Main body and electronic atomization device

An electronic atomization device and main body technology, applied in the field of tobacco, etc., can solve the problem of high identification cost of atomizers, and achieve the effect of reducing material and process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

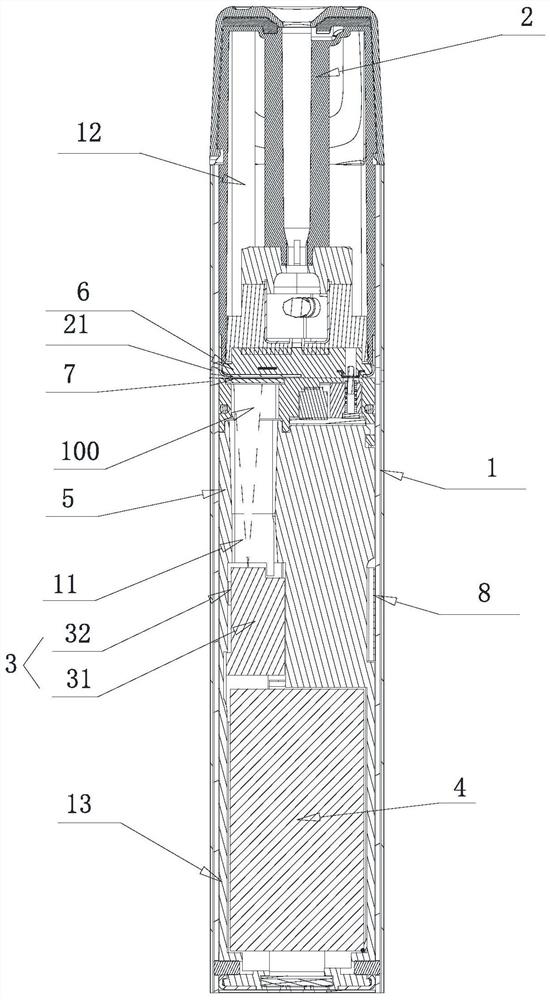

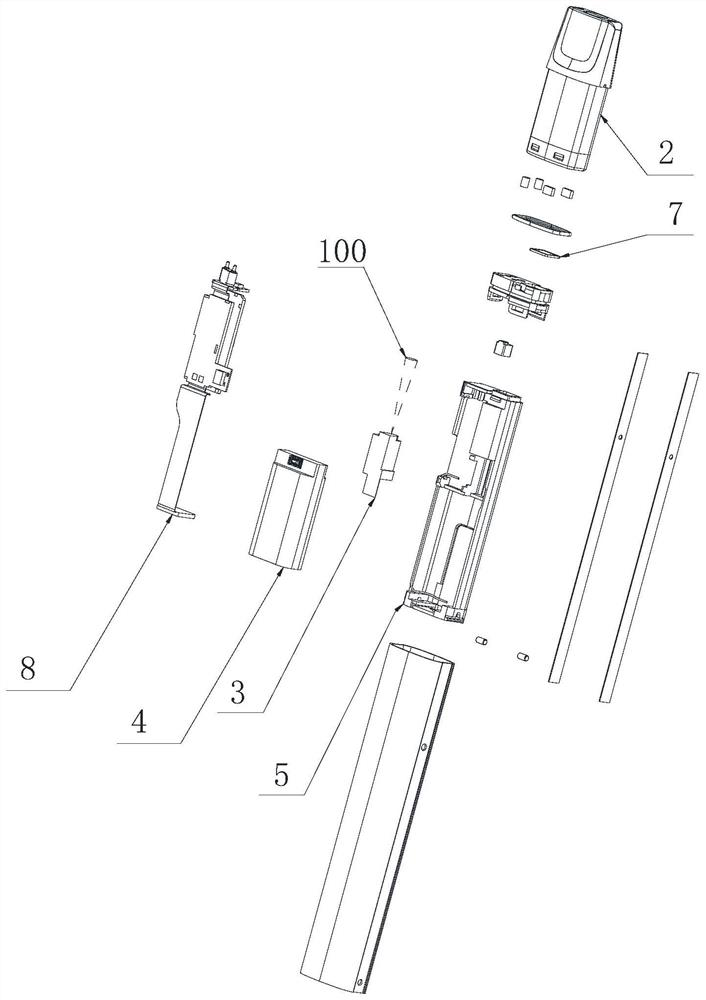

[0034] see Figure 1 to Figure 3 , figure 1 is a schematic diagram of the electronic atomization device of the present invention, figure 2 for figure 1 cutaway view of image 3 for figure 1 The disassembled structure schematic diagram of the electronic atomization device includes a detachable connection of the main body 1 and the atomizer 2 .

[0035] Wherein, the main body 1 is used for cooperating with the atomizer 2 provided with the identification pattern 21 .

[0036] The main body 1 is provided with a light sensor 3 and a control circuit 8, and the atomizer 2 is provided with an identification pattern 21, and the light sensor 3 is used to identify the identification pattern 21 when the main body 1 and the atomizer 2 are connected or matched to obtain The identification information, specifically, can be identified when the main body 1 and the atomizer 2 are electrically connected or mechanically connected to obtain the identification information; 1 When electricall...

Embodiment 2

[0091] see Figure 12-Figure 20 , the present invention also provides a main body 1, the main body 1 includes a light sensor 3 and a control circuit 8 electrically connected to each other. Specifically, the main body 1 can be used in cooperation with the atomizer 2 provided with a logo pattern 21 on the side. And the main body 1 can be detachably assembled with the atomizer 2, and the side of the atomizer 2 is provided with a logo pattern.

[0092] Wherein, the optical sensor 3 is used to identify the logo pattern 21 on the side of the atomizer 2 when the main body 1 is mated with the atomizer 2 to obtain logo information.

[0093]Optionally, the logo graphic 21 can be the label of the atomizer 2, or it can be a pattern, text, symbol, barcode or two-dimensional code or a dot matrix code arranged on the surface of the atomizer 2. The setting of the logo graphic 21 The method can be inkjet painting, laser engraving or printing. The above-mentioned labels, patterns, characters...

Embodiment 3

[0124] please see Figure 12-Figure 20 , the present application provides a main body 1, which is used to cooperate with an atomizer 2 provided with a logo pattern 21 . The main body 1 includes a light sensor 3 and a control circuit 8 electrically connected to each other.

[0125] Wherein, the optical sensor 3 is used to identify the logo pattern 21 on the side of the atomizer 2 when the main body 1 is mated with the atomizer 2 to obtain logo information. The control circuit 8 is used to control the atomizer 2 according to the identification information.

[0126] Wherein, the light sensor 3 further includes a lens 34 and a light-transmitting sheet 33 . The lens 34 can be used to capture the image of the logo graphic 21. Specifically, the lens 34 includes a collection direction. When the logo graphic 21 is located in the collection direction of the lens 34, the lens 34 can capture the image of the logo graphic 21. Wherein, the light-transmitting sheet 33 is also arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com