Continuous packaging equipment for Chinese yam slices

A technology for packaging equipment and yam tablets, which is applied in the field of continuous packaging equipment for yam tablets, can solve the problems of high labor cost, low production efficiency, waste of packaging, sealing, and packing time, etc., and achieves simple operation, high degree of automation, and security. Packed evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

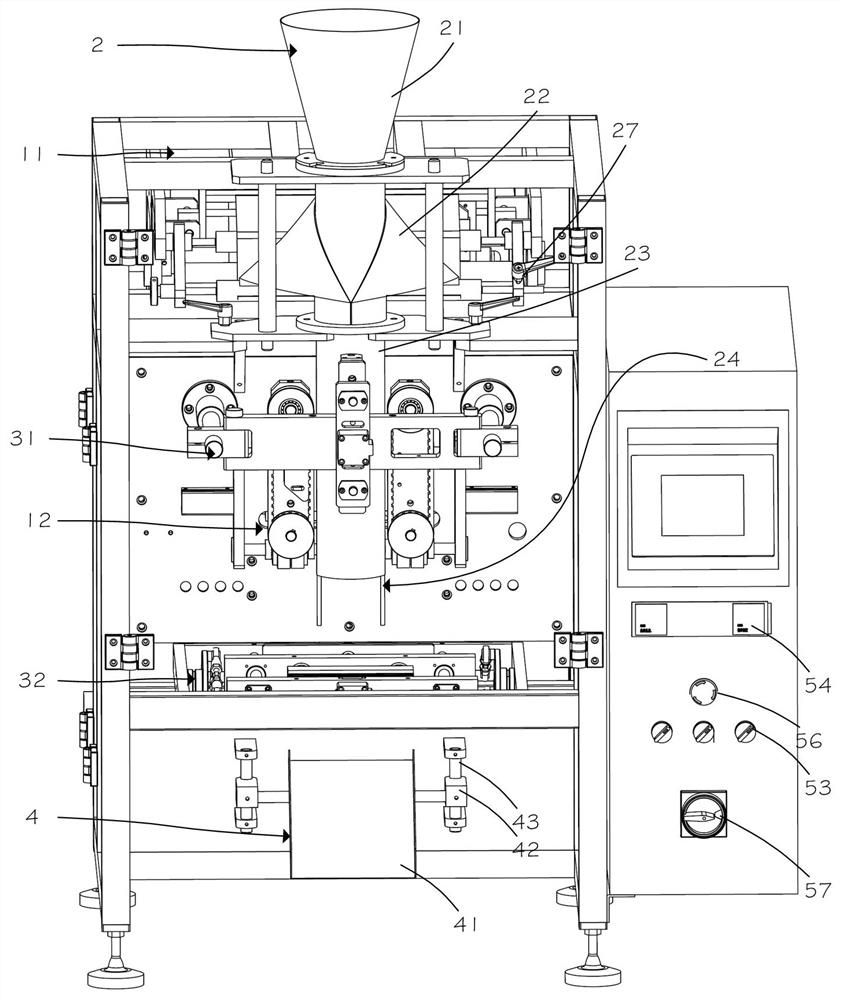

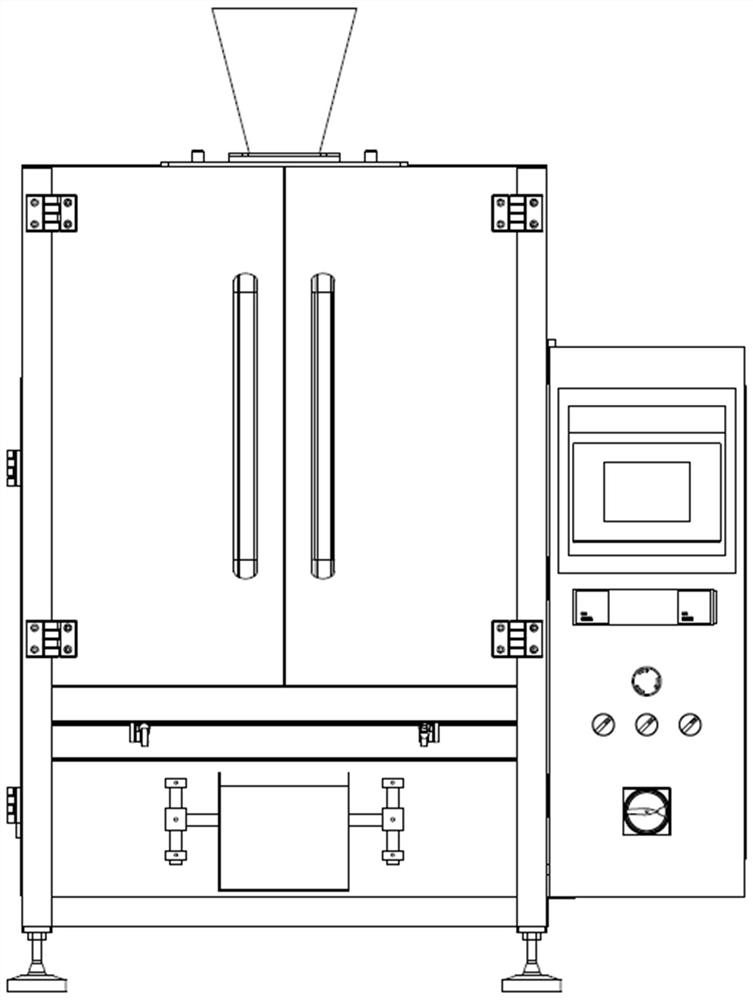

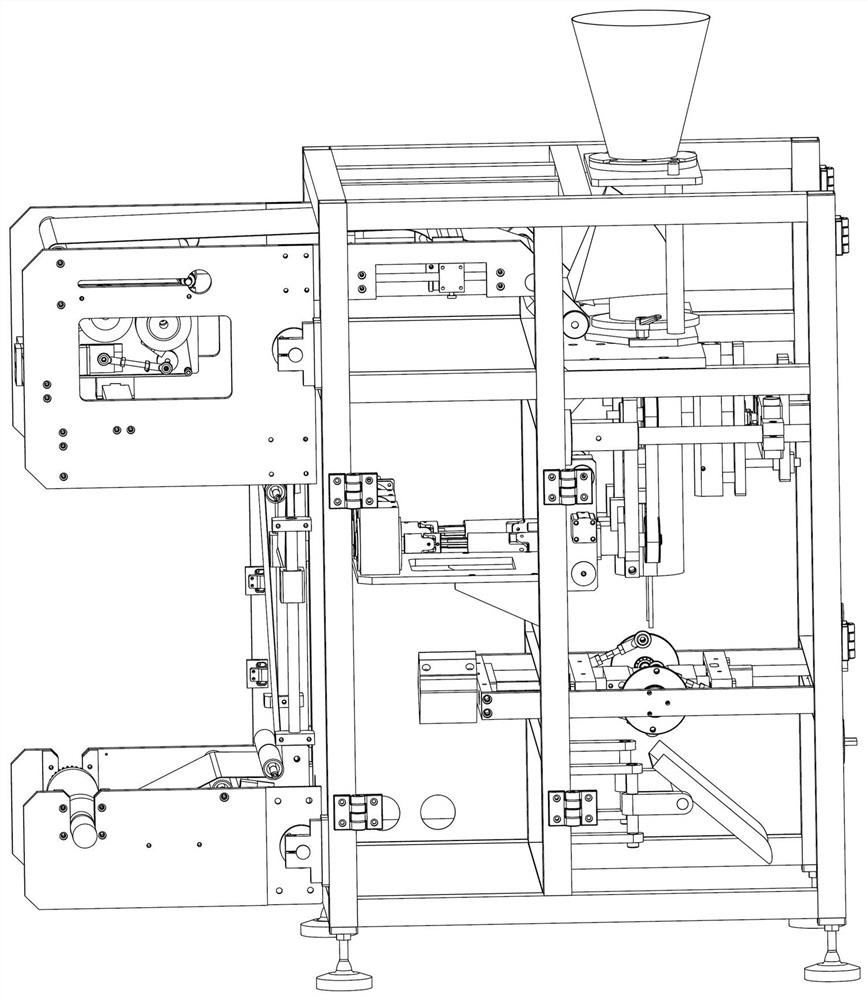

[0030] Such as Figures 1 to 7 Shown, in the embodiment of the present invention, a kind of continuous packaging equipment of Chinese yam sheet, such as figure 1 It includes a frame, a film transport component, a forming component 2, a pressure sealing component, a material receiving component 4, and an electric box 5. It is characterized in that the sealing pressure component 3 includes a longitudinal pressing mechanism 31 and a horizontal sealing mechanism 32. The forming component 2 includes a transition bucket 21, a shaper 22, a barrel 23, and a guide foot 24. The electric box 5 is on the right side of the frame, the molding assembly 2 is on the uppermost end of the frame, the longitudinal pressing mechanism 31, the horizontal The sealing mechanism 32 is positioned at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com