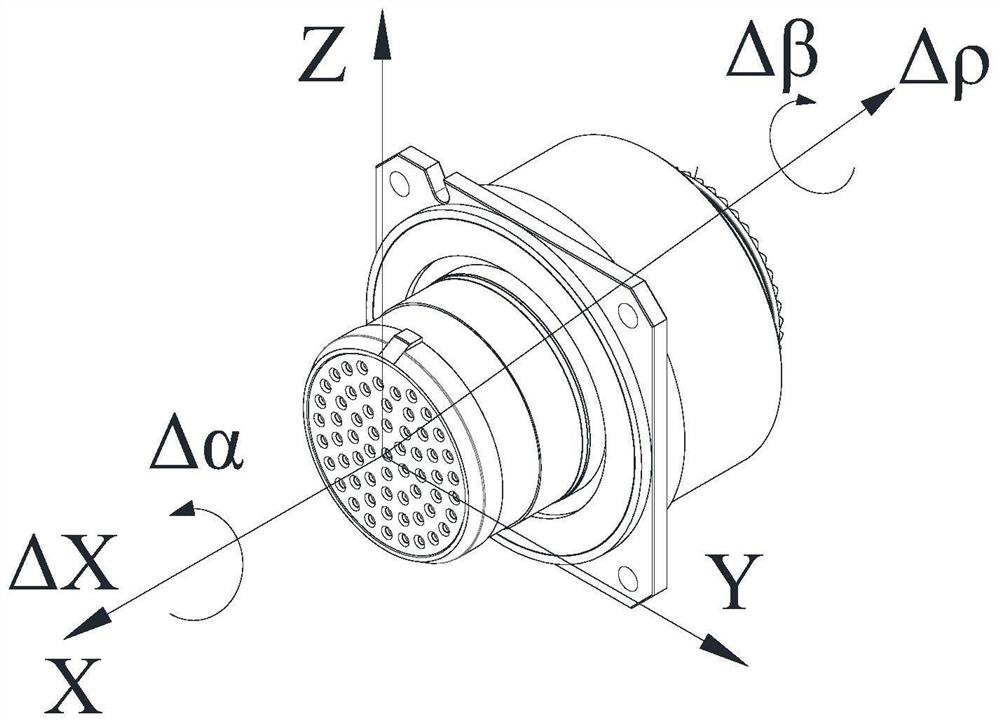

Multi-degree-of-freedom large-tolerance circular self-floating connector

A floating connector, large tolerance technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problem of positioning failure of the rotation direction of the plug housing, serious accidents of the connector that cannot be realized, and damage to the electrical connector and other problems, to achieve the effect of improving the rotation range, easy space docking, and reducing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

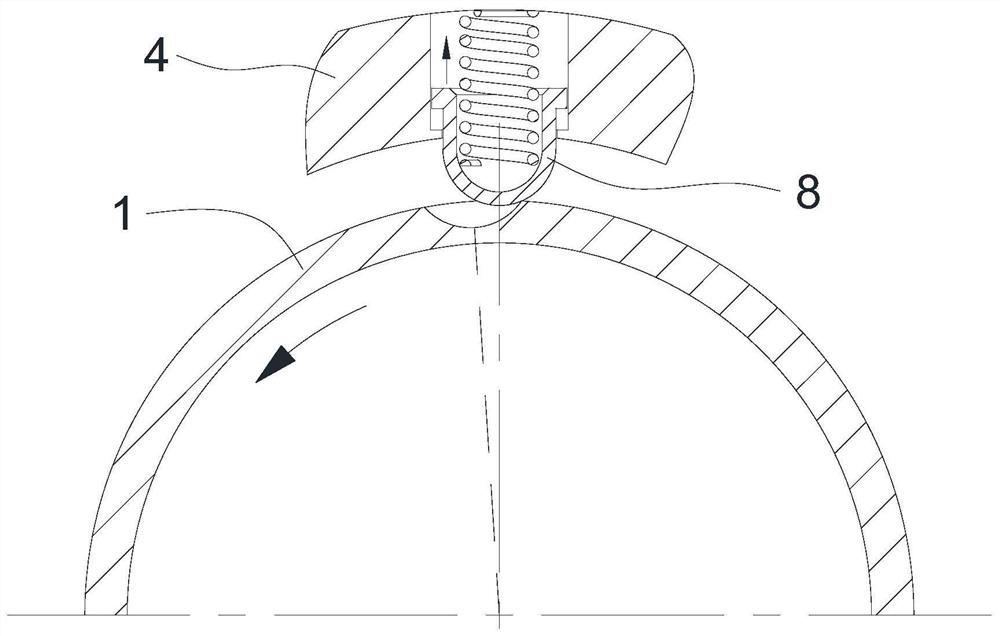

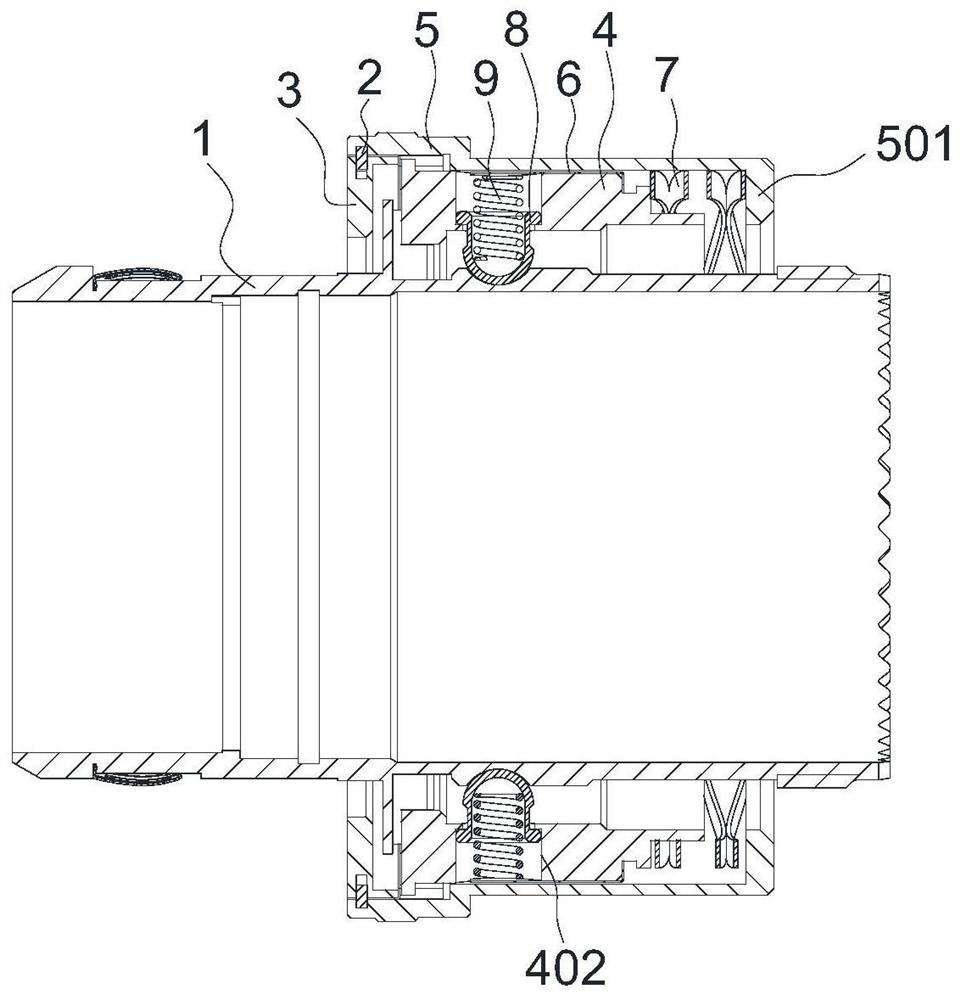

[0032] Such as image 3 , Figure 4 As shown, the multi-degree-of-freedom and large-tolerance circular self-floating connector includes a floating plug and a fixed socket that can be docked with each other. The floating plug includes a plug shell 1, a collar 2, a retaining ring 3, a floating sleeve 4, and a floating shell 5. The outer ring of the plug housing 1 is fitted with a floating sleeve 4, and the floating sleeve 4 is slidably installed in the inner cavity of the floating housing 5. One end of the floating housing 5 is provided with a retaining ring 501, and a corrugated spring 7 is arranged between the floating sleeve 4 and the retaining ring 501. The retaining ring 3 is fixedly installed on the other end of the floating shell 5 through the collar 2, and the outer ring of the plug shell 1 is provided with a flange 101, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com