Novel assembly type planting roof drainage groove and drainage system

A drainage system and prefabricated technology, applied in the direction of roof drainage, roof, roof covering, etc., can solve the problems of increasing the difficulty of on-site splicing by construction personnel, increasing the difficulty and complexity of construction, and increasing the difficulty of planting roof construction, etc., to achieve Strong designability, reduce the difficulty and complexity of assembly, and avoid the effect of roof moisture seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

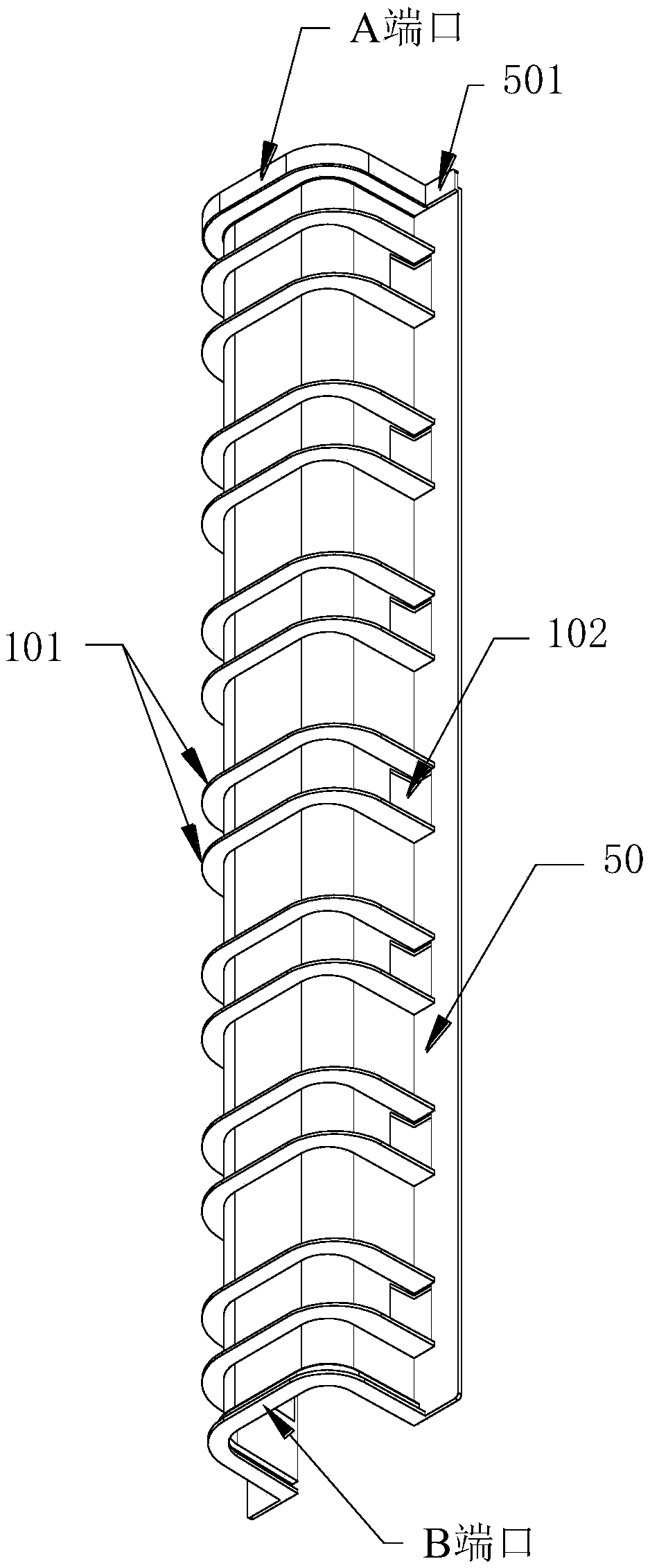

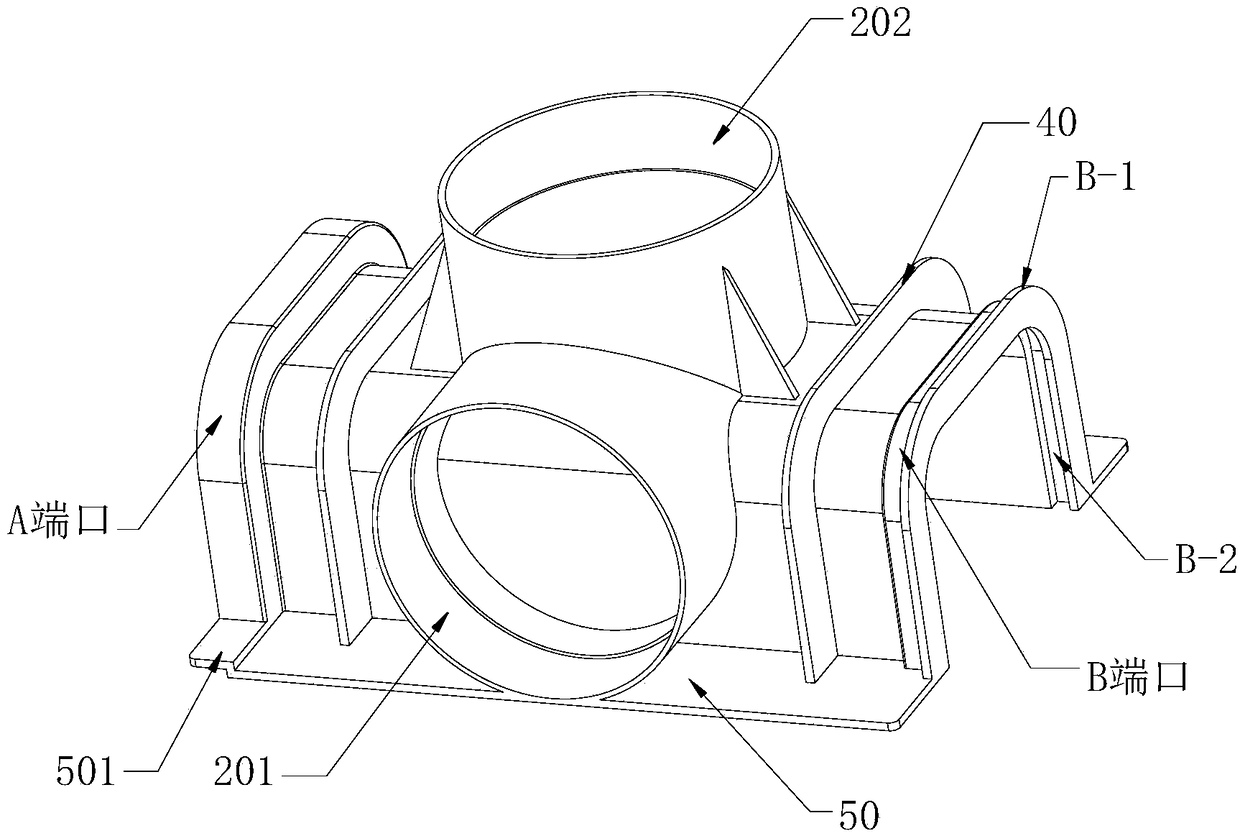

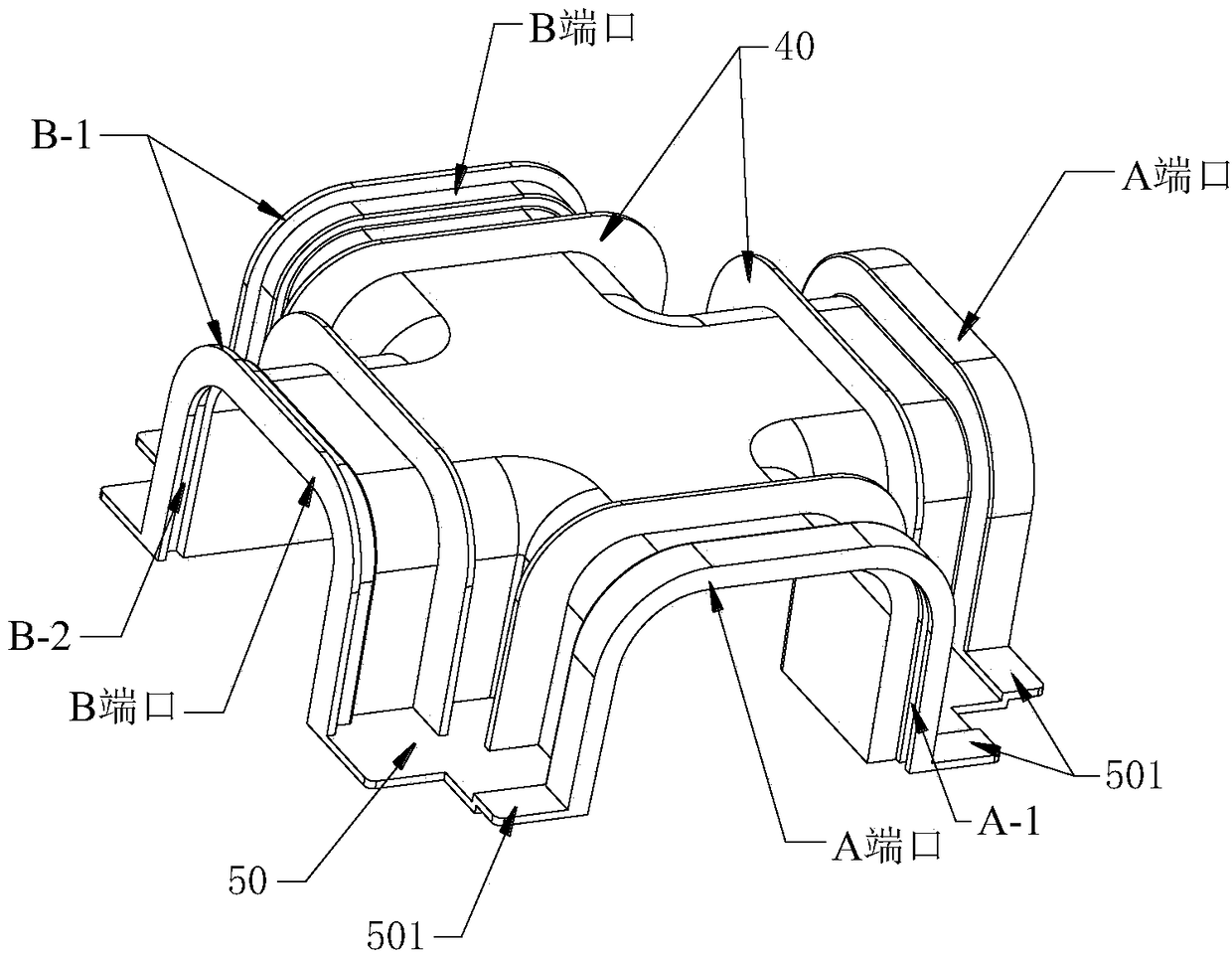

[0038] This embodiment provides a new type of assembled planting roof gutter, such as Figure 1~3 As shown, it includes drainage blind groove 1, three-way drainage assembly 2 and four-way drainage assembly 3. The drainage blind groove 1, the three-way drainage assembly 2 and the four-way drainage assembly 3 are all provided with an A port and a B port which can engage with each other to realize assembly connection.

[0039] Wherein, the A port is provided with a first groove A-1, and the B port is provided with an upwardly protruding rib structure B-1. During assembly, by pressing down the first groove of the A port against the B port, the protruding strip structure of the B port is inserted into the first groove of the A port, so as to realize the assembly connection. This assembly method is to achieve a fixed connection by snapping up and down between the A port and the B port.

[0040] Such as figure 1 As shown, the drainage blind groove 1 is a groove body with an invert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com