Novel planar mask sheet feeding machine

A technology of plane and mask, which is applied in the field of new plane mask feeding machine, can solve the problems of reducing work efficiency and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

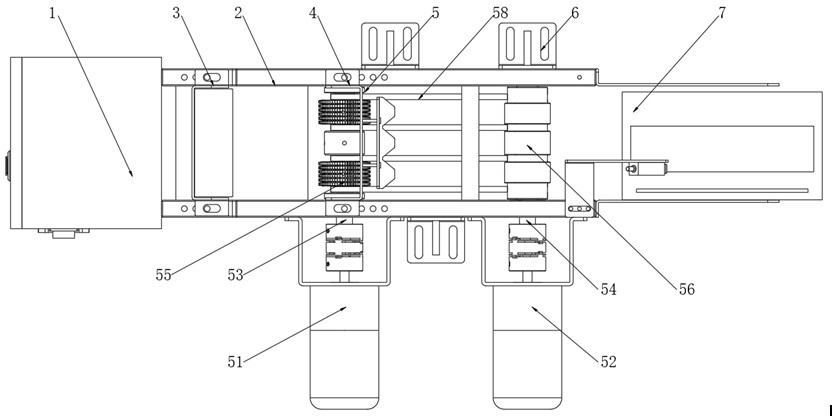

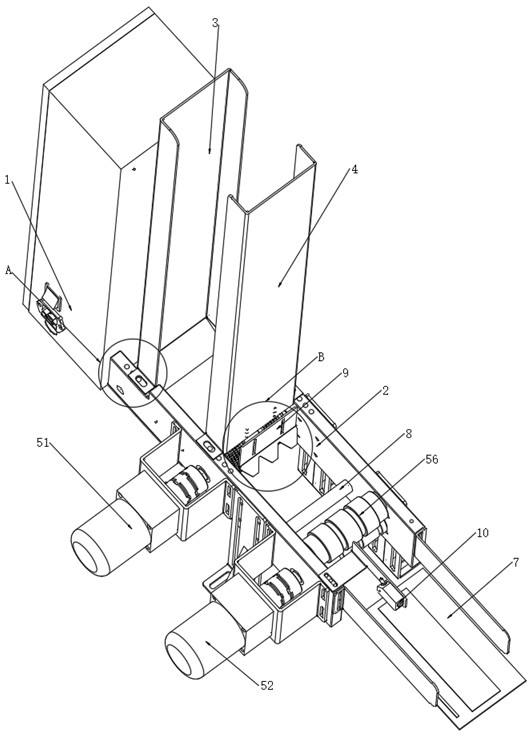

[0022] Such as Figure 1-3 As shown, the new flat mask feeding machine includes an electric control box 1, a side plate 2, a first U-shaped baffle 3, a second U-shaped baffle 4, a conveying mechanism 5, a receiving plate 7, and a photoelectric sensor 10. Both ends of one side of the box 1 are equipped with side plates 2, and the two side plates 2 are vertically connected with a first U-shaped baffle 3 and a second U-shaped baffle 4 from left to right, and the first U-shaped baffle 3 and A storage cavity is formed between the second U-shaped baffles 4; a conveying mechanism 5 is installed between the two side plates 2;

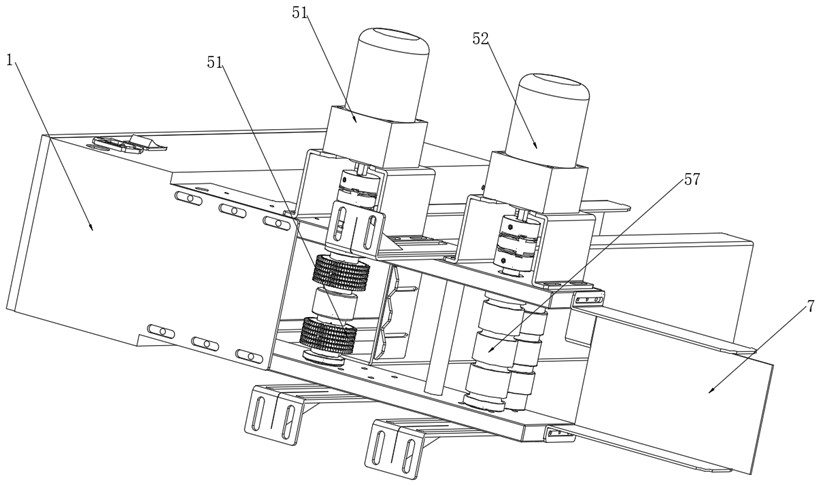

[0023] The conveying mechanism 5 includes a stepper motor 51, a servo motor 52, a first transmission shaft 53, a second transmission shaft 54, a feeding gear 55, a pressing shaft 56, a belt roller 57 and a transmission belt 58, and one of the side plates 2 is respectively from left to right. A stepping motor 51 and a servo motor 52 are installed, and the outpu...

Embodiment 2

[0028] Such as Figure 4 As shown, the new flat mask sheet feeding machine also includes a pressing sheet 9, a pressing sheet 9 is installed on the right side of the second U-shaped baffle plate 4, and a second bolt hole is arranged at both ends of the pressing sheet 9 and the two ends of the second U-shaped baffle plate 4 12 bolts are connected, and the second bolt hole 12 equidistantly is provided with a plurality of, and the bottom end of pressing sheet 9 is the planar shape of outwardly inclined tooth notch, in order to prevent deviation when the mask is conveyed.

Embodiment 3

[0030] Such as Figure 5 As shown in the new flat mask feeding machine, the two ends of the bottom of the first U-shaped baffle 3 and the two ends of the bottom of the second U-shaped baffle 4 are connected with the first bolt holes 11 bolted on the top of the side plate 2, and the first bolt holes 11 Equidistance is provided with multiple, which is conducive to adjusting the distance between the first U-shaped baffle 3 and the second U-shaped baffle 4, which is convenient for placing masks of different types and sizes, improves the convenience of use, and saves equipment costs.

[0031] Working principle of the present invention: masks are stacked and placed in the storage cavity, the bottom of a mask at the bottom falls on the feeding gear 55, when the photoelectric sensor 10 senses the mask on the receiving plate 7, the PLC controller controls the stepping motor 51 to start Once, drive the feeding gear 55 to rotate once, so that a mouth mask on the bottom layer is transmitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com