Method of concentrating and recycling hydrogen sulfide in industrial acid gas by absorption of organic solvent

An organic solvent, hydrogen sulfide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of less foam and low viscosity, and achieve the effect of less foam, low viscosity and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

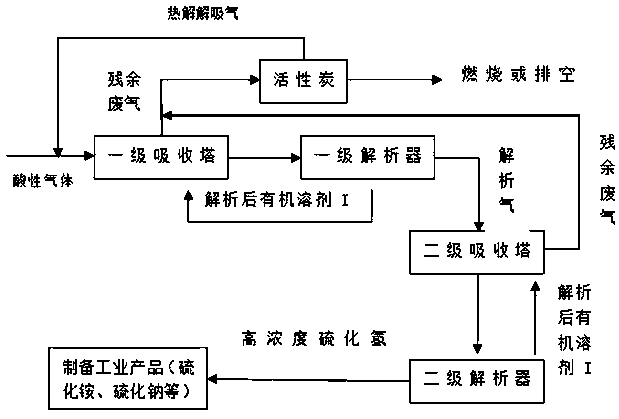

[0028] Example 1, such as figure 1 As shown, the methods of absorbing and enriching hydrogen sulfide and resource utilization in industrial acid gas by the organic solvent are as follows:

[0029] Industrial acid gas containing hydrogen sulfide: hydrogen sulfide content 30.1% (v / v), carbon dioxide content 66.2% (v / v), other impurity components 3.7% (v / v), pressure 0.3MPa, gas temperature 38°C; Composition of primary organic solvent I: 35% (v / v) MDEA, 40% (v / v) of glycerol, 25% (v / v) of water; Composition of secondary organic solvent I: 60% (v / v) MDEA, Glycerol 20% (v / v), Water 20% (v / v).

[0030] The industrial acid gas containing hydrogen sulfide enters the primary absorption tower and contacts with the primary organic solvent I countercurrently, the liquid-gas ratio is L:m 3 15, the hydrogen sulfide and a small amount of carbon dioxide in the industrial acid gas containing hydrogen sulfide are absorbed, and the remaining components such as most of the carbon dioxide, a sma...

Embodiment 2

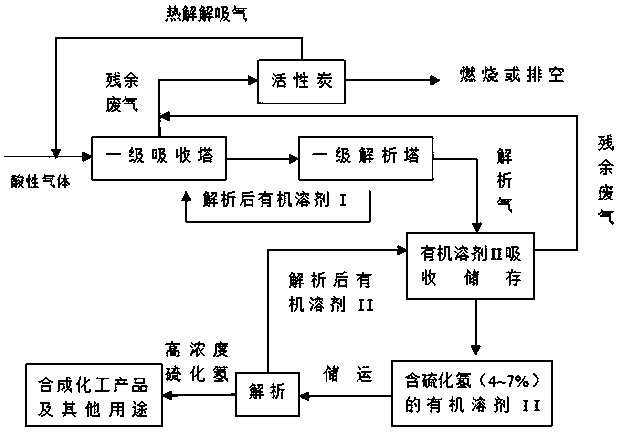

[0033] Embodiment 2: as figure 2 As shown, the methods of absorbing and enriching hydrogen sulfide and resource utilization in industrial acid gas by the organic solvent are as follows:

[0034] Industrial acid gas containing hydrogen sulfide: hydrogen sulfide content 24.6% (v / v), carbon dioxide content 67.4% (v / v), other impurity components 8% (v / v), pressure 0.35MPa, flue gas temperature 42 ℃ ;Organic solvent I composition: MEDA50% (v / v), glycerin 30% (v / v), water 20% (v / v); organic solvent II composition: MDEA90% (v / v), octanol 10 %(v / v).

[0035] The industrial acid gas containing hydrogen sulfide enters the primary absorption tower and contacts with the organic solvent I countercurrently, the liquid-gas ratio L:m 3 For 18, the hydrogen sulfide and a small amount of carbon dioxide in the industrial acid gas containing hydrogen sulfide are absorbed, and the remaining components such as most of the carbon dioxide, a small amount of hydrogen sulfide, nitrogen and other imp...

Embodiment 3

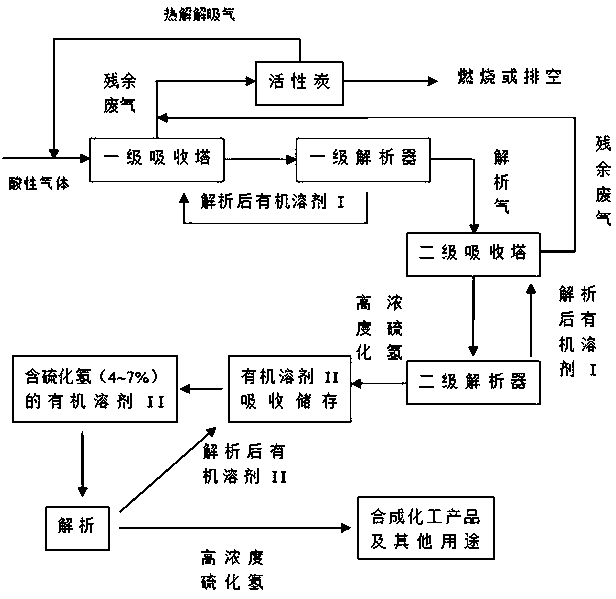

[0038] Embodiment 3: as image 3 As shown, the methods of absorbing and enriching hydrogen sulfide and resource utilization in industrial acid gas by the organic solvent are as follows:

[0039] Industrial acid gas containing hydrogen sulfide: hydrogen sulfide content 40.1% (v / v), carbon dioxide content 55% (v / v), other impurity components 4.9% (v / v), pressure 0.4MPa, gas temperature 35°C; Composition of primary organic solvent I: 30% (v / v) MDEA, 40% (v / v) ethanol, 30% (v / v) water; composition of secondary organic solvent I: 40% (v / v) MDEA, 20% ethanol % (v / v), water 40% (v / v); organic solvent II composition: MEDA70% (v / v), ethylene glycol 30% (v / v);

[0040] The industrial acid gas containing hydrogen sulfide enters the primary absorption tower and contacts with the primary organic solvent I countercurrently, the liquid-gas ratio is L:m 3 10, the hydrogen sulfide and a small amount of carbon dioxide in the industrial acid gas containing hydrogen sulfide are absorbed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com