A non-contact automatic detection method for paste concentration

A non-contact, automatic detection technology, applied in neural learning methods, measuring devices, character and pattern recognition, etc., can solve the problems of low degree of automation and low accuracy, and achieve the effect of improving measurement accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

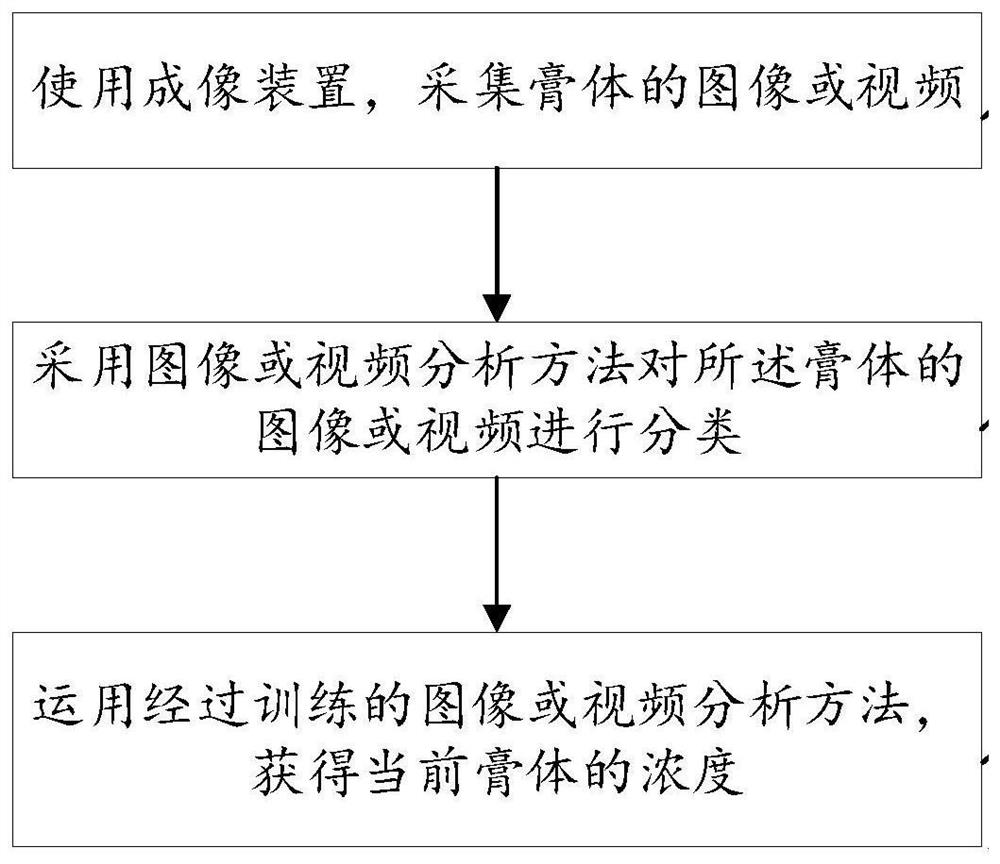

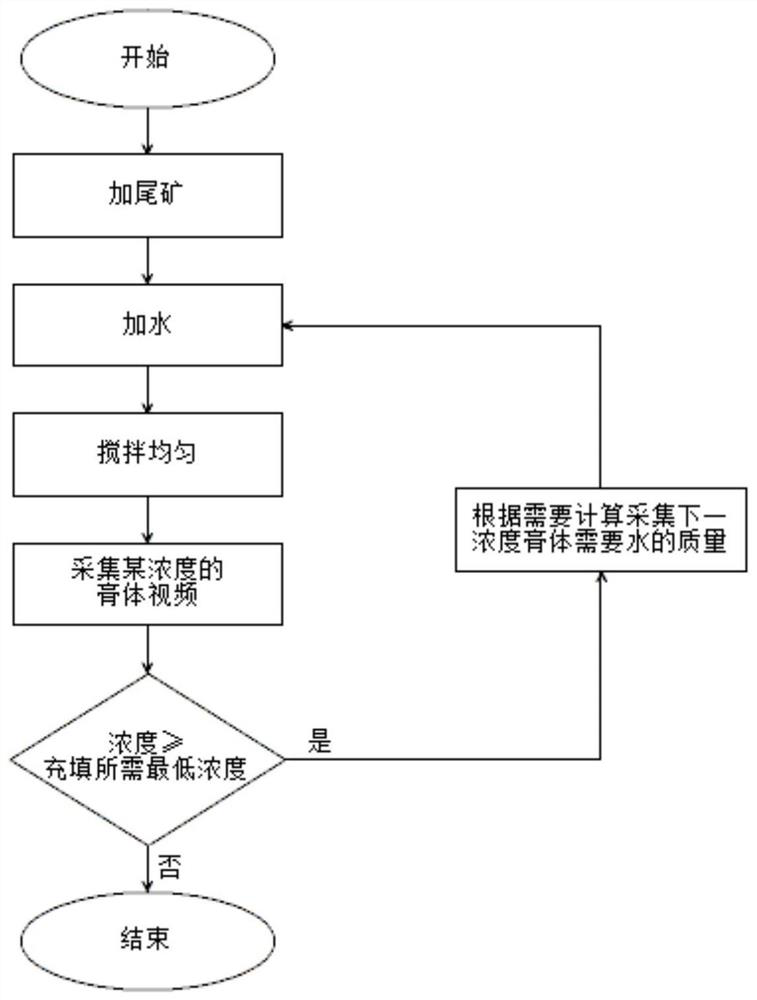

[0060] like figure 1 Shown is a schematic flowchart of a method for detecting the concentration of paste according to an embodiment of the present invention, including:

[0061] (1) Use an imaging device to collect images or videos of the paste;

[0062] (2) using image or video analysis method to classify the image or video of the paste;

[0063] (3) Obtain the concentration of the current paste according to the image or video classification result of the paste.

[0064] In the specific embodiment of the aforementioned paste concentration detection method, further, the use of an imaging device to collect images or videos of the paste includes:

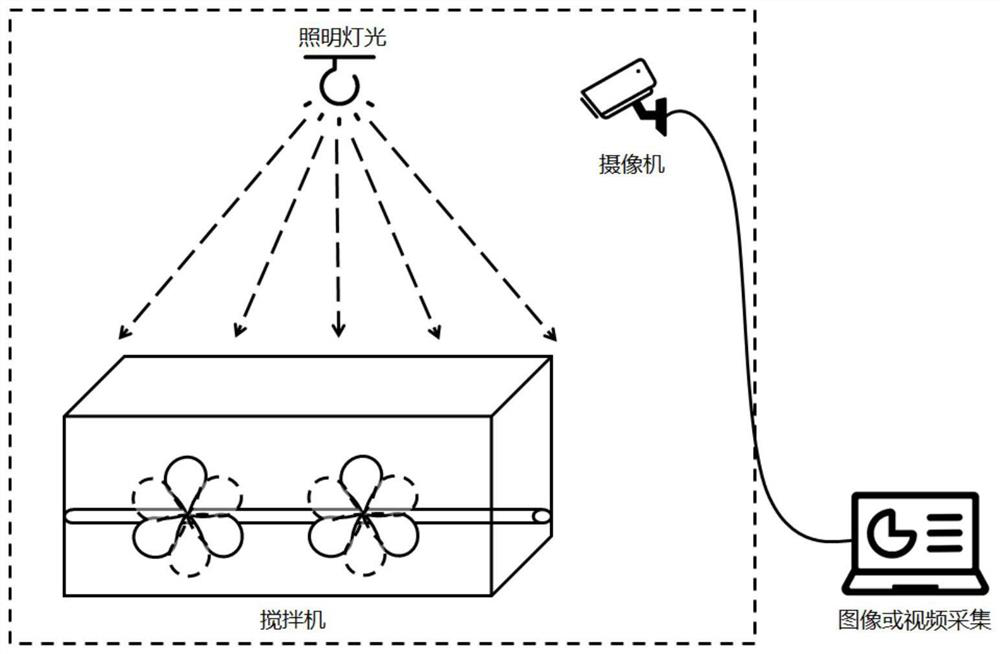

[0065] Step (1-1): Build a paste preparation and labeling data collection environment. like figure 2 As shown, the environment includes an imaging device, a stirring tank, constant lighting, and tailings. An imaging device is set up around the stirring tank, so that the imaging device can capture the image or video of the paste ...

Embodiment 2

[0096] The present invention also provides a paste concentration detection device. Since the paste concentration detection device provided by the present invention corresponds to the specific embodiment of the above-mentioned paste concentration detection method, the paste concentration detection device can be implemented by executing the specific embodiment of the above method. Therefore, the explanations in the specific embodiments of the above-mentioned paste concentration detection method are also applicable to the specific embodiments of the paste concentration detection device provided by the present invention, and the following specific implementations of the present invention The method will not be repeated here.

[0097] like Figure 10 As shown, an embodiment of the present invention further provides a multi-target tracking device for a series of cross-sectional images, including:

[0098] The acquisition module 11 is used for acquiring the image or video of the pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com