A kind of alumina composite ceramic and its preparation method and application

A technology of composite ceramics and alumina, which is applied in the field of ceramic materials, can solve the problems of high sintering temperature, low thermal conductivity, and high sintering cost, and achieve the effects of reducing scattering, improving mechanical properties, and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

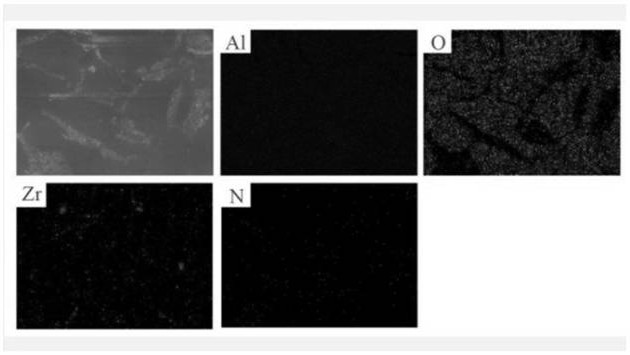

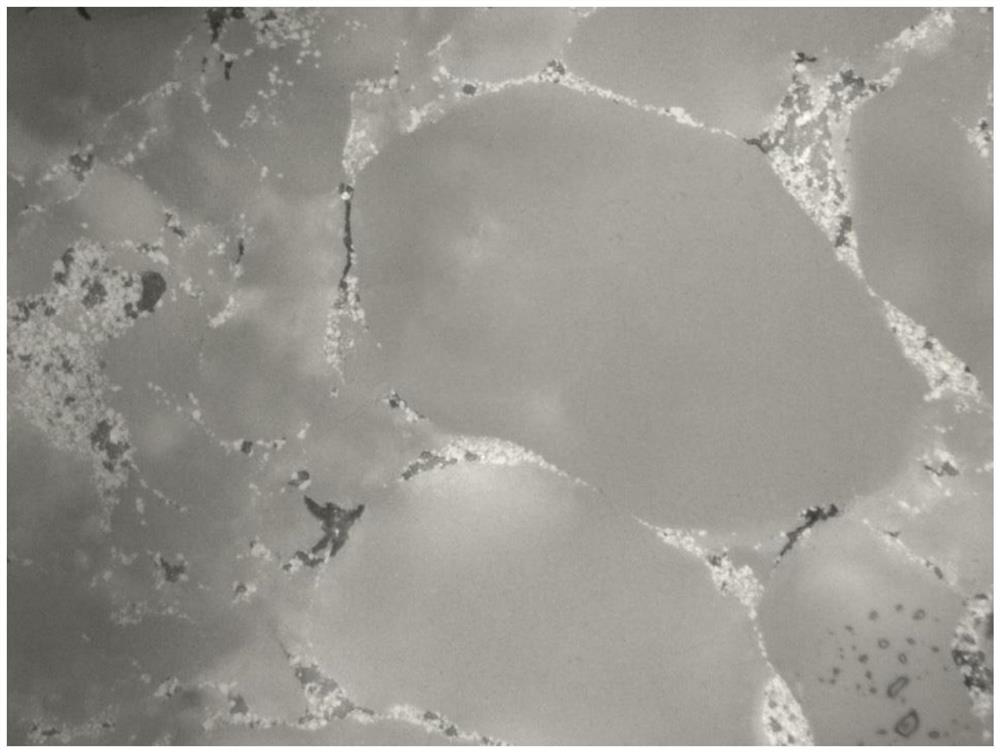

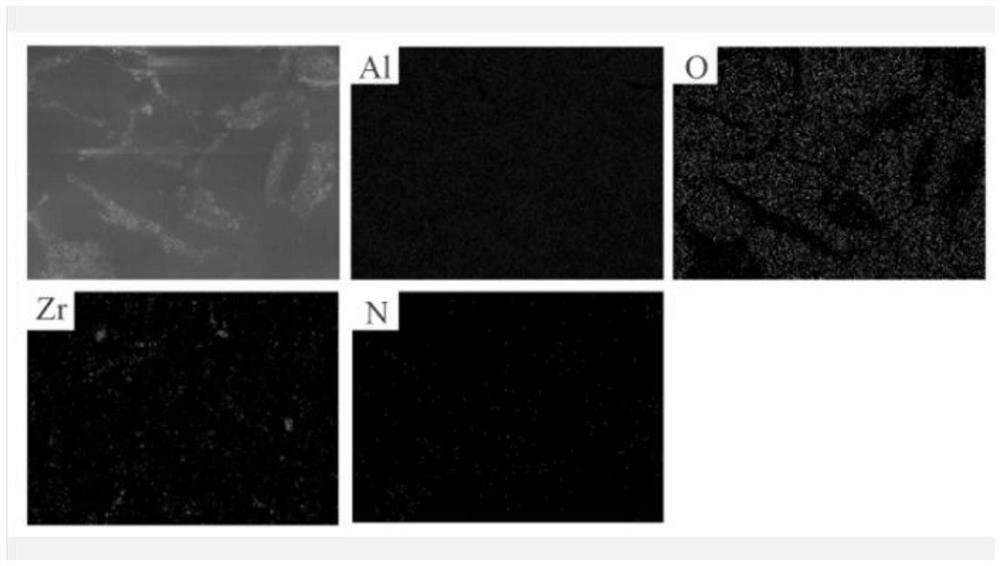

Image

Examples

Embodiment 1

[0042] Embodiment 1 of the present application provides the first alumina composite ceramic, and its specific preparation method is as follows:

[0043] 1. In parts by mass, 80.7 parts of Al 2 O 3 , 13.6 parts of m-ZrO 2 , 0.7 copies of Y 2 O 3 mixed, with ethanol as solvent, with Al 2 O 3It is a ball milling medium, mixed on a roller ball mill for 12 hours, and the first composite powder is obtained after mixing and drying;

[0044] 2. Put the first composite powder into a spray granulator, and spray granulation to obtain a first composite particle with a particle size of 50 μm;

[0045] 3. In parts by mass, ball mill 95 parts of the first composite particles and 5 parts of AlN particles on a planetary ball mill at a rotational speed of 250 r / min for 12 hours to obtain the second composite particles;

[0046] 4. Molding the second composite particles to obtain an alumina composite ceramic body;

[0047] 5. Put the alumina composite ceramic body into the boron nitride ...

Embodiment 2

[0049] Embodiment 2 of the present application provides a second alumina composite ceramic, and its specific preparation method is as follows:

[0050] 1. In parts by mass, 80.7 parts of Al 2 O 3 , 14.6 parts of m-ZrO2, 2.7 parts of Y 2 O 3 mixed, with ethanol as solvent, with Al 2 O 3 It is a ball milling medium, mixed on a roller ball mill for 24 hours, and the first composite powder is obtained after mixing and drying;

[0051] 2. Put the first composite powder into a spray granulator, and spray granulation to obtain a first composite particle with a particle size of 50 μm;

[0052] 3. In parts by mass, ball mill 92 parts of the first composite particles and 8 parts of AlN particles on a planetary ball mill at a rotational speed of 250 r / min for 8 hours to obtain a second composite powder;

[0053] 4. Molding the second composite particles to obtain an alumina composite ceramic body;

[0054] 5. Put the alumina composite ceramic body into the boron nitride crucible, ...

Embodiment 3

[0056] Embodiment 3 of the present application provides a third alumina composite ceramic, and its specific preparation method is as follows:

[0057] 1. In parts by mass, 82.5 parts of Al 2 O 3 , 12.3 parts of m-ZrO2, 1.2 parts of Y 2 O 3 mixed, with ethanol as solvent, with Al 2 O 3 It is a ball milling medium, mixed on a roller ball mill for 48 hours, and the first composite powder is obtained after mixing and drying;

[0058] 2. Put the first composite powder into a spray granulator, and spray granulation to obtain a first composite particle with a particle size of 60 μm;

[0059] 3. In parts by mass, ball mill 88 parts of the first composite particles and 12 parts of AlN particles on a planetary ball mill at a rotational speed of 250 r / min for 6 hours to obtain the second composite particles;

[0060] 4. Molding the second composite particles to obtain an alumina composite ceramic body;

[0061] 5. Put the alumina composite ceramic body into the boron nitride cruci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com