Steel structure butt welding adjusting device

A technology for adjusting devices and steel structures, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of reduced power consumption and small range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

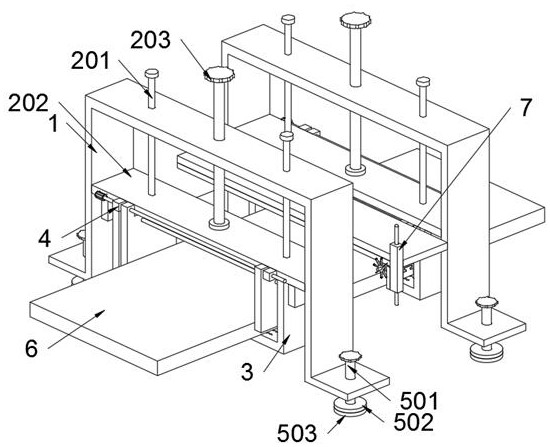

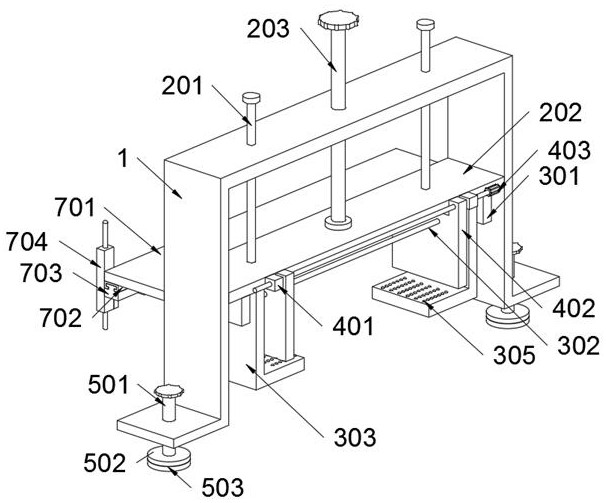

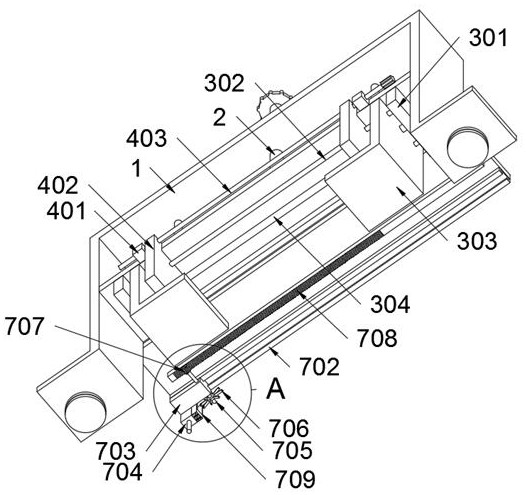

[0033] as attached figure 1 to attach Image 6 Shown:

[0034] The invention provides a steel structure butt welding adjustment device, which includes a frame body 1; there are two frame bodies 1 in total, and a first adjustment structure 2 is installed on the two frame bodies 1, and each first adjustment structure 2 A second adjustment structure 3 is installed on each of the second adjustment structures 3; a third adjustment structure 4 is installed on each second adjustment structure 3, and a steel structure 6 is placed on each second adjustment structure 3; each frame body 1 Two support structures 5 are installed on the top, and a welding structure 7 is installed on the right frame body 1; refer to as Figure 4 and Image 6The welding structure 7 includes a gear 707, a row of teeth 708, an air collecting seat 709 and a through hole 710, the gear 707 is welded on the rotating shaft 705; the row of teeth 708 is welded on the bottom surface of the mounting plate B701, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com