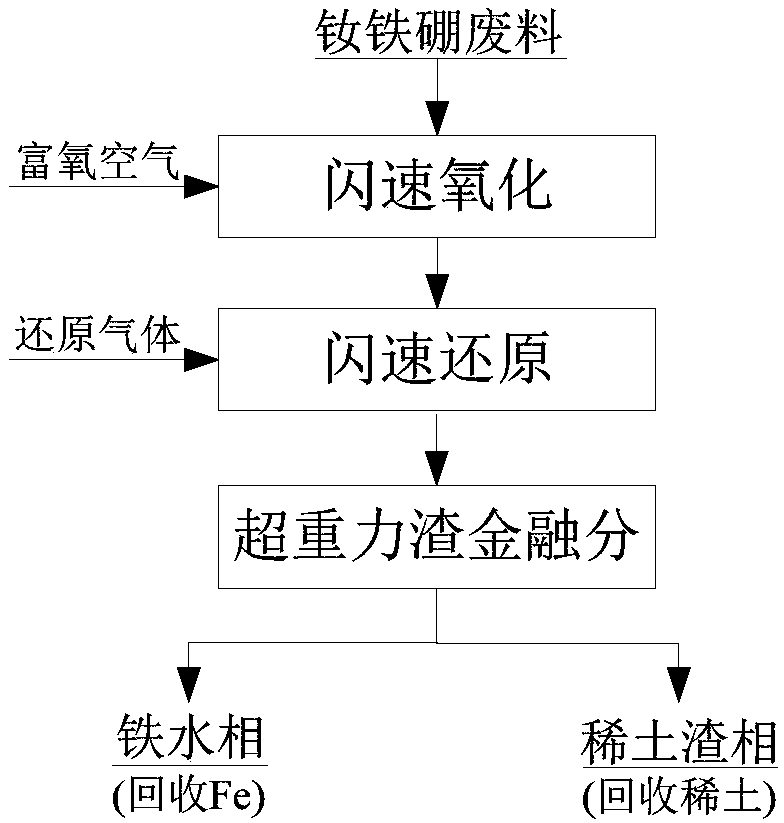

Neodymium iron boron waste double-flash supergravity slag metal melting comprehensive recovery method

A neodymium-iron-boron and super-gravity technology is applied in the field of comprehensive recovery of neodymium-iron-boron waste double-flash super-gravity slag, which can solve the problems of inability to precisely control temperature and atmosphere, difficulty in comprehensive utilization of leaching slag, and decrease in the total recovery rate of rare earth. , to achieve the effects of superior reaction kinetic conditions, good popularization and application value, and easy control of furnace atmosphere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

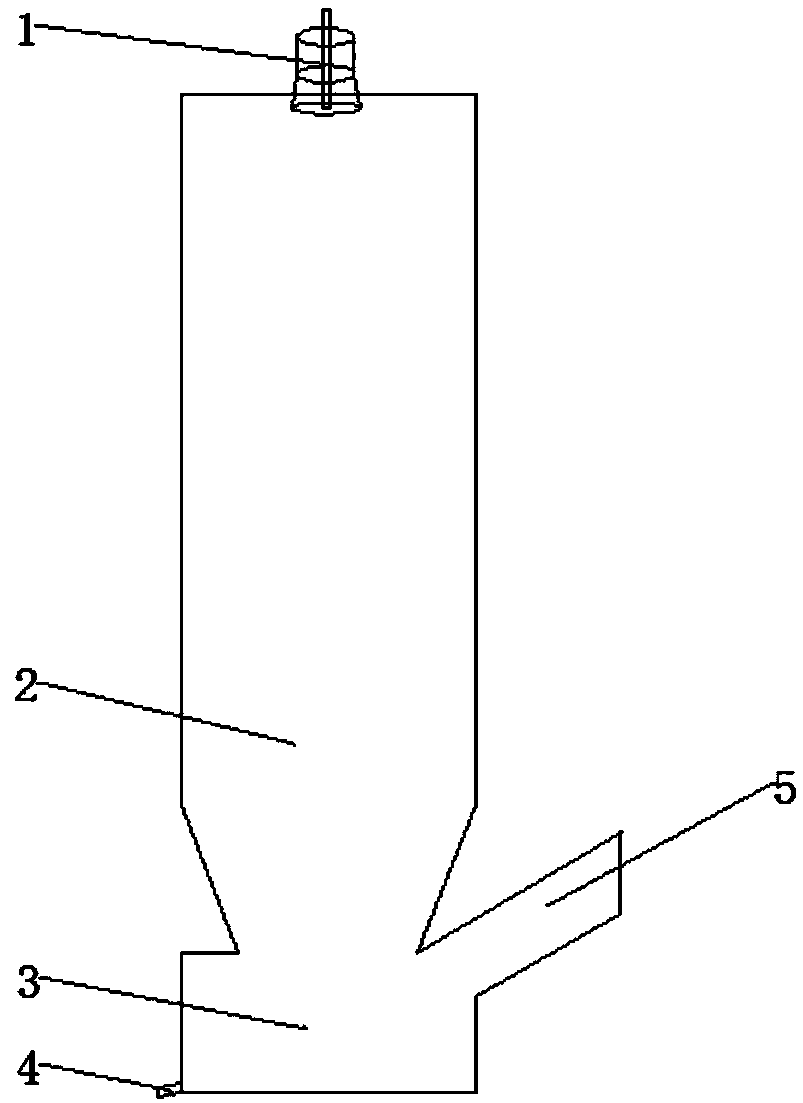

[0033] Spray the powdery NdFeB waste with a particle size of 100 mesh and oxygen-enriched air with an oxygen mass percentage concentration of 40% into a reaction tower (2) with a height of 2.5 meters and a temperature of 800 °C through a nozzle (1). In a highly dispersed floating state, it falls from the upper end of the reaction tower to the lower end. During this process, the iron and rare earth in the material are rapidly oxidized by oxygen-enriched air. The oxidation rate of iron in the waste is 99.41%, and the oxidation rate of rare earth is 99.82%. Oxidation products fall into the collector (3) below the reaction tower, and are released from the outlet (4) before entering the flash reduction furnace. The oxidized flue gas is discharged through the flue (5) at the upper end of the collector (3), and is emptied after dust collection.

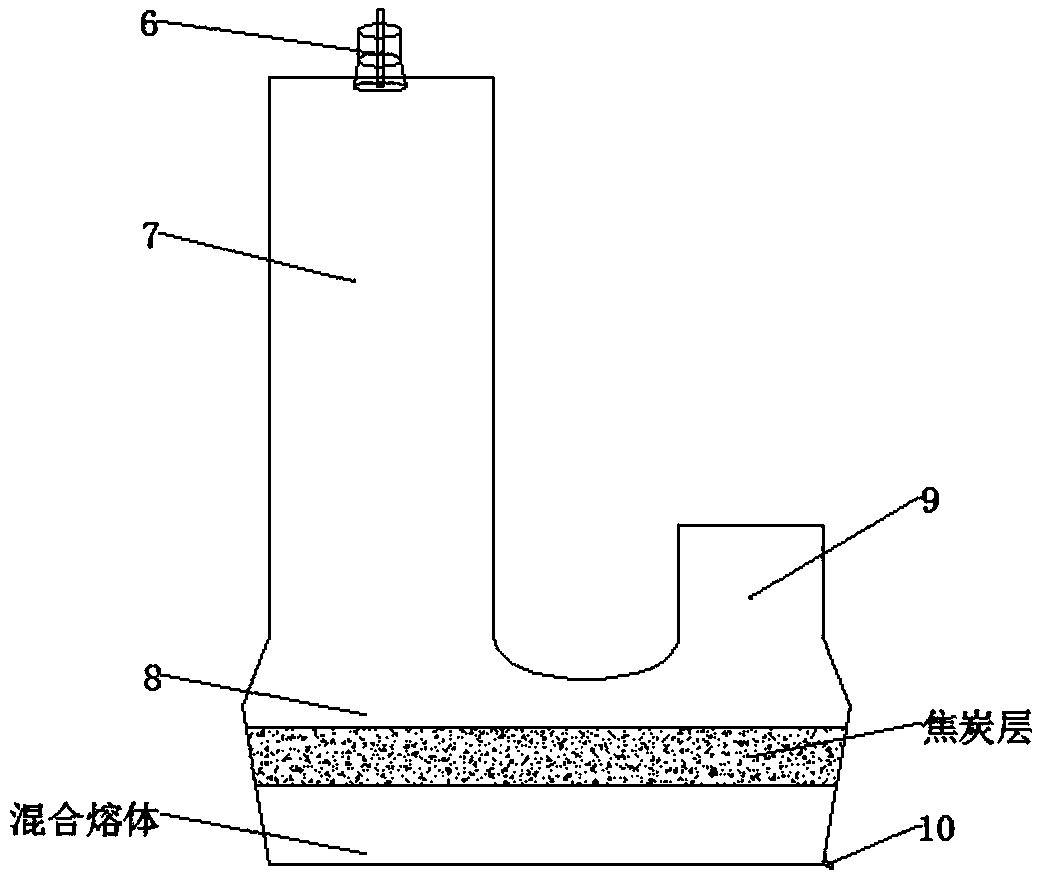

[0034] After the flash oxidation product is mixed with 6% CaO powder by weight of the product, it is sprayed together with hydrogen into a ...

Embodiment 2

[0037]Spray the powdery NdFeB waste with a particle size of 200 mesh and oxygen-enriched air with an oxygen mass percentage concentration of 30% into a reaction tower (2) with a height of 3.5 meters and a temperature of 1000 °C through a nozzle (1). In a highly dispersed floating state, it falls from the upper end of the reaction tower to the lower end. During this process, the iron and rare earth in the material are rapidly oxidized by oxygen-enriched air. The oxidation rate of iron in the waste is 99.85%, and the oxidation rate of rare earth is 99.94%. Oxidation products fall into the collector (3) below the reaction tower, and are released from the outlet (4) before entering the flash reduction furnace. The oxidized flue gas is discharged through the flue (5) at the upper end of the collector (3), and is emptied after dust collection.

[0038] The flash oxidation product was mixed with 5% SiO by weight of the product 2 After the powder is mixed, it is sprayed together with...

Embodiment 3

[0041] Spray the powdery NdFeB waste with a particle size of 300 mesh and oxygen-enriched air with an oxygen mass percentage concentration of 50% into a reaction tower (2) with a height of 2.5 meters and a temperature of 900 °C through a nozzle (1). In a highly dispersed floating state, it falls from the upper end of the reaction tower to the lower end. During this process, the iron and rare earth in the material are rapidly oxidized by the oxygen-enriched air. The oxidation rate of iron in the waste is 99.75%, and the oxidation rate of rare earth is 99.91%. Oxidation products fall into the collector (3) below the reaction tower, and are released from the outlet (4) before entering the flash reduction furnace. The oxidized flue gas is discharged through the flue (5) at the upper end of the collector (3), and is emptied after dust collection.

[0042] The flash oxidation product was mixed with 3% SiO by weight of the product 2 Powder and 2% CaO powder are mixed, sprayed togeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com