Gradient heating sheet for power battery of new energy automobile

A new energy vehicle and power battery technology, applied in the direction of ohmic resistance heating, ohmic resistance heating parts, secondary batteries, etc., can solve the problems of heat waste, inability to assist functions, low functionality, etc., to prevent shaking and prolong replacement The effect of spacing and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

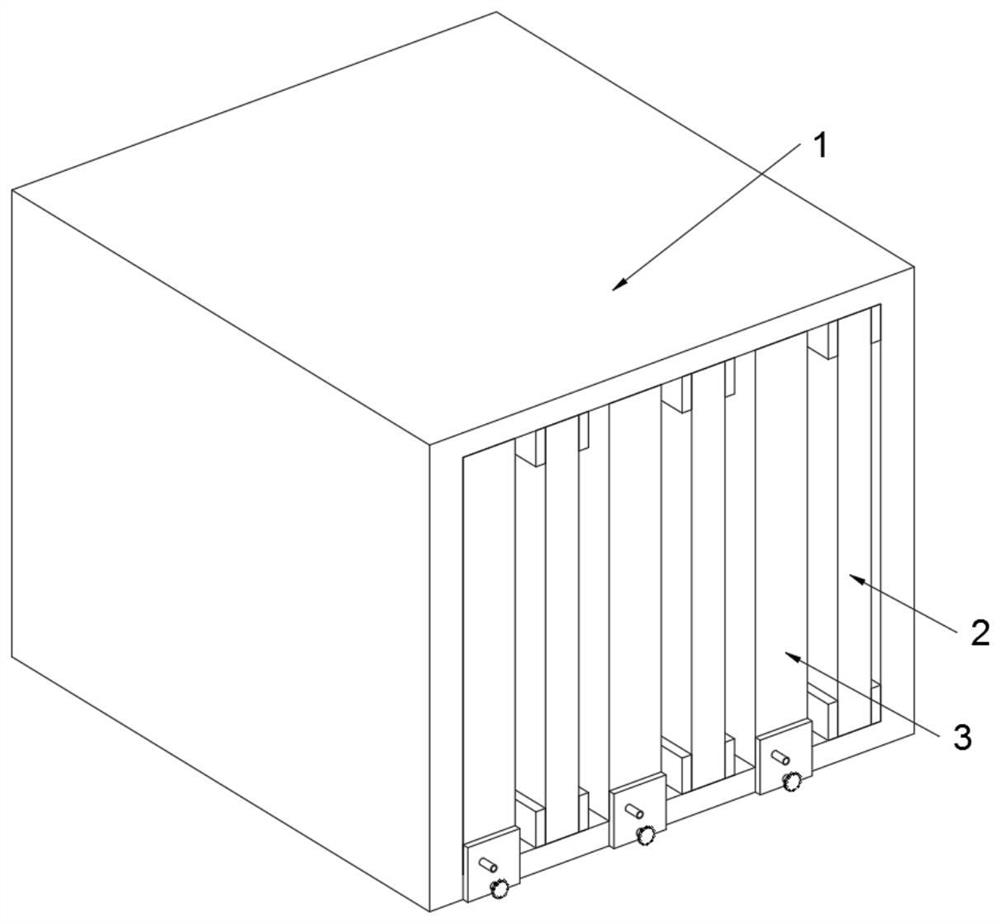

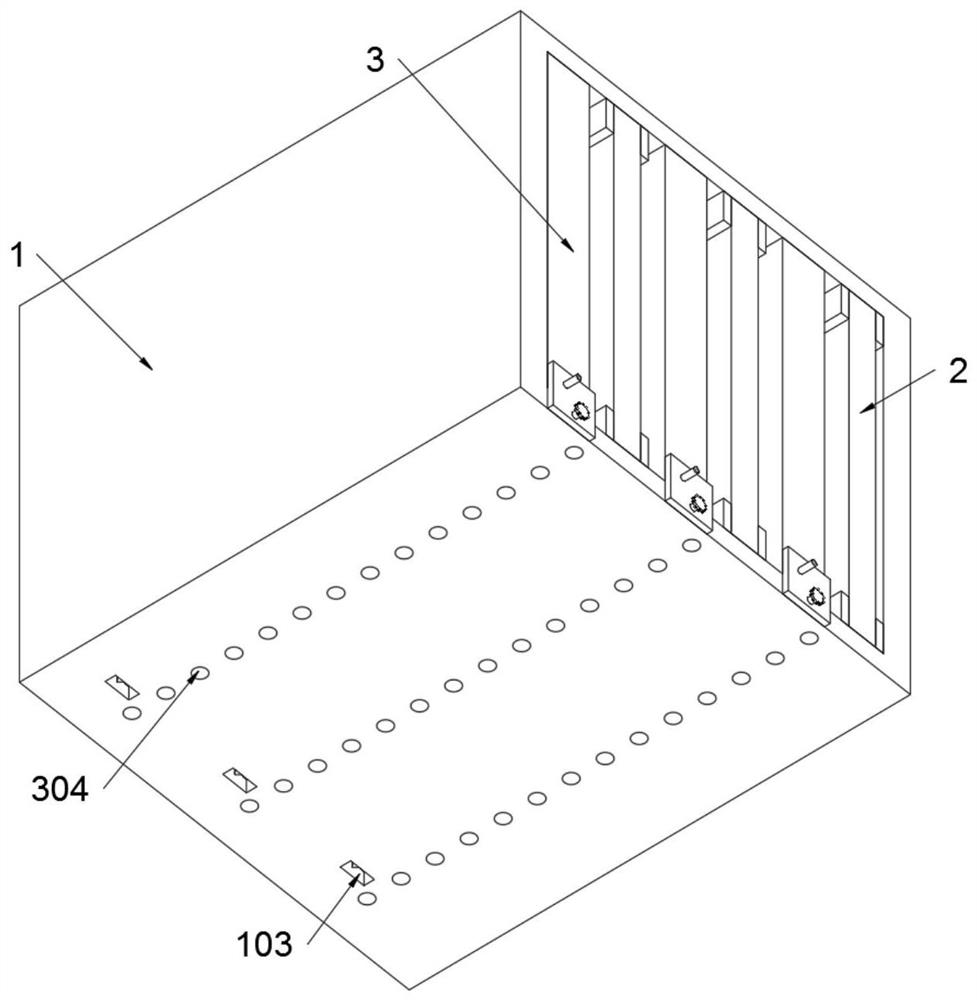

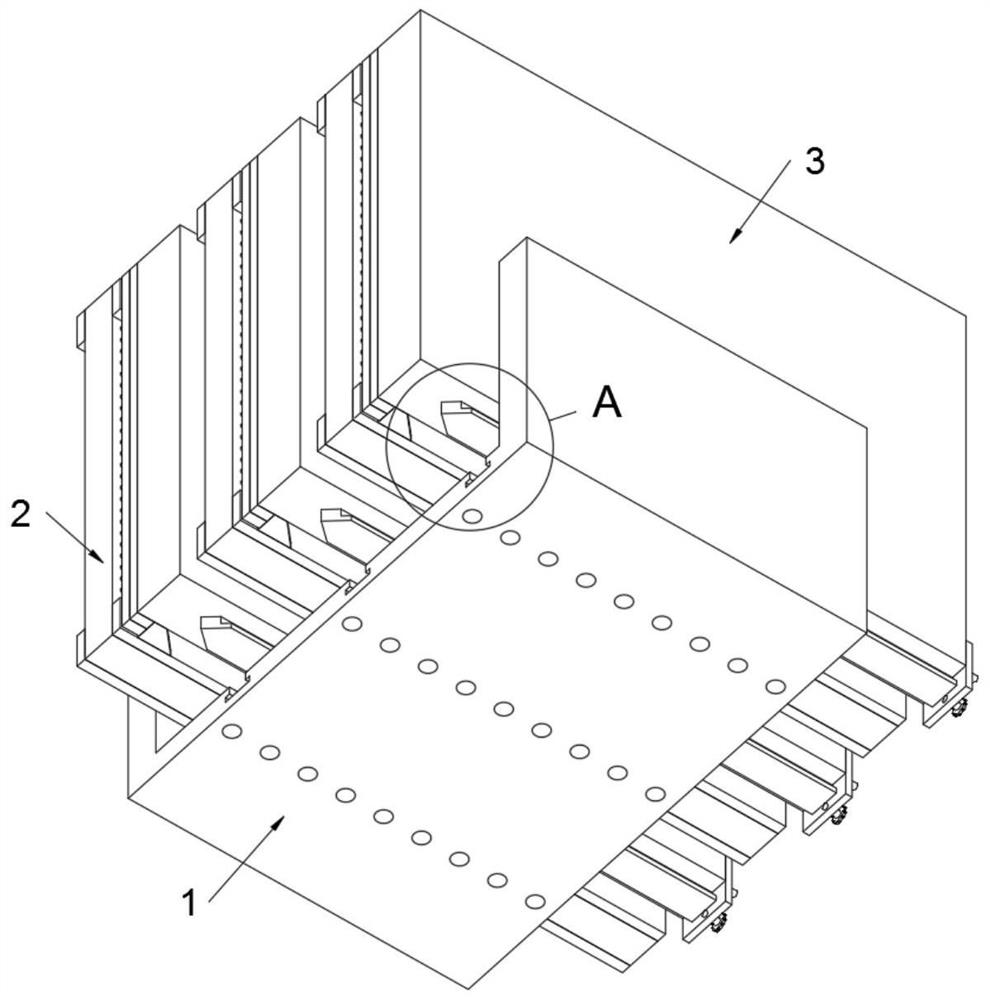

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The present invention provides a new energy vehicle power battery gradient heater, which includes a casing 1; a battery body 2 is installed in the casing 1, and three heating sheet structures 3 are installed in the casing 1; refer to Image 6 with Figure 7, the heating sheet structure 3 includes an elastic member 305 and a cleaning brush 306, the elastic member 305 is adhered to the heating sheet main body 301, and a cleaning brush 306 is attached to the elastic member 305; the cleaning brush 306 forms the cleaning structure of the battery main body 2 , and the cleaning brush 306 is in elastic contact with the battery main body 2, so that when the heating sheet main body 301 is pulled, the cleaning brush 306 can clean the dust on the surface of the battery main body 2, thereby improving the thermal conductivity of the surface of the battery main body 2, and due to the elastic member 305 setting, when the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com