Vertical engine oil complete recycling and filtering structure and method for engine crankcase

A technology of filtering structure and filtering method, applied in the directions of engine components, crankcase ventilation, machine/engine, etc., can solve the problems of incomplete oil recovery, less dirty oil, pollution of oil discharge, etc., to achieve an optimized integrated design, Improve quality and ensure the effect of cooling and liquefaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

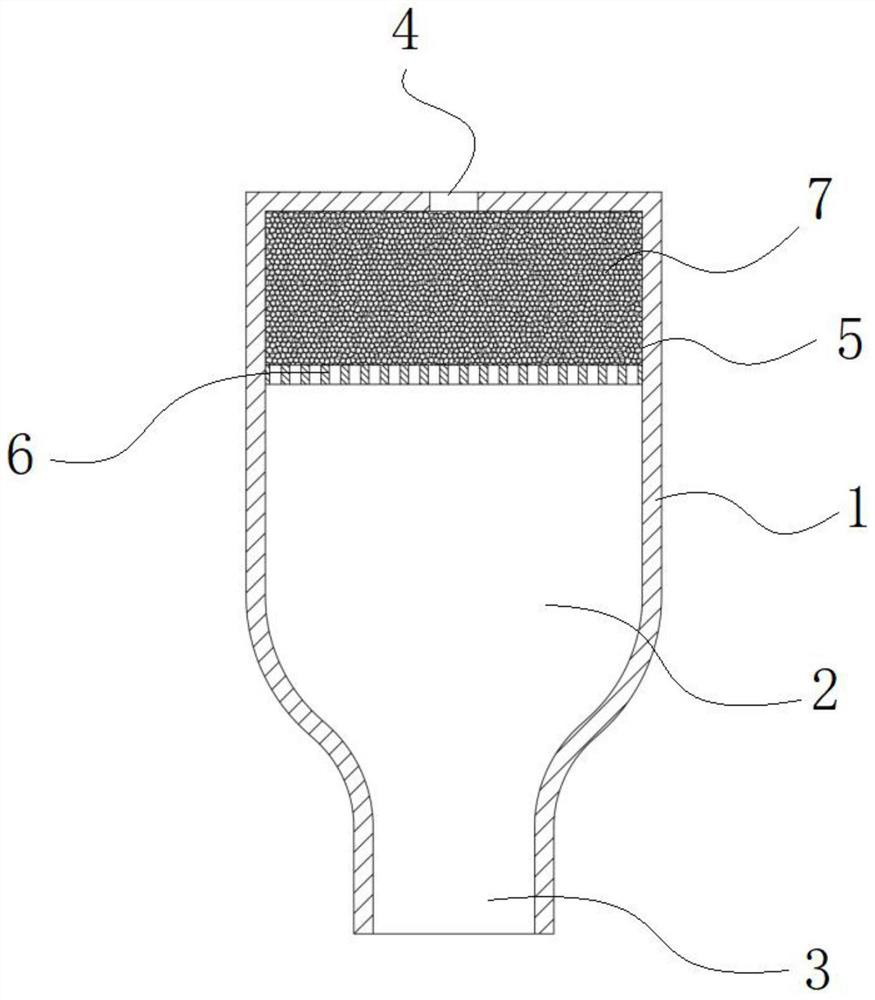

[0034] A complete vertical oil recovery filter structure for engine crankcases, including: an oil filter tank 1 installed vertically and connected to the inside of the crankcase, the middle section of the oil filter tank 1 is a gas buffer recovery chamber 2, and the bottom is connected to the crankshaft The liquid gas inlet and outlet 3 inside the box has a small air outlet 4 on the top, the upper section of the oil filter tank 1 is a filter chamber 5, the top of the filter chamber 5 is a small air outlet 4, and the bottom is provided with a valve installed on the inner wall of the oil filter tank 1 The perforated partition 6 and the oil filter element 7 are placed in the filter chamber 5 .

[0035] Preferably, the oil filter tank 1 can be square, ellipsoidal or cylindrical, and the gas buffer recovery chamber 2 has a structure with a narrow bottom and a wide top. The narrow structure is more conducive to the backflow of the engine oil; the oil filter element 7 is a high tempe...

Embodiment 2

[0038] A method for fully recovering and filtering vertical machine oil used in engine crankcases, comprising the following steps:

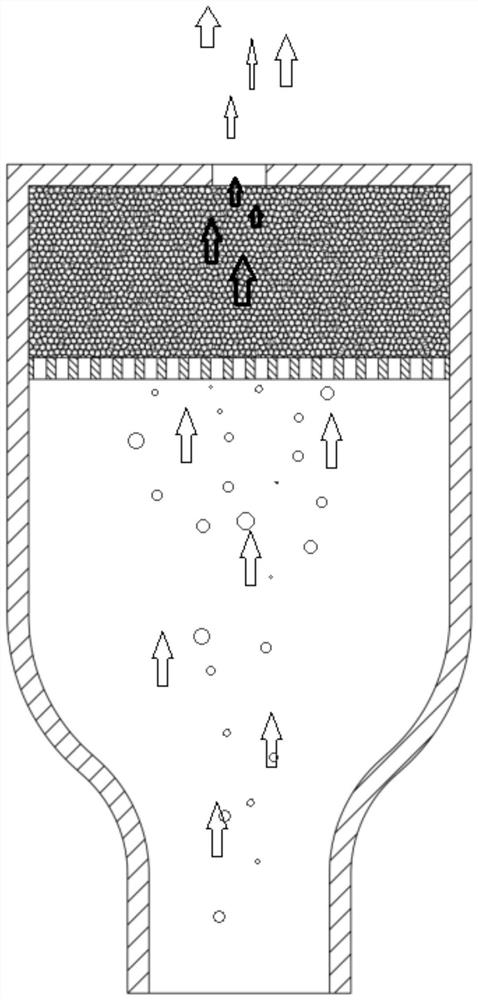

[0039] S1. The piston moves inward, and the gas in the crankcase and a large amount of mist oil are pressed into the oil filter tank 1 from the bottom step liquid gas inlet and outlet 3 of the oil filter tank 1;

[0040] S2. Gas and a large amount of mist oil pass through the oil filter element 7 in the filter chamber 5 on the upper part of the oil filter tank 1, the temperature of the gas decreases, and the oil-free gas is discharged from the small air outlet 4 on the top of the oil filter tank 1, and the condensed The mist oil is absorbed and intercepted by the filter element;

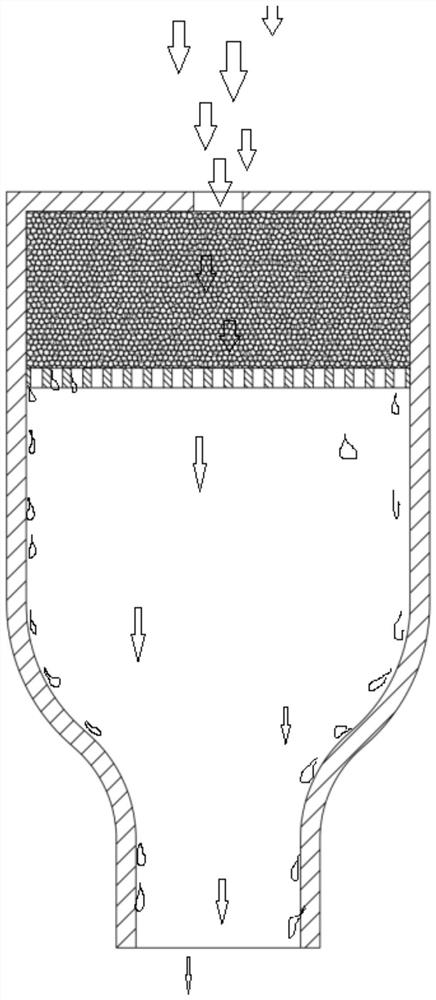

[0041] S3. The piston moves in reverse, forming a negative pressure in the crankcase and the oil filter tank 1, the external air is sucked in from the small air outlet 4, and the external air passes through the oil filter element 7 to cool the filter element, and at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com