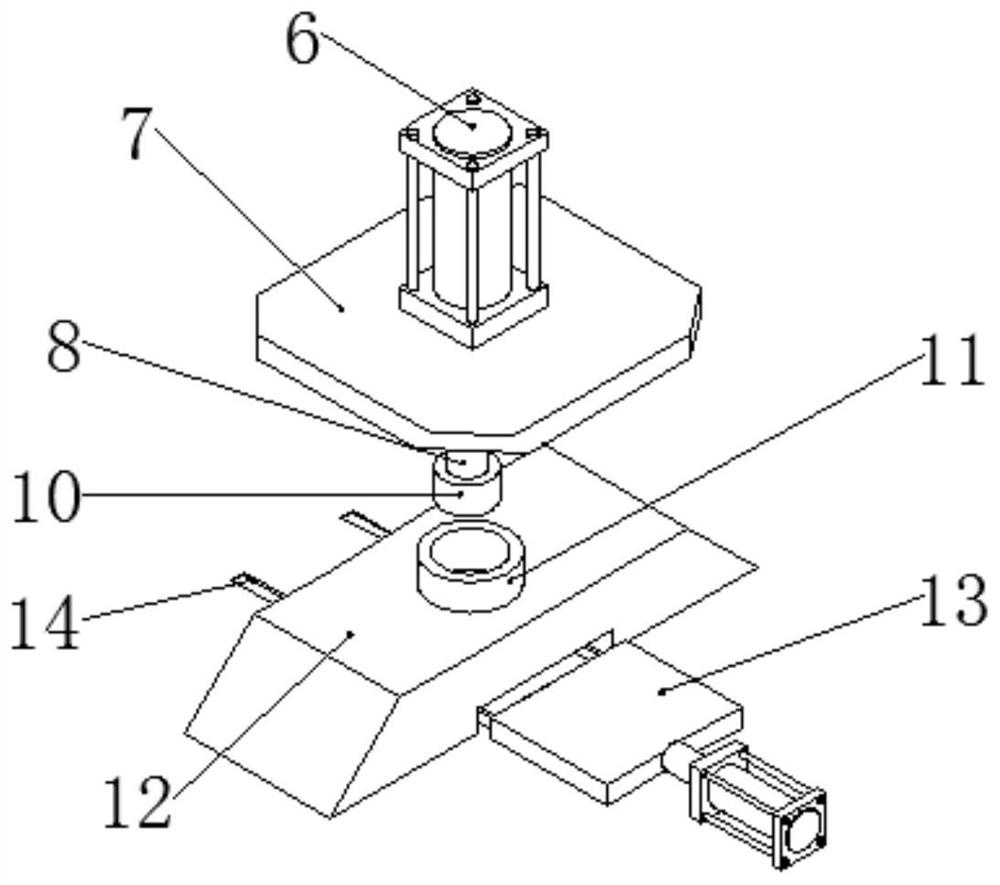

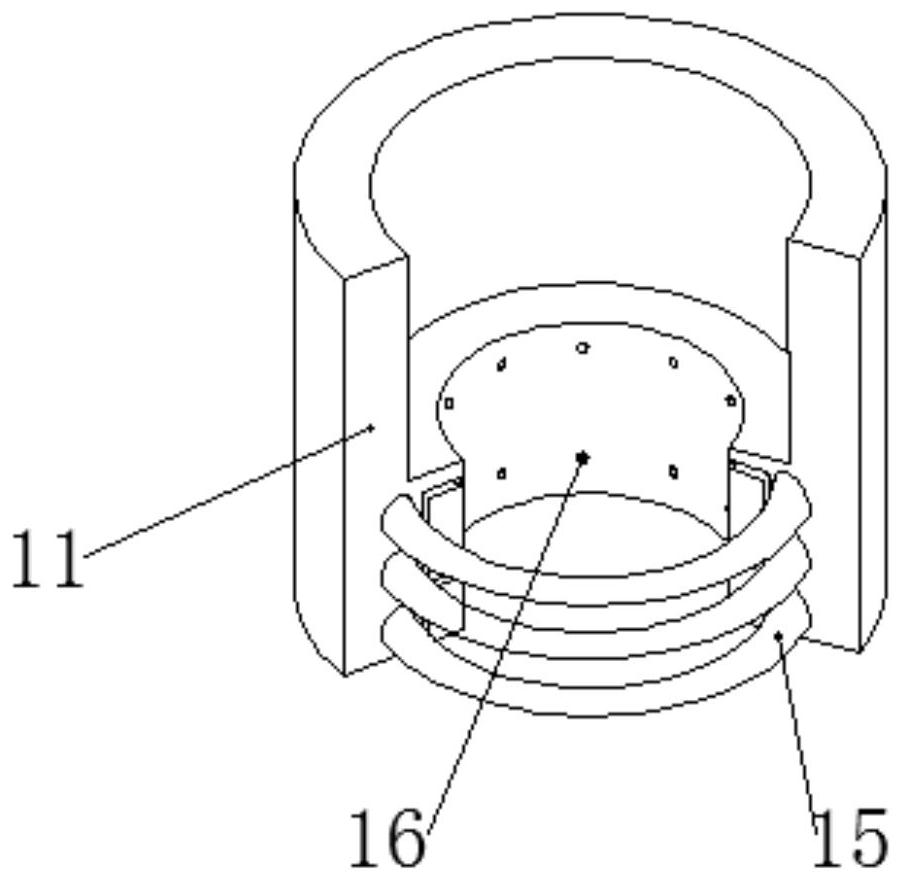

[0020] Example: such as Figure 1-3 As shown, an extrusion device for processing mechanical parts of the present invention includes a base 1 and a water tank 2. The four corners of the bottom of the base 1 are fixedly welded with support legs 3, and the inner sides of the support legs 3 are fixedly welded with a connecting frame 4. The support legs 3 The bottom of the base is fixedly connected with a roller 5, and the middle part of the top of the base 1 is equipped with a stamping mechanism and a load-carrying mechanism. The top of the connecting rod 8 is fixedly connected with the bottom end of the vertical pneumatic cylinder 6, and the top of the connecting rod 8 passes through the middle part of the bottom end of the support plate 7, and is fixedly connected with the central axis of the vertical pneumatic cylinder 6. 12. The bottom plate 13 and the chute 14 are composed. The bottom of the support platform 12 is fixedly welded to the base 1. The middle part of the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com