Excavator bucket capable of swinging through gear drive and hydraulically enhancing digging force

A gear-driven, excavating force technology, applied in the direction of earth mover/shovel, construction, etc., can solve problems such as difficulty in meeting construction requirements, limited excavation force, and upper and lower rotation restrictions, and achieves improved excavation efficiency, large excavation force, The effect of structural optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

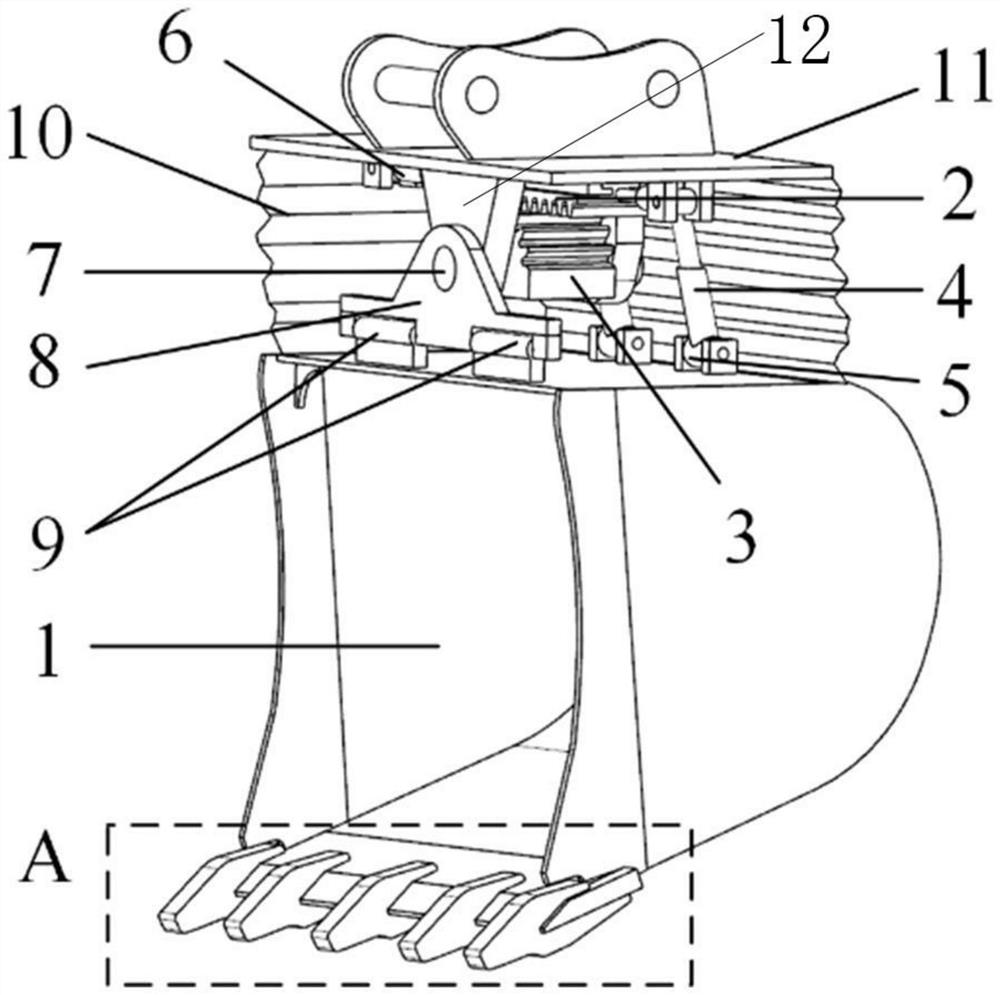

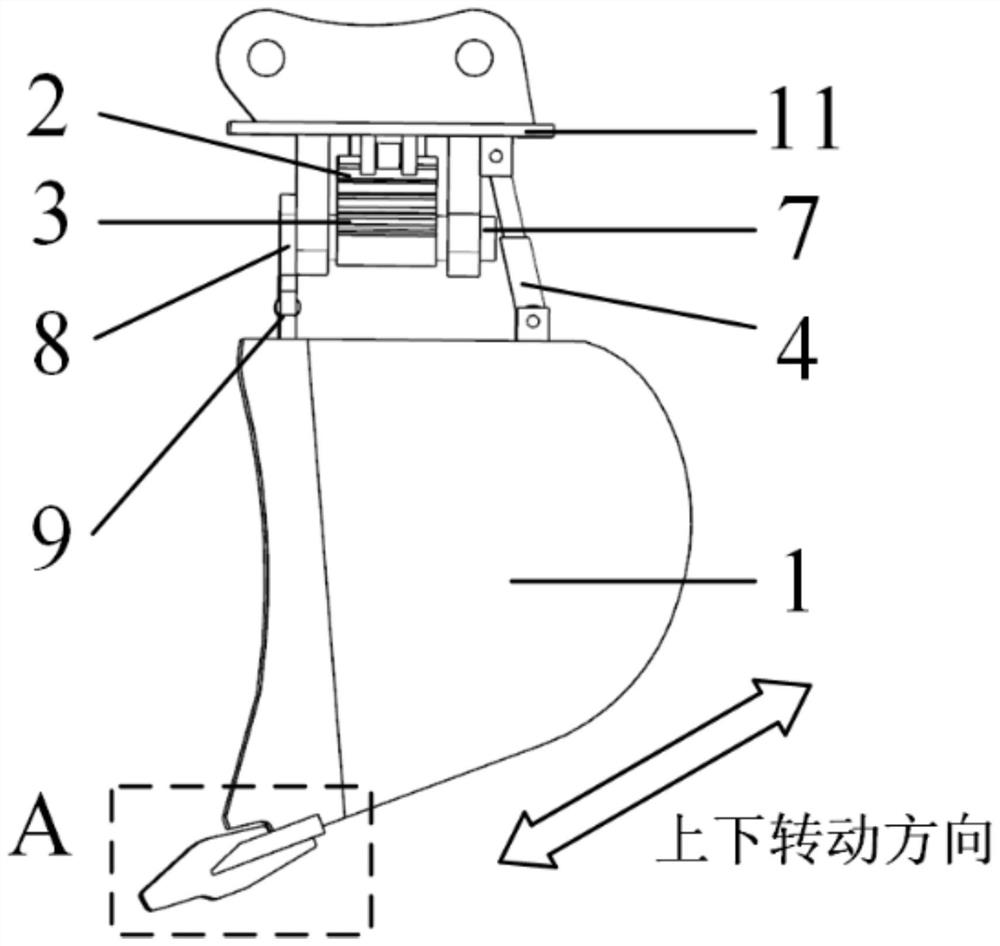

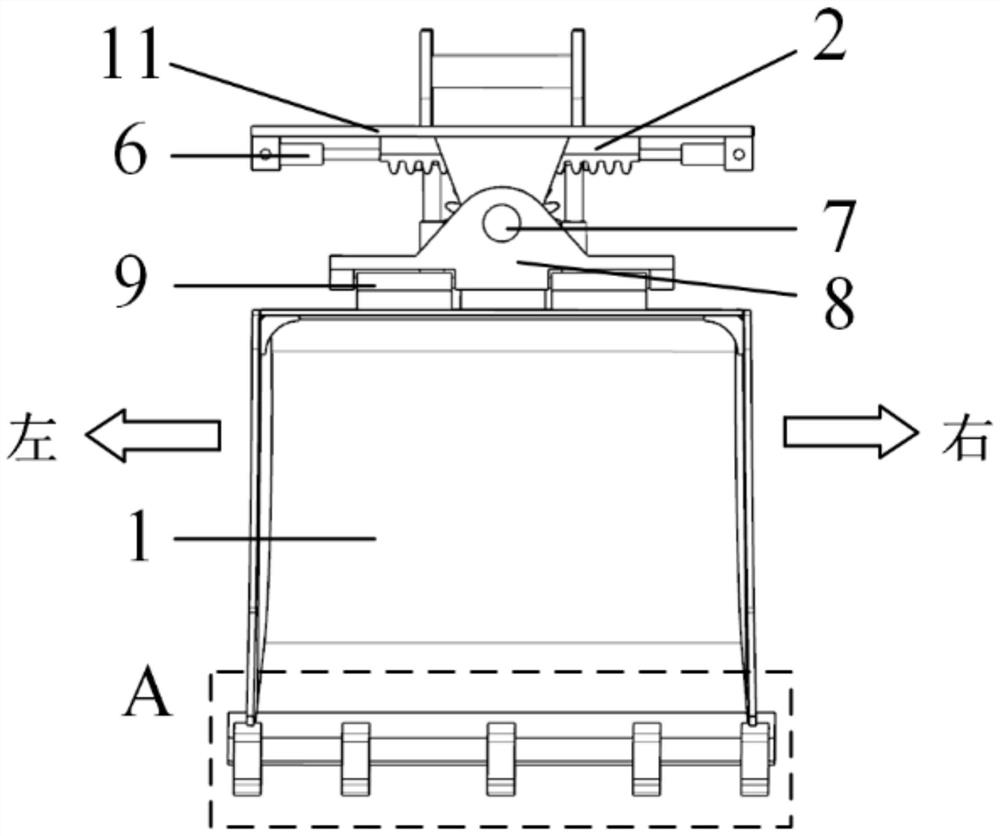

[0020] Such as Figures 1 to 3 , a gear-driven bucket with hydraulically enhanced digging force, comprising a bucket body 1, an upper fixed plate 11, a translational rack 2, a semicircular gear 3, and the semicircular gear 3 is fixedly mounted on the gear central shaft 7, and the translational movement The rack 2 and the semi-circular gear 3 are meshed with each other. A set of first hydraulic cylinders 6 are arranged at both ends of the translation rack 2. One end of the first hydraulic cylinder 6 is connected to the upper fixed plate 11, and the other end is connected to the translation rack 2. , the first hydraulic cylinder 6 is used to drive the translation rack 2 to reciprocate in the horizontal direction; the upper front side of the bucket body 1 is connected with the lower connecting piece 8, and the lower front side of the upper fixing plate 11 is fixed with the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com