Patents

Literature

46results about How to "Realize pooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

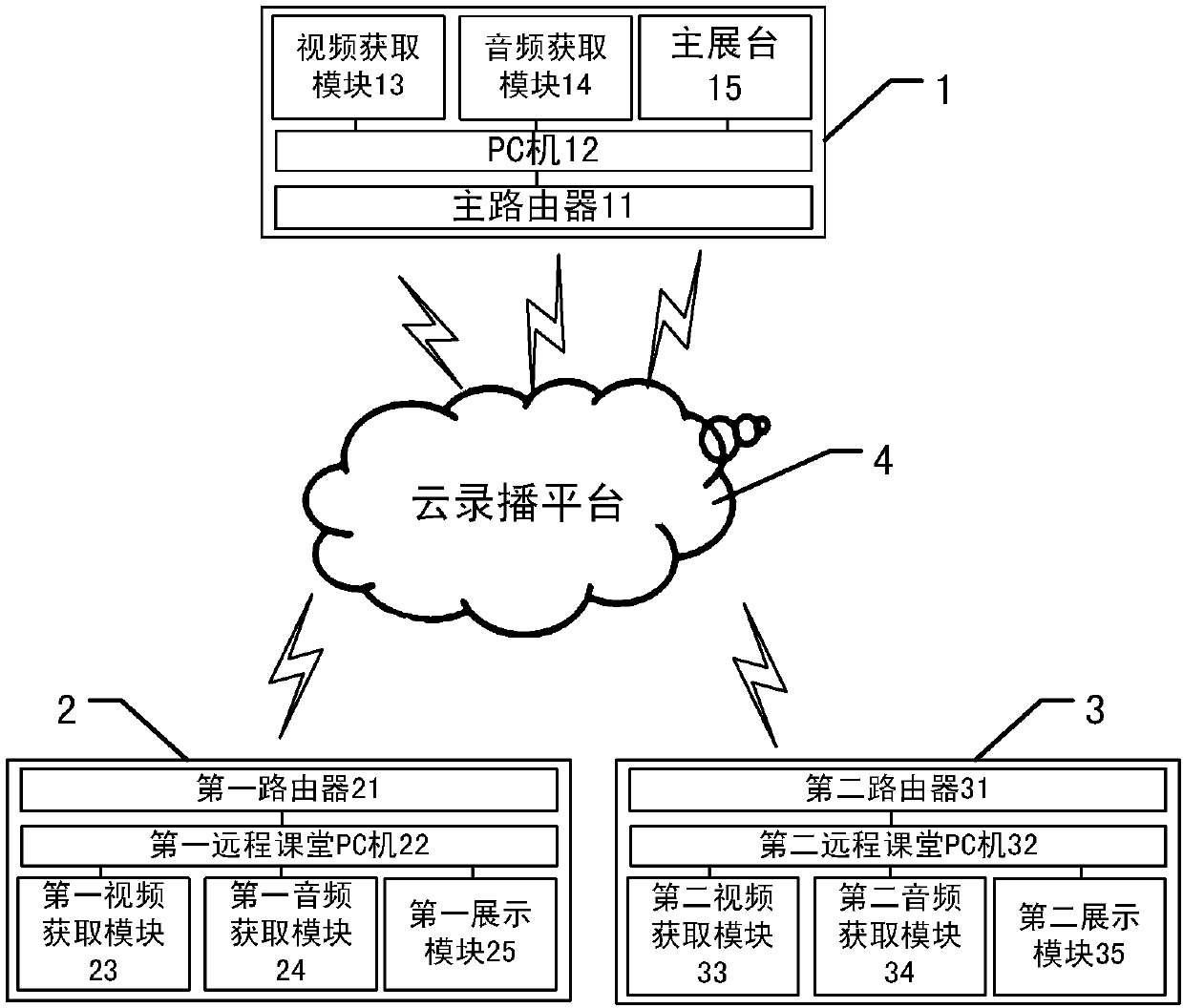

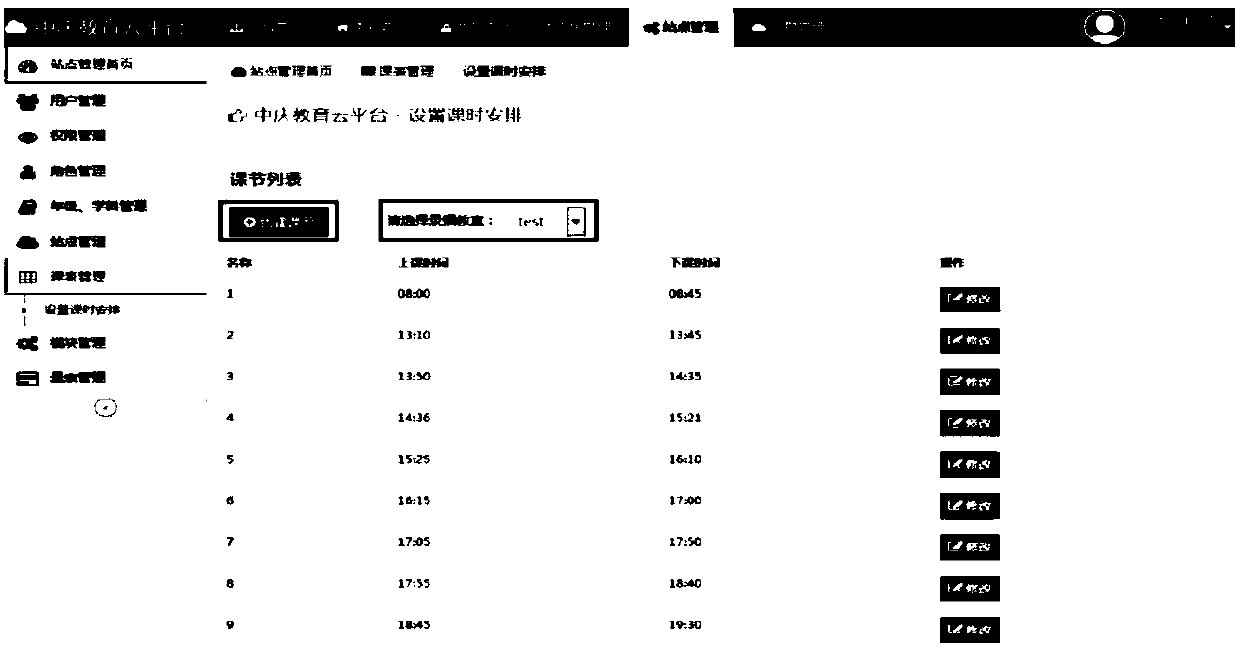

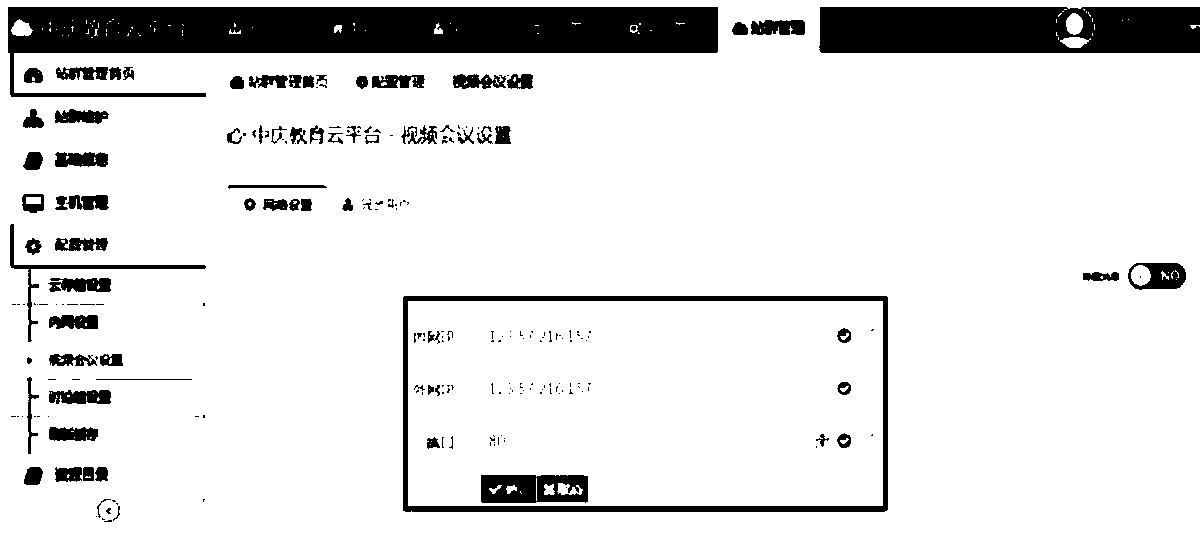

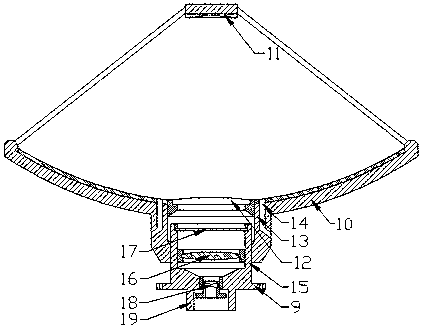

Synchronous mutual-assistance classroom teaching system

PendingCN107945592AEnable real-time interactionRealize "face-to-face" interactive question answeringTelevision system detailsColor television detailsPickupBroadcasting

The invention provides a synchronous mutual-assistance classroom teaching system comprisi a main classroom unit and two remote classroom units. The main classroom unit arranged in a high-quality recoding and broadcasting teaching room has an interactive terminal. The two remote classroom units are provided with normalized recording and broadcasting systems and are equipped with interactive terminals, high-definition cameras, pickup units, audio processors, all-in-one units, and loudspeakers and the like. The omnidirectional pickup units pick up sounds in all directions and the collected soundsare processed by the audio processors in a high-quality manner. A cloud recoding and broadcasting platform carried out operation by means of network school connection. With interactive teaching and paired assistance, good-quality resource sharing is realized and an objective of education balancing is achieved. Therefore, the children in low-quality schools can share the high-quality education resources. During the process of interactive teaching, main teachers and assisted teachers prepare lessons jointly and teaching reflection and teaching evaluation are carried out, so that the professional development of teachers is realized and the collection of high-quality education resources is realized.

Owner:杨斌

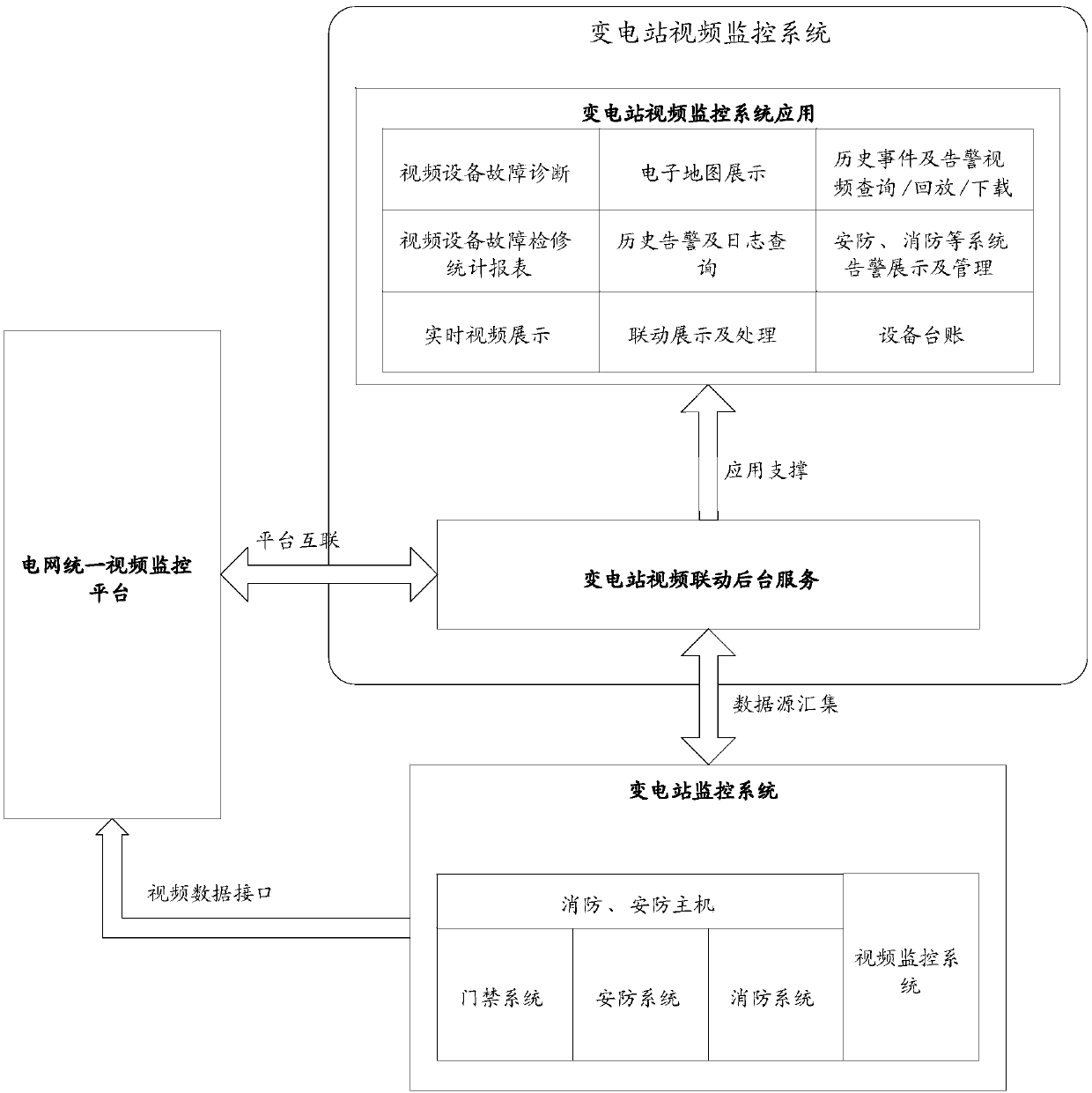

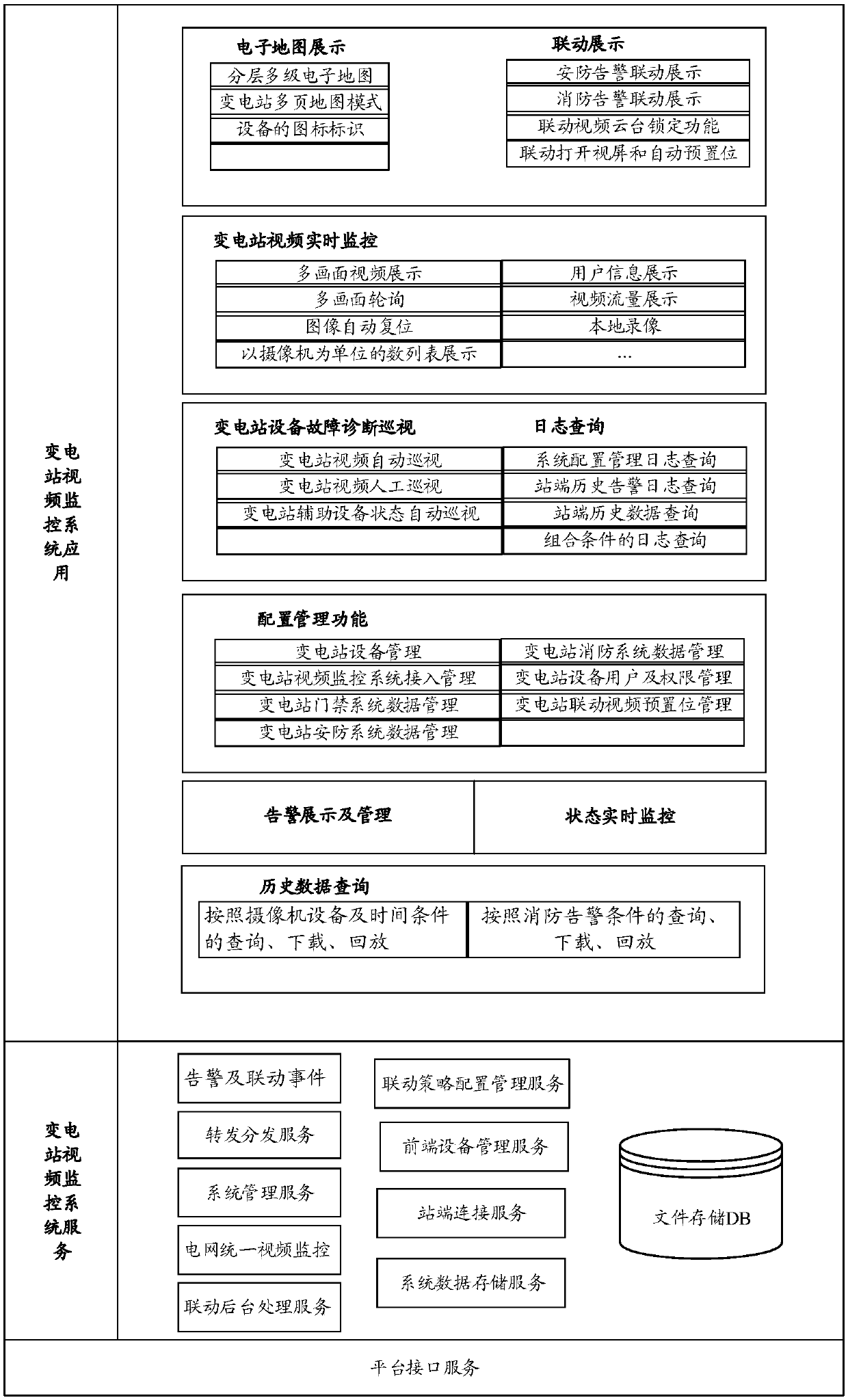

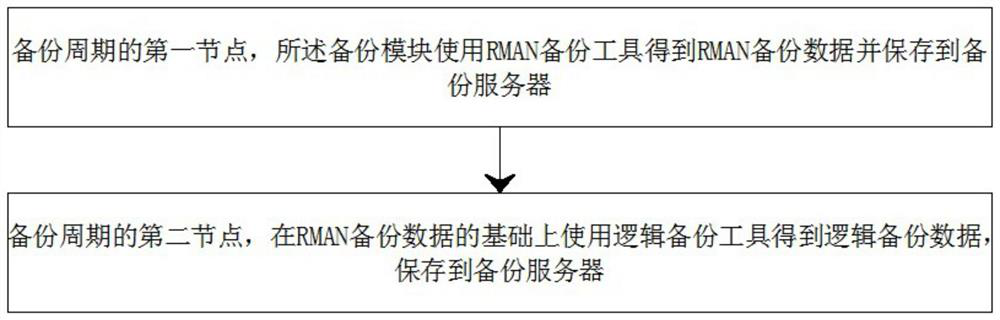

Substation auxiliary monitoring system based on micro-service architecture

InactiveCN109038832ARealize data interconnectionRealize poolingCircuit arrangementsClosed circuit television systemsMonitoring systemComputer terminal

The invention relates to a substation auxiliary monitoring system based on a micro-service architecture, comprising a monitoring module, a background server and a terminal application platform, wherein the monitoring module is used for monitoring and displaying data in the substation. The background server is used for centralized integration of the data in the station; The terminal application platform is used for providing application services according to the centrally integrated in-station data. The invention adopts the substation auxiliary monitoring system based on the micro-service structure, The terminal application platform realizes the data interconnection and collection of each monitoring platform by receiving the centralized and integrated station data of the background server,and can provide application services including electronic map display, log query, and video real-time monitoring of the substation, which ensures that the staff can fully grasp all the information ofthe equipment.

Owner:上海许继电气有限公司 +2

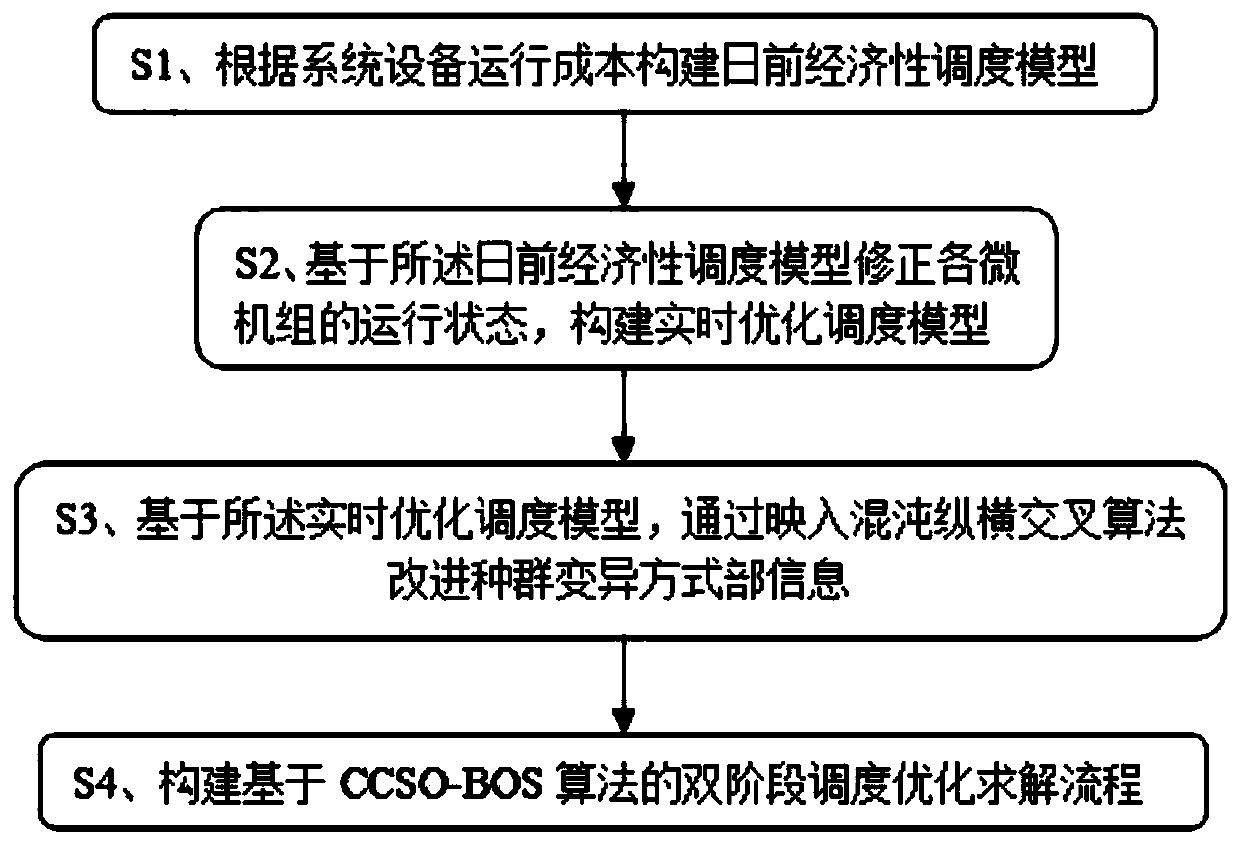

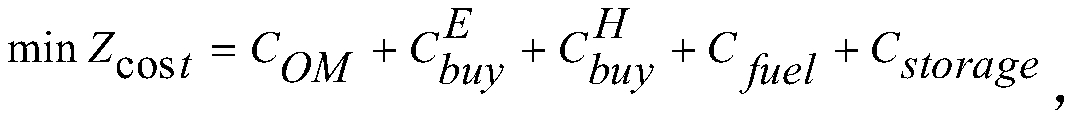

Two-stage scheduling model optimization method for integrated energy system

PendingCN110363363ATo achieve consumptionRealize comprehensive utilizationForecastingResourcesPopulation variationLoad forecasting

The invention discloses a two-stage scheduling model optimization method for an integrated energy system. The method comprises the following steps: S1, constructing a day-ahead economic scheduling model according to the operation cost of system equipment; S2, correcting the operation state of each micro-unit based on the day-ahead economic scheduling model, and constructing a real-time optimization scheduling model; S3, based on the real-time optimization scheduling model, improving a population variation mode by mapping a chaotic crisscross algorithm so as to ensure population diversity and all information of excellent individuals; and S4, constructing a two-stage scheduling optimization solving process based on a CCSO-BOS algorithm. According to the method, a day-ahead scheduling optimization model and a real-time scheduling optimization model of the comprehensive energy system are established on the basis of load prediction and renewable energy processing prediction data. The proposed multi-objective nonlinear optimization problem can be solved, so that renewable energy can be consumed and utilized to the maximum extent. The operation cost of the system is effectively reduced.

Owner:GUANGDONG POWER GRID CO LTD +1

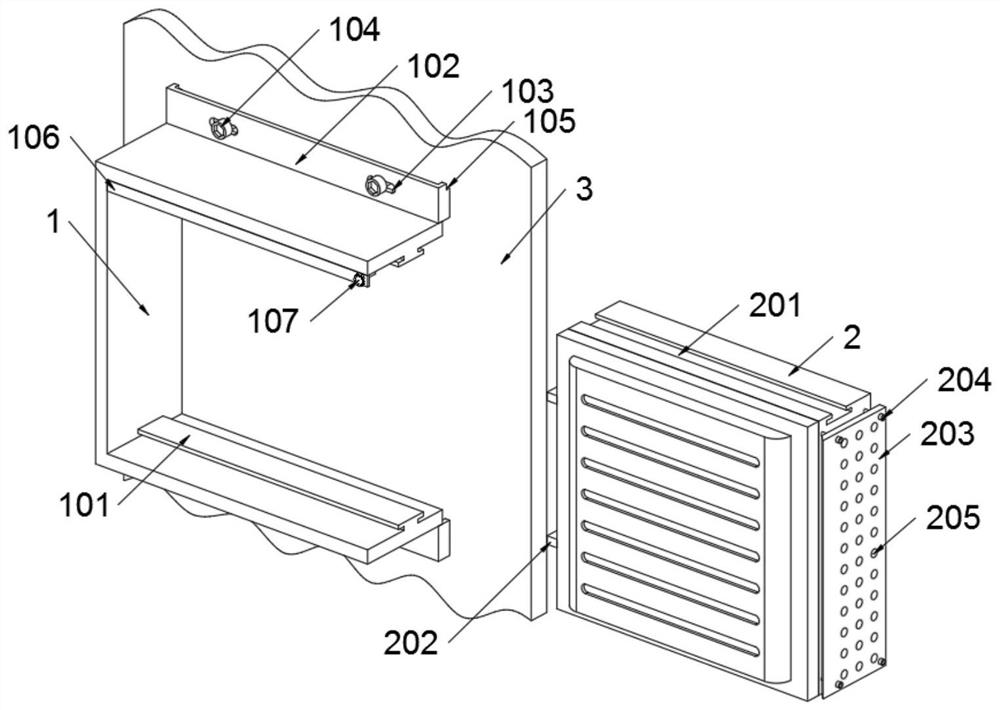

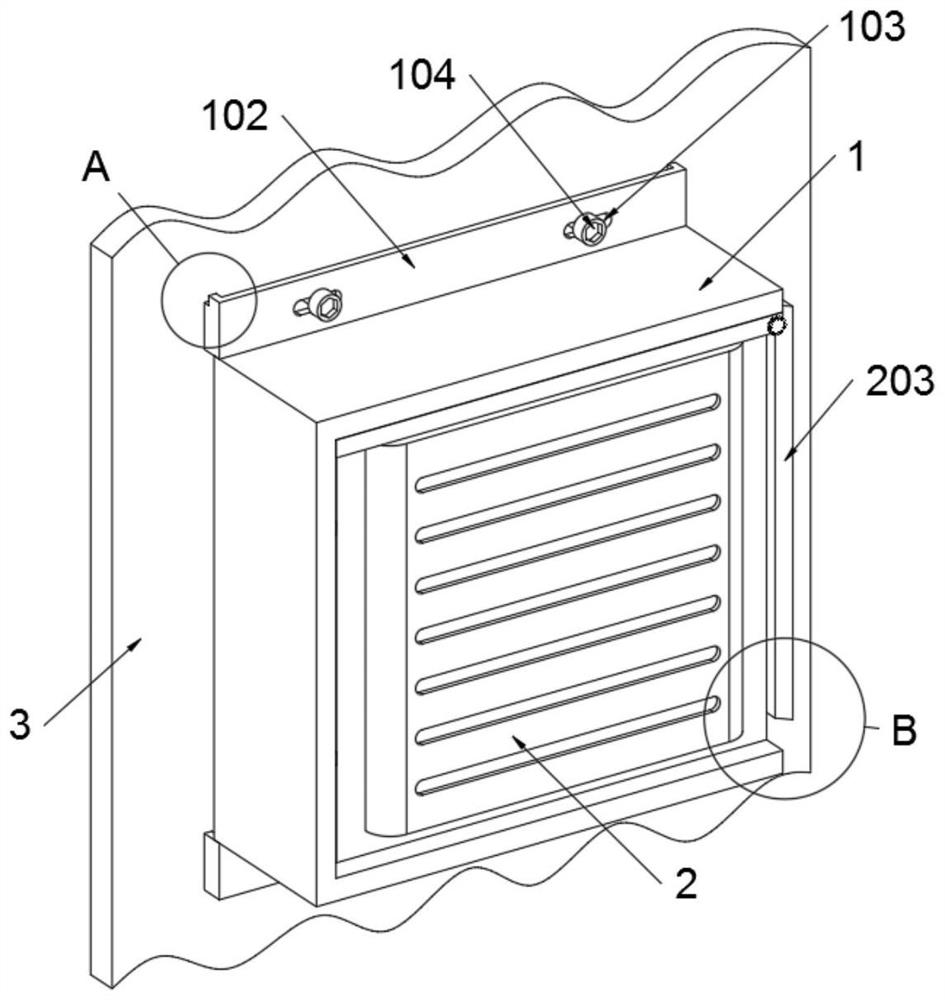

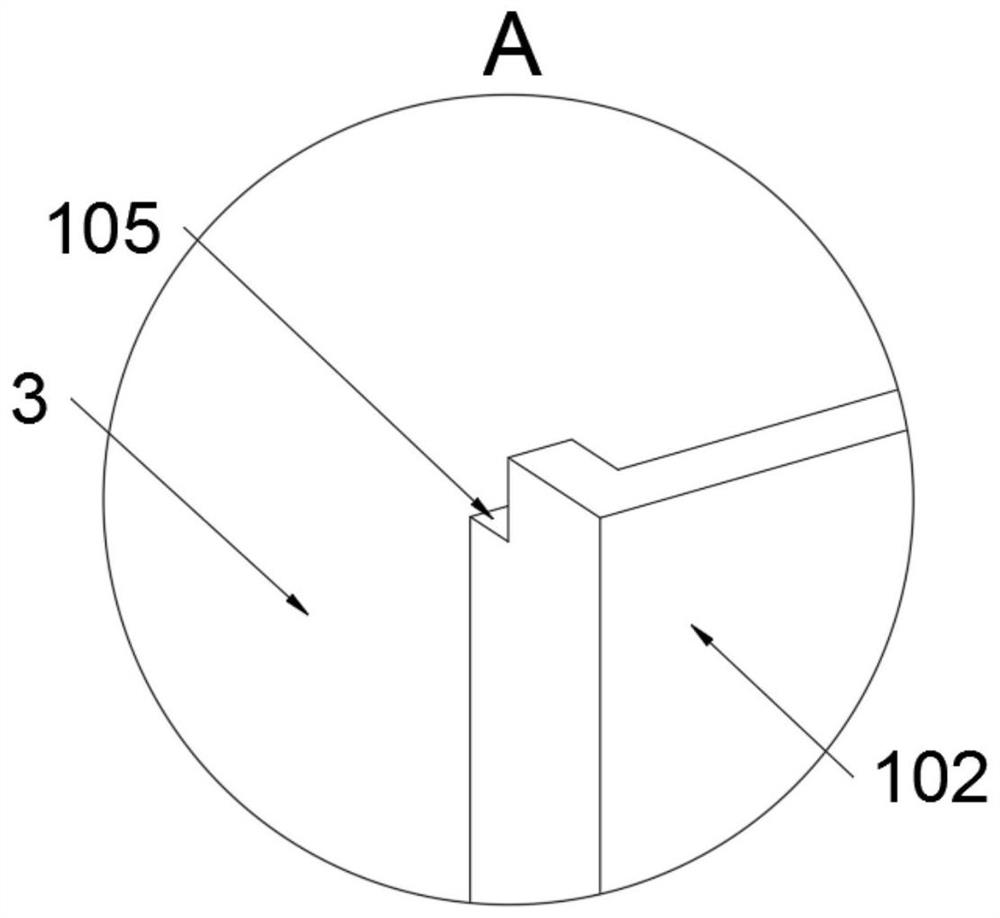

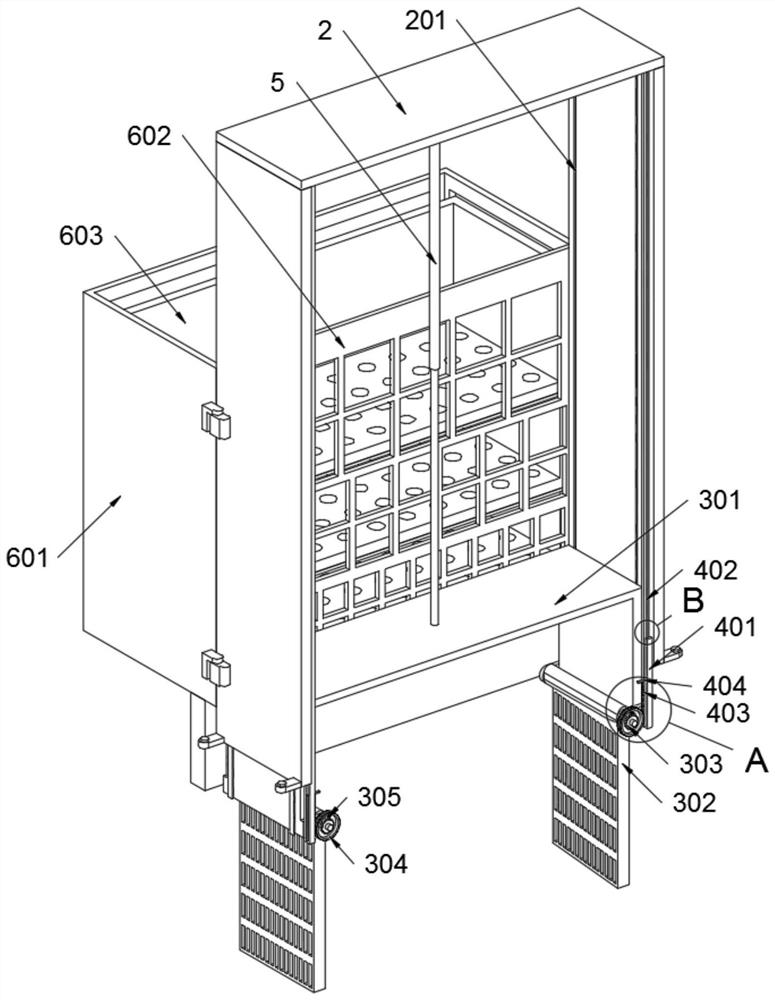

External information acquisition device of computer Internet of things

ActiveCN112631165AImprove stabilityImprove convenienceProgramme controlComputer controlStructural engineeringMechanical engineering

The invention provides an external information acquisition device of a computer Internet of things, relates to the technical field of Internet-of-things information acquisition, and solves the problems as follows: rainwater can not be avoided while elastic looseness prevention of a bolt is realized; an elastic buffer structure and a narrow air channel cannot be organically combined with each other through structural improvement; and organic combination of rainwater drainage and elastic looseness prevention of a bolt cannot be achieved through structural improvement. The external information acquisition device of the computer Internet of things comprises a mounting base, and an acquisition device body is mounted in the mounting base. A rectangular plate is welded to the bottom end face of the inner wall of the mounting base, the rectangular plate is in threaded connection with a fastening bolt, and the head end of the fastening bolt makes contact with an acquisition device body. The rectangular plate forms a drainage structure of rainwater at the top of the mounting base and further forms an elastic anti-loosening structure of the fastening bolt, so that the rectangular plate can achieve drainage of rainwater flowing down from the top of the mounting base and elastic anti-loosening of the fastening bolt.

Owner:CHONGQING VOCATIONAL COLLEGE OF TRANSPORTATION

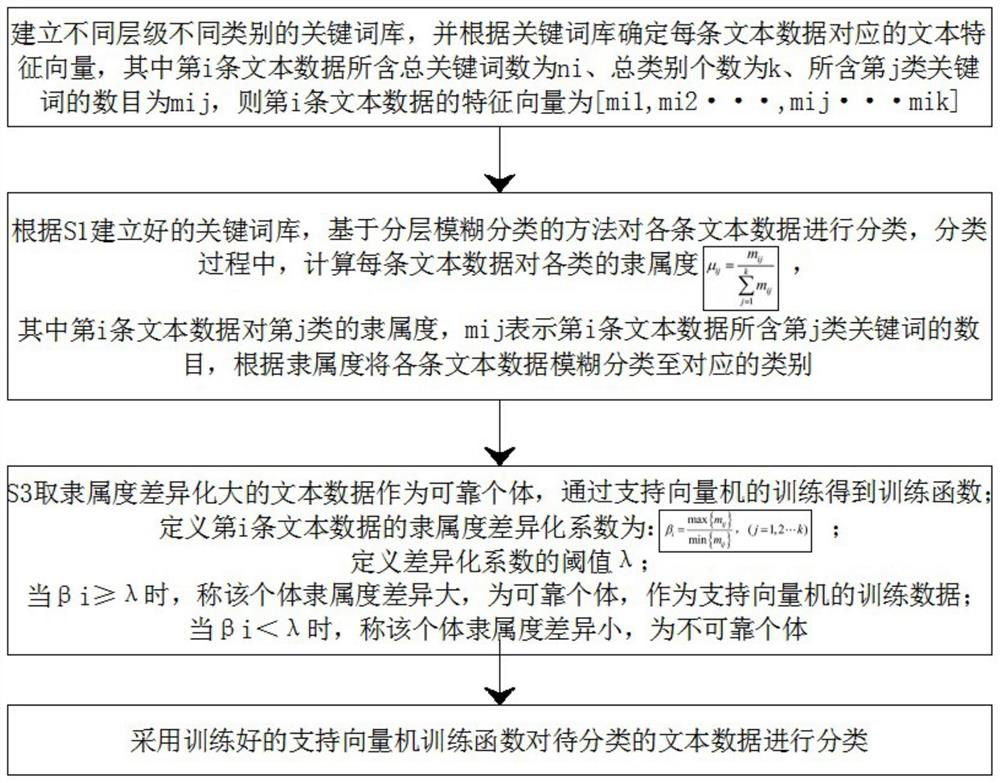

Pool classifying method of swimming fishes

InactiveCN103081829AImprove securityGood anesthesiaClimate change adaptationPisciculture and aquariaMedicineMortality rate

The invention belongs to fish culture management technology and particularly provides a pool classifying method of swimming fishes. The swimming fishes in a culture system are moved into an anesthesia box, the swimming fishes can lose capacity of action completely by adjusting anesthetic concentration in the anesthesia box and anesthesia time of the fishes, the swimming fishes after being anesthetized are classified according to sizes and transported to other culture systems in an out-of-water mode, and then the swimming fishes are revived so that the purposes of lowering density and breeding in a classification mode can be achieved. The pool classifying method can achieve the fact that the large fishes such as Atlantic salmon of 800-3000g can be safely transported in an out-of-water mode through a classifying pool in no less than 15 minutes, and remarkably lowers a death rate within 0.2%.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

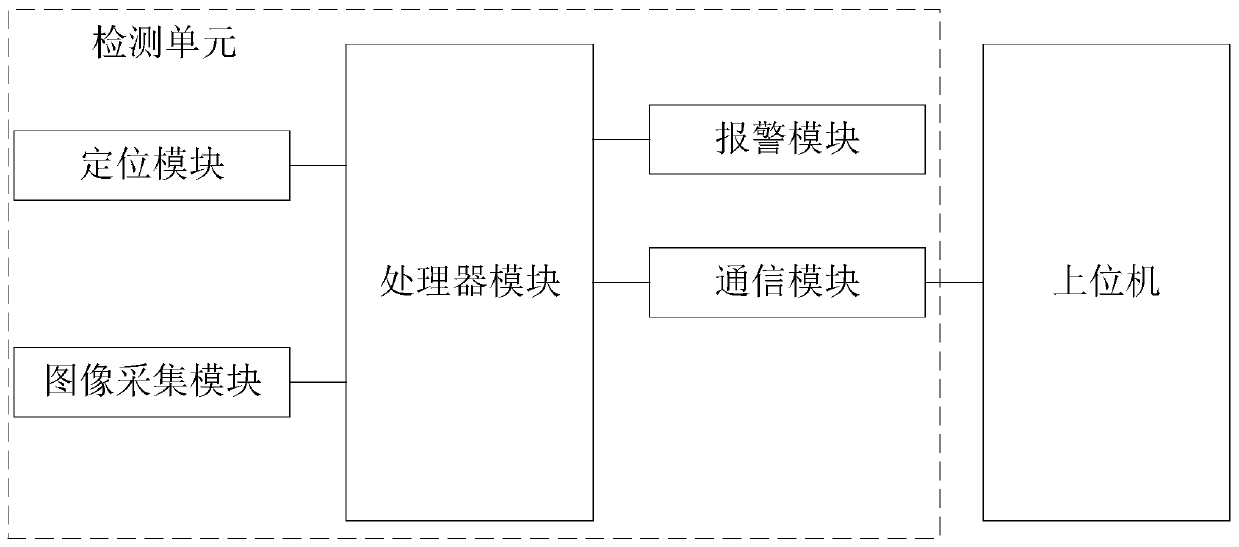

Intelligent grounding line system and working method

InactiveCN110504753ASolve mistakesAchieve sharingCircuit arrangementsInformation technology support systemEngineeringInformation sharing

The invention relates to an intelligent grounding line system and a working method. The intelligent grounding line system includes a grounding line device, a detection unit installed on the groundingline device, and a host computer. The grounding line device is suitable for clamping a grounding line for operation. The detection unit is suitable for detecting status information of the grounding line device, and sending the same to the host computer. According to the system, grounding line status is monitored in real time, and is uploaded to the host computer for centralized monitoring and management, thus collection, centralized display and information sharing of the temporary grounding line status are realized, and thus the problems of grounding line mis-taking, error-hanging, mis-hangingand removal missing in a jurisdiction are safely and effectively solved.

Owner:CHANGZHOU AITE TECH

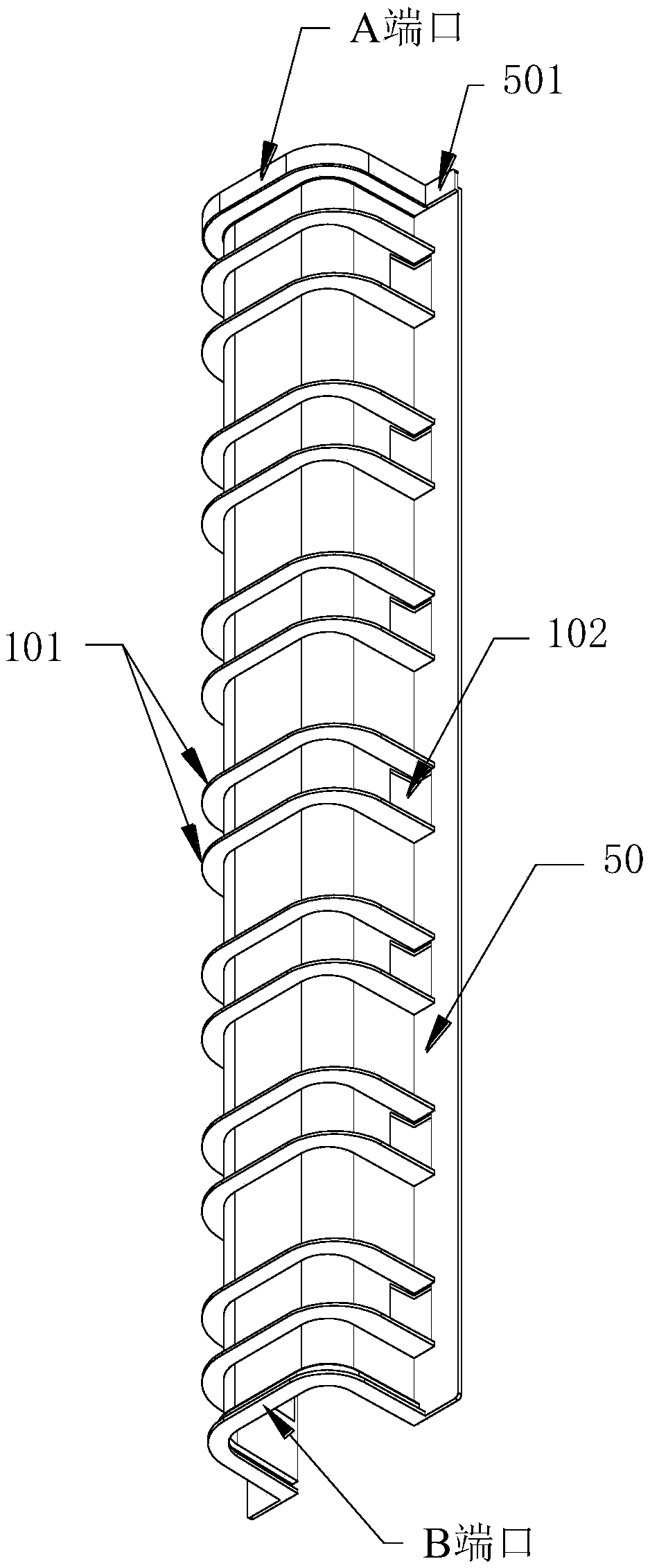

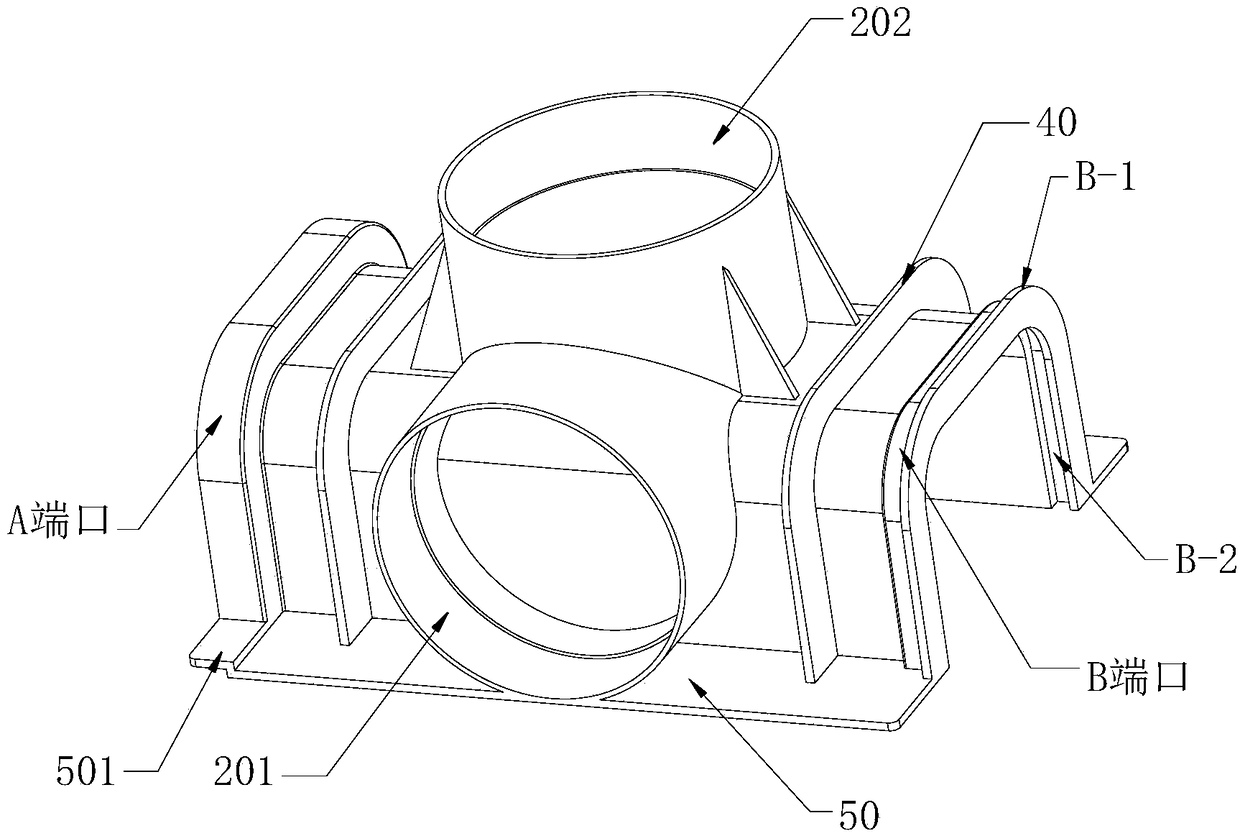

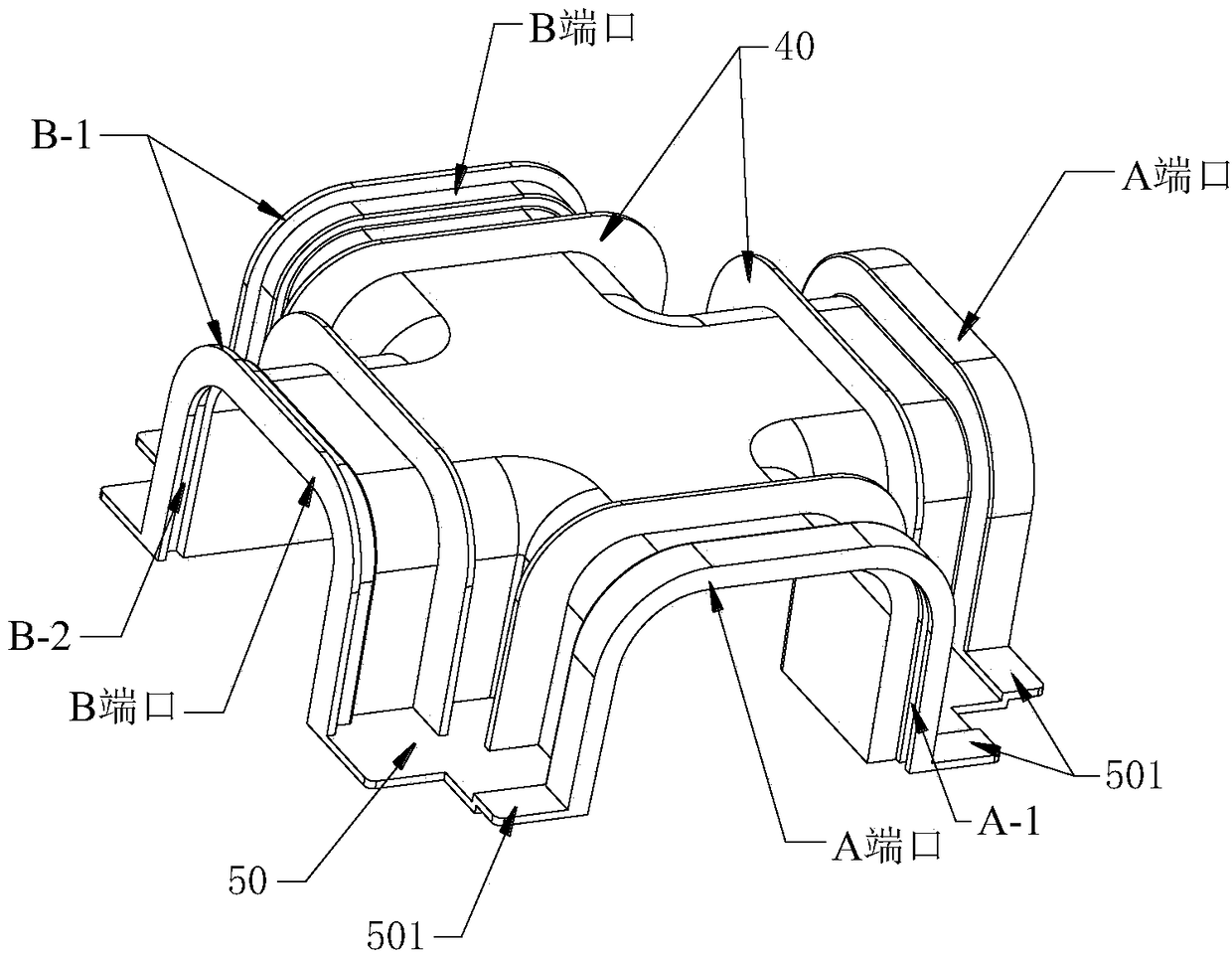

Novel assembly type planting roof drainage groove and drainage system

PendingCN109296145ASimple structureEasy and flexible assemblyRoof drainageEngineeringSpace requirements

The invention discloses a novel assembly type planting roof drainage groove. The novel assembly type planting roof drainage groove comprises a drainage blind groove, a three-way drainage assembly anda four-way drainage assembly. The drainage blind groove is a groove body with two ends opened. A protruding strip is arranged at one end of the drainage blind groove. A groove used for the protrudingstrip to insert in formed in the other end of the drainage blind groove. Water storing holes are formed in the lateral face of the drainage blind groove. The three-way drainage assembly comprises three openings. A protruding strip is arranged at one opening. A groove used for the protruding strip to insert is formed in one opening. A drainage opening is formed in another opening. The four-way drainage assembly comprises four openings. A protruding strip is arranged at one opening. A groove used for the protruding strip to insert is formed in one opening. A protruding strip / groove used for theprotruding strip to insert is formed in the rest two openings. The openings provided with the grooves can be matched with the openings provided with the protruding strips in an up and down mode to achieve sealing connection. Ventilation pipe inserting openings are formed in the upper portion of the three-way drainage assembly and / or the four-way drainage assembly. The structure is simple, assembling is flexible and convenient, mounting difficulty is little, and mounting space requirements are few.

Owner:KESHUN WATERPROOF TECH CO LTD

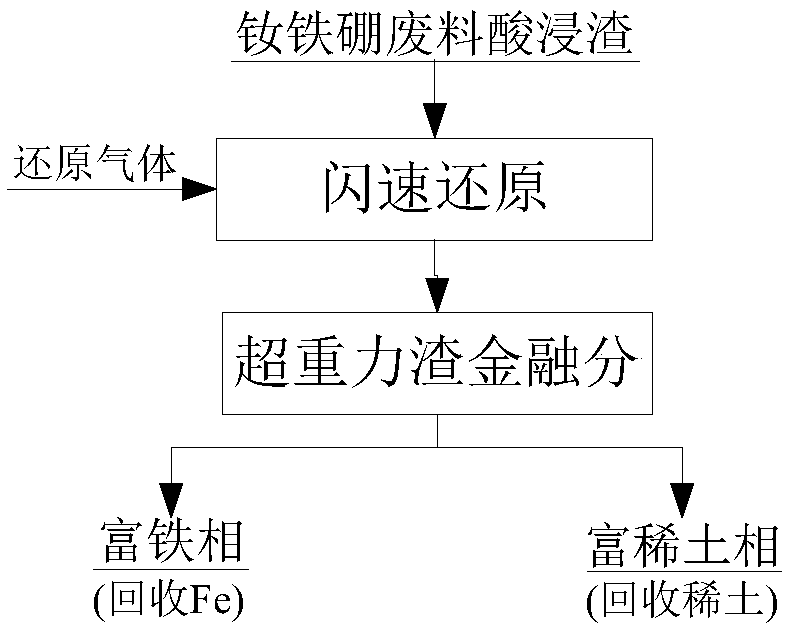

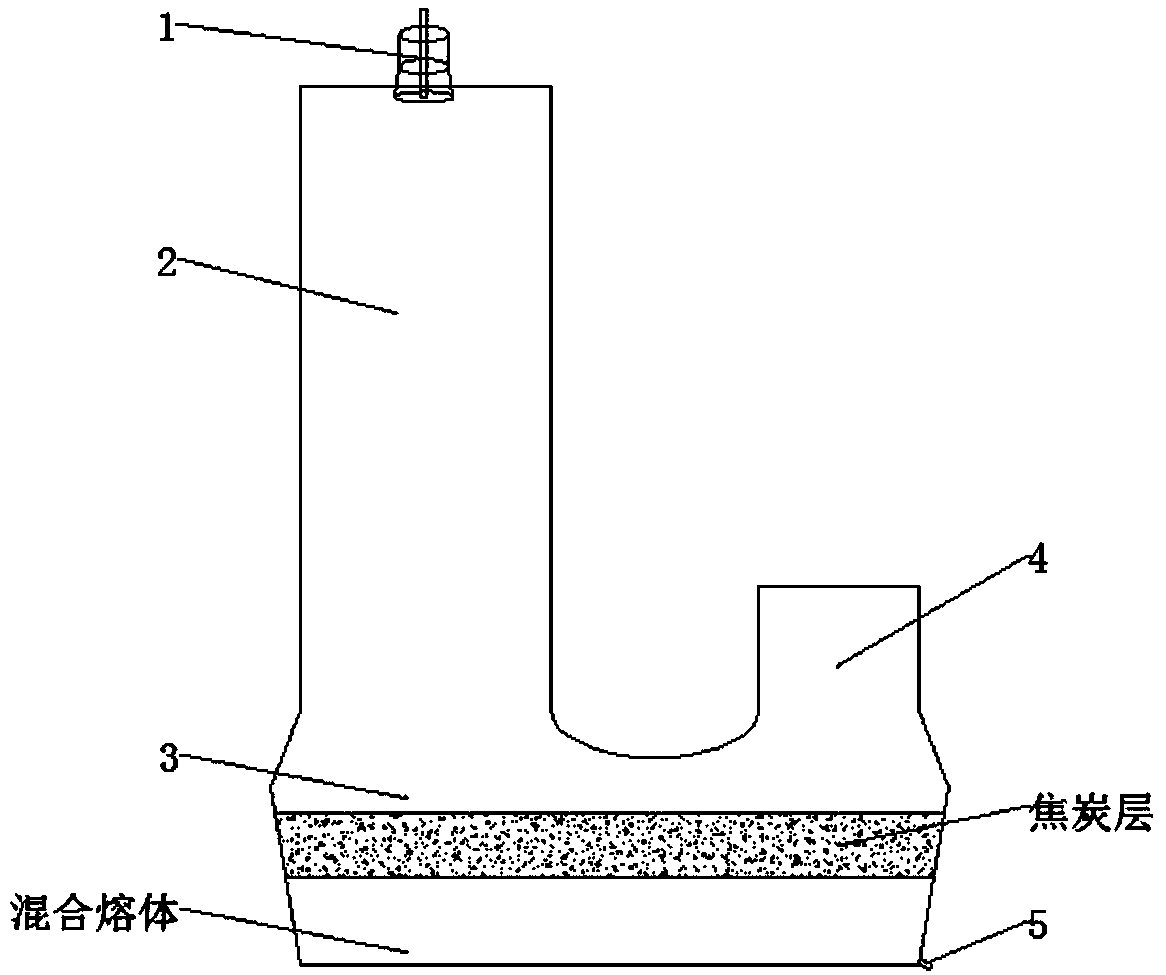

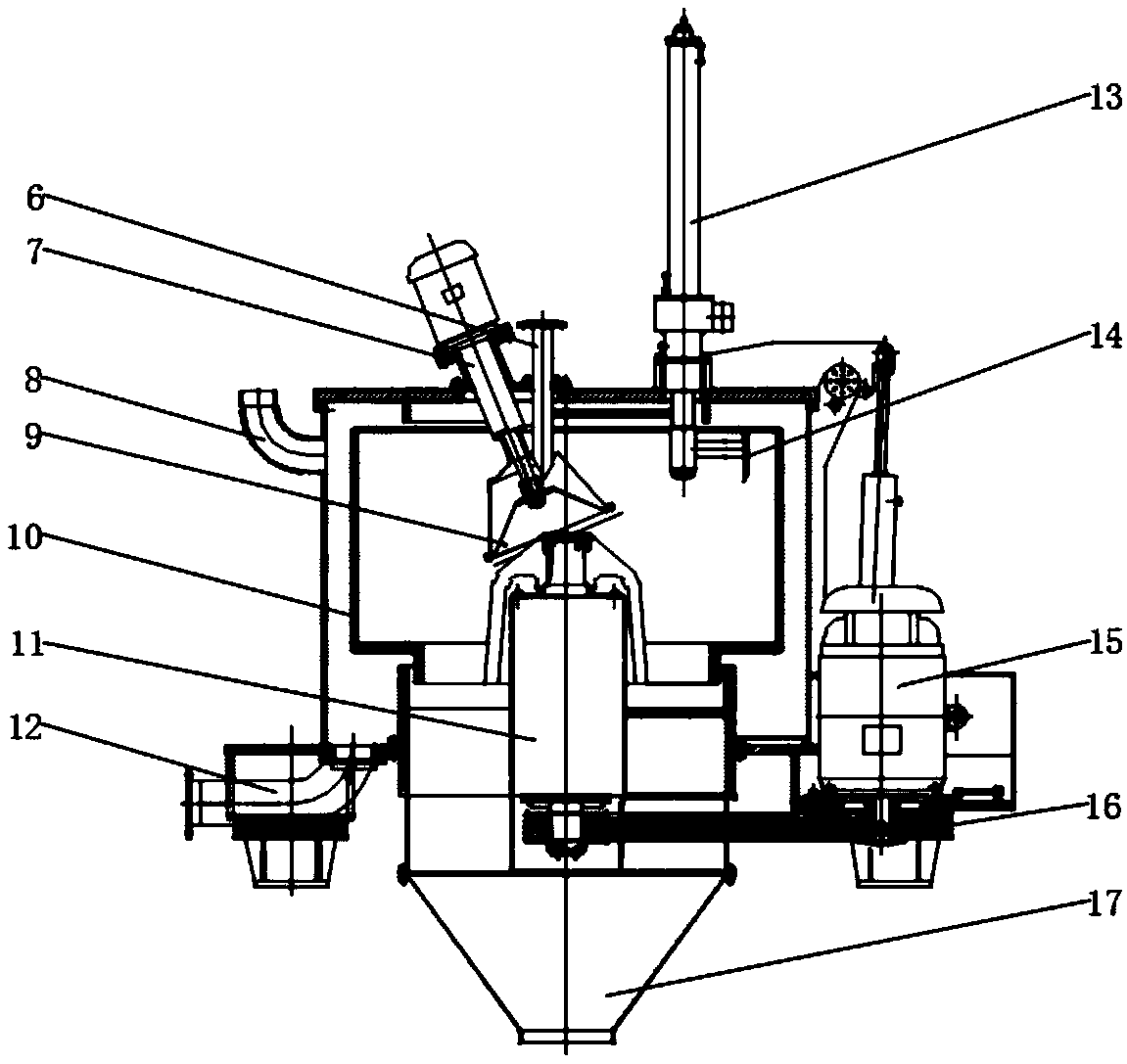

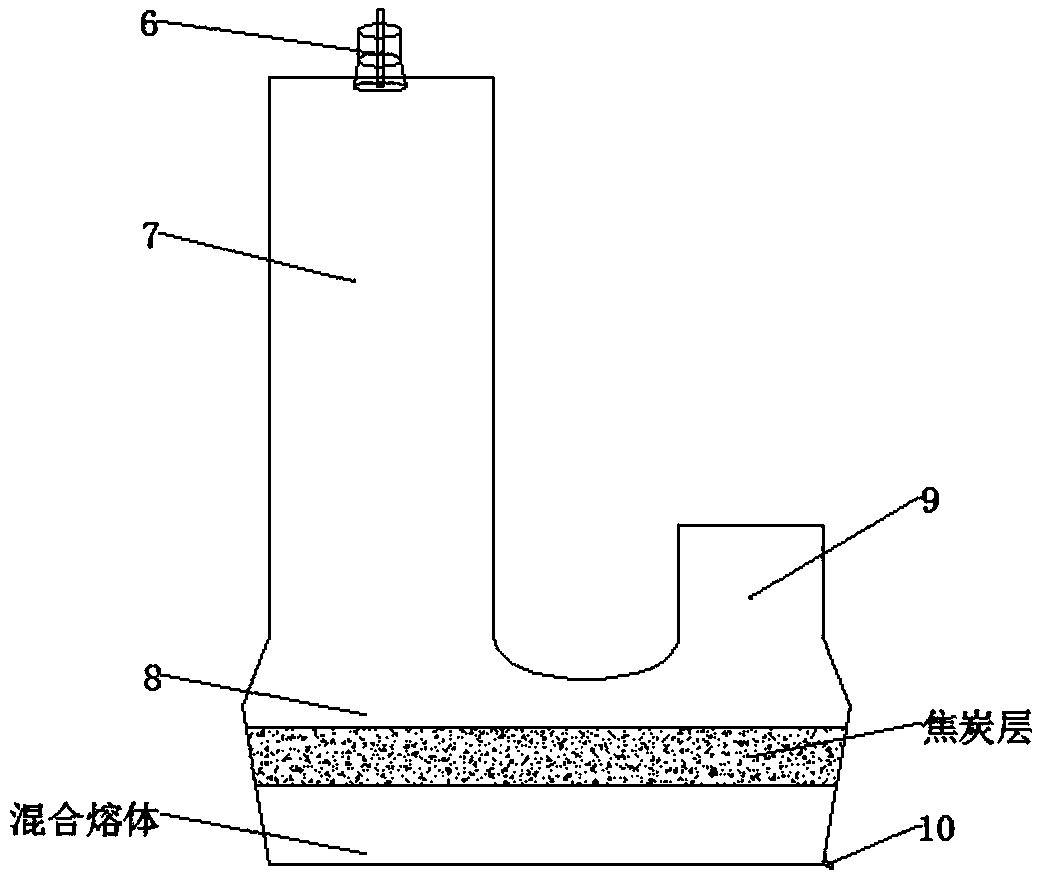

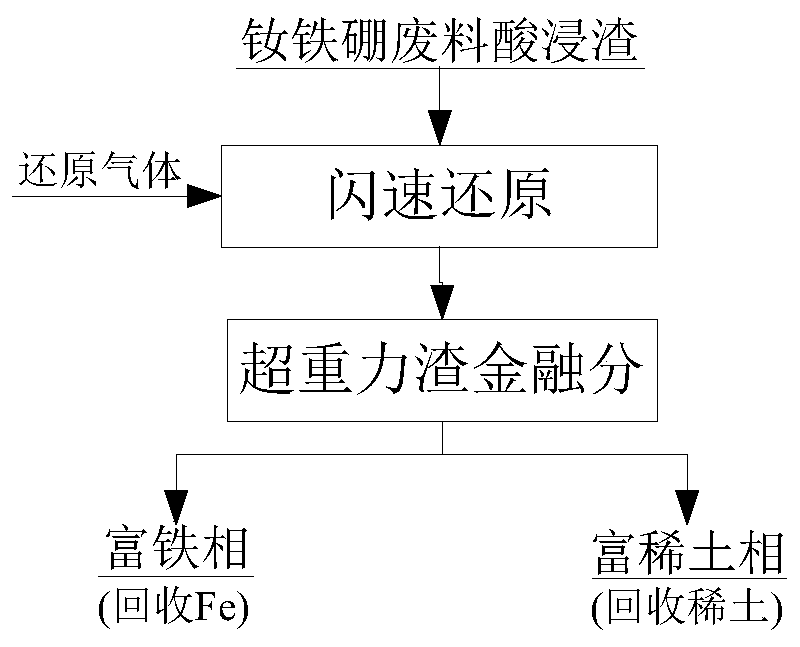

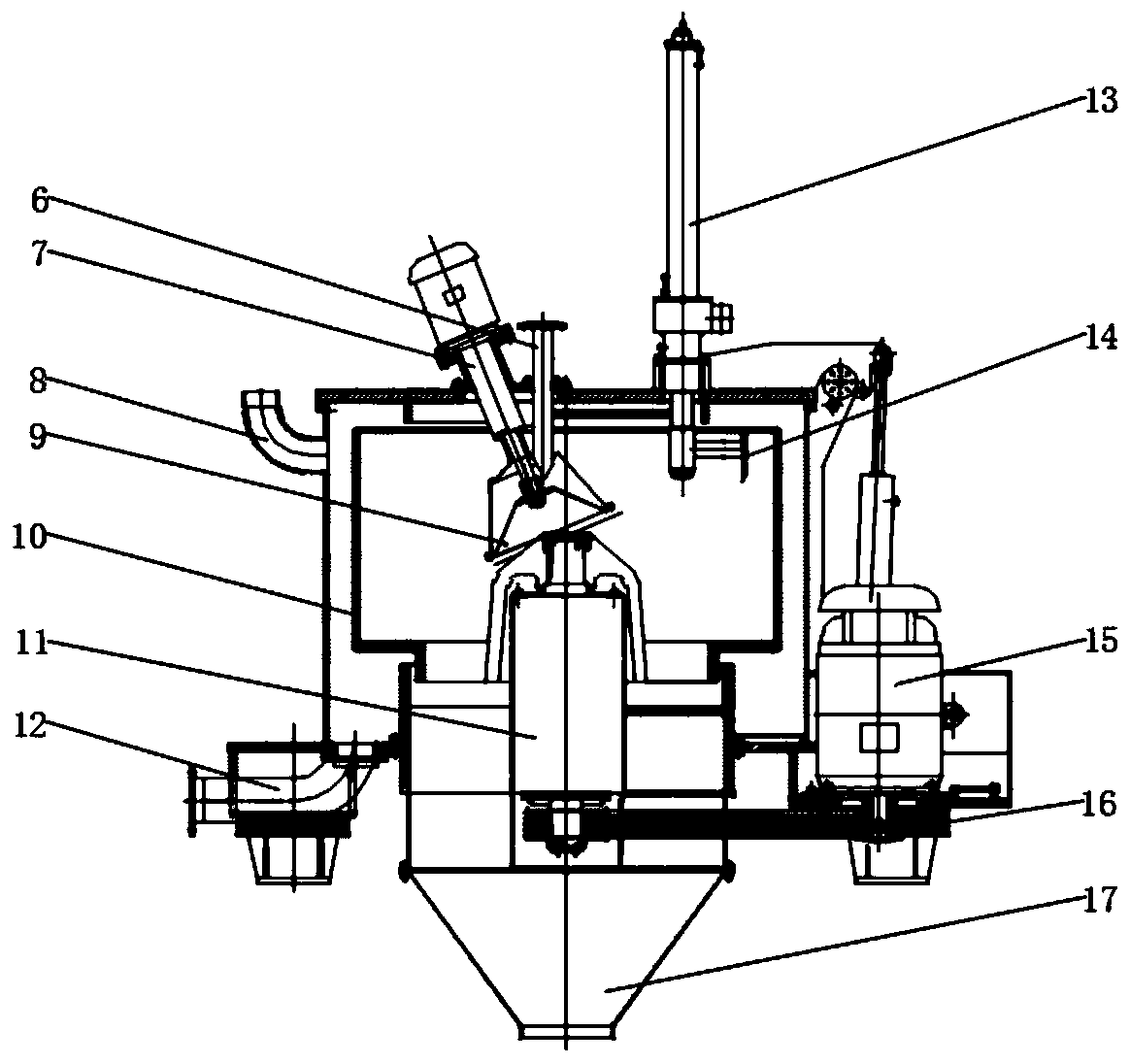

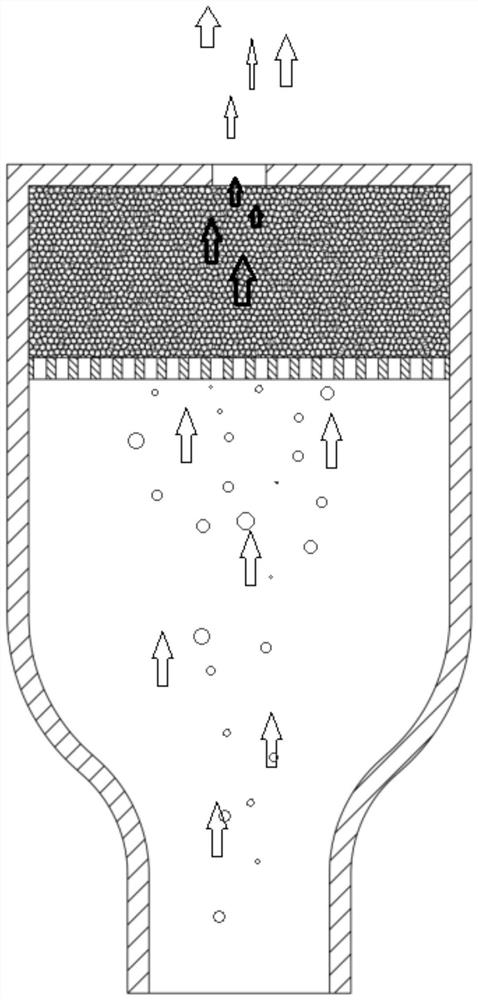

Neodymium iron boron waste acid-leaching slag flashing-reduction super-gravity metal-slag melting and separating comprehensive recycling method

ActiveCN109402316ASuperior reaction kinetic conditionsImprove recovery rateProcess efficiency improvementBrown iron oxideScrap

The invention discloses a neodymium iron boron waste acid-leaching slag flashing-reduction super-gravity metal-slag melting and separating comprehensive recycling method. The method comprises the following steps: uniformly mixing neodymium iron boron waste acid-leaching slag and a fluxing agent, spraying the mixture together with reduction gas into a high-temperature vertical reaction tower spacevia a spray nozzle, wherein a majority of iron oxide in the material is reduced into metal iron, little iron which is not reduced is reduced into metal iron when passing by a hot coke layer arranged above a settling pond, and rare earth in the material is mixed with the slag in an oxide form; discharging the molten iron and rare-earth slag high-temperature mixed melt into a super-gravity metal-slag melting and separating device, under a super-gravity effect, enabling the molten iron to pass through a porous ceramic filter membrane, intercepting the rare-earth slag in a rotary drum, so that therare earth and the iron in the neodymium iron boron waste can be efficiently concentrated and separated, the defect that the traditional neodymium iron boron waste acid-leaching slag is difficult tocomprehensively recycle can be overcome, and the economic benefit and the environmental protection benefit are good.

Owner:JIANGXI UNIV OF SCI & TECH

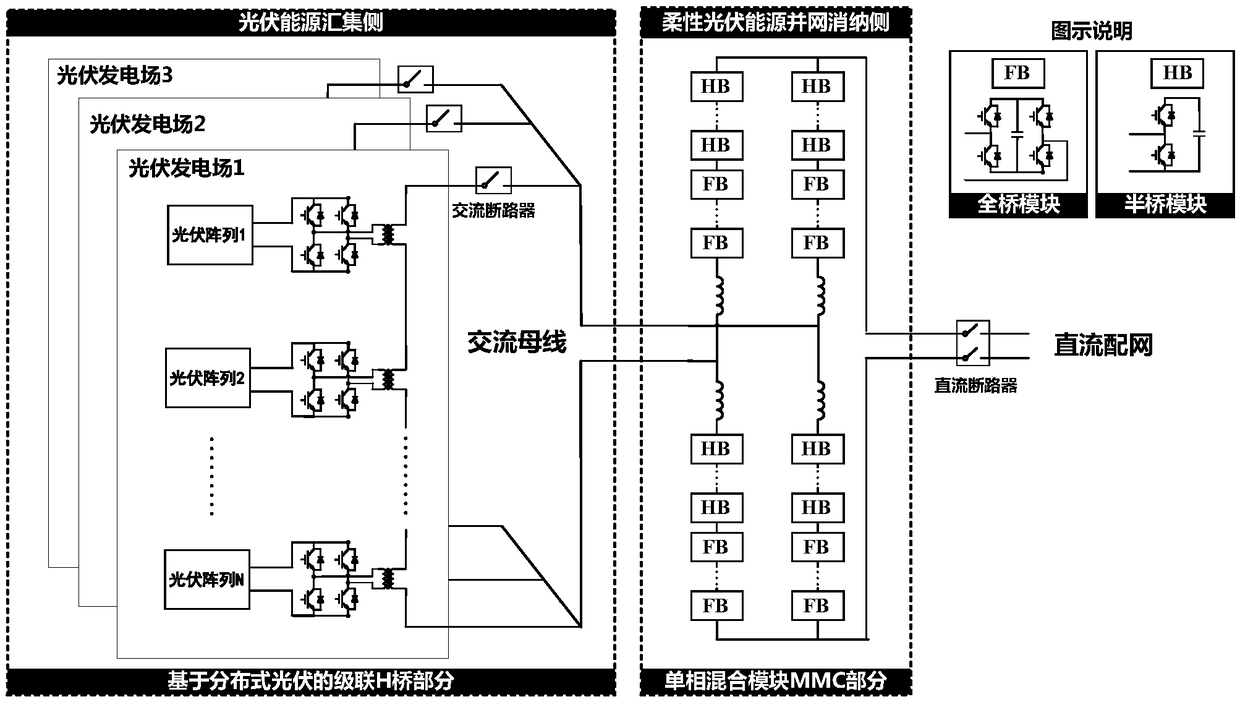

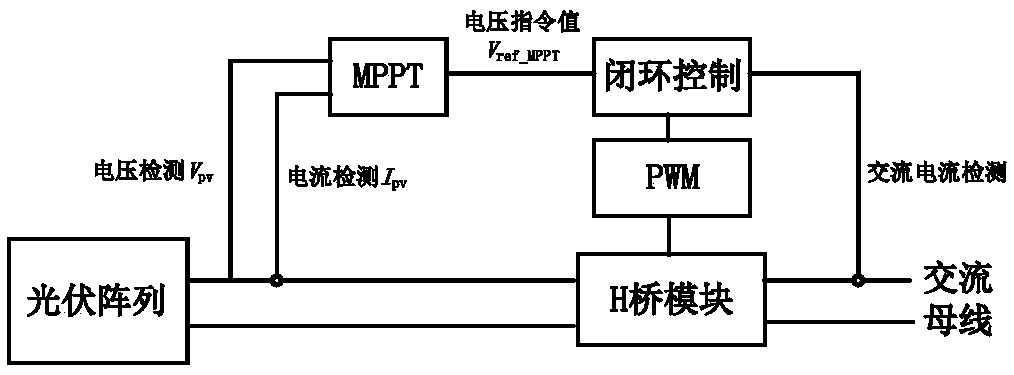

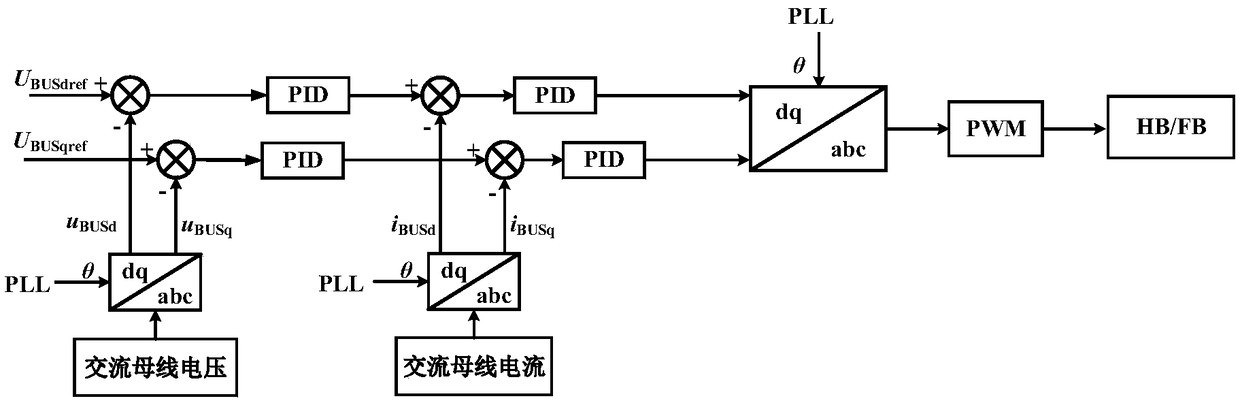

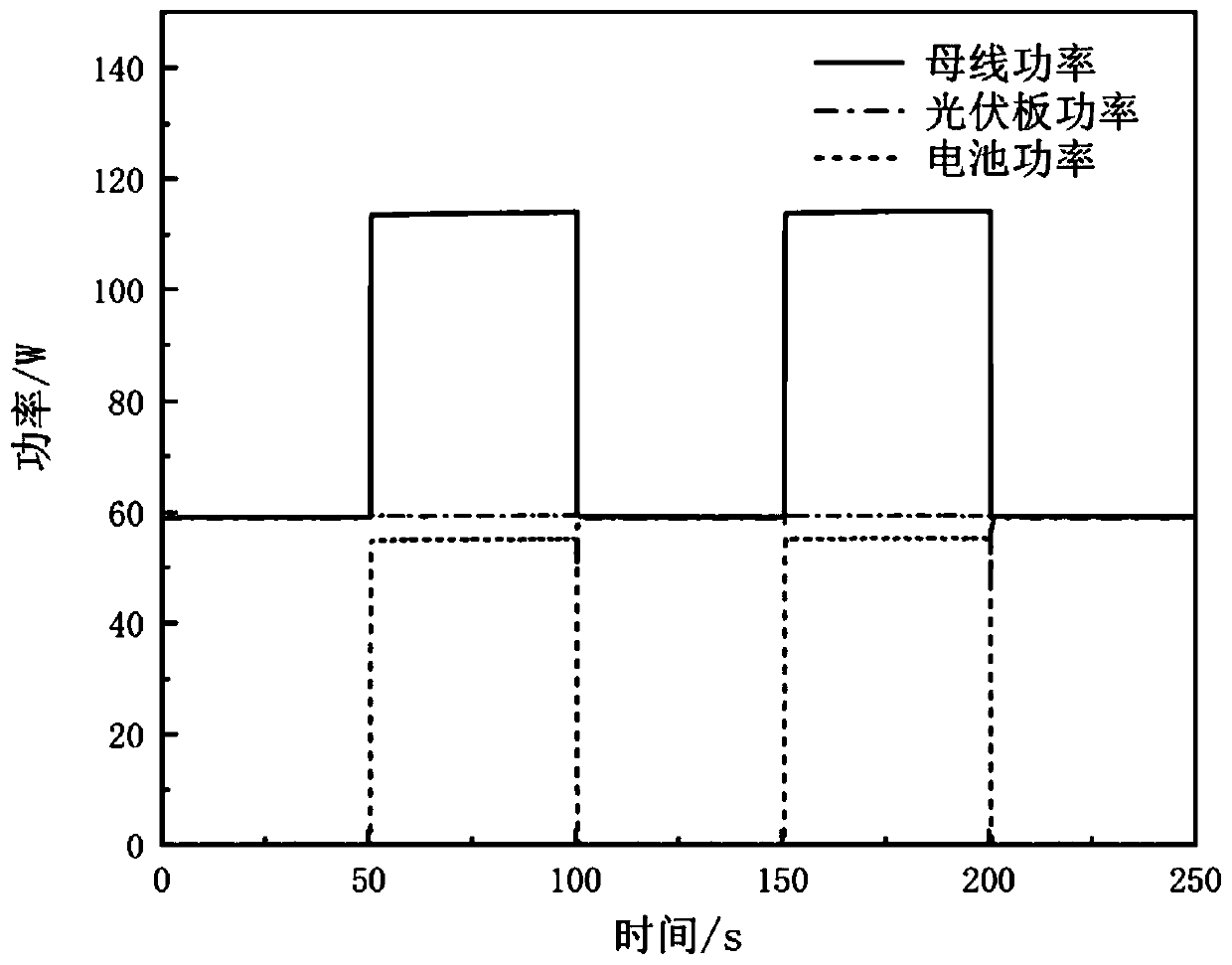

Flexible gathering topology, suitable for DC distribution network, of photovoltaic system and control method of topology

InactiveCN108695842AShorten wiring distanceImprove efficiencyDc-dc conversionDc source parallel operationElectric fieldEngineering

The invention discloses a flexible gathering topology, suitable for a DC distribution network, of a photovoltaic system and a control method of the topology. The flexible gathering topology comprisesphotovoltaic power generation fields, each photovoltaic power generation field comprises photovoltaic arrays, output of each photovoltaic array is connected with the input end of one H bridge module,the output ends of all H bridge modules in one photovoltaic power generation field are connected in series to an AC bus, the AC bus is connected to a bridge arm middle point of a modularized cascadedmulti-level converter (MMC), the output end of the MMC is connected to the DC distribution network, and the output ends of all photovoltaic power generation fields are connected in parallel. The large-scale or ultra-large-scale photovoltaic power generation field structure is analyzed and optimized from the aspect of the whole structure of the photovoltaic power generation field system and aimed at the developing trend towards DC of the distribution network, so that the total operation efficacy of the photovoltaic system is improved.

Owner:XI AN JIAOTONG UNIV

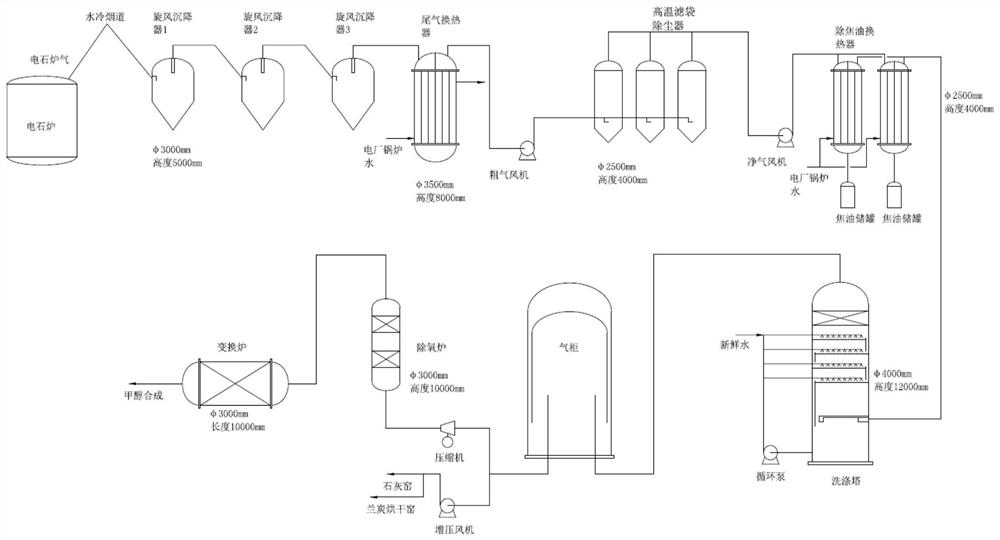

Calcium carbide furnace tail gas comprehensive utilization system and process

InactiveCN112705000ASolve the purificationSolve processingCombination devicesHydrogenProcess engineeringGas holder

The invention relates to a comprehensive utilization system and process for tail gas of calcium carbide furnace gas. The system comprises a water cooling flue, a cyclone settler, a tail gas heat exchanger, a high-temperature filter bag dust collector, a tar removal heat exchanger, a washing tower and a gas holder. According to the invention, a dry-process and wet-process purification treatment technology is adopted, tail gas generated by a plurality of calcium carbide furnaces can be treated at the same time, and the problem that follow-up furnace gas user production is unstable due to large fluctuation of gas quantity and components of a single calcium carbide furnace in a large-scale calcium carbide factory is solved. The purified and washed calcium carbide furnace tail can be used for calcining limestone and producing methanol, meanwhile, boiler water of a power plant is utilized for heat recovery, circulating water is replaced, energy is saved, meanwhile, emission of calcium carbide furnace gas is correspondingly reduced, and the calcium carbide furnace tail gas comprehensive utilization systemis environmentally friendly.

Owner:恒力石化(大连)炼化有限公司

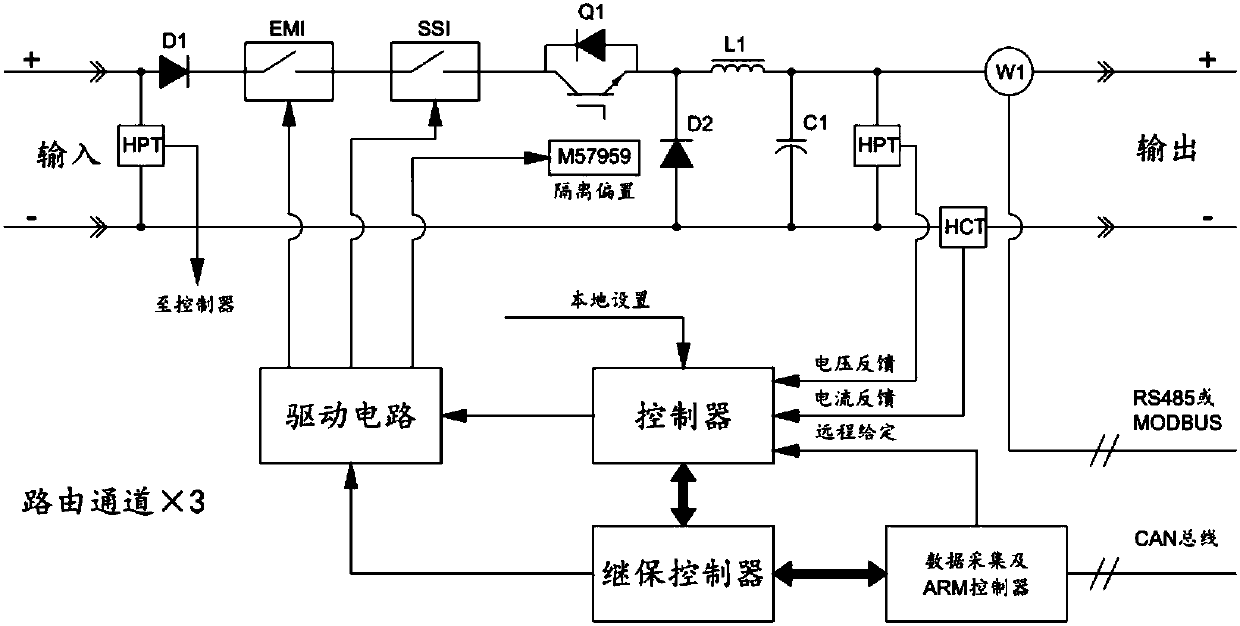

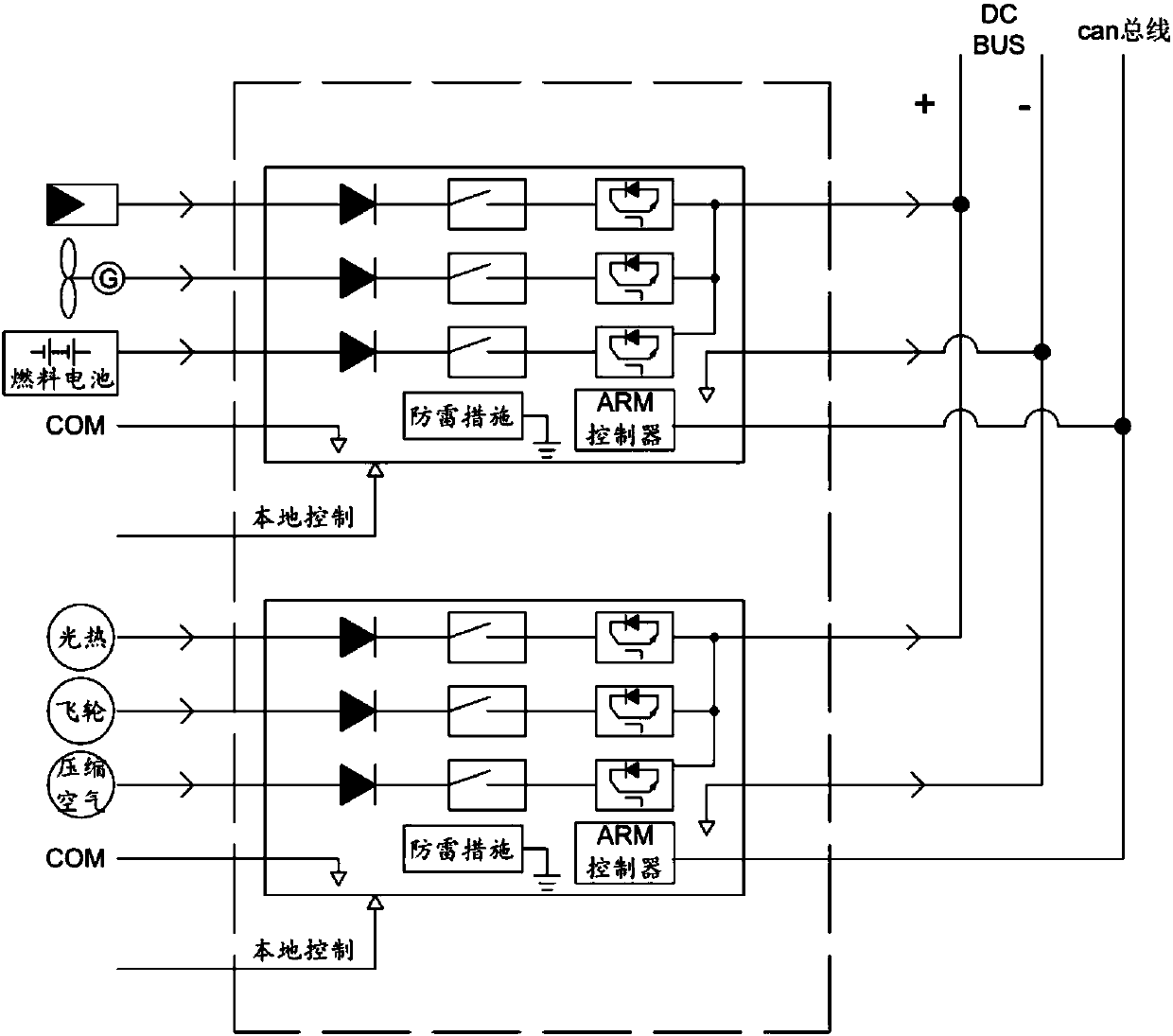

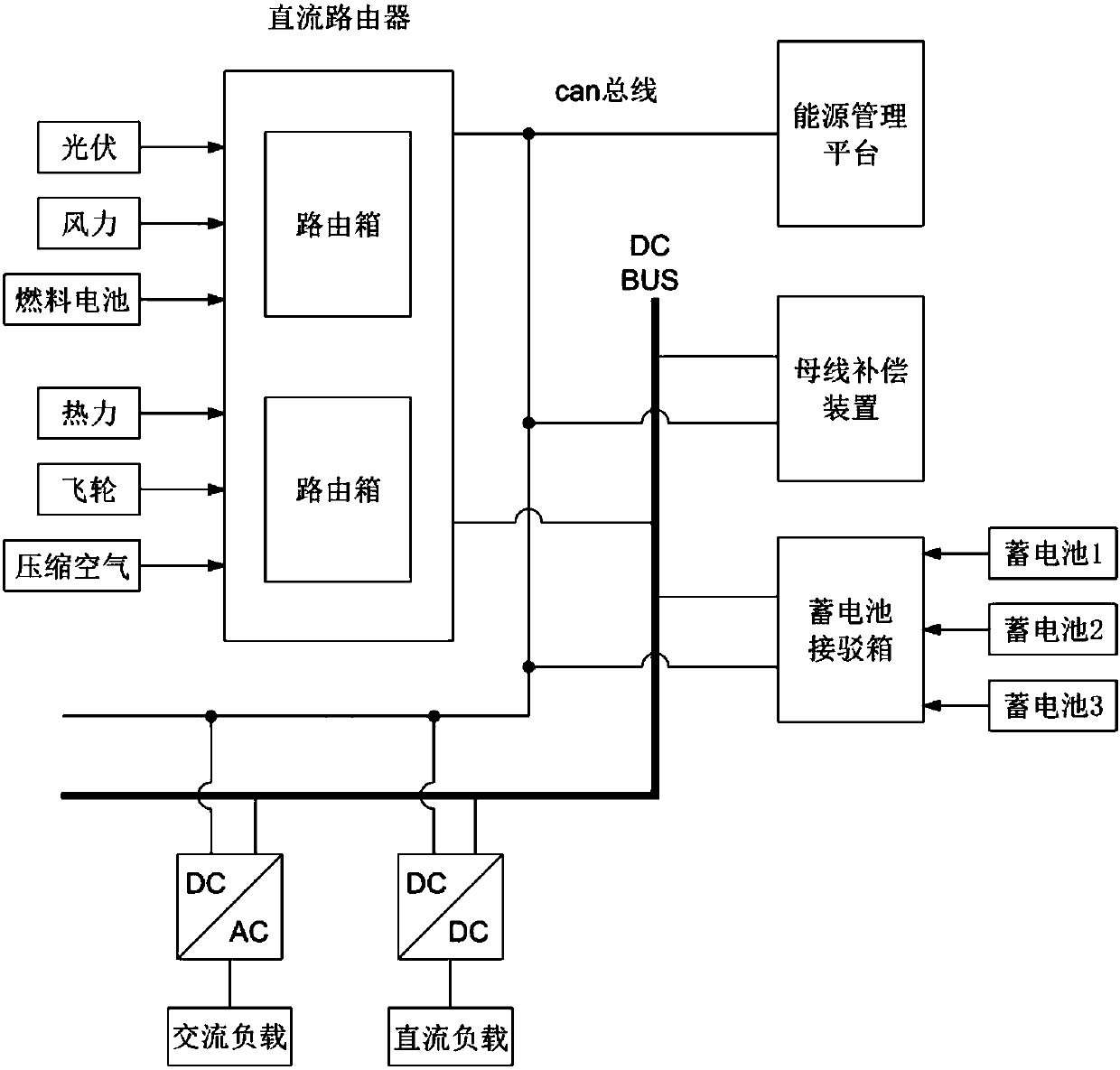

DC energy router with multiple input ends

PendingCN107591790AControl flow distributionEasy constructionDc source parallel operationDriver circuitControl circuit

The present invention discloses a DC energy router with multiple input ends. The DC energy router comprises at least one router set, each set of routers comprises n router units, and n is not less than 2 and is a natural number. Each router unit comprises a main circuit, the router sets are equipped with the driving circuits and the control circuits, and the main circuits comprise the input ports,the buck conversion circuits and the output ports. The input ports are used to connect an external DC micro-power supply, the output ports are used to connect an external DC bus, and the buck conversion circuits are driven by the driving circuits and are controlled by the control circuits. The DC energy router with multiple input ends is easy to implement, and can switch multiple energy input intelligently.

Owner:HUNAN LINENG TECH

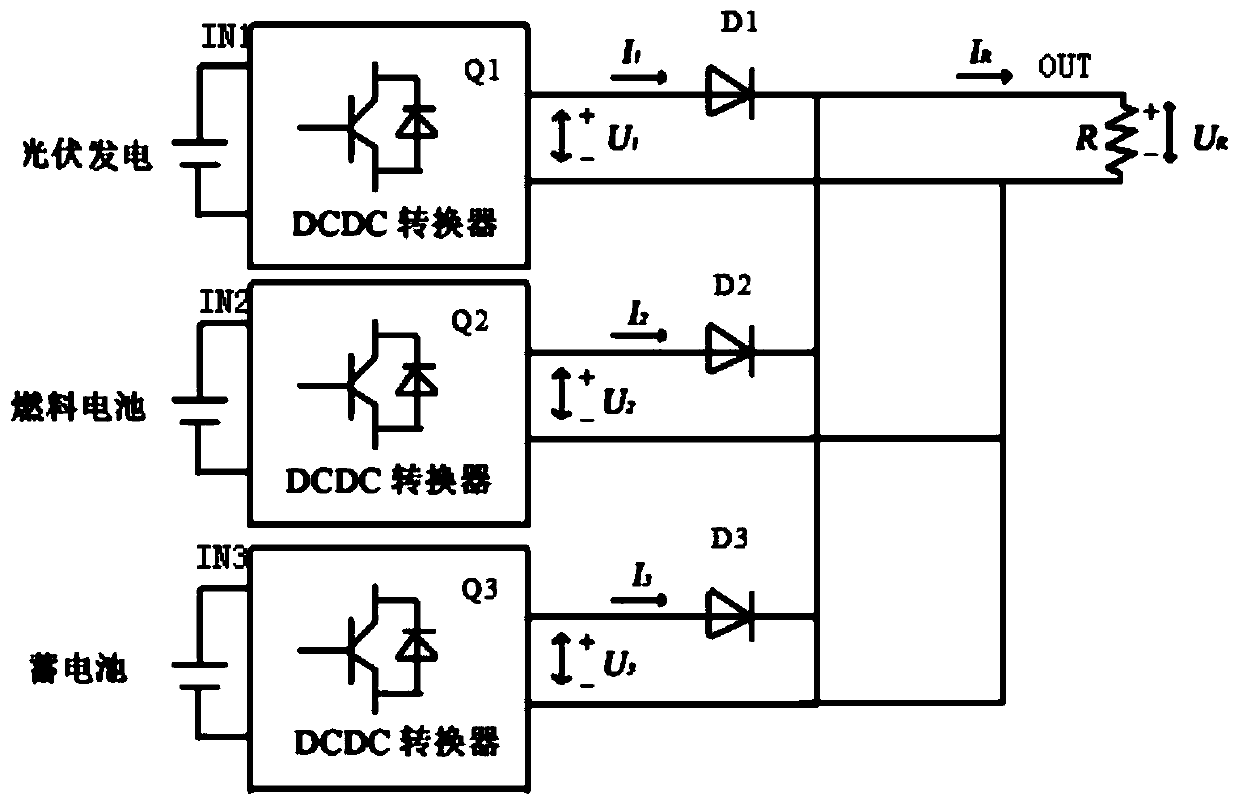

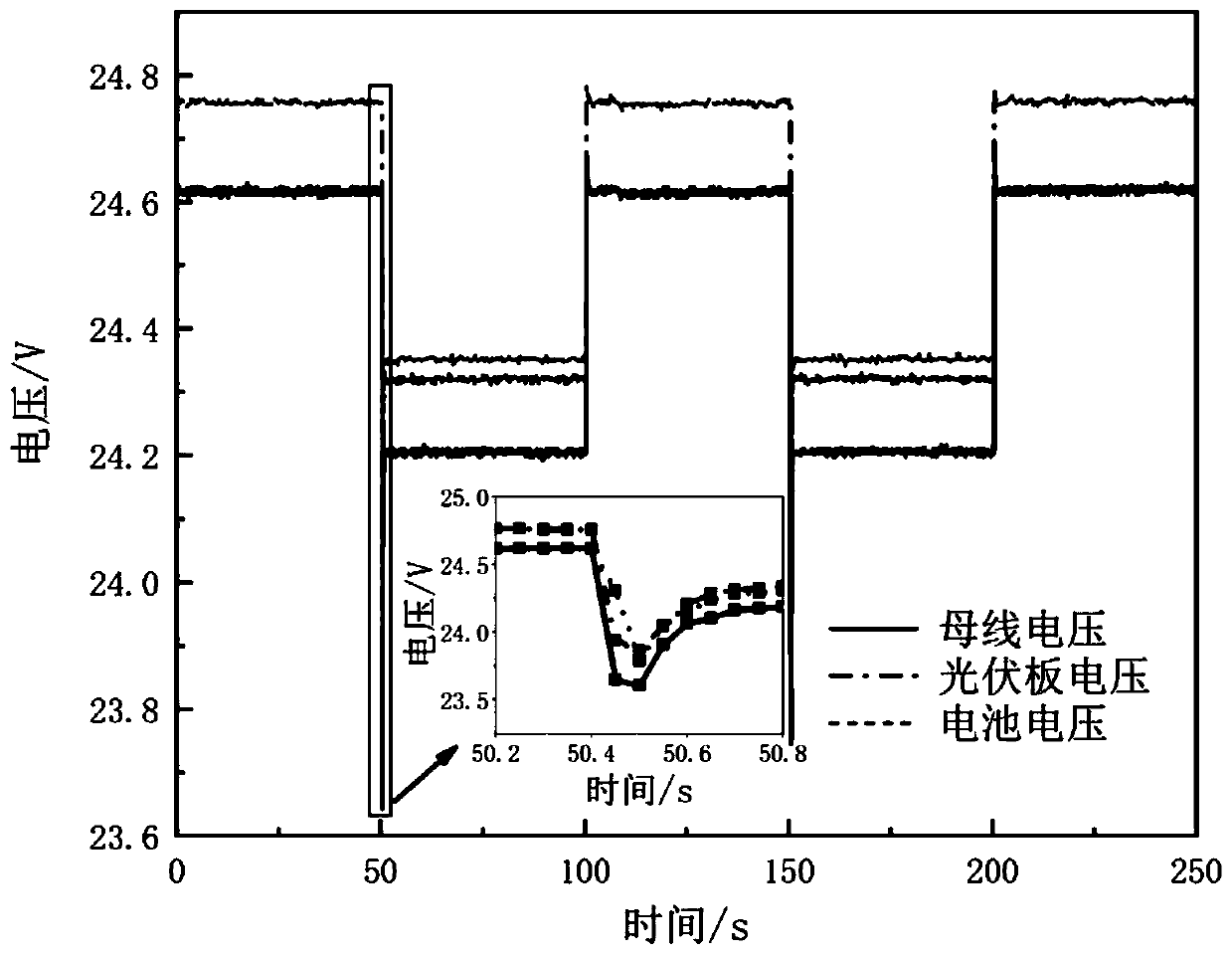

Energy router based on direct-current micro-grid inverter and load distribution control method of energy router

InactiveCN109787214AImplement inputAchieve outputBatteries circuit arrangementsDc source parallel operationGrid-tie inverterEngineering

The invention discloses an energy router based on a direct-current micro-grid inverter and a load distribution control method of the energy router. The energy router comprises n input ports, n buck-boost conversion circuits, n diodes and one output port; n is a positive integer; the input end of each buck-boost conversion circuit is connected with one input port, and the output end of each buck-boost conversion circuit is connected with one diode in series; the output ends of all the diodes are all connected to the output port in parallel; and when in use, each input port is connected with anexternal direct-current power supply, and the output port is connected with an external direct-current bus. The energy router is simple in structure, easy to implement and higher in accuracy.

Owner:SOUTHEAST UNIV

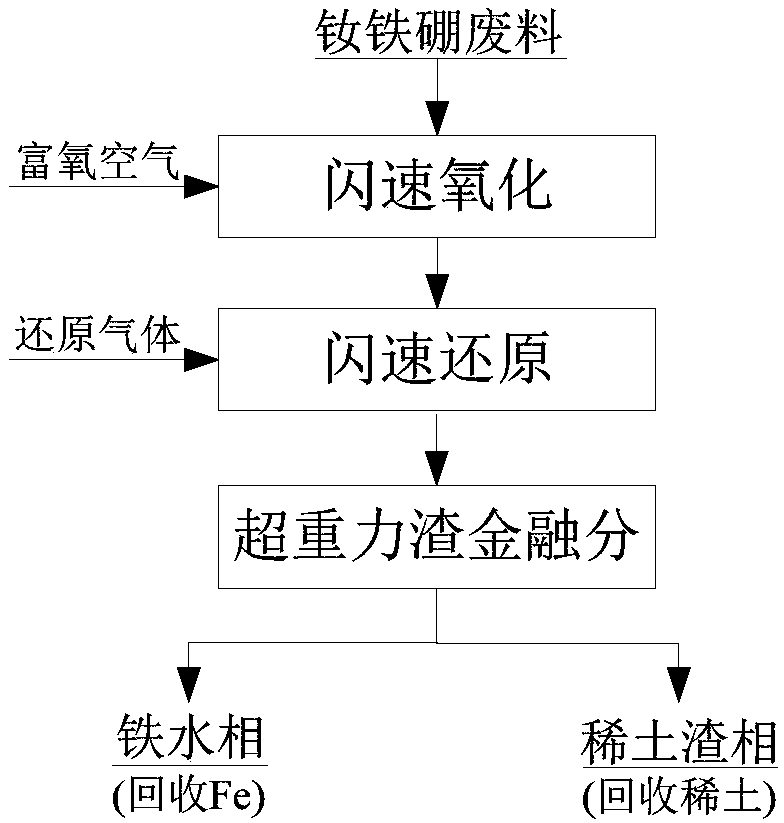

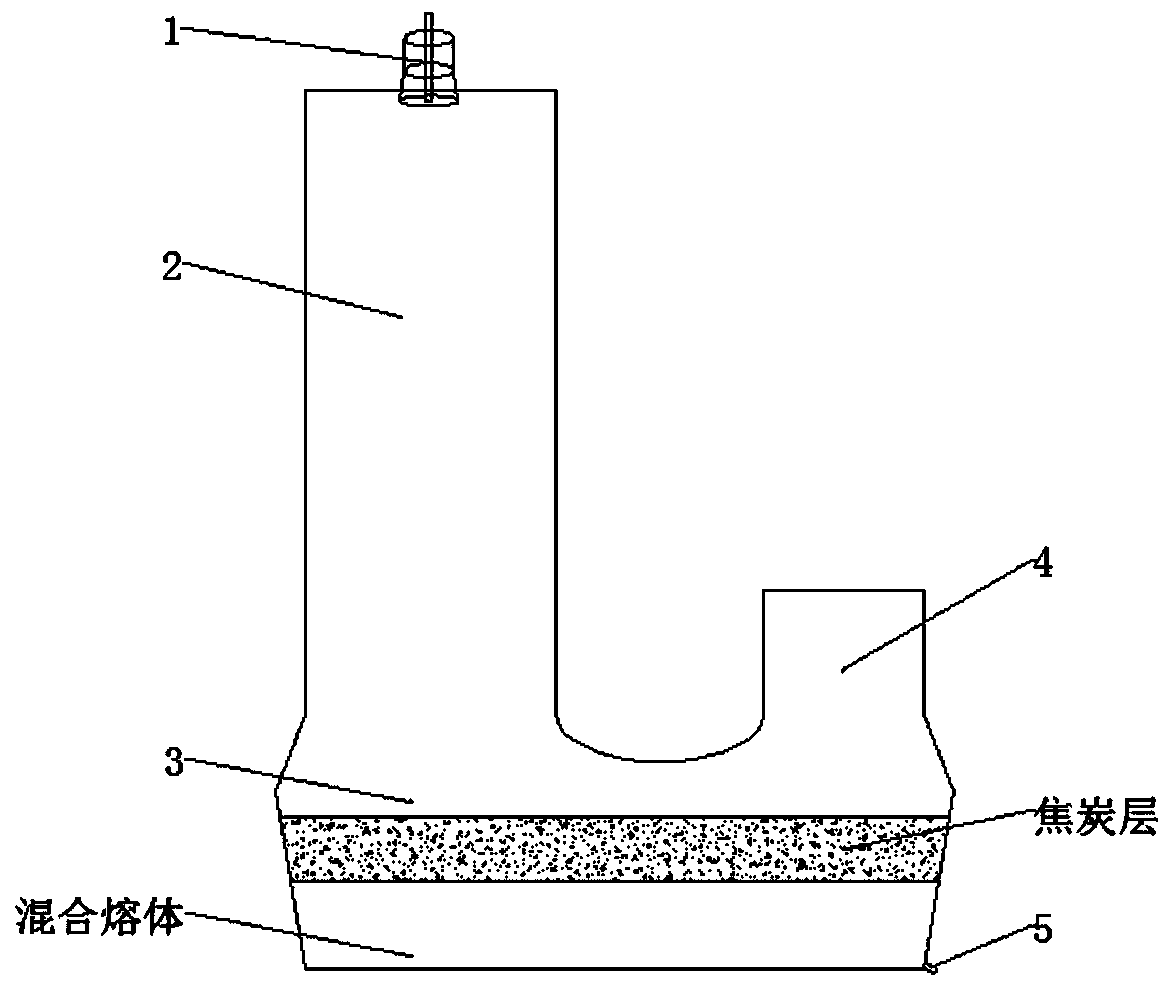

Neodymium iron boron waste double-flash supergravity slag metal melting comprehensive recovery method

ActiveCN109487028AHigh speedImprove efficiencyProcess efficiency improvementGas emission reductionRecovery methodSlag

The invention discloses a neodymium iron boron waste double-flash supergravity slag metal melting comprehensive recovery method. According to the method, neodymium iron boron waste and oxygen-rich airare sprayed into a reaction tower through a spray nozzle, the materials float down to the lower end from the upper end of the reaction tower in a highly dispersed floating state, and rare earth and iron in the materials are fast and fully oxidized; oxidation products and reducing gas are sprayed into another reaction tower through a spray nozzle, most of ferric oxide is reduced into metal iron, and the small amount of iron not reduced is reduced into metal iron when passing through a molten coke layer; and molten iron and rare earth slag high-temperature mixed melt enters a supergravity slagmetal melting device, under the effect of supergravity, molten iron permeates porous ceramic filter film, rare earth slag is retained in a drum, accordingly, efficient enriching and separation of therare earth and iron in the neodymium iron boron waste is achieved, the defects that a traditional neodymium iron boron waste treatment method is long in process, high in energy consumption, large in acid dissolution iron slag amount, low in rare earth recovery rate, difficult in iron resource recovery are overcome, and the economic and environment friendliness benefits are good.

Owner:JIANGXI UNIV OF SCI & TECH

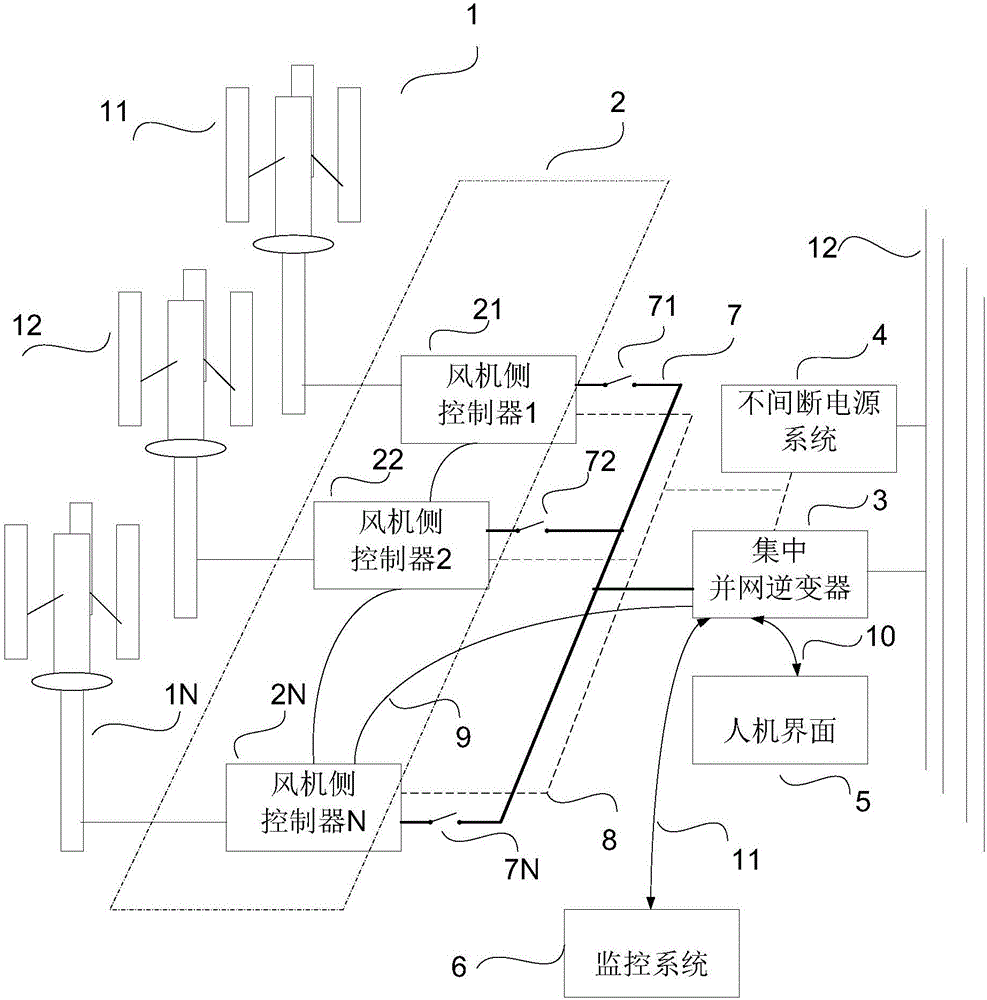

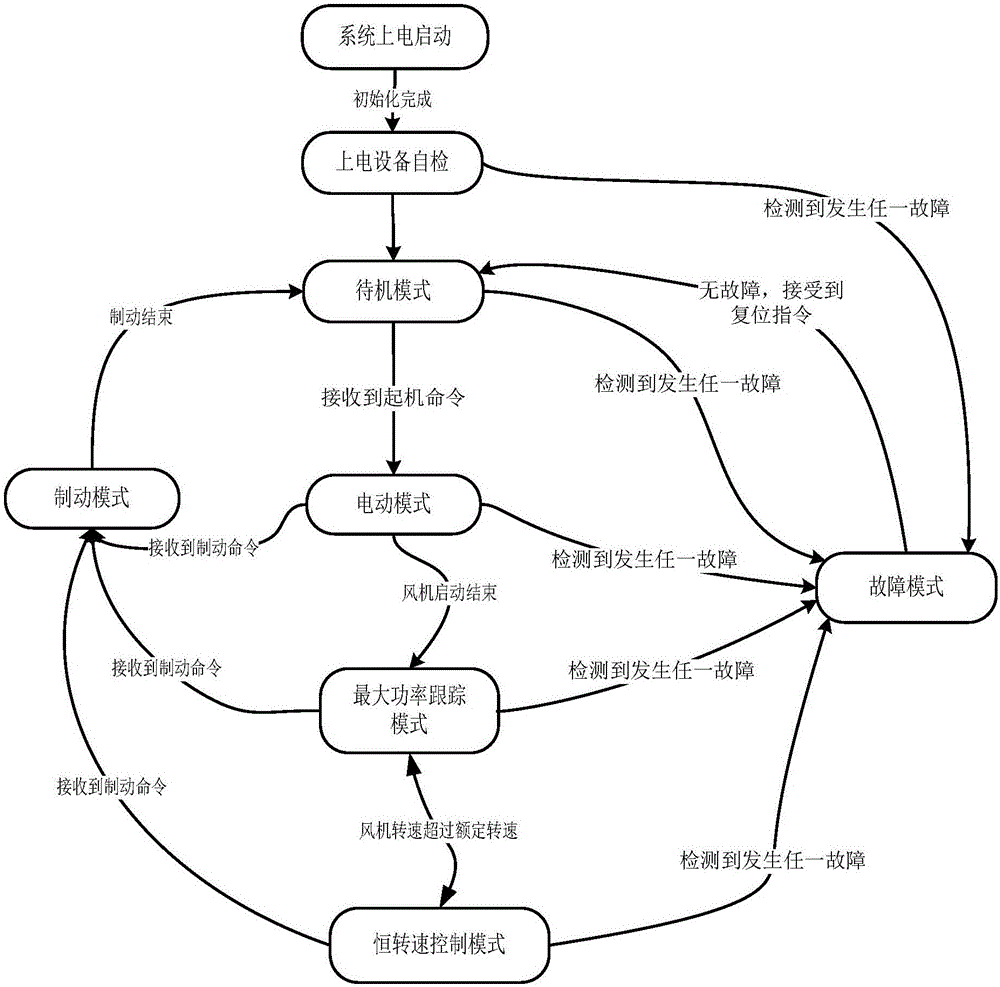

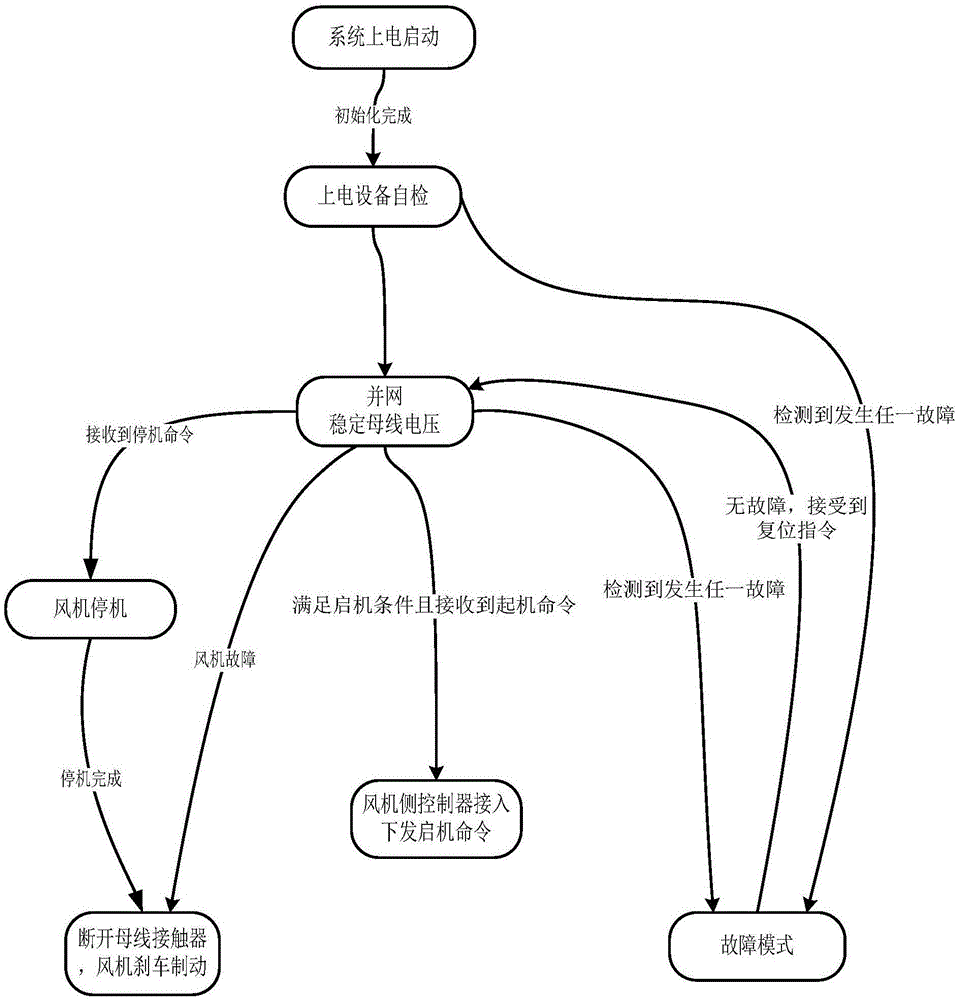

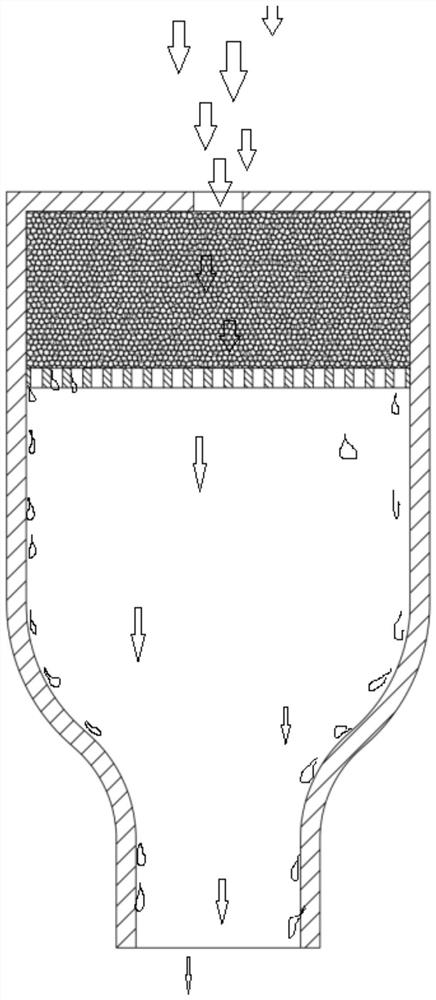

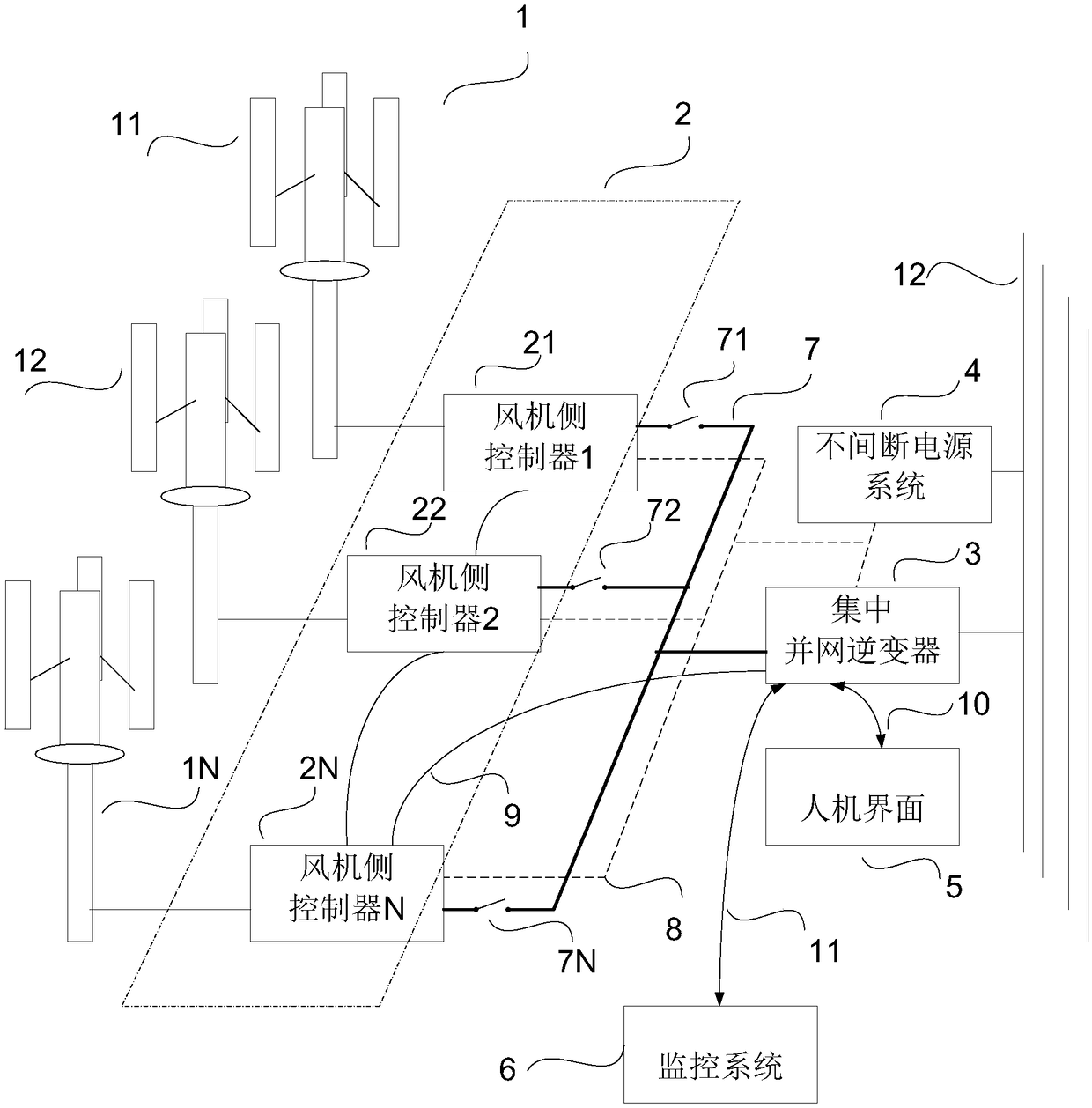

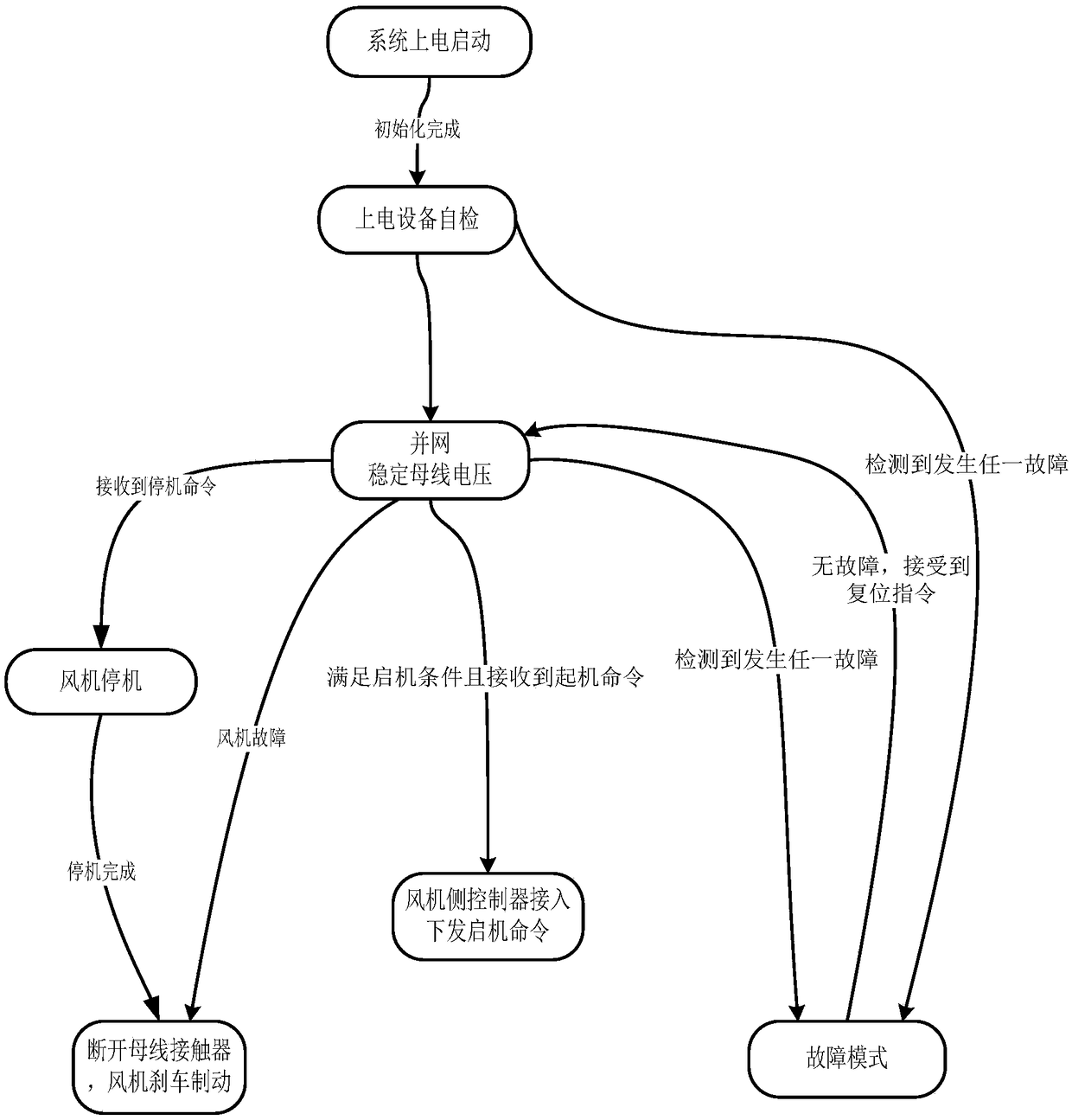

Vertical axis wind power generation system start-up control method and wind power generation system

InactiveCN106089583AEasy to implementFlexible controlWind motor controlEngine fuctionsVertical axis wind turbineControl switch

The invention relates to a vertical axis wind power generation system start-up control method and a wind power generation system. When the wind power generation system is started up, a centralized net-connected controller starts net connection and controls various control switches to be off; a machine side controller drags the corresponding vertical axis wind power generator to rotate to the set start-up speed; and the working mode of the vertical axis wind power generator is switched to the power generation mode, thereby carrying out wind power generation. The start-up method can control the vertical axis wind power generator to be effectively started up, thereby solving the problem of difficulty in starting up the vertical axis wind power generator.

Owner:XUJI GRP +2

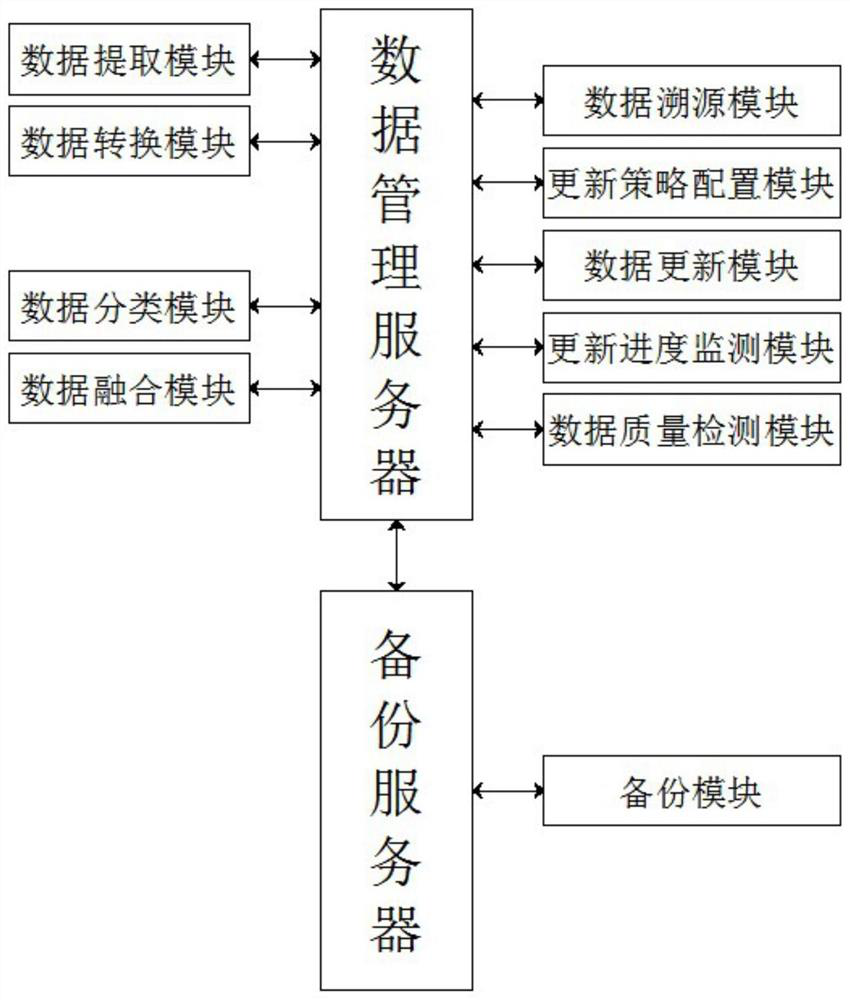

Wind cloud satellite remote sensing surveying and mapping data management system

PendingCN112650850AImprove utilization efficiencyImprove accuracyCharacter and pattern recognitionRedundant operation error correctionData transformationData file

The invention discloses a wind cloud satellite remote sensing surveying and mapping data management system, which comprises a data management server, a data extraction module, a data conversion module, a data classification module and a data fusion module, and is characterized in that the data extraction module, the data conversion module, the data classification module and the data fusion module are in communication connection with the data management server. The system is connected with databases of different types, receives data files of different file formats, extracts wind cloud satellite remote sensing surveying and mapping data from the databases and the data files, converts the wind cloud satellite remote sensing surveying and mapping data extracted by the data extraction module into text data, classifies the text data converted by the data conversion module and performs data fusion on the text data classified by the data classification module, thereby realizing collection of multi-source wind cloud satellite remote sensing surveying and mapping data, enhancing the classification accuracy of the wind cloud satellite remote sensing surveying and mapping data and improving the utilization efficiency of later data.

Owner:胡友彬

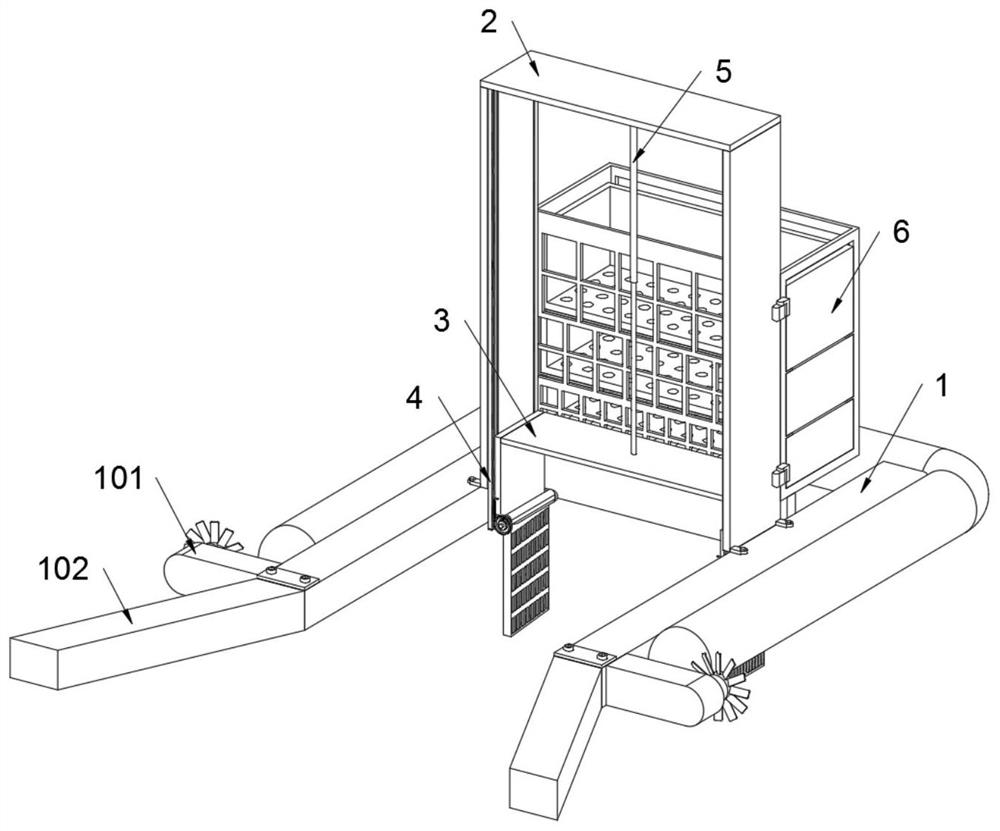

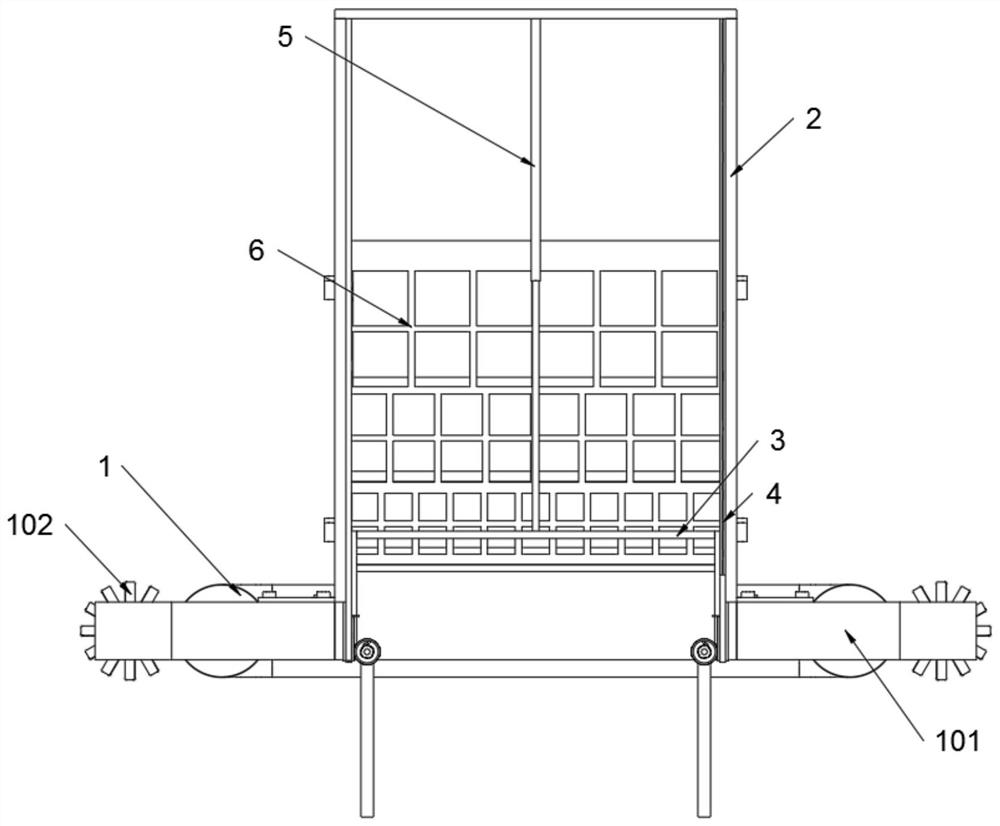

Water-conservancy-based fishing and classified collection device for water floating object cleaning

InactiveCN111608150AFishing achievedAchieve one-way rotationWater cleaningRefuse receptaclesMarine engineeringZoology

The invention provides a water-conservancy-based fishing and classified collection device for water floating object cleaning, and relates to the field of environmental protection cleaning. The problems are solved that classified collection of floating objects in different sizes cannot be simultaneously performed in a fishing process, and manual classification is often needed after fishing; and a plurality of electric components are needed to realize the up-down moving, rotating fishing and unloading actions of fishing arms, and the actions cannot be realized through a flew electric componentsin cooperation with a linkage structure. The water-conservancy-based fishing and classified collection device for water floating object cleaning comprises a hovercraft body, and a body frame is fixedly connected to the hovercraft body through bolts. When an electric telescopic rod pushes a fishing frame to move downwards, gear rows and the fishing frame move downwards synchronously, when the gearrows touch the bottom end faces of the inner walls of sliding seats, fishing arms are released from limitation and automatically switched to a vertical state due to their gravity, and finally the fishing frame continues to move downwards to make the fishing arms plunge into water.

Owner:王艳丽

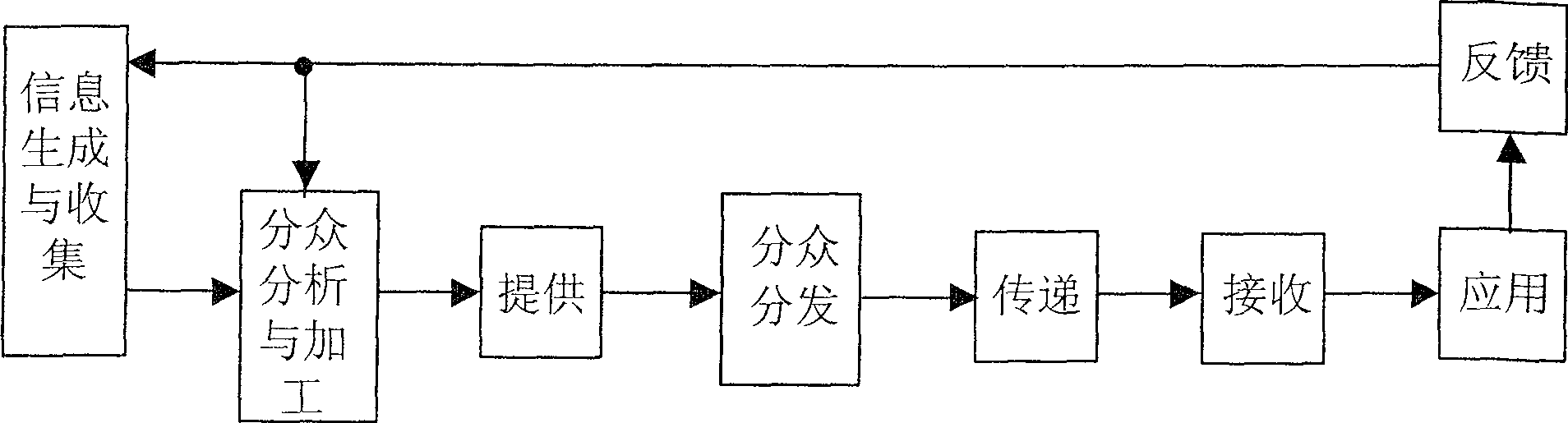

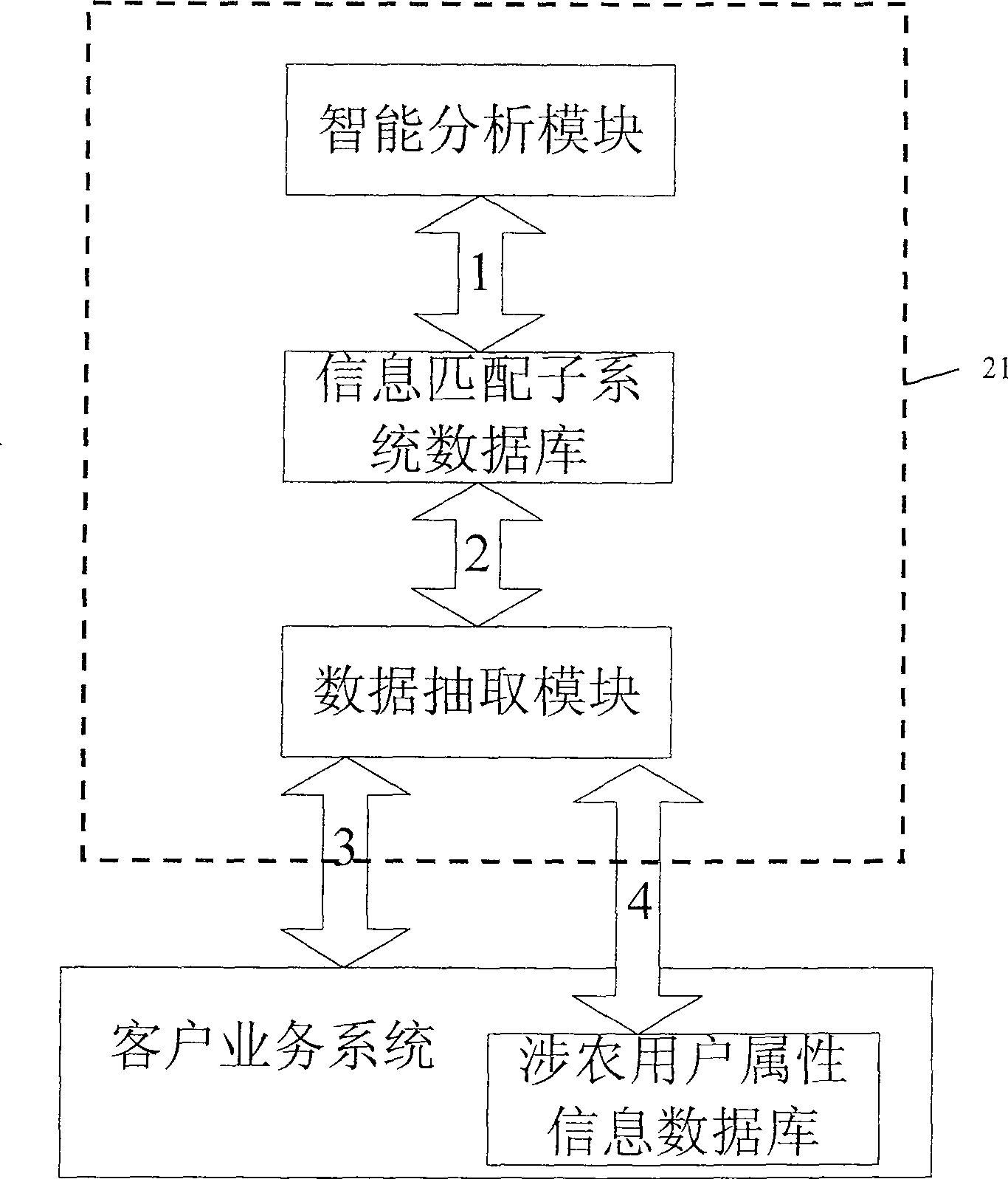

Packet broadcasting system with agricultural information relation and method thereof

ActiveCN100474948CGood point-to-point exact matchRealize poolingSpecial service provision for substationBroadcast with distributionInformation gainComputer science

The method comprises: 1) collecting agriculture information, and sending the information to the analyzing and processing module; 2) classifying the agriculture information; 3) based on the attributes of user, releasing the agriculture information; 4) transmitting the agriculture information through network; 5) users receives the information through communication terminal.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

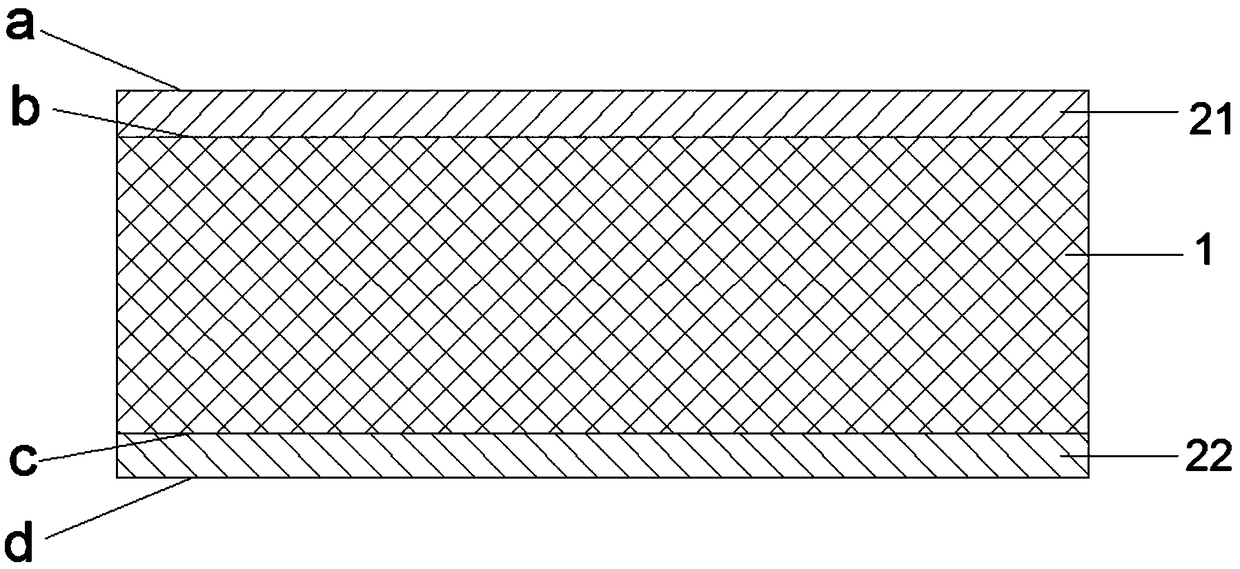

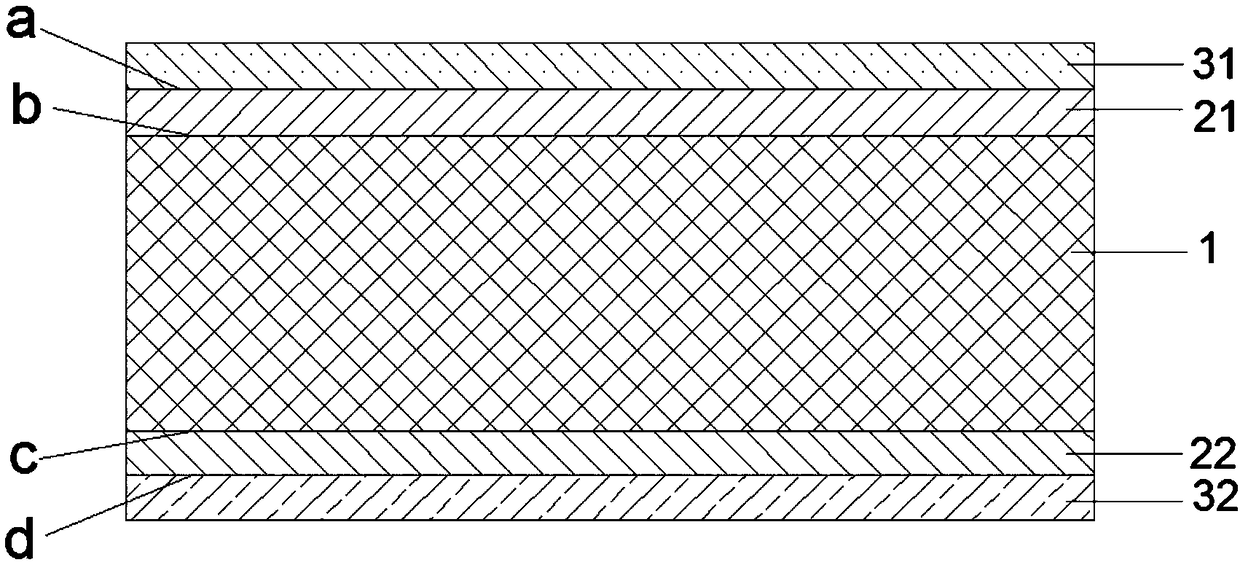

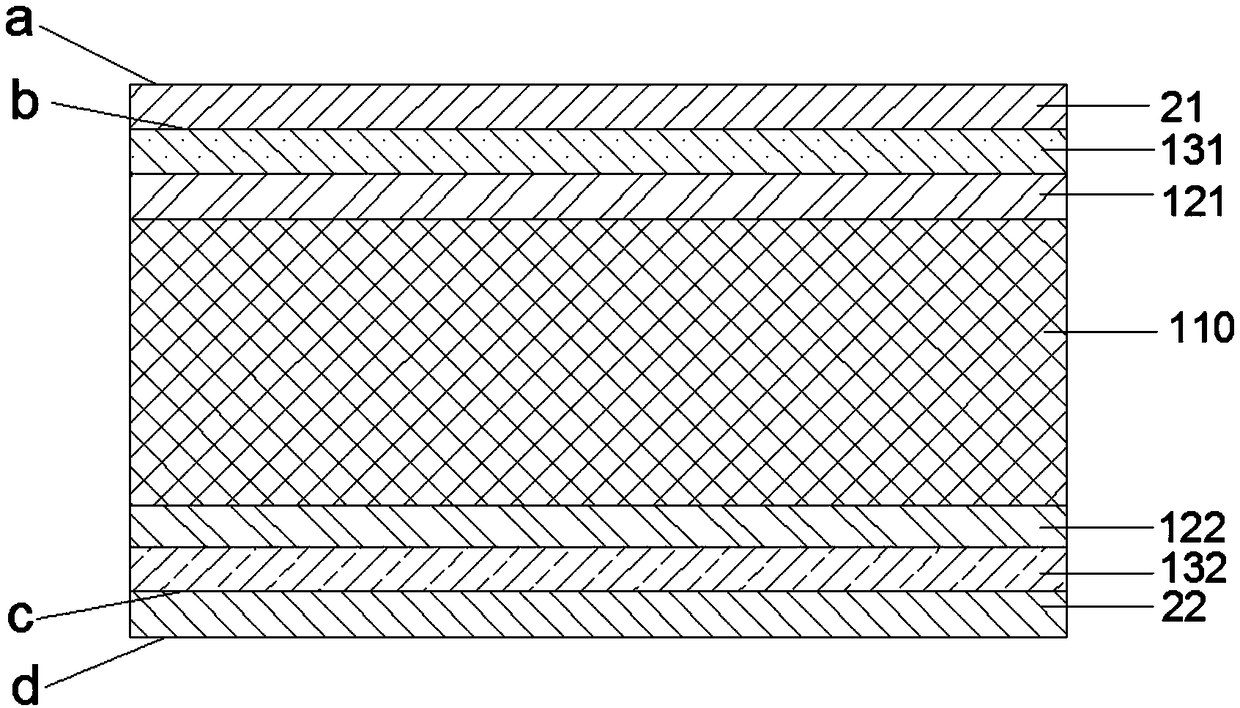

Solar cell and preparation method thereof

PendingCN109065647AGood electrical conductivityImprove light transmittanceFinal product manufacturePhotovoltaic energy generationHigh resistivityTransmittance

The invention relates to a solar cell and a preparation method thereof. The solar cell includes a power generation body, a first electrode and a second electrode. The power generation body includes alight receiving side and a backlight side arranged opposite to each other. The first electrode is arranged on the light receiving side of the power generation body, and the second electrode is arranged on the backlight side of the power generation body. Wherein the first electrode comprises a first graphene layer. The solar cell of the invention adopts a graphene layer as a transparent conductivelayer, has the advantages of good conductivity and high light transmittance, solves the problems of light shielding of grid lines, high resistivity and high cost, and improves the conversion efficiency of the solar cell. The invention uses molten gallium-containing catalyst and inert gas containing alkane to directly grow graphene layer at low temperature, improves the quality of transparent conductive layer of graphene and simplifies the preparation step.

Owner:德运创鑫(北京)科技有限公司

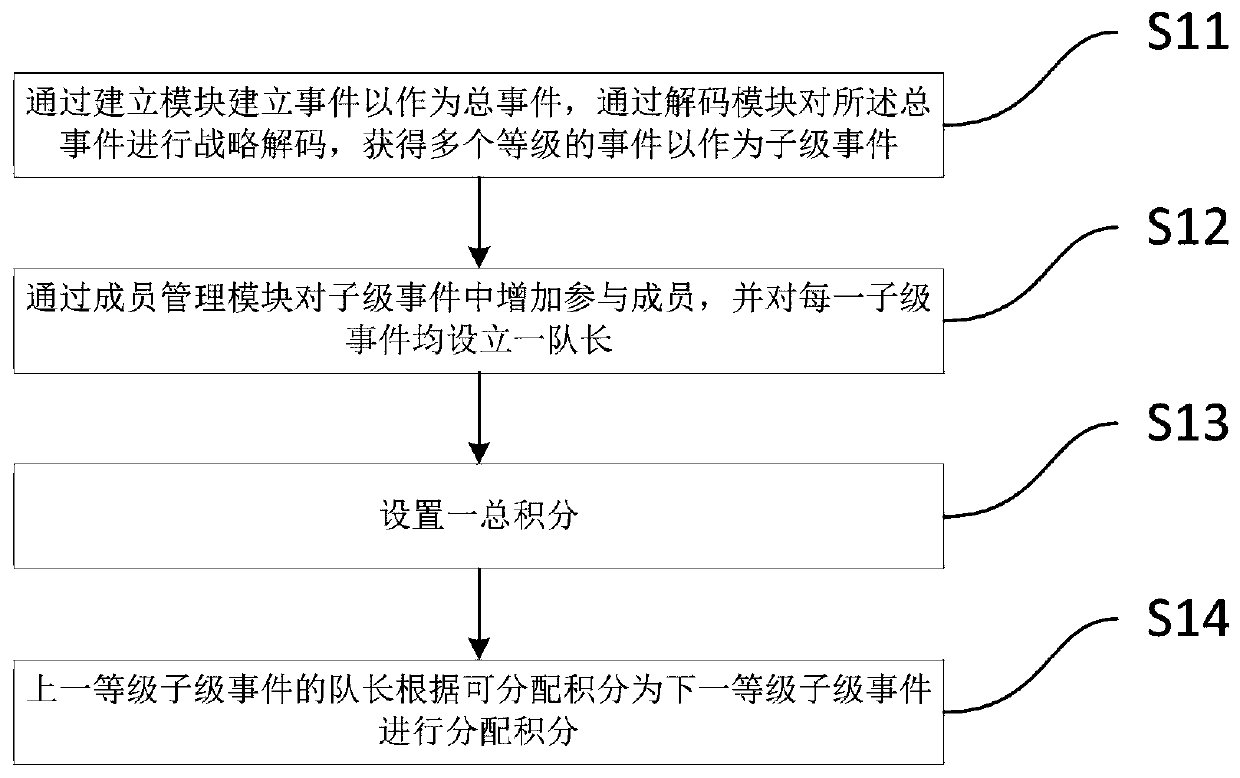

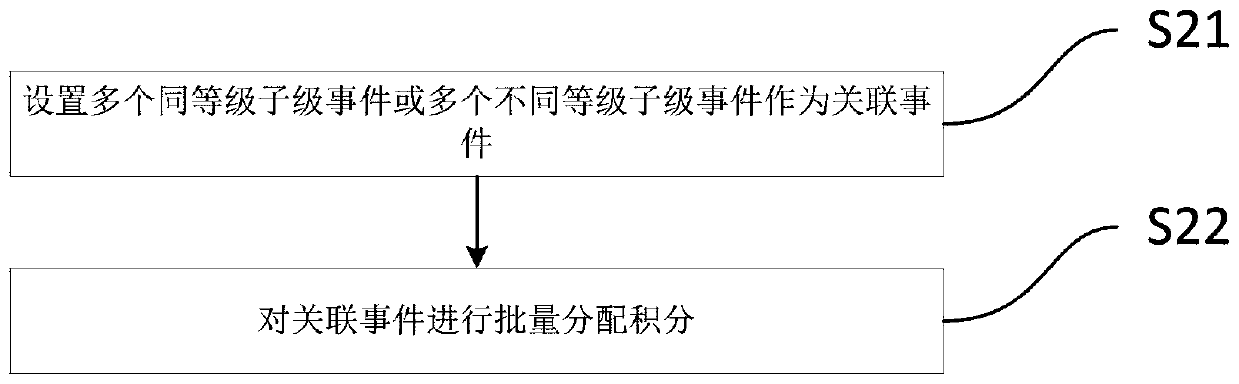

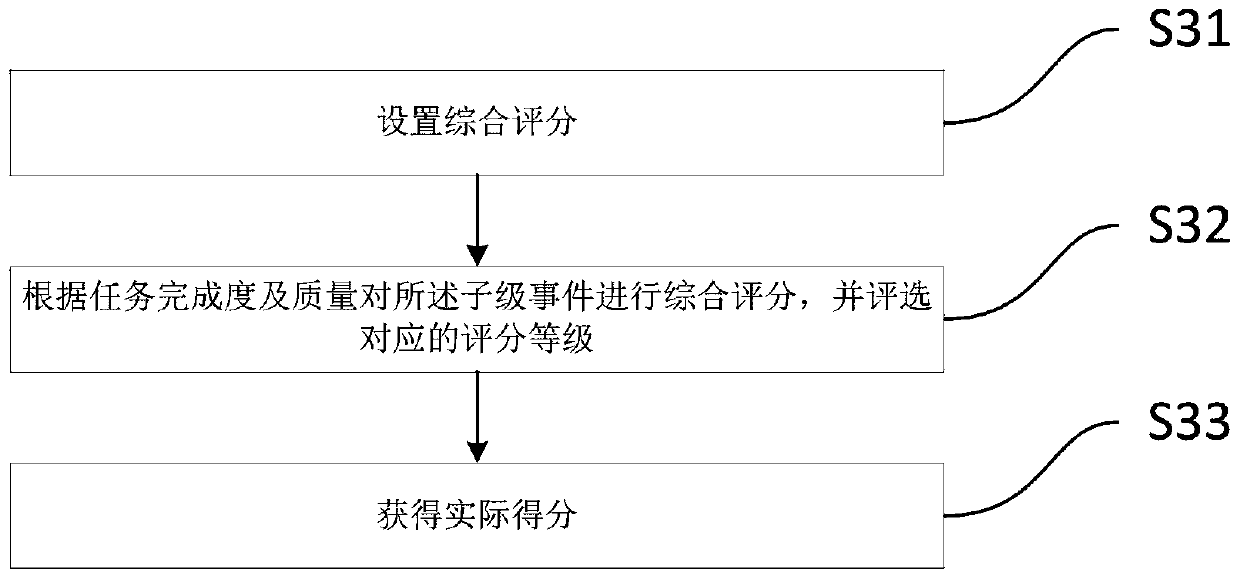

A partner alliance platform and an assignment method and system

InactiveCN109816332ASimplify the procedureEfficient points distributionOffice automationCollections dataAssignment methods

The invention relates to the technical field of management platforms, in particular to a partner alliance platform and an assignment method and system. The assignment method comprises the following steps: establishing an event as a total event through an establishment module, and strategically decoding the total event through a decoding module to obtain events of multiple grades as sub-grade events; adding participation members in the sub-level events through a member management module, and setting a queue leader for each sub-level event; Setting a total integral; And the queue length of the sub-level event of the previous level distributes integrals for the sub-level event of the next level according to the distributable integrals. The contribution standard based on the partner alliance platform event is established through the assignment method, the program process is simplified, objective and efficient integral distribution is achieved, a fair, fair and public management platform iscreated, and the enthusiasm of employees is improved; Furthermore, the comprehensive score is quoted, the working weight is improved, the monitoring importance is embodied, data collection is realized, and data loss is prevented.

Owner:WANYI TECH

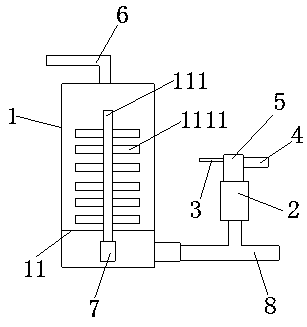

Multipurpose industry automatic flow dividing device

The invention relates to a multipurpose industry automatic flow dividing device. The multipurpose industry automatic flow dividing device comprises a box, a connecting sleeve, a thin pipe, a thick pipe and a thread connector. The box is of a two-layer structure. An output pipe is arranged at the upper end of the box and is made of stainless steel. A retainer is arranged at the lower end of the boxand provided with a vertical pipe. A filter net cover is arranged at the lower end of the vertical pipe. Flow dividing transverse pipes are arranged on the two sides of the vertical pipe. A connectoris arranged at the right end of the box. A water inlet communicates with a conveying pipe. A backflow pipe is arranged at the middle portion of the conveying pipe. Through the arrangement of the box,the retainer, the connecting sleeve, the thin pipe, the thick pipe and the thread connector, liquid different in diameter flow can be better gathered into the conveying pipe while the vertical pipe position fixing function can be better achieved as well; and through the arrangement of the vertical pipe, the flow dividing transverse pipes, the output pipe and the filter net cover, the functions ofliquid flow dividing and liquid filtering are better achieved.

Owner:ZHANGZHOU PULIHUI TECH SERVICE CO LTD

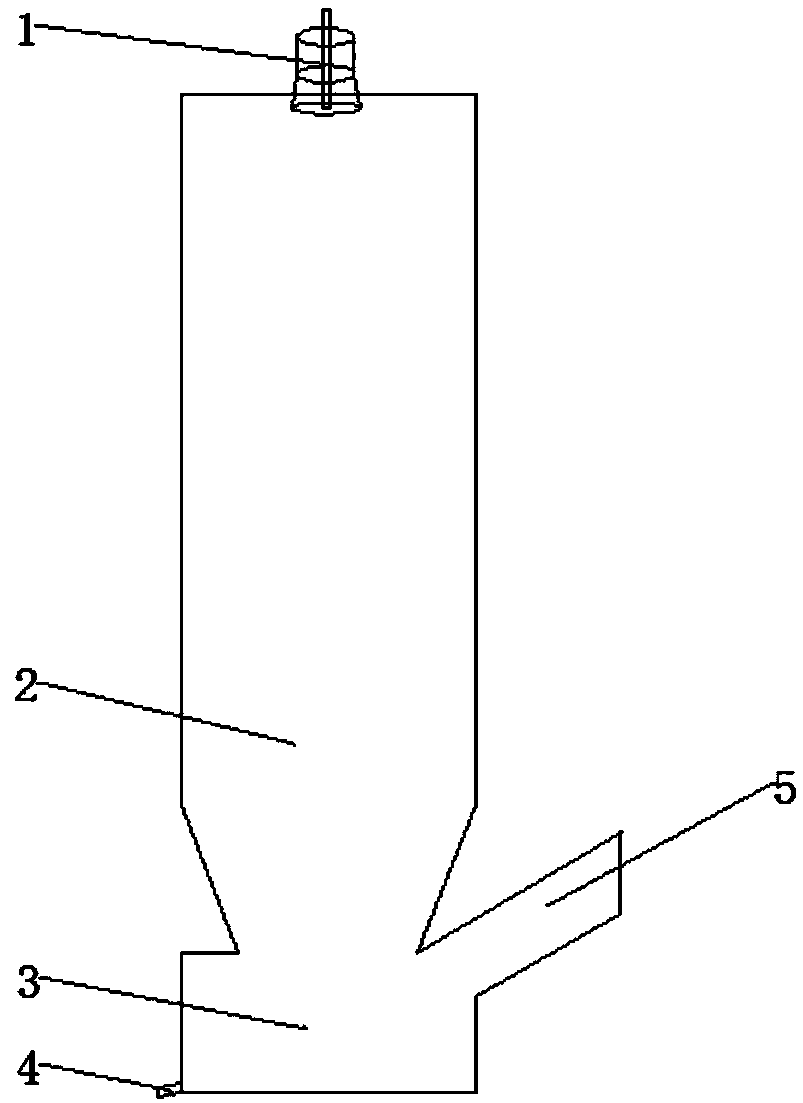

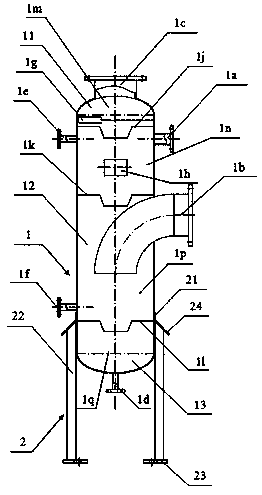

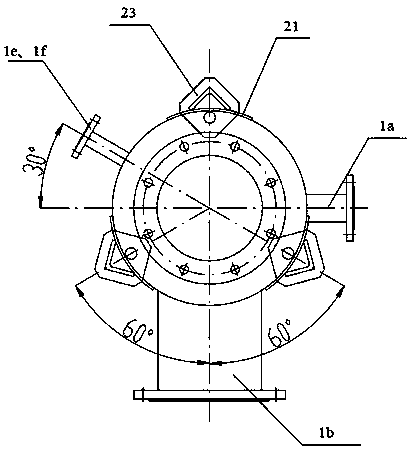

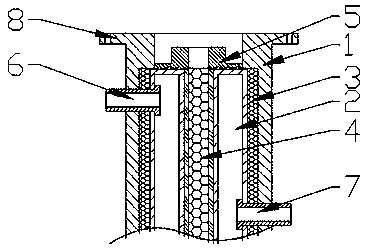

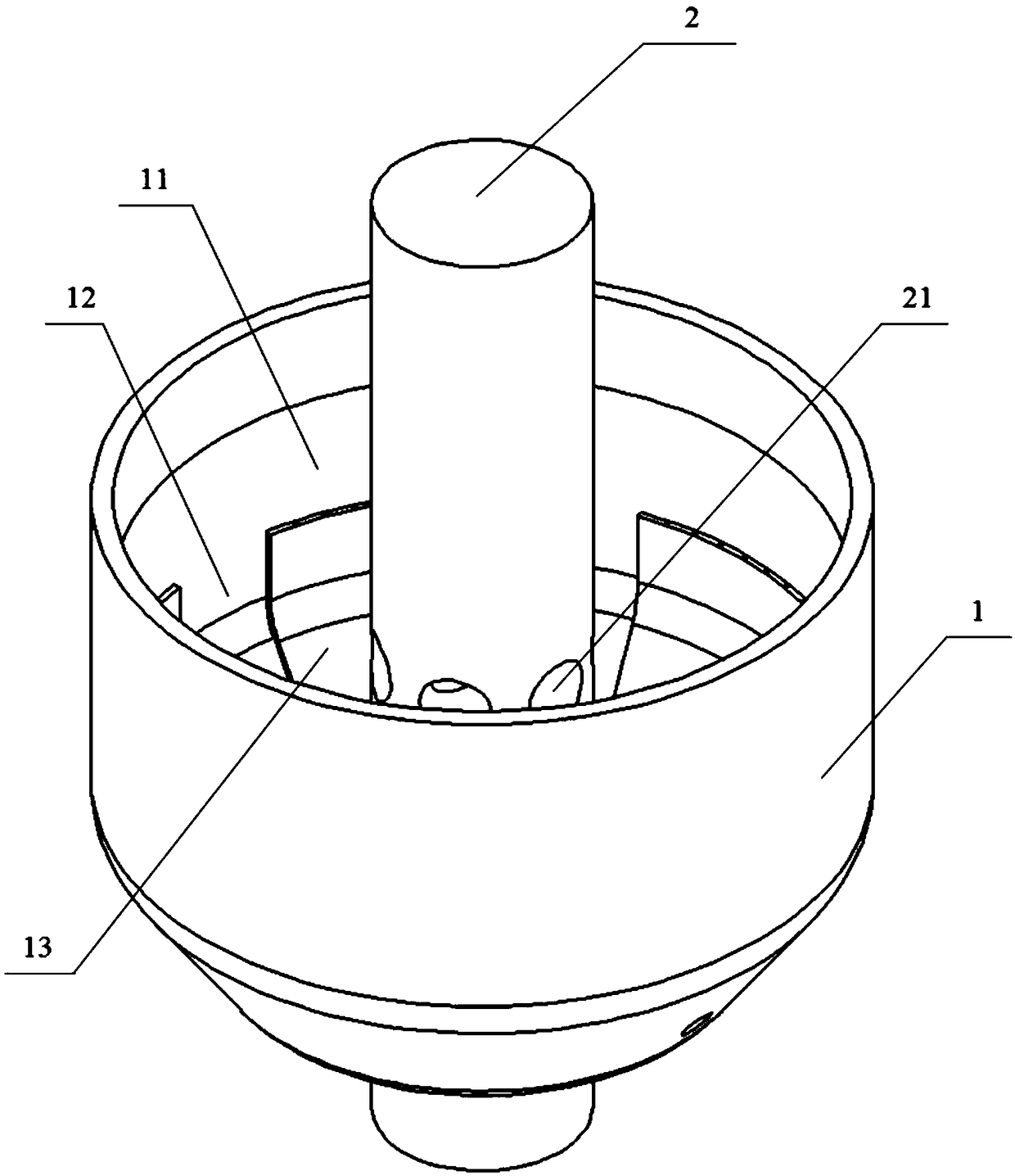

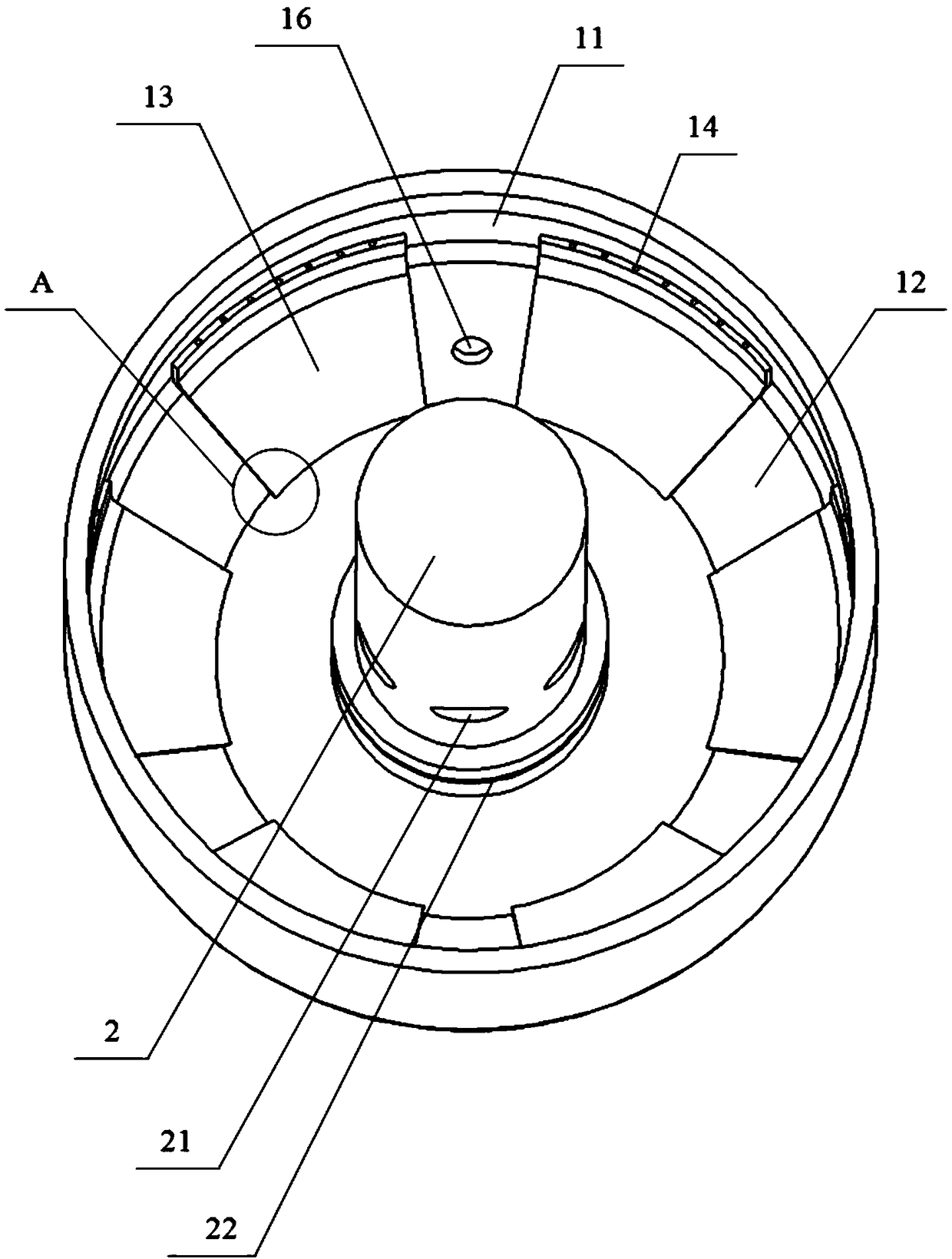

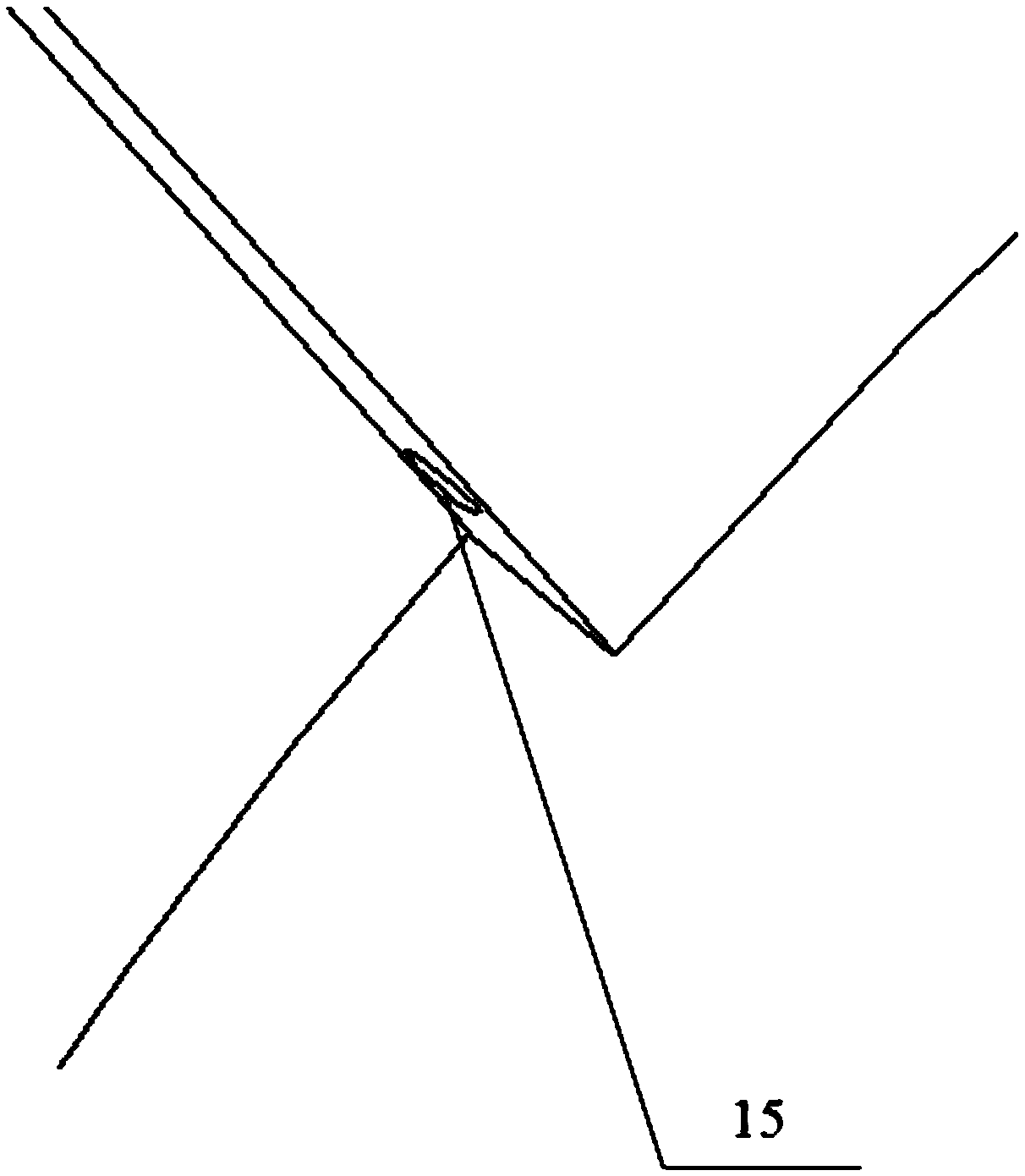

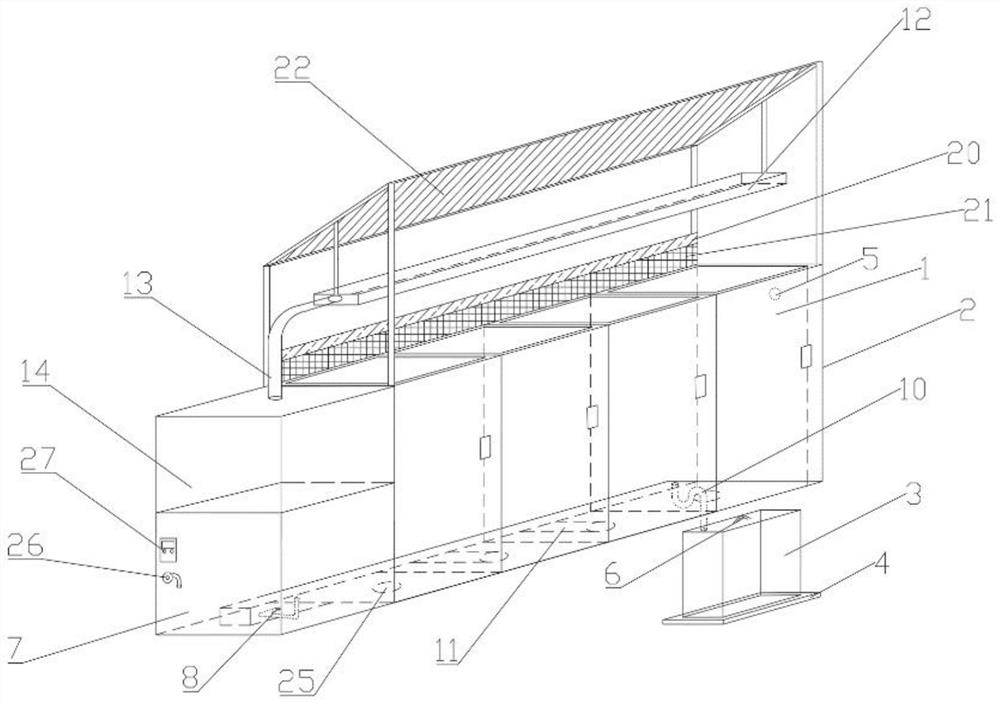

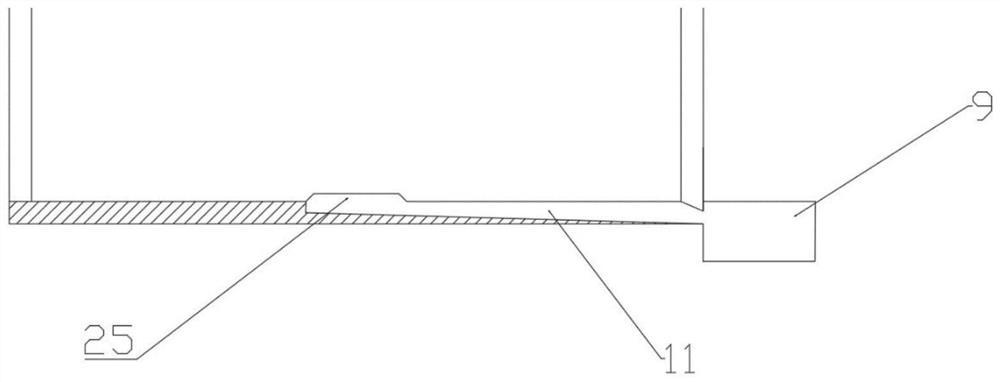

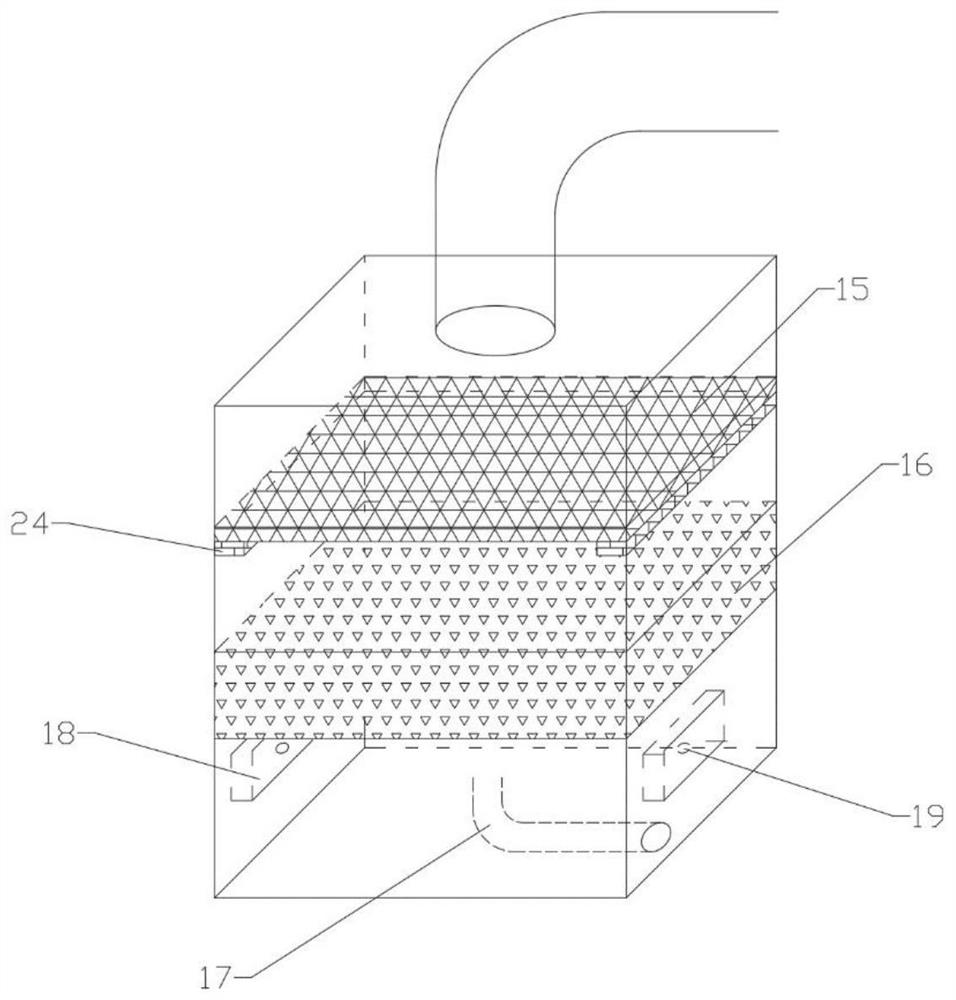

A tail gas scrubber using a gas-liquid separation membrane

ActiveCN108554129BEasy to replace and maintainGuaranteed connection strengthDispersed particle filtrationUsing liquid separation agentTowerMechanical engineering

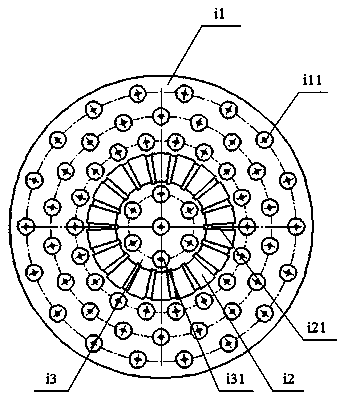

The invention relates to a tail gas scrubber using a gas-liquid separation membrane, which consists of a tower body (1) and a fixed part (2) located below the tower body (1). A cover-shaped top (11), an arc-shaped bottom (13) located below, and a hollow cylindrical middle part (12) located between the top (11) and the bottom (13); it is characterized in that: The interior of the tower body (1) is separated by the first separation membrane (1j), the second separation membrane (1k) and the third separation membrane (1l) arranged in sequence from the top (11) to the bottom (13). Outlet chamber (1m), first separation chamber (1n), second separation chamber (1p) and bottom deposition chamber (1q); said first separation membrane (1j), second separation membrane (1k); The liquid separation membrane improves the gas-liquid separation effect and facilitates the effective discharge of gas. At the same time, the cost is low, it is convenient for later cleaning and maintenance, and it is convenient to use.

Owner:昌和化学新材料(江苏)有限公司

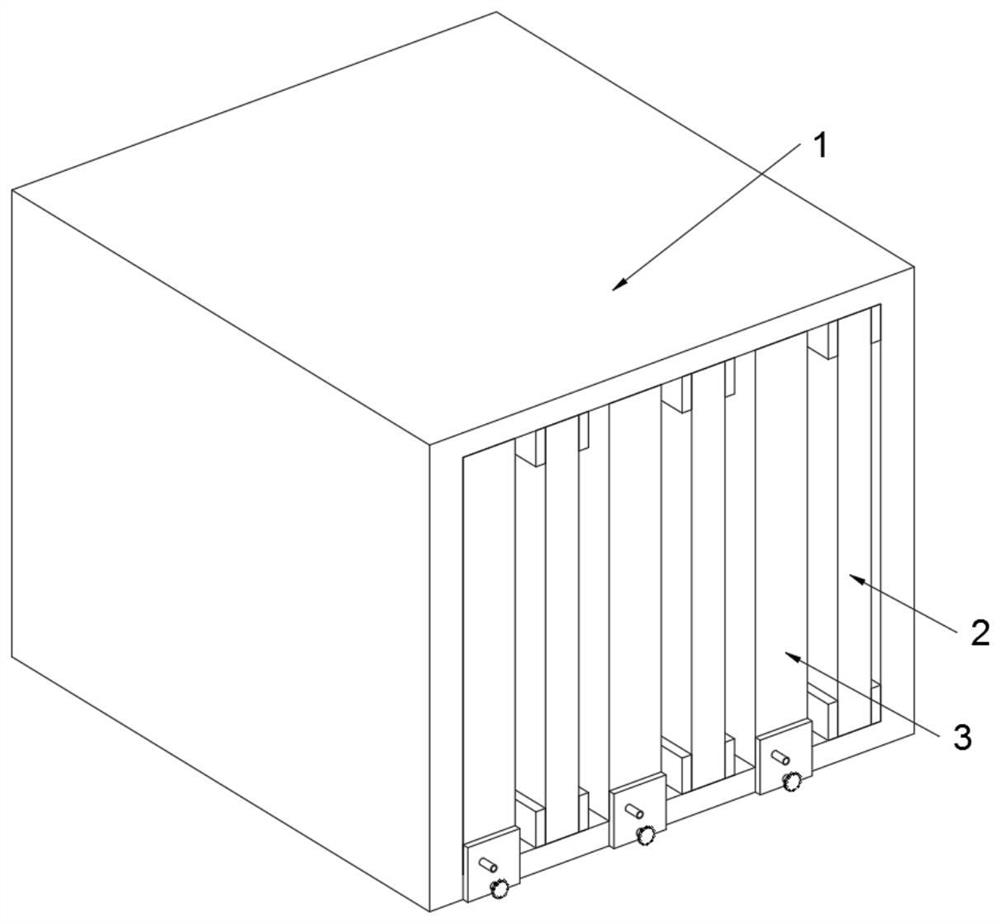

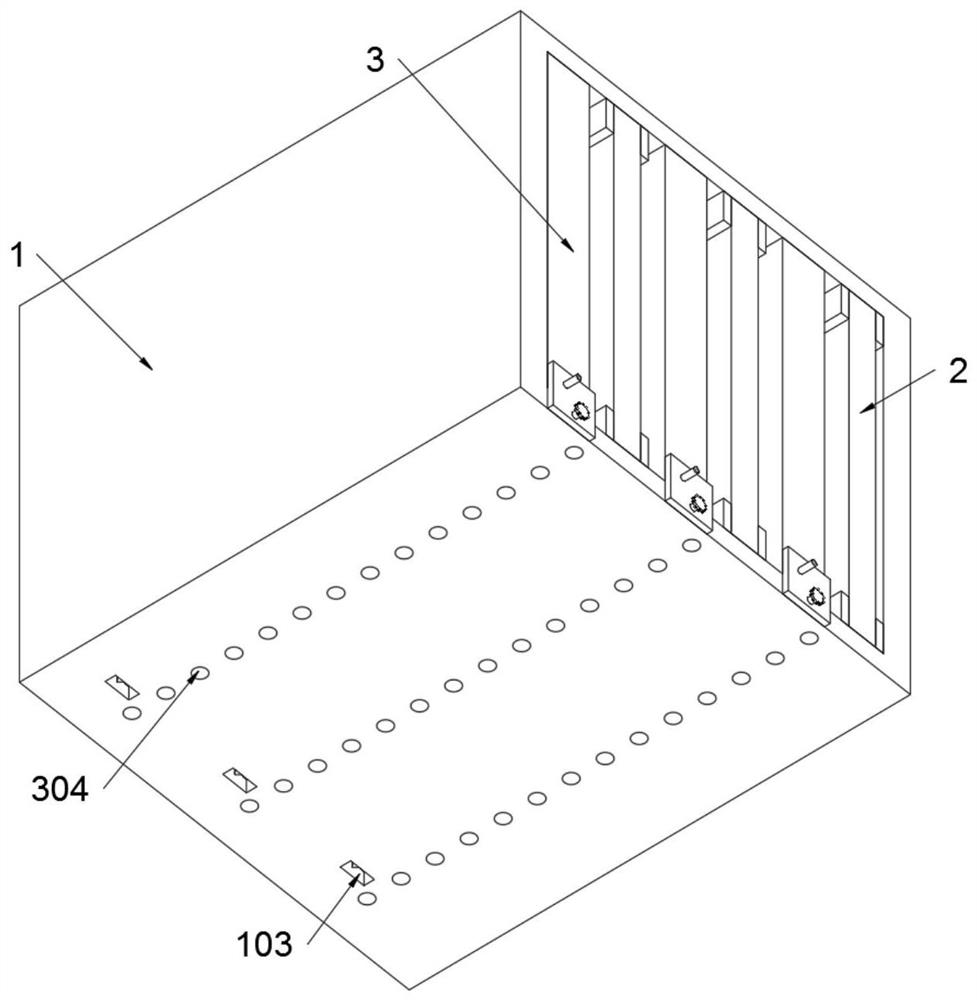

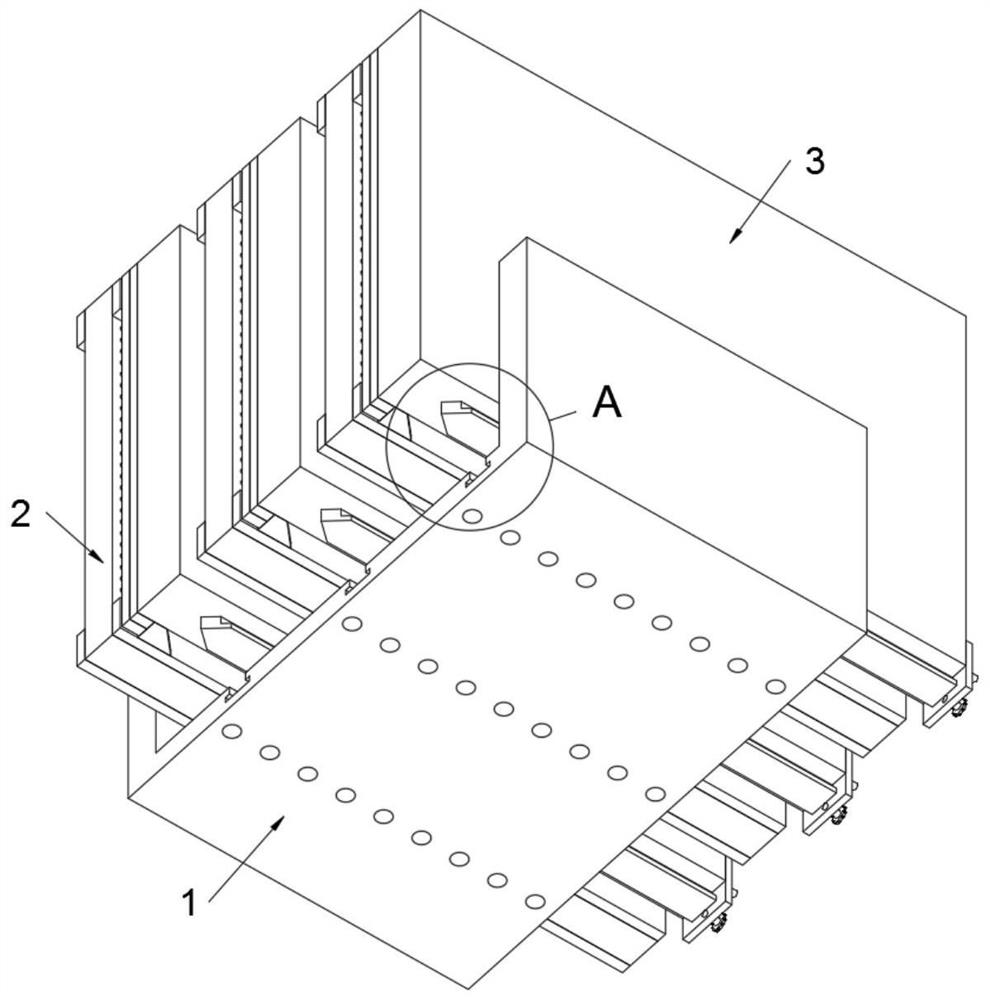

Steel structure butt welding adjusting device

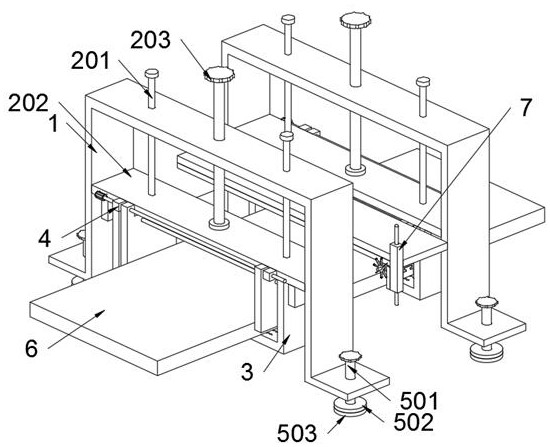

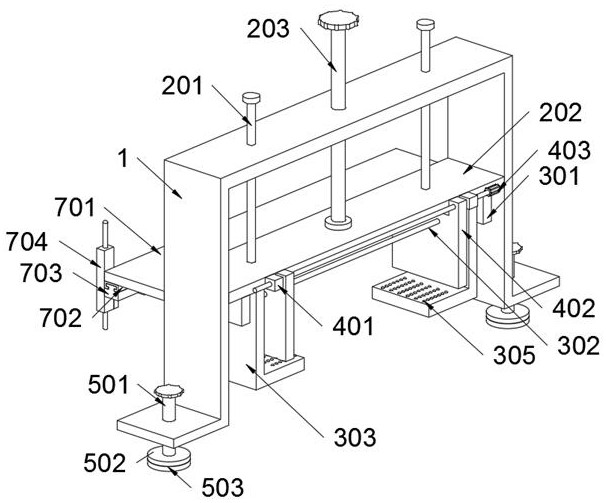

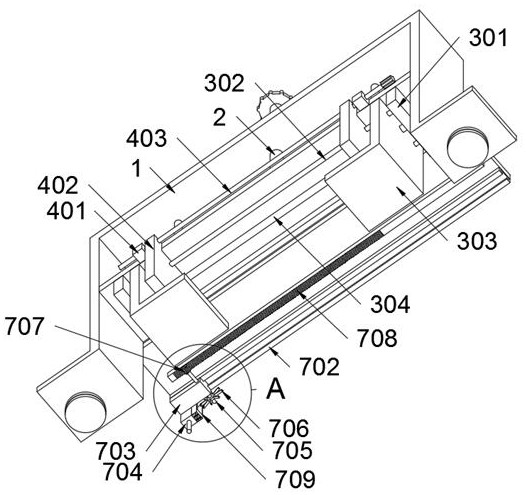

ActiveCN113245761ARealize poolingRealize horizontal position adjustmentWelding/cutting auxillary devicesAuxillary welding devicesEngineeringManufacturing engineering

The invention provides a steel structure butt welding adjusting device, and relates to the technical field of steel structure welding. The problems that horizontal displacement, vertical displacement and inclined adjustment cannot be achieved through structural improvement, strength consumption during adjustment cannot be reduced, and wind power heat dissipation at the welding position cannot be achieved during welding through structural improvement are solved. The steel structure butt welding adjusting device comprises frame bodies; the number of the frame bodies is two, the two frame bodies are each provided with a first adjusting structure, and each first adjusting structure is provided with a second adjusting structure; a tooth row is welded on the bottom end face of a mounting plate B and is meshed with a gear; a wind collecting seat is mounted on a welding body, the wind collecting seat is aligned to blades, and through holes are formed in the wind collecting seat in a rectangular array shape so that wind power generated by the blades can be collected through the wind collecting seat, and the collected wind power is vertically blown to the welding position.

Owner:康红礼

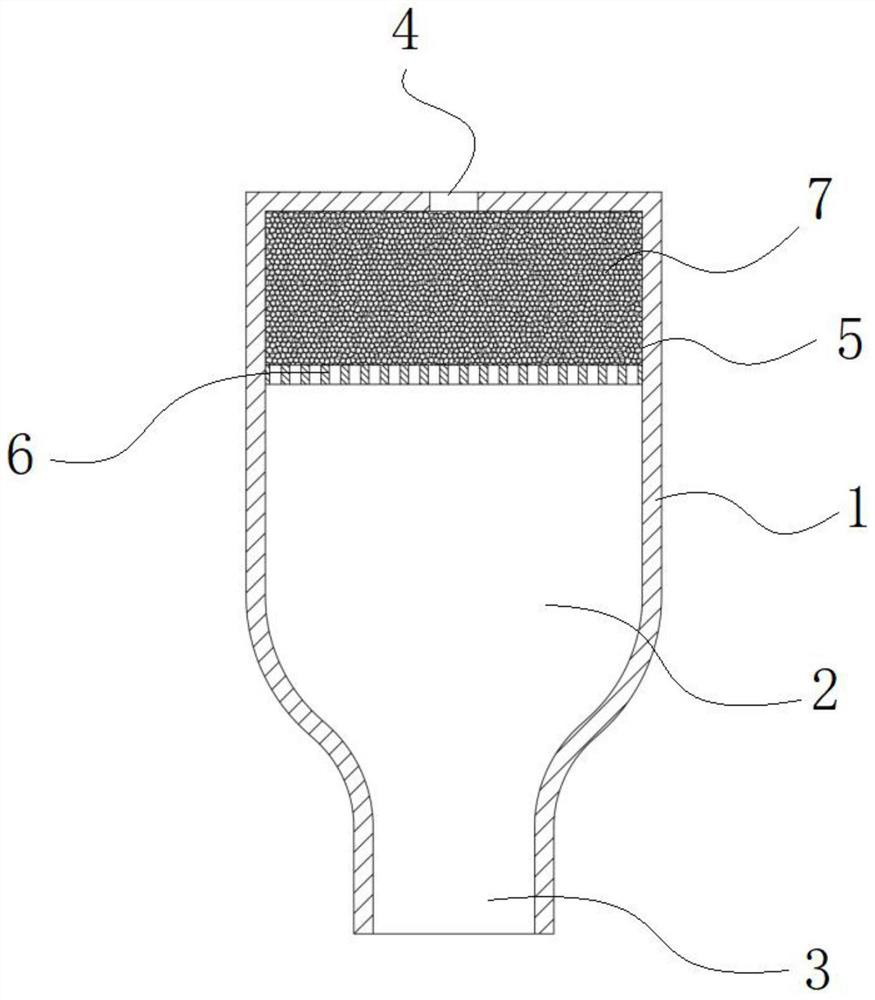

Gradient heating sheet for power battery of new energy automobile

InactiveCN112290122AAutomatic cleaningAutomatically implement automatic cleaningOhmic-resistance waterproof/air-tight sealsSecondary cellsPower batteryThermodynamics

The invention provides a gradient heating sheet for a power battery of a new energy automobile, relates to the technical field of batteries of new energy automobiles, and solves the problems that duston a storage battery cannot be cleaned in a linkage manner and the cleaned dust cannot be automatically cleaned when a heating device is dismounted, temporary storage of heat cannot be realized in the use process, and the problem of heat waste is easily caused. The gradient heating sheet comprises a shell, a storage battery body is installed in the shell, and three heating piece structures are further installed in the shell. A cleaning plate is welded on a heating piece main body, is in contact with the bottom end surface of the inner wall of the shell, and is aligned to the slag discharginghole; the front end face of the cleaning plate is of an inclined structure, so that when the heating piece body is pulled, the cleaning plate can automatically achieve collection of dust cleaned by the cleaning brush, and finally the dust is discharged through the slag discharging holes.

Owner:阳江吉优蓝电子科技有限公司

Condensation solar water heater

ActiveCN109654751AReduce weight loadRealize poolingSolar heating energyCollector thermal insulationLight guideSolar water

The invention relates to a condensation solar water heater. The water heater comprises a condensation assembly and a heating assembly, wherein the condensation assembly comprises a condensation plate,the condensation plate comprises a spherical reflecting plate, a reflecting layer is arranged on the surface of the reflecting plate, the condensation plate is connected with a retroreflector througha support, and the retroreflector is located at the sphere center position of the spherical reflecting plate; a light collecting cylinder is arranged at the center of the spherical surface of the condensation plate, a light collecting lens is arranged at one end of the light collecting cylinder, the light collecting lens is located on one face, provided with a reflecting layer, of the light collecting plate, a condensation assembly is arranged at the other end of a reflecting cylinder, the condensation assembly further comprises a light guide cylinder installed in the reflecting cylinder, a condensation lens is arranged in the light guide cylinder, and an enoscope is further arranged in the light guide cylinder; and the heating assembly comprises a connecting cylinder which is fixedly connected with the light guide cylinder, a heat collecting cylinder with an annular section is arranged in the connecting cylinder, an annular heat collecting cavity is formed in the heat collecting cylinder, and a light-transmitting hole is formed in the annular middle of the heat collecting cylinder.

Owner:JIANGSU SUNNIC SOLAR ENERGY INDAL

A method for comprehensive recovery of NdFeB waste acid leaching slag flash reduction supergravity slag financial fraction

ActiveCN109402316BImprove recovery rateAccurate temperatureProcess efficiency improvementSlagSpray nozzle

Owner:JIANGXI UNIV OF SCI & TECH

Oil collecting device for air compressor safety valve

PendingCN108953969AConvenient whereaboutsEasy to collectLubrication elementsInlet valveAir compressor

The invention relates to an oil collecting device for an air compressor safety valve. The oil collecting device is installed on one side of an air compressor head (3) for keeping the interior of an air compressor clean, and the oil utilization rate is increased. The oil collecting device is additionally installed on the safety valve, oil is sprayed to the inner wall of the oil collecting device, slides along the curved shape of the inner wall downwards and is collected in a centralized mode, the oil collecting device is connected to an intake valve through an oil return pipe, and recycling ofoil is achieved.

Owner:釜玛机械(江苏)有限公司

Confluence field of multi-end flexible direct-current electric transmission system

InactiveCN103855613ARealize poolingRealize distributionBus-bar/wiring layoutsDc network circuit arrangementsElectricityPower flow

The invention discloses a confluence field of a multi-end flexible direct-current electric transmission system. The confluence field comprises a confluence field bus, at least three ends of direct-current cable incoming lines are connected with the confluence field bus, a lightning arrester, a current measuring device and an isolation switch are connected between each end of direct-current cable incoming line and the confluence field bus, two ends of direct-current cable incoming lines are connected with the two ends of the confluence field bus respectively, and a single bus wiring mode is adopted as the wiring mode of the confluence field. Because the at least three ends of direct-current cable incoming lines are connected with the confluence field bus in different directions and the lightening arrester, the current measuring device and the isolation switch are arranged between each end of cable and the confluence field bus, energy convergence and distribution for multi-power source power supply and multi-drop point electricity receiving is achieved. Because the single bus wiring mode is adopted, segmented arrangement is not needed, the wiring mode is simple and practical, the economical efficiency is good, and the wiring requirement of the multi-end flexible direct-current electric transmission system is met.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Vertical engine oil complete recycling and filtering structure and method for engine crankcase

PendingCN113969811AImprove consistencyImprove reflux efficiencyMachines/enginesCrankcase ventillationProcess engineeringCrankcase

The invention discloses a vertical engine oil complete recycling and filtering structure and method for an engine crankcase. An engine oil filtering tank is vertically mounted in and communicated with the interior of the crankcase, the middle section of the engine oil filtering tank is provided with a gas buffering and recycling cavity, the bottom of the engine oil filtering tank is provided with a liquid-gas inlet and outlet connected to the interior of the crankcase, and a small air outlet is formed in the top of the engine oil filtering tank; and the upper section of the engine oil filtering tank is provided with a filtering chamber, the top of the filtering chamber is provided with a small air outlet, the bottom of the filtering chamber is provided with a perforated partition plate mounted on the inner wall of the engine oil filtering tank, and the engine oil filtering element is placed in the filtering chamber. According to the innovative structure, the integrated design of an engine is optimized on the whole, the recovery rate and recovery quality of engine oil are improved, and therefore the quality of the engine is improved on the whole, and the maintenance cost is reduced.

Owner:云南优航无人机科技有限公司

Vertical axis wind power generation system startup control method and wind power generation system

InactiveCN106089583BEasy to implementFlexible controlWind motor controlEngine fuctionsVertical axis wind turbineWind power system

The invention relates to a vertical axis wind power generation system start-up control method and a wind power generation system. When the wind power generation system is started up, a centralized net-connected controller starts net connection and controls various control switches to be off; a machine side controller drags the corresponding vertical axis wind power generator to rotate to the set start-up speed; and the working mode of the vertical axis wind power generator is switched to the power generation mode, thereby carrying out wind power generation. The start-up method can control the vertical axis wind power generator to be effectively started up, thereby solving the problem of difficulty in starting up the vertical axis wind power generator.

Owner:XUJI GRP +2

Garbage collection station suitable for residential area

PendingCN113911595ARealize poolingAchieve flushingWaste collection and transferRefuse receptaclesSewageResidential area

The invention discloses a garbage collection station suitable for a residential area. The garbage collection station comprises a garbage can body, a recycling assembly and a purifying assembly, wherein the interior of the garbage can body is divided into a plurality of garbage cans through a plurality of baffles arranged in parallel; the recycling assembly comprises a sewage tank, a sewage tank and a water collecting tank; the bottom of each garbage can is provided with a recovery ditch enabling leachate to automatically flow into the sewage tank; the water collecting tank is located at one end of the sewage tank and flushes the sewage tank, and the sewage tank is located at the other end of the sewage tank and collects flushing liquid; the purifying assembly comprises an air exhaust fan and a purification chamber; and the air exhaust fan exhausts air from each garbage can, and the air is conveyed into the purification chamber, filtered, adsorbed and deodorized through a purification component in the purification chamber and then discharged. The garbage collection station suitable for the residential area is simple in structure, not only achieves collection, flushing and collection of garbage leachate and avoids overflow of the garbage leachate, but also effectively achieves purification treatment of peculiar smell of garbage and avoids pollution to the surrounding environment.

Owner:XUZHOU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com