Multi-stage self-transmission swing arm lifting device

A lifting device, self-transmission pendulum technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of easy inclination, unfavorable placement, large space on the bottom of the lifting device, etc., to achieve powerful functions, simplified structure, and solve the change of lifting height. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

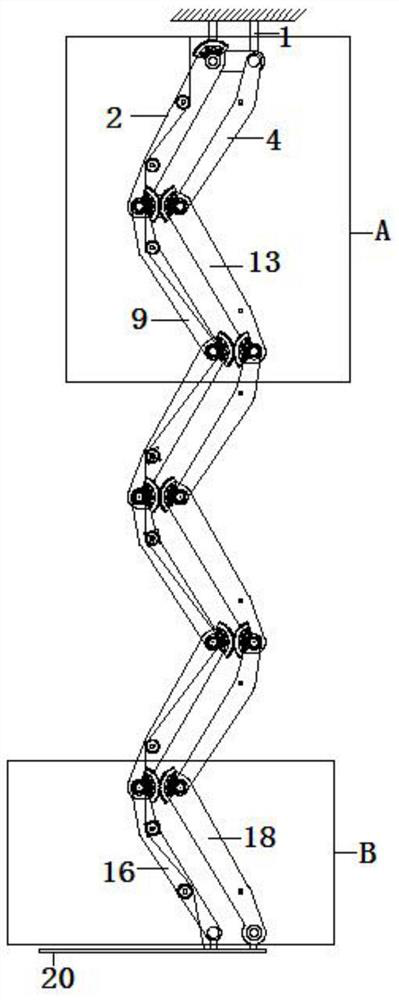

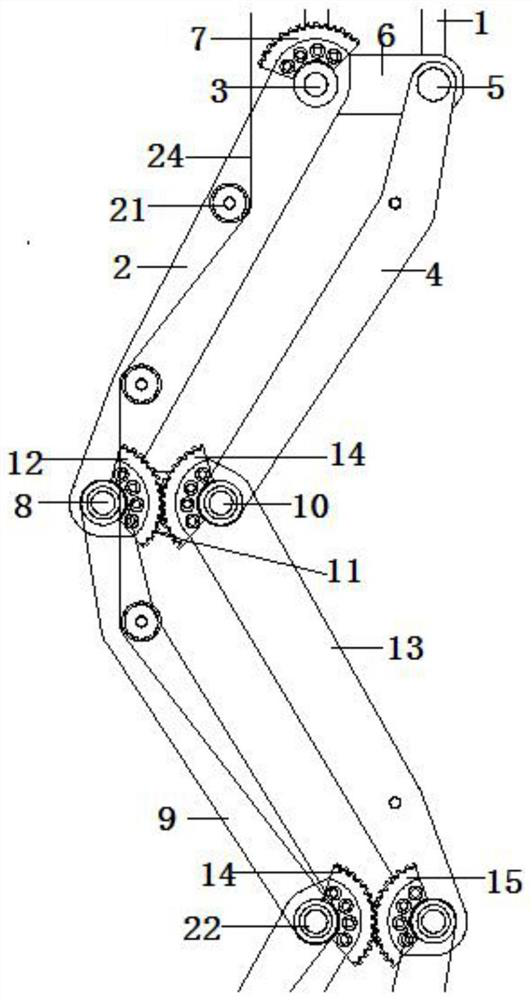

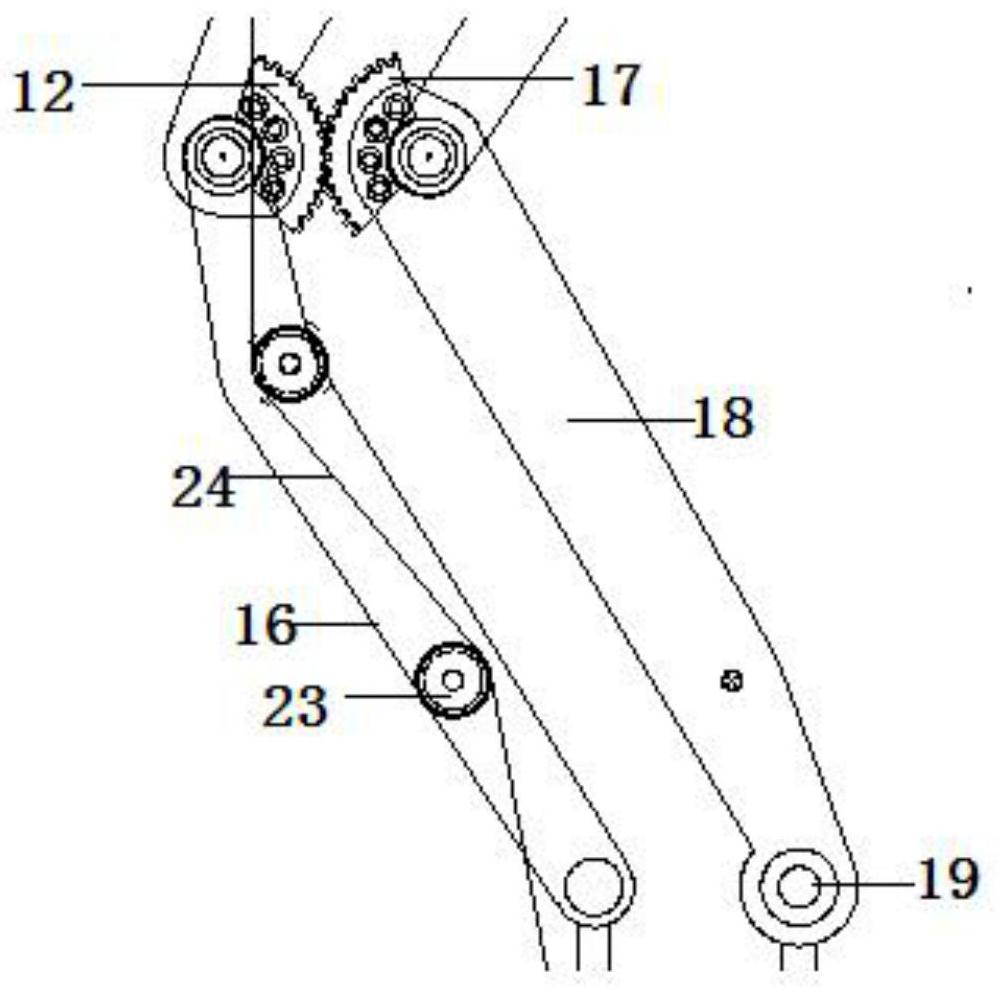

[0016] Such as Figure 1-Figure 4 The shown multi-stage self-driving swing arm lifting device includes an upper fixing part 1, the upper shaft 3 of the primary transmission arm 2 and the upper shaft I5 of the primary link arm 4 are connected below the upper fixing part 1, and the upper shaft 3 It is connected with the upper shaft I5 through the coupling shaft seat 6, the upper shaft 3 is equipped with a 0-stage transmission gear 7, the bottom of the primary transmission arm 2 is installed on the lower shaft 8, and is coaxially connected with the grading link arm 9, and the primary The bottom of the connecting rod arm 4 is installed on the lower shaft I10, the lower shaft 8 and the lower shaft I10 are connected through the coupling seat I11, the primary transmission gear 12 is installed on the lower shaft 8, and the primary transmission gear 12 is connected to the top of the stepping transmission arm 13 The upper gear 14 meshes, the upper gear 14 is coaxially connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com