Calcium carbide furnace tail gas comprehensive utilization system and process

A technology of calcium carbide furnace tail gas and tail gas, which is applied in the chemical industry, combined devices, climate sustainability, etc., can solve problems such as pollution and waste of energy, and achieve obvious effects of reducing device energy consumption, saving energy, and saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

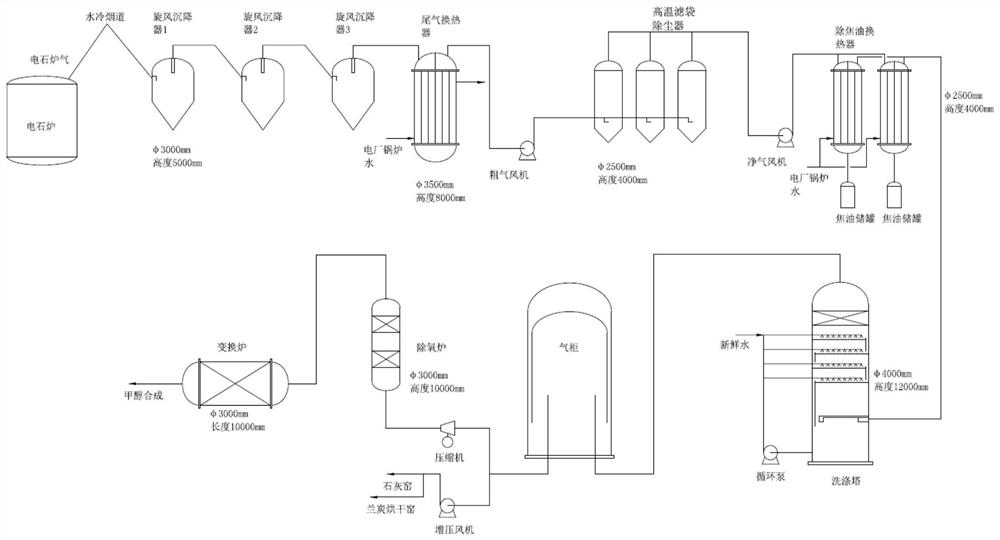

[0036] As shown in the figure, a comprehensive utilization system of calcium carbide furnace tail gas, including water-cooled flue, cyclone settler, tail gas heat exchanger, high-temperature filter bag dust collector, tar removal heat exchanger, scrubber and gas cabinet;

[0037] The cyclone settler adopts three-stage cyclone settler (the height of each cyclone settler is 5000mm, Ф3000mm) connected in series. After the calcium carbide furnace exhaust passes through the water-cooled flue, it passes through the cyclone settler 1, the cyclone settler 2 and the cyclone settler 3 in sequence. The gas outlet of the settler 3 is connected to the gas inlet of the tail gas heat exchanger (height 8000mm, Ф3500mm); the gas outlet of the tail gas heat exchanger is connected to the high temperature filter bag filter through the rough gas fan;

[0038] The high-temperature filter bag dust collector adopts three-stage filter bag dust collector (the height of each filter bag dust collector is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com