Automatic feeding, positioning and assembling machine for schoolbag straps

An automatic feeding and positioning group technology, applied in travel products, applications, clothing, etc., can solve the problems of reduced work efficiency, inconvenient operation, complicated steps, etc., and achieve the effect of improving work efficiency and avoiding artificial injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

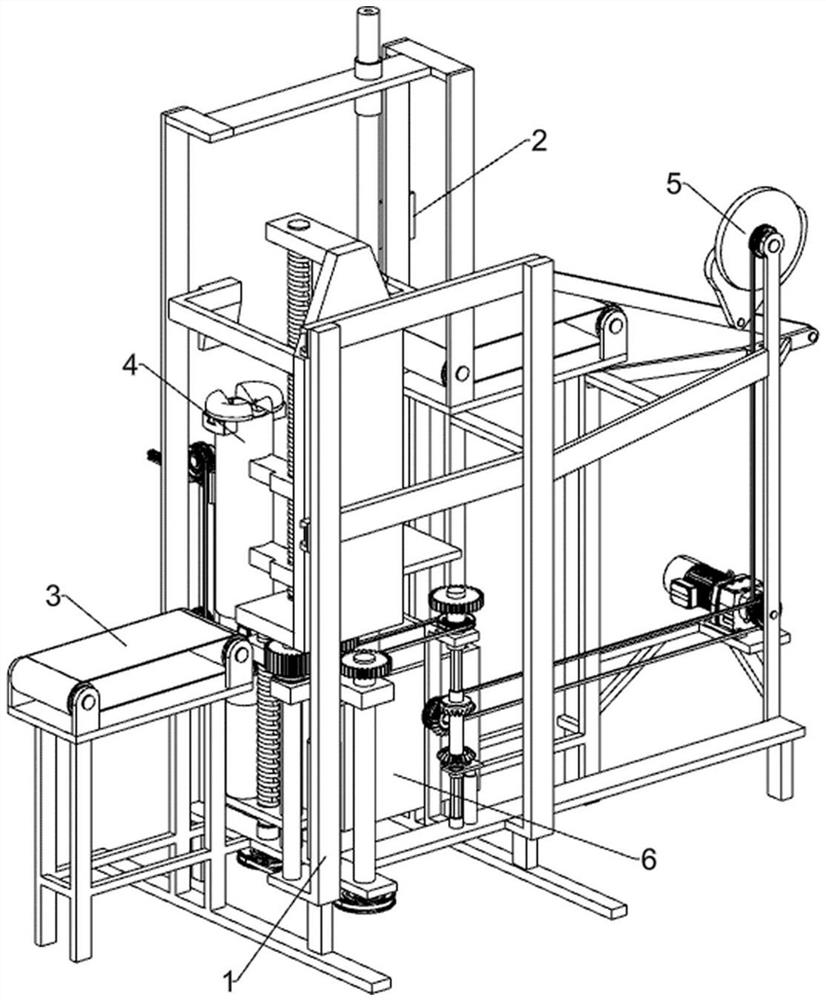

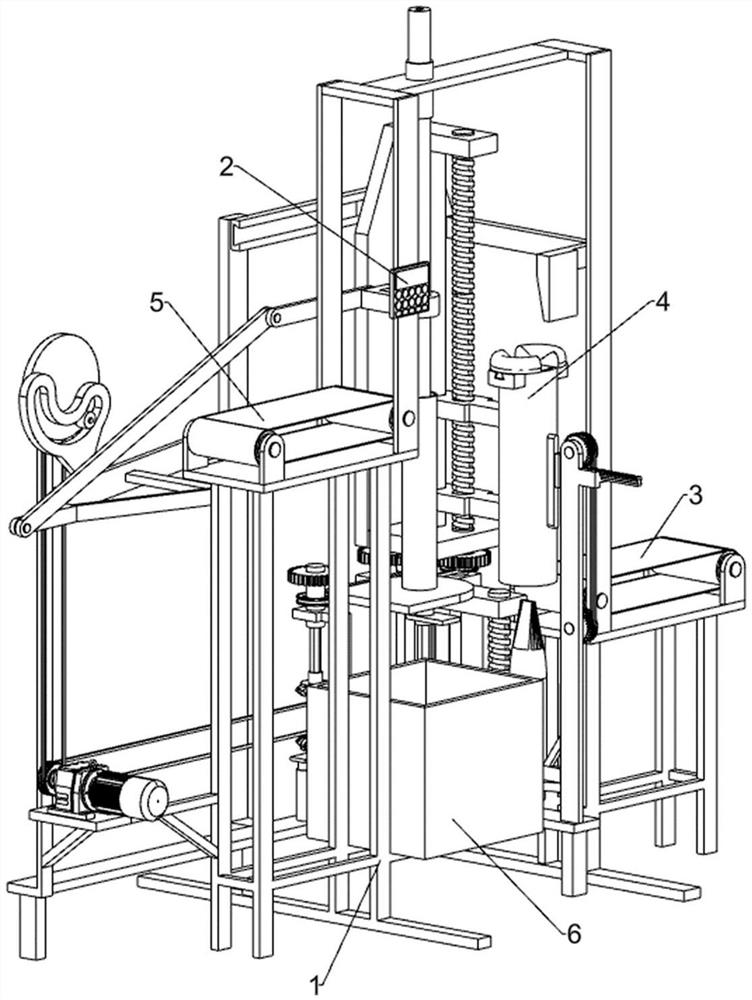

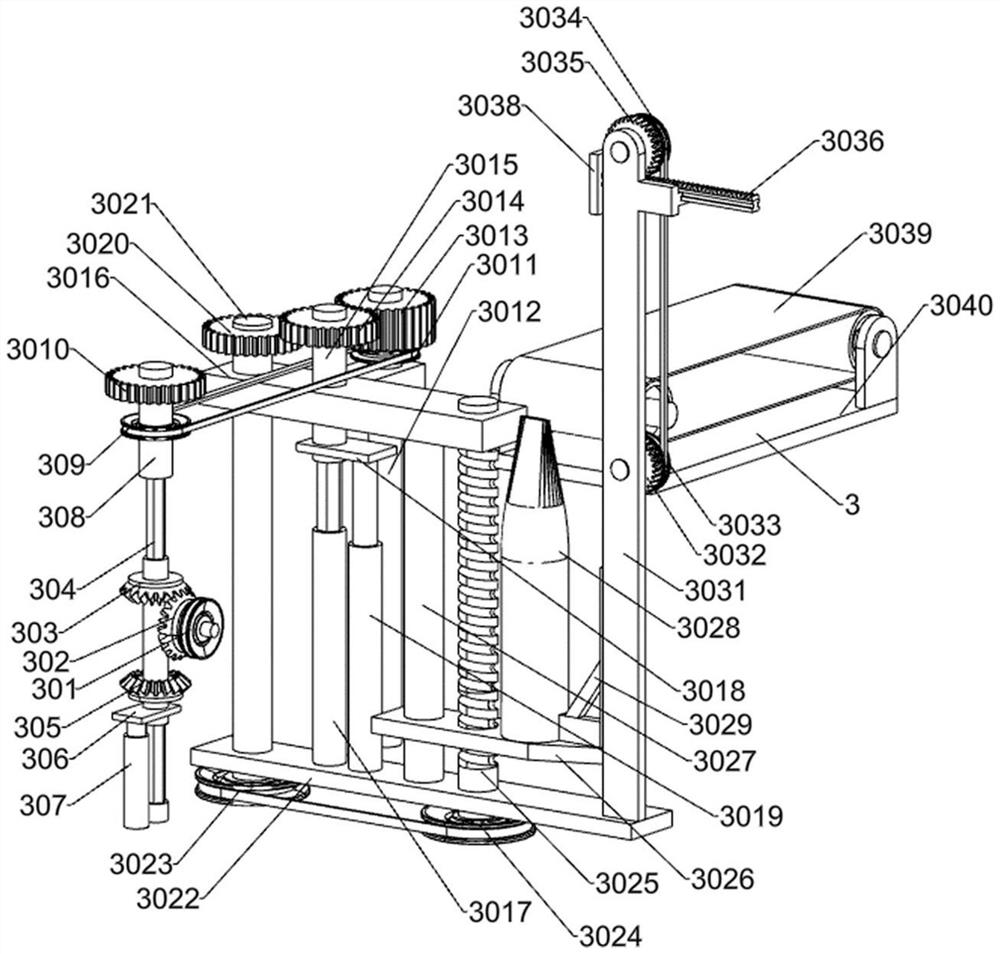

[0030] An automatic feeding and positioning assembly machine for schoolbag belts, such as Figure 1-8 As shown, it includes a frame 1, a control panel 2, a feeding mechanism 3, a transmission mechanism 4, an assembly mechanism 5 and a collection box 6; the frame 1 is connected with the feeding mechanism 3; the frame 1 is connected with the transmission mechanism 4 , and the transmission mechanism 4 is connected with the feeding mechanism 3; the frame 1 is connected with the assembly mechanism 5, and the assembly mechanism 5 is connected with the feeding mechanism 3; the collection box 6 is placed on the frame 1; the assembly mechanism 5 is connected with the control Screen 2 bolted connection.

[0031] Working process: when the device is in use, first place the device in the place where it is used, then connect the assembly mechanism 5 to the air pipe, then turn on the power supply and then start the internal power of the device through the control panel 2, at this time put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com