Lens wiping device for glasses

A technology for lenses and glasses, applied in the field of lens cleaning, can solve problems such as reducing work efficiency, wasting water resources, and wasting a lot of time, and achieves the effects of improving efficiency, saving time, and being easy to take out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

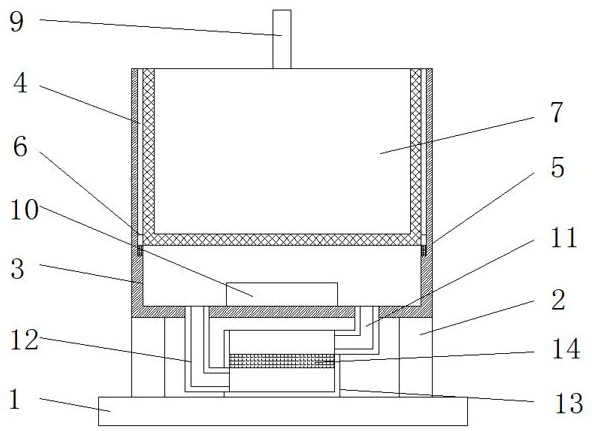

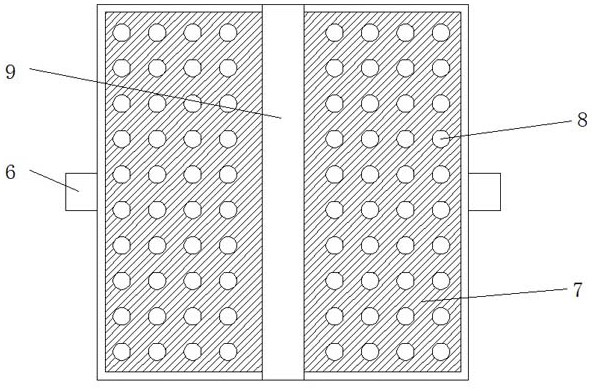

[0019] Embodiment 1, with reference to Figure 1-2 , a lens wiping device for spectacles, comprising a base 1, a column 2 is welded on both sides of the top of the base 1, and a shell 3 is welded on the top of the column 2, the inner walls of both sides of the shell 3 are provided with chute 4, and the sliding The bottom of the groove 4 is welded with a limit block 5, and the slider 6 is slidably connected in the chute 4, and the placement frame 7 is welded between the sliders 6, and the bottom of the placement frame 7 is opened with equidistant distribution. There is a water hole 8, and a handle 9 is welded on the top of the placement frame 7, an ultrasonic vibrator 10 is provided on the inner wall of the bottom of the housing 3, the liquid contained in the inner wall of the housing 3 is pure water, and the outer diameter of the placement frame 7 is the same as The inner diameter of the housing 3 is compatible, the placement frame 7 forms a sliding fit with the housing 3, the...

Embodiment 2

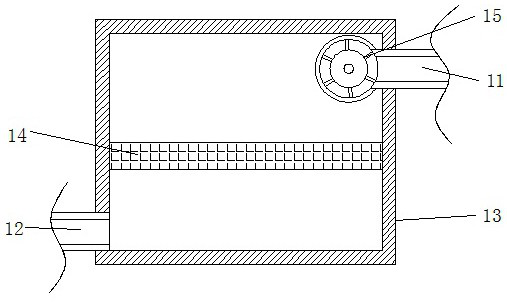

[0020] Embodiment 2, with reference to figure 1 with image 3 , a lens wiping device for glasses, comprising a casing 3, a water inlet pipe 11 is welded through one side of the bottom of the casing 3, and a water outlet pipe 12 is welded through and welded on the other side of the bottom of the casing 3, the water inlet pipe 11 and the water outlet pipe 12 A water storage tank 13 is welded between the clips, and a screen 14 is welded between the inner walls of the two sides of the water storage tank 13. One end of the water inlet pipe 12 is connected to a water pump 15, and the ultrasonic vibrator 10 communicates with the outside world through wires. The power supply is connected, and the water pump 15 is connected with the external power supply through wires, the height of the connection position between the water inlet pipe 11 and the water storage tank 13 is greater than the height of the connection position between the water outlet pipe 12 and the water storage tank 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com