Ultraviolet gas analysis method and ultraviolet gas analyzer

A gas analyzer and gas analysis technology, applied in the field of measurement, can solve the problems of affecting the measurement accuracy of gas concentration, the error of consistent measurement results, and high cost, and achieve the effects of low maintenance cost, long service life and improved shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

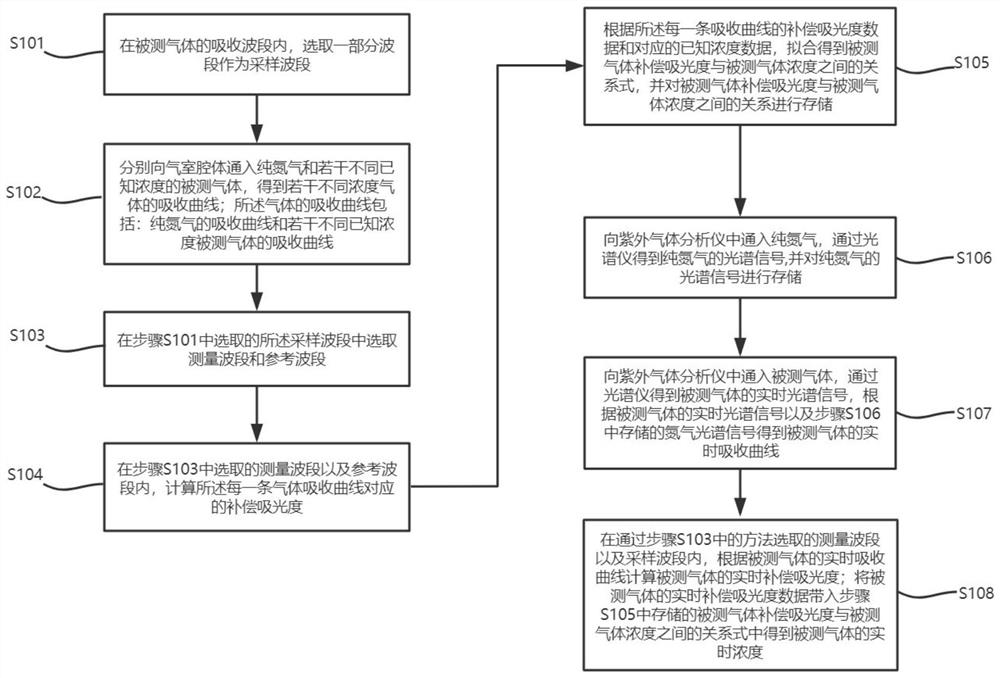

[0041] Please refer to figure 1 , a kind of ultraviolet gas analysis method, specifically comprises the following steps:

[0042] S101: within the absorption band of the gas to be measured, select a part of the band as the sampling band;

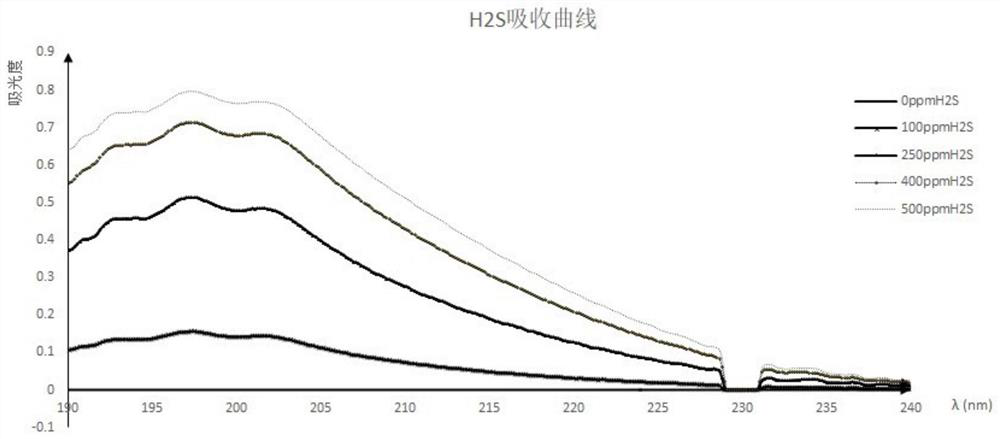

[0043] In the background technology and examples of the present application, hydrogen sulfide gas is used as an example, but this is not limited; it is known that hydrogen sulfide gas absorbs ultraviolet light at a wavelength of 190-240nm. When measuring other measured gases, different gases The absorption band of ultraviolet light will be different.

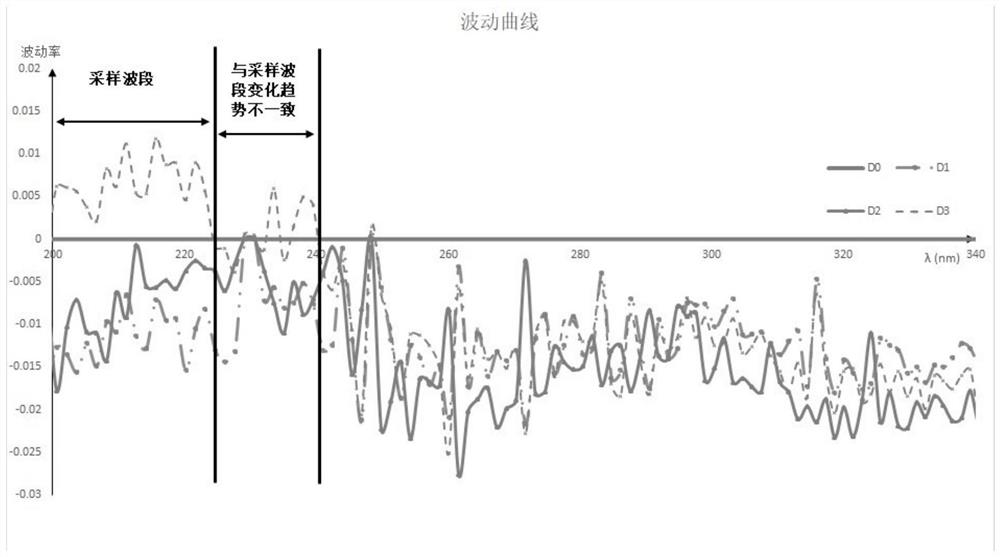

[0044] The sampling band is selected in the following way: by passing pure nitrogen into the gas chamber cavity, the pure nitrogen spectrum is obtained through spectro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com