Preparation method of novel anti-ultraviolet antistatic elastic fabric

An elastic fabric, anti-static technology, applied in conductive/anti-static filament manufacturing, rayon manufacturing, fiber chemical characteristics, etc. Anti-static/anti-ultraviolet effect, comfortable experience, damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

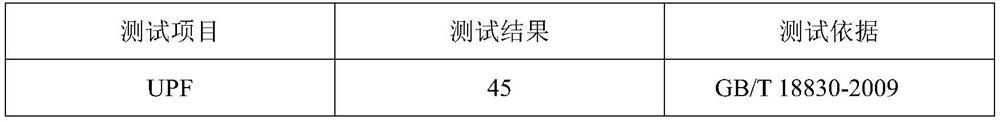

Embodiment 1

[0031] The preparation method of the antistatic / anti-ultraviolet warp-knitted elastic fabric of the present invention comprises yarn preparation, weaving, dyeing, setting, fluffing, softening on a setting rolling machine, and finishing.

[0032] 1) Two-component PET, PBT antistatic / anti-ultraviolet elastic fiber: conductive nano-tin oxide is premixed with PBT resin powder according to the mass ratio of 1%, the speed of the premixer is 200rpm, and it is prepared by a twin-screw extruder with anti-static properties. Electrostatic functional PBT polyester chips, twin-screw processing temperature is 250°C; UV1020 and dibutyltin are compounded at a ratio of 20:1 and dispersed in ethylene glycol by ultrasonic, and terephthalic acid is mixed at a molar ratio of 1:1 Proportional in-situ polymerization reaction, the addition of ultraviolet compounding additives is 0.5%, the polymerization temperature is 275 ° C, and the polymerization reaction time is 6 hours to obtain PET polyester chi...

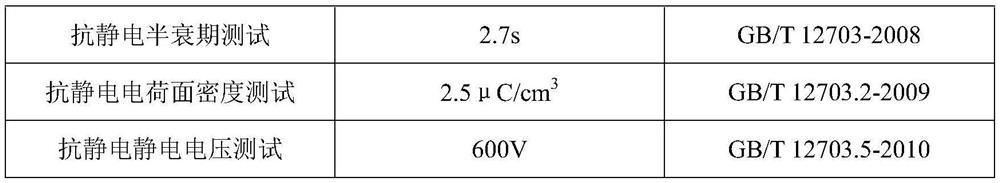

Embodiment 2

[0042] The preparation method of the antistatic / anti-ultraviolet warp-knitted elastic fabric of the present invention comprises yarn preparation, weaving, dyeing, setting, fluffing, softening on a setting rolling machine, and finishing.

[0043] 1) Two-component PET, PBT antistatic / anti-ultraviolet elastic fiber: conductive nano-tin oxide is premixed with PBT resin powder according to the mass ratio of 1%, the speed of the premixer is 200rpm, and it is prepared by a twin-screw extruder with anti-static properties. Electrostatic functional PBT polyester chips, twin-screw processing temperature is 250°C; UV1020 and dibutyltin are compounded at a ratio of 20:1 and dispersed in ethylene glycol by ultrasonic, and terephthalic acid is mixed at a molar ratio of 1:1 Proportional in-situ polymerization reaction, the addition of ultraviolet compounding additives is 0.5%, the polymerization temperature is 275 ° C, and the polymerization reaction time is 6 hours to obtain PET polyester chi...

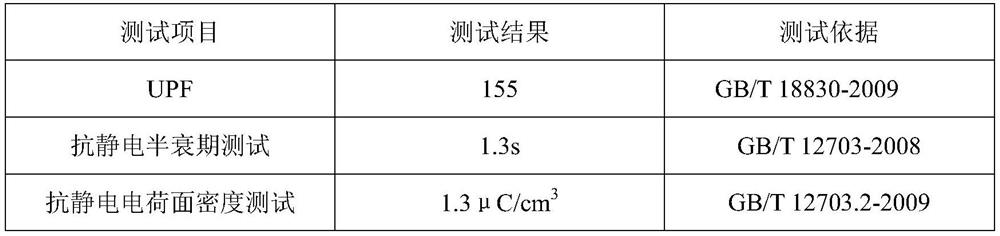

Embodiment 3

[0053] The preparation method of the antistatic / anti-ultraviolet warp-knitted elastic fabric of the present invention comprises yarn preparation, weaving, dyeing, setting, fluffing, softening on a setting rolling machine, and finishing.

[0054] 1) Two-component PET, PBT antistatic / anti-ultraviolet elastic fiber: conductive nano-tin oxide is premixed with PBT resin powder according to the mass ratio of 1%, the speed of the premixer is 200rpm, and it is prepared by a twin-screw extruder with anti-static properties. Electrostatic functional PBT polyester chips, twin-screw processing temperature is 250°C; UV1020 and dibutyltin are compounded at a ratio of 20:1 and dispersed in ethylene glycol by ultrasonic, and terephthalic acid is mixed at a molar ratio of 1:1 Proportional in-situ polymerization reaction, the addition of ultraviolet compounding additives is 0.5%, the polymerization temperature is 275 ° C, and the polymerization reaction time is 6 hours to obtain PET polyester chi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Lateral density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com