Steel column mounting structure with rapid mounting function and construction process thereof

A technology for installing structures and steel columns, which is applied in the field of steel columns, can solve the problems of reducing the bearing stability of steel columns to buildings, low connection strength, loose connections, etc., and achieve the goal of improving connection strength and connection stability, and improving connection strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

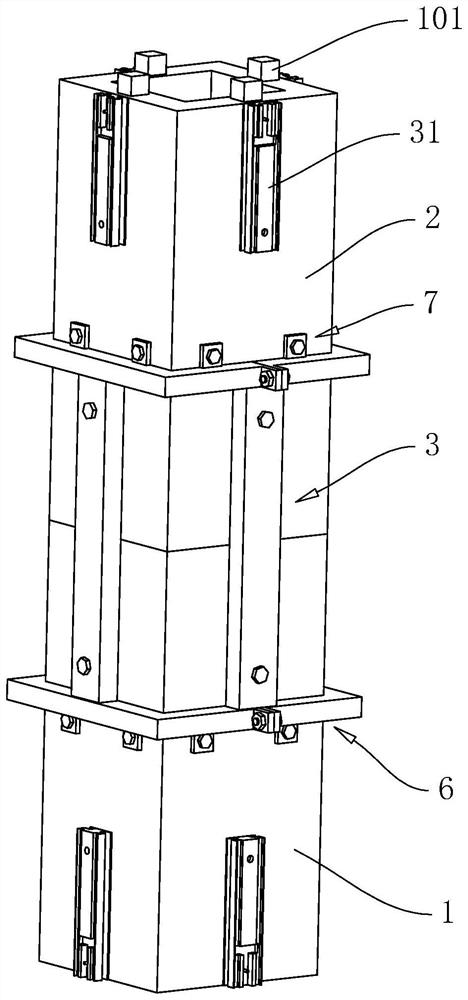

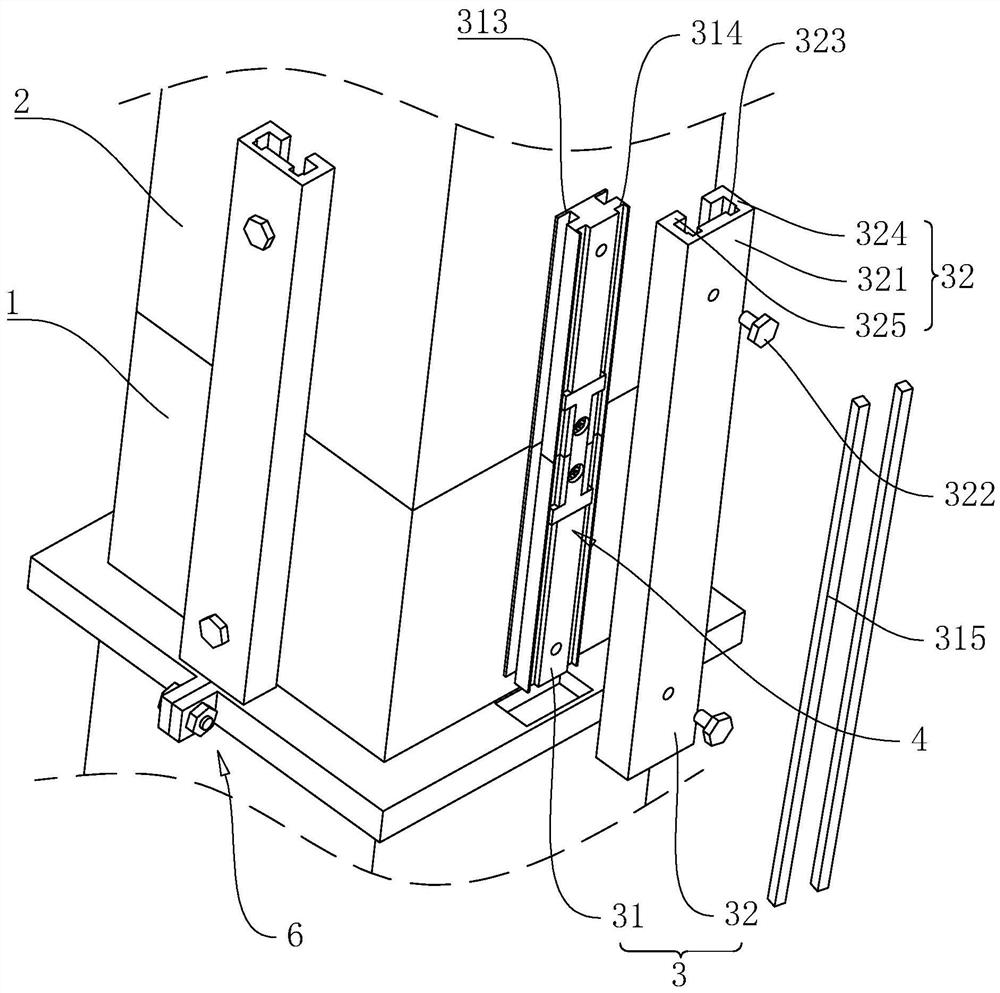

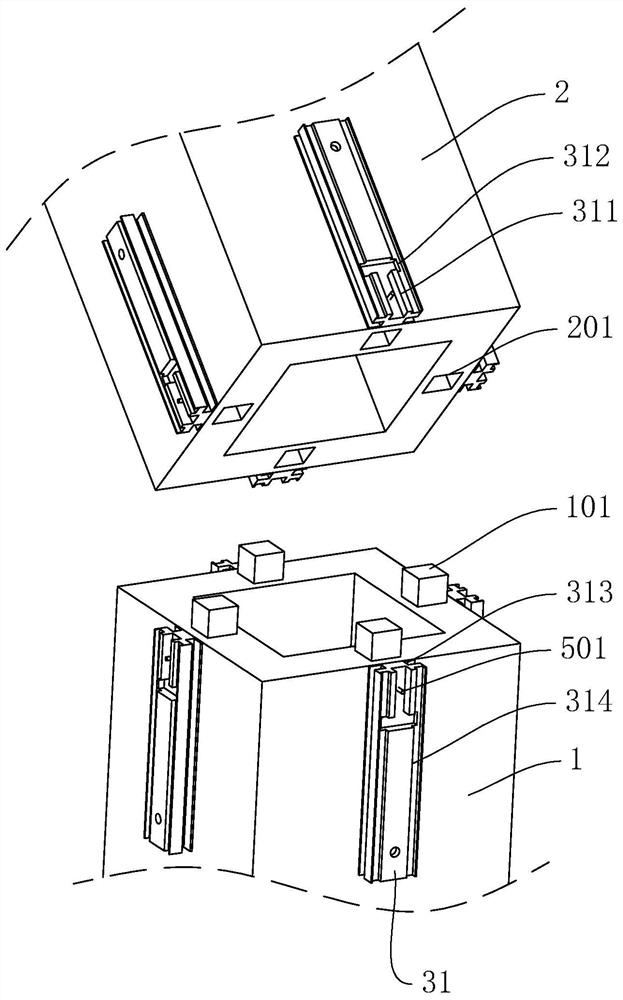

[0037] The following is attached Figure 1-4 The application is described in further detail.

[0038] The embodiment of the present application discloses a quick-installation steel column installation structure. refer to figure 1 , 2 , including a first steel column 1 and a second steel column 2 . A connection assembly 3 is jointly arranged between the first steel column 1 and the second steel column 2 , and the connection assembly 3 includes a side strip 31 and a locking member 32 . The side strips 31 are respectively fixed on the outer walls of the first steel column 1 and the second steel column 2. When the ends facing each other of the first steel column 1 and the second steel column 2 touch each other, the end walls of the side strips 31 facing each other offset. Between the opposing side bars 31 , a pair of pull assemblies 4 are jointly arranged, and the pull assemblies 4 make the first steel column 1 and the second steel column 2 fixedly connected. The engaging pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com