Forming method of high-reliability columnar supporting structure for metal additive manufacturing

A support structure and metal additive technology, applied in additive manufacturing, additive processing, etc., can solve the problems of poor support removal, waste of raw materials, increased difficulty, etc., to ensure stability and strength, easy to clean and recycle, and provide support strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below in conjunction with embodiment.

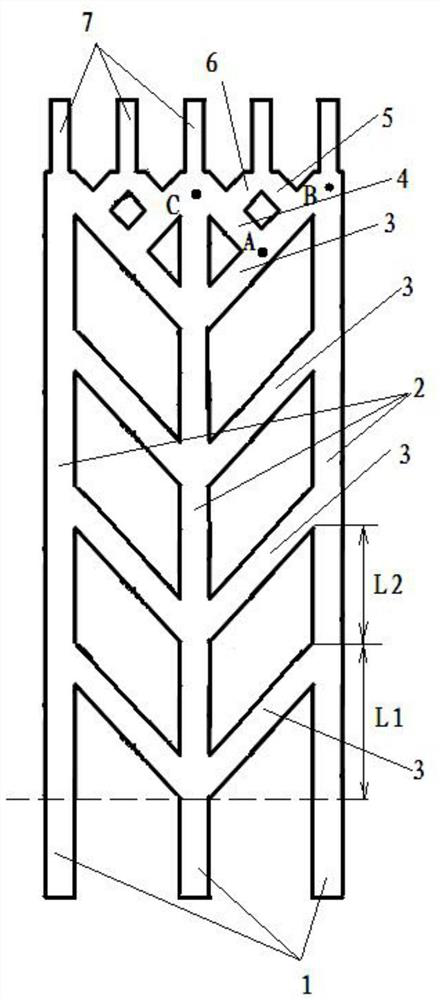

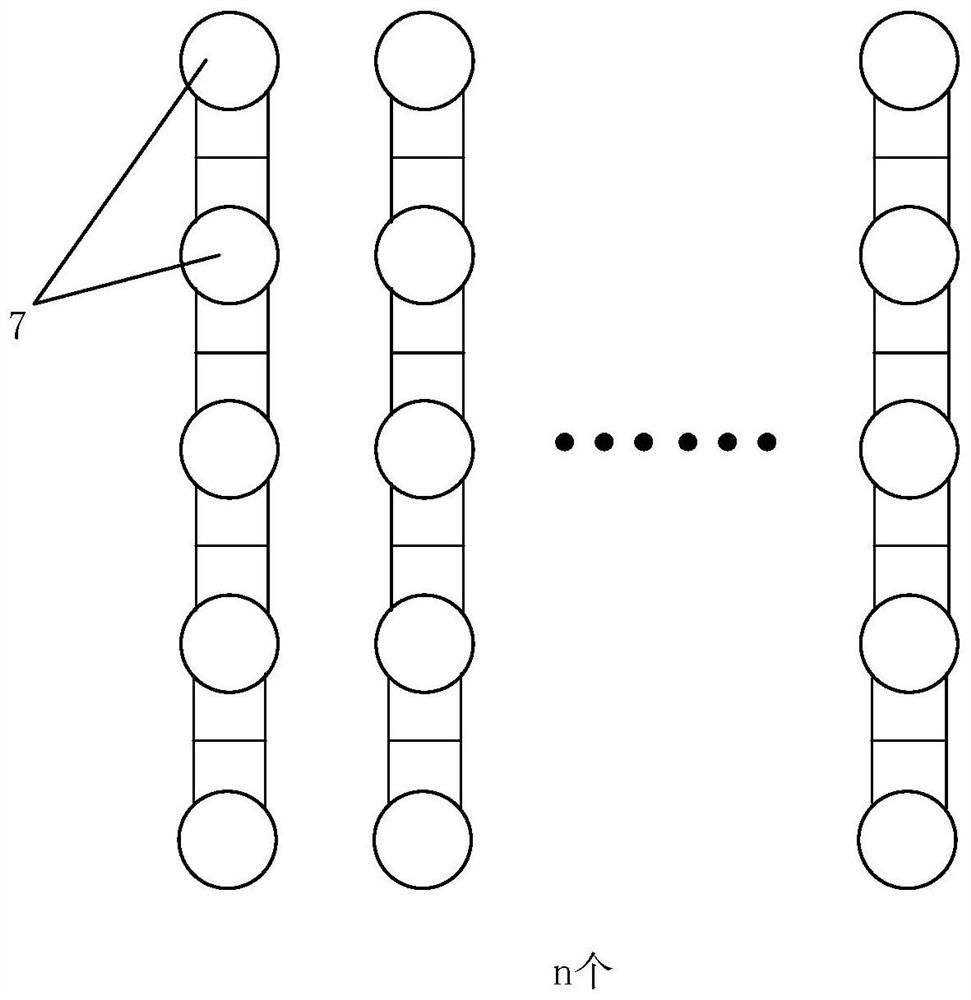

[0029] The invention provides a high-reliability columnar support structure forming method for metal additive manufacturing, which is mainly used for the support of the hanging surface in the additive manufacturing process to ensure the forming quality of the formed parts, and belongs to the rapid prototyping in advanced laser manufacturing field.

[0030] When metal additive manufacturing forms metal parts, it is often necessary to add support structures. Currently commonly used support styles include solid support, grid support and columnar support. In the process of laser selective melting and forming, solid supports often need to grow upwards from the substrate surface in a large area to ensure the firmness of the bottom of the support. Because the contact surface with the part is too large, it is difficult to remove this type of support, which affects the surface of the part. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com