Building metal pile pulling and recycling device

A recovery device and technology for construction, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of high labor intensity and low efficiency of metal pile recovery, so as to reduce labor intensity, improve recovery efficiency, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

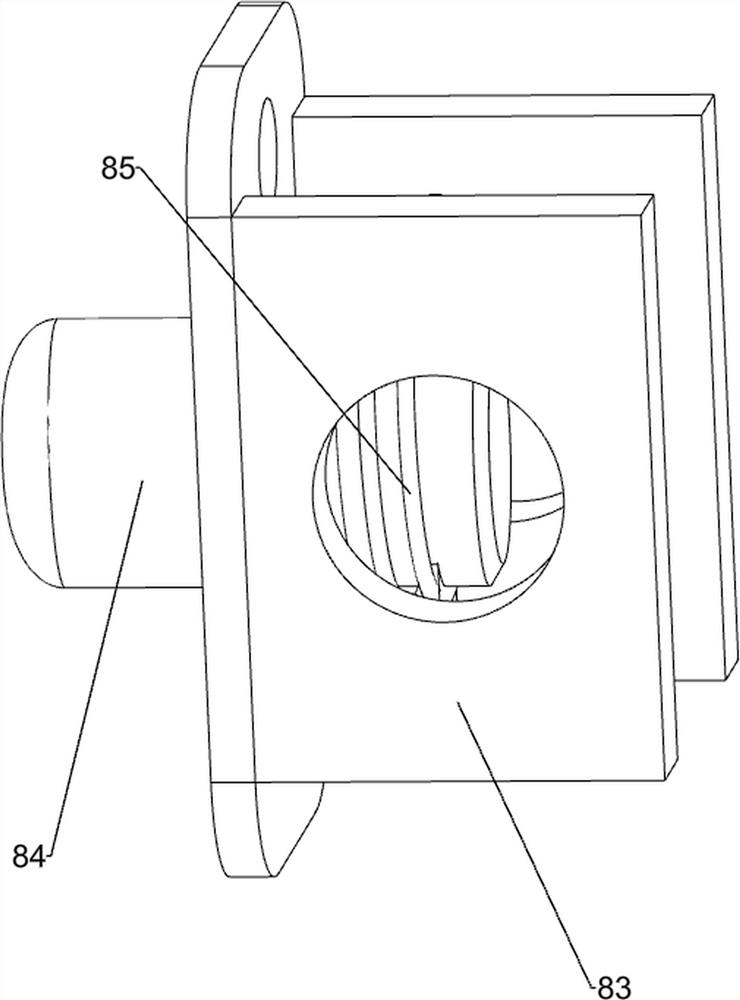

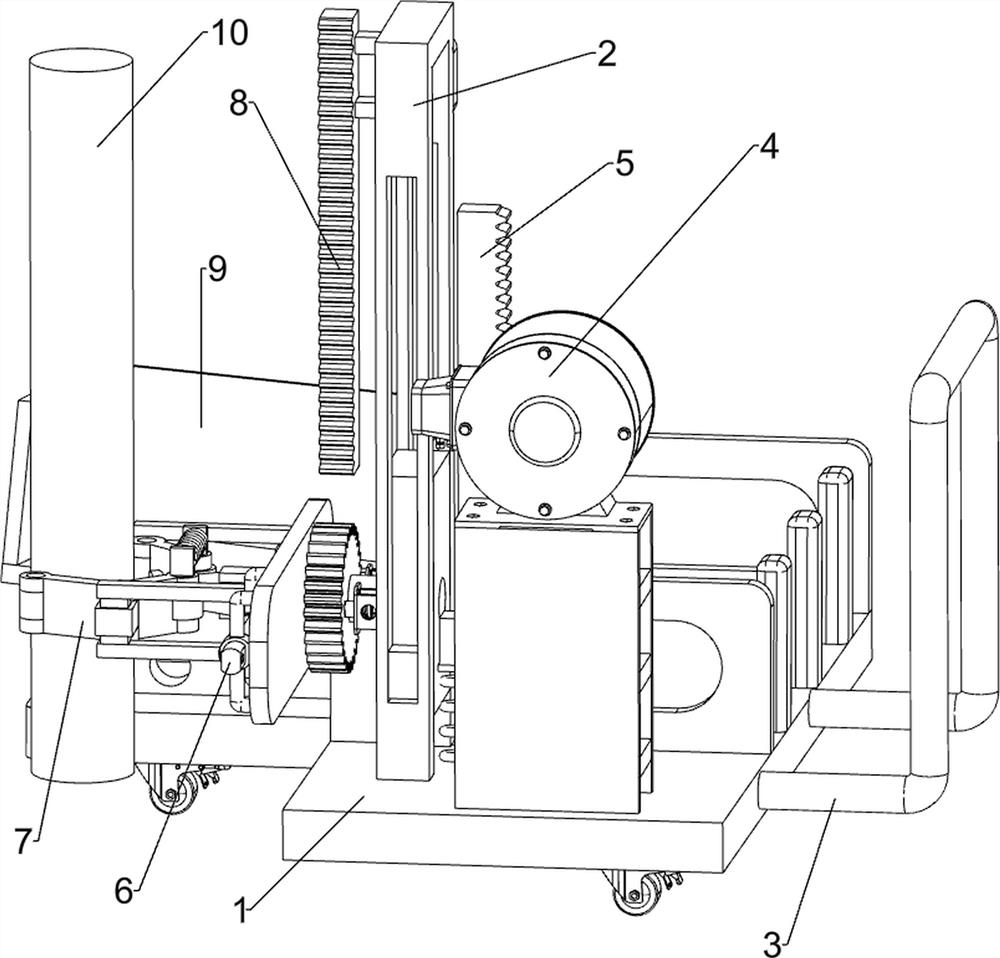

[0030] A construction metal stake pull up recovery device such as Figure 1-8 As shown, it includes a bottom plate 1, a mounting frame 2, a moving mechanism 3, a driving mechanism 4, a lifting mechanism 5, an ejection mechanism 6, a clamping mechanism 7 and a rotating mechanism 8. The left front side of the top of the bottom plate 1 is connected with the mounting frame 2, The top of the base plate 1 is connected with a drive mechanism 4, the base plate 1 is connected with a moving mechanism 3, the right side of the mounting frame 2 is connected with a lifting mechanism 5, the left side of the mounting frame 2 is connected with a rotating mechanism 8, and the left side of the rotating mechanism 8 is connected There is a clamping mechanism 7, and the left side of the clamping mechanism 7 is connected with an ejection mechanism 6.

[0031] The moving mechanism 3 includes universal wheels 31, diagonal braces 32 and push rods 33. The left and right sides of the bottom of the bottom...

Embodiment 2

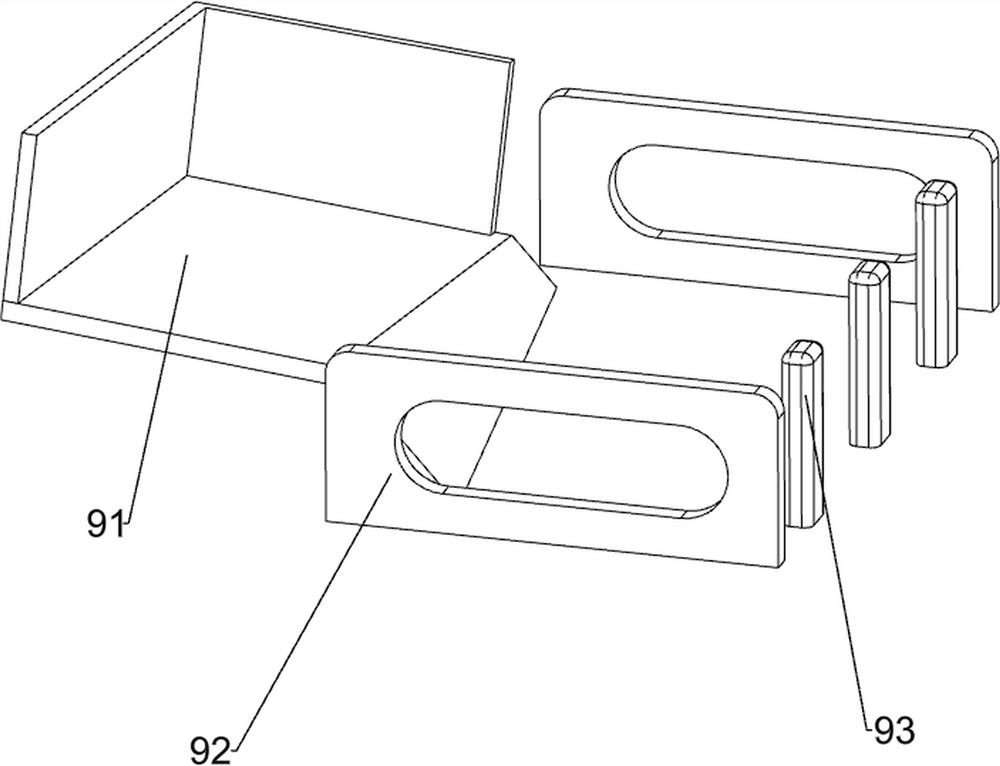

[0039] On the basis of Example 1, such as Figure 9 As shown, a discharge mechanism 9 is also included, and the discharge mechanism 9 includes a discharge plate 91, a baffle plate 92 and a block 93, and a discharge plate 91 is connected between the top of the diagonal brace 32 and the bottom plate 1, and the bottom plate 1 Both front and rear sides of the top are connected with baffles 92 , and the right rear side of the top of the bottom plate 1 is connected with multiple blocks 93 .

[0040] When people need to reclaim the metal pile 10 pulled out of the ground, under the collection effect of the discharge plate 91, the metal pile 10 detached from the fixed claw 75 falls on the discharge plate 91 thereupon, because the discharge plate 91 is Inclined design, and under the blocking effect of the baffle plate 92 and the stopper 93, the metal pile 10 will roll down to the bottom plate 1, so that people can quickly realize the collection and recovery of the metal pile 10 without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com