Device and method for absorbing gas

An absorption device and a technology for absorbing gas, which are applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as large errors in manual control and monitoring, safety accidents and environmental pollution, and increase labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

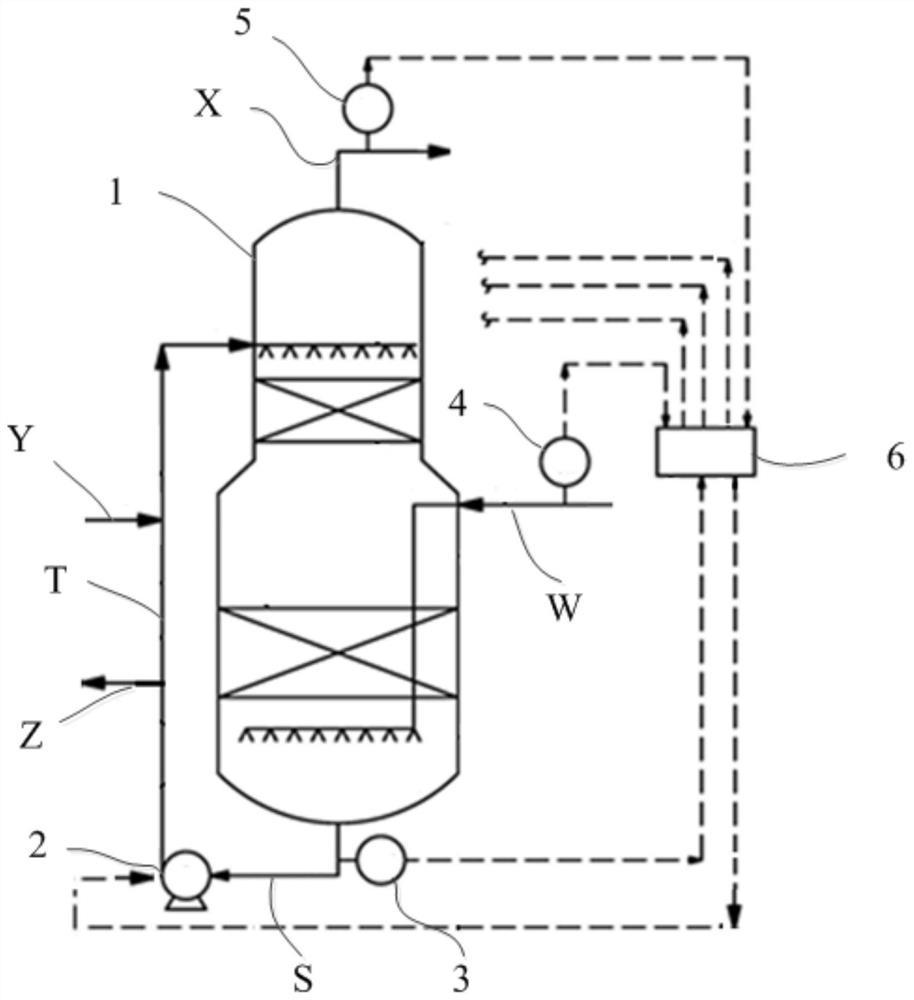

[0083] This embodiment provides a device for absorbing gas. See figure 1 , figure 1 A schematic diagram of a device for absorbing gas provided by the present invention is shown. Such as figure 1 As shown, the device includes: absorption device 1, circulating pump 2, component analyzer 3, inlet analyzer 4, outlet analyzer 5, automatic control system 6, circulating liquid outlet pipeline S, circulating liquid inlet pipeline T, gas inlet Pipeline W, gas outlet pipe X, liquid inlet pipe Y, and liquid discharge pipe Z; the liquid inlet and outlet ends of the circulation pump 2 communicate with the absorption device 1 through the circulation liquid outlet pipe S and the circulation liquid inlet pipe T respectively; The sub-analyzer 3 is set on the circulating liquid outlet pipeline S; the gas inlet pipeline W, the gas outlet pipeline X, the liquid inlet pipeline Y, and the liquid discharge pipeline Z are all connected with the absorption device 1; the inlet analyzer 4 is arranged...

Embodiment 2

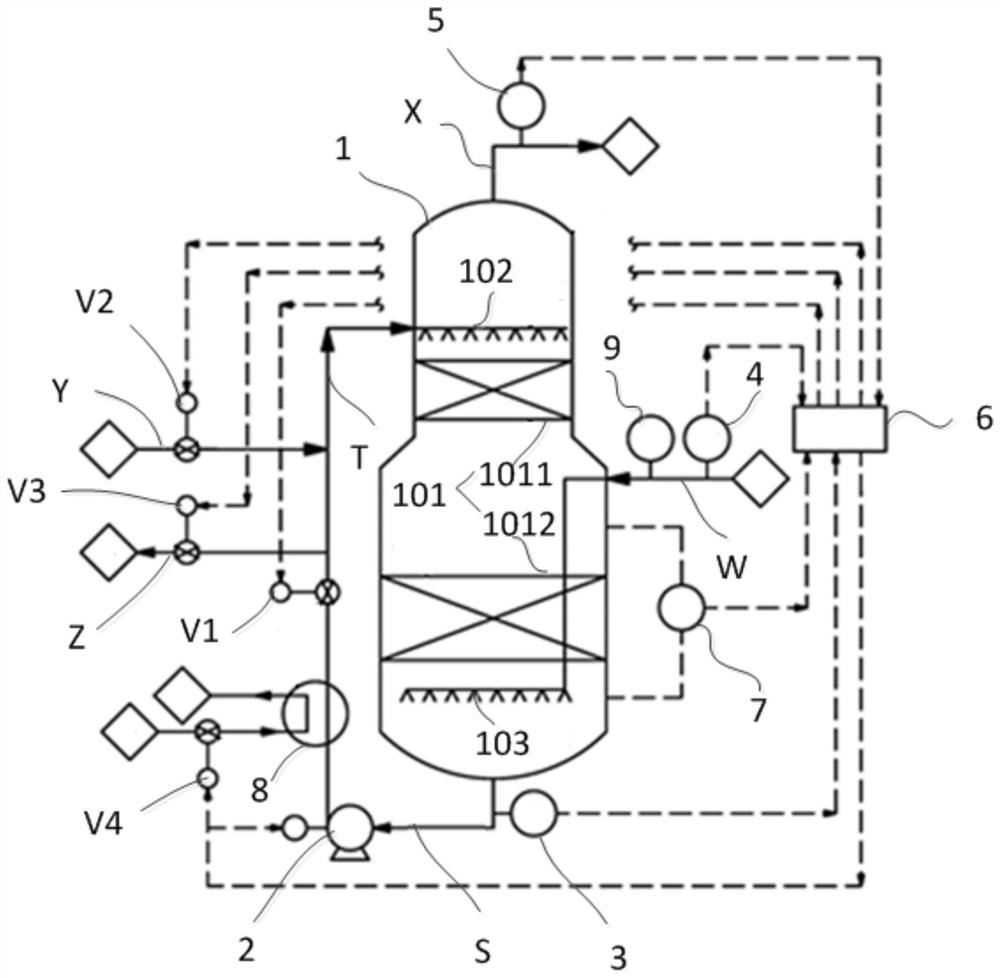

[0086] This embodiment provides a device for absorbing gas. See figure 2 , figure 2 A schematic diagram of another device for absorbing gas provided by the present invention is shown. Such as figure 2 As shown, the device includes: absorption device 1, circulating pump 2, component analyzer 3, inlet analyzer 4, outlet analyzer 5, automatic control system 6, liquid level gauge 7, cooler 8, thermometer, circulating liquid outlet Pipeline S, circulating liquid inlet pipe T, gas inlet pipe W, gas outlet pipe X, liquid inlet pipe Y, liquid discharge pipe Z, first valve V1, second valve V2, third valve V3, and fourth valve V4.

[0087] The liquid inlet end and the liquid outlet end of the circulation pump 2 communicate with the absorption device 1 through the circulation liquid outlet pipeline S and the circulation liquid inlet pipeline T respectively; the component analyzer 3 is arranged on the circulation liquid outlet pipeline S; the gas inlet pipe W, the gas The outlet pi...

Embodiment 3

[0089] This embodiment provides a method for absorbing gas. See figure 1 , the method includes the following steps:

[0090] The gas enters the absorption device 1 through the gas inlet pipe W; the inlet analyzer 4 detects that the gas content in the absorption device increases, and sends the result of the gas content increase to the automatic control system 6, and the automatic control system 6 receives the result, And control the liquid inlet pipe Y to deliver the absorption liquid to the absorption device 1 to absorb the gas.

[0091] The circulating pump 2 sucks part of the liquid into the circulating liquid outlet pipe S, and returns to the absorption device 1 through the circulating liquid inlet pipe T.

[0092] The component analyzer 3 detects the liquid in the circulating liquid outlet pipe S, and sends the detected result to the automatic control system 6, and the automatic control system 6 receives the result, and controls the Y-direction absorption through the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com