Remote monitoring and optimizing method for fuel evaporation leakage of gasoline vehicle

A technology of remote monitoring and optimization method, applied in design optimization/simulation, fluid tightness test, machine/structural component test, etc. It can solve the problem of poor data robustness, limited collected data, and increased after-sales problems. Probability and maintenance costs, etc., to achieve the effect of reducing labor and material costs and improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] see Image 6 , the remote monitoring and optimization method of gasoline vehicle fuel evaporation leakage of the present invention, the realization process is as follows:

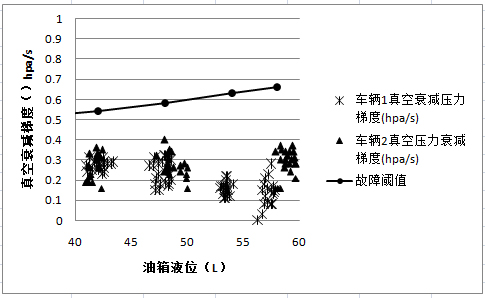

[0033]1) Use the remote acquisition system to transmit the attenuation gradient value of the fuel tank vacuum pressure calculated by the ECU to the cloud server through the 4G / 5G / WIFI network, and use the model built by Simulink on the cloud server to determine the vacuum pressure of the vehicle at different fuel levels Statistical attenuation gradient values are generated to generate corresponding statistical charts of vacuum pressure attenuation gradients;

[0034] 2) Perform normalized dimensionless parameter processing to generate a normalized dimensionless parameter statistical graph. The normalized parameter value is the ratio of the value of the vacuum pressure decay gradient to the fault threshold. If the normalized parameter is greater than or equal to 1, the corresponding leakage fault w...

Embodiment 2

[0037] The remote monitoring and optimization method of gasoline vehicle fuel evaporation leakage in this embodiment is different from Embodiment 1 in that further, according to the leakage diagnosis fault on the cloud server, find out some abnormal points with poor robustness, and call And analyze the operating parameters of the car when the abnormal point occurs, find out the root cause of the abnormal occurrence in time, and optimize the fuel leakage diagnosis and development data online through the cloud. When the robustness data of some working conditions is found to be abnormal, the fuel leakage diagnosis and calibration parameters under the working conditions are directly optimized online in real time on the cloud server and updated to the vehicle ECU. The ECU data is optimized and updated until the engineering goal is achieved.

[0038] The remote monitoring and optimization method for fuel evaporation and leakage of gasoline vehicles can clearly see the vacuum pressur...

Embodiment 3

[0040] The remote monitoring and optimization method of gasoline vehicle fuel evaporation leakage in this embodiment is as follows:

[0041] 1. Fuel evaporation system

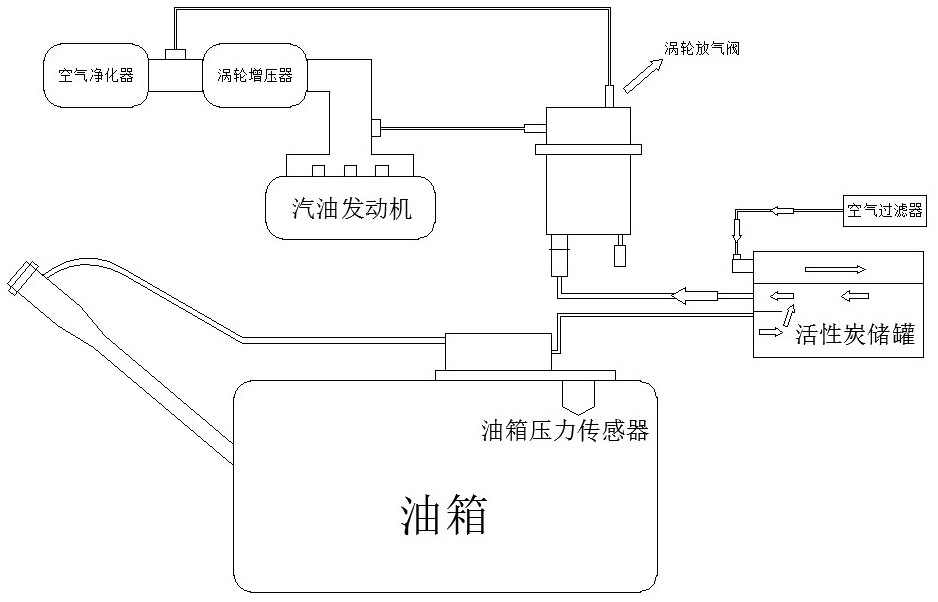

[0042] fuel evaporation system figure 1 As shown, it is mainly composed of fuel tank, carbon tank, carbon tank solenoid valve, carbon tank ventilation valve and corresponding pipelines. Since gasoline is easy to evaporate, the evaporated oil vapor will fill the fuel tank and corresponding evaporation system pipelines. If the entire fuel tank If the evaporation system is not well sealed and leaks, the oil vapor will easily leak into the atmosphere and pollute the environment. The National VI regulations for light vehicles require the detection of leakage faults larger than 1mm.

[0043] 2. Diagnosis principle of fuel evaporation system:

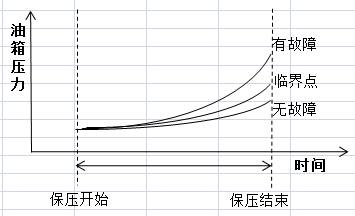

[0044] When the diagnostic conditions are satisfied, close the canister ventilation valve, open the canister solenoid valve, pump the pressure in the fuel tank to a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com