Intelligent laser tester

A tester and laser technology, applied in the field of measurement, can solve the problems of increasing the difficulty of work and inconvenient operation of the staff, and achieve the effect of reducing the difficulty of work, easy operation and improving the accuracy of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

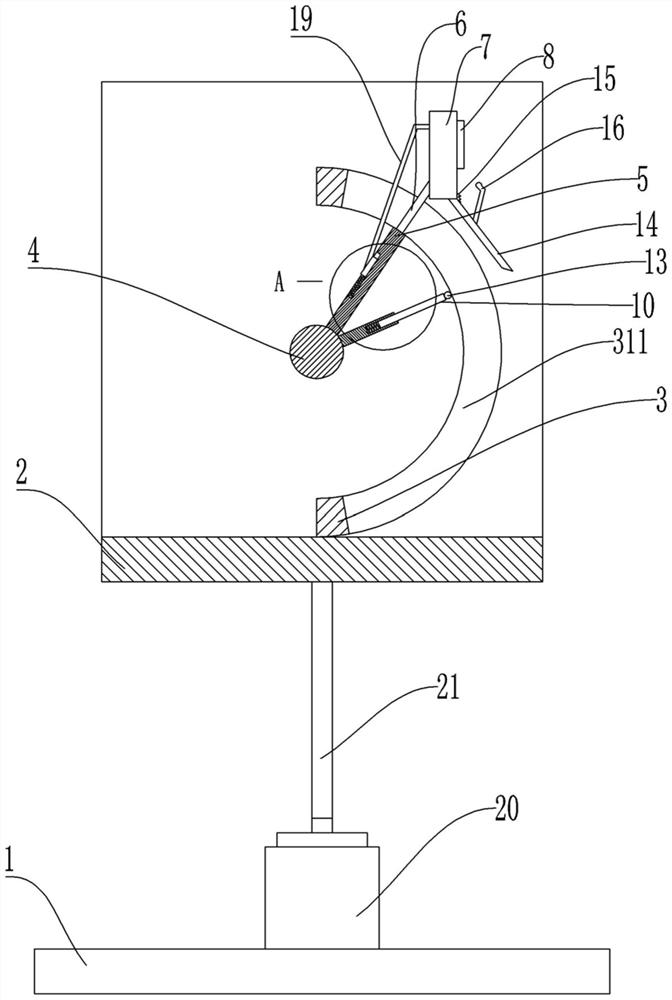

[0035] Basic as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 Shown: an intelligent laser tester, including a base 1 and a lifting platform 2, the base 1 is provided with a lifting mechanism for driving the lifting platform 2 up and down, and the lifting mechanism includes a cylinder 20 symmetrically fixed on the base 1 along the center line of the base 1 , a vertical block 21 affixed to the output shaft of the cylinder 20, and the free end of the vertical block 21 is affixed to the bottom of the lifting platform 2.

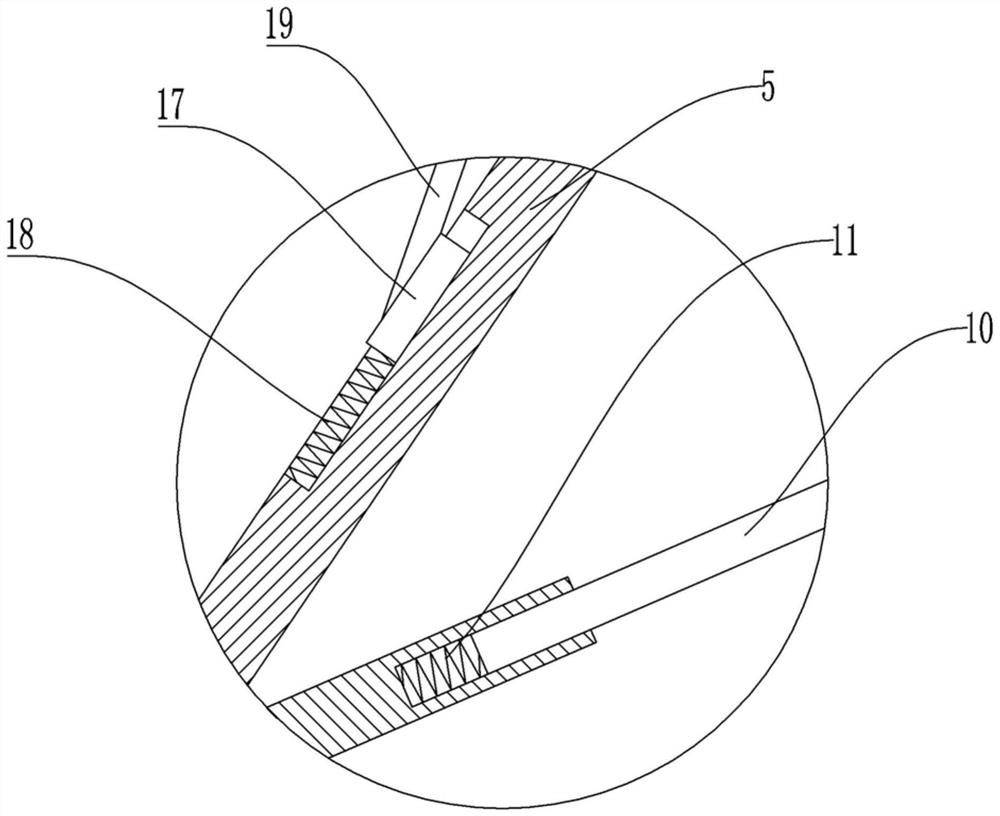

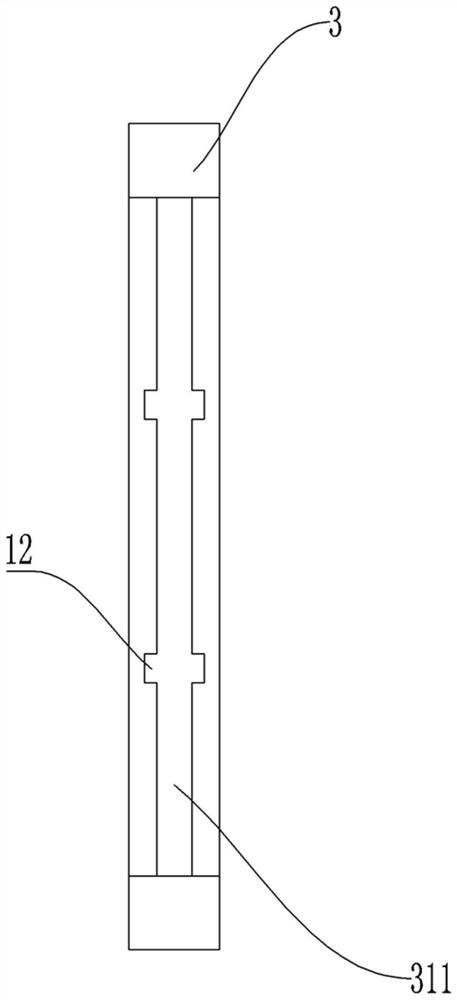

[0036]The lifting platform 2 is concave, and the lifting platform 2 is fixedly connected with an arc-shaped block 3, and the arc-shaped block 3 is provided with an arc-shaped hole 311; shaft setting; the arc surface of the rotating shaft 4 is fixedly connected with the adjusting rod 5, and the free end of the adjusting rod 5 is fixedly connected with the guide block 6, and the guide block 6 is slidingly connected with the ar...

Embodiment 2

[0046] Basic as attached Figure 5 As shown, the structure and implementation of Embodiment 2 are basically the same as Embodiment 1, the difference is that: the base 1 is fixed with a transverse plate 22, and the transverse plate 22 is located between the lifting platform 2 and the base 1; the transverse plate 22 are symmetrically provided with a vertical hole and a transverse groove 23 along the center line of the transverse plate 22, and the distance between the two vertical holes is greater than the distance between the two transverse grooves 23; the vertical block 21 is slidingly connected with the vertical hole, and the transverse groove 23 The horizontal block 24 is slidingly connected inside; the horizontal plate 22 is vertically slidably connected with a rack 25 passing through the lifting platform 2, and the rack 25 is located between the two transverse grooves 23; The gear 26 of gear; The both sides of rack 25 are all hinged with linkage arm 27, and the free end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com