Multi-cavity flow guide type foam-free building coating stirring device

A technology for architectural coatings and stirring devices, applied in mixers with rotary stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems affecting the mixing of different coatings, insufficient uniformity, and unfavorable uniform mixing, etc., to improve quality and production. the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

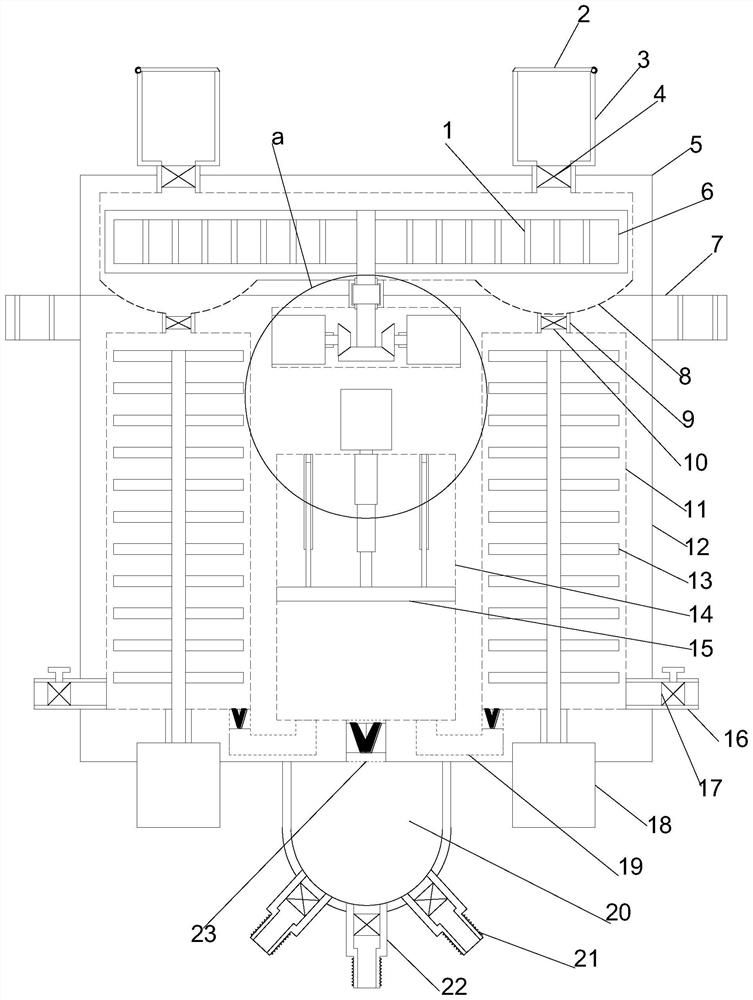

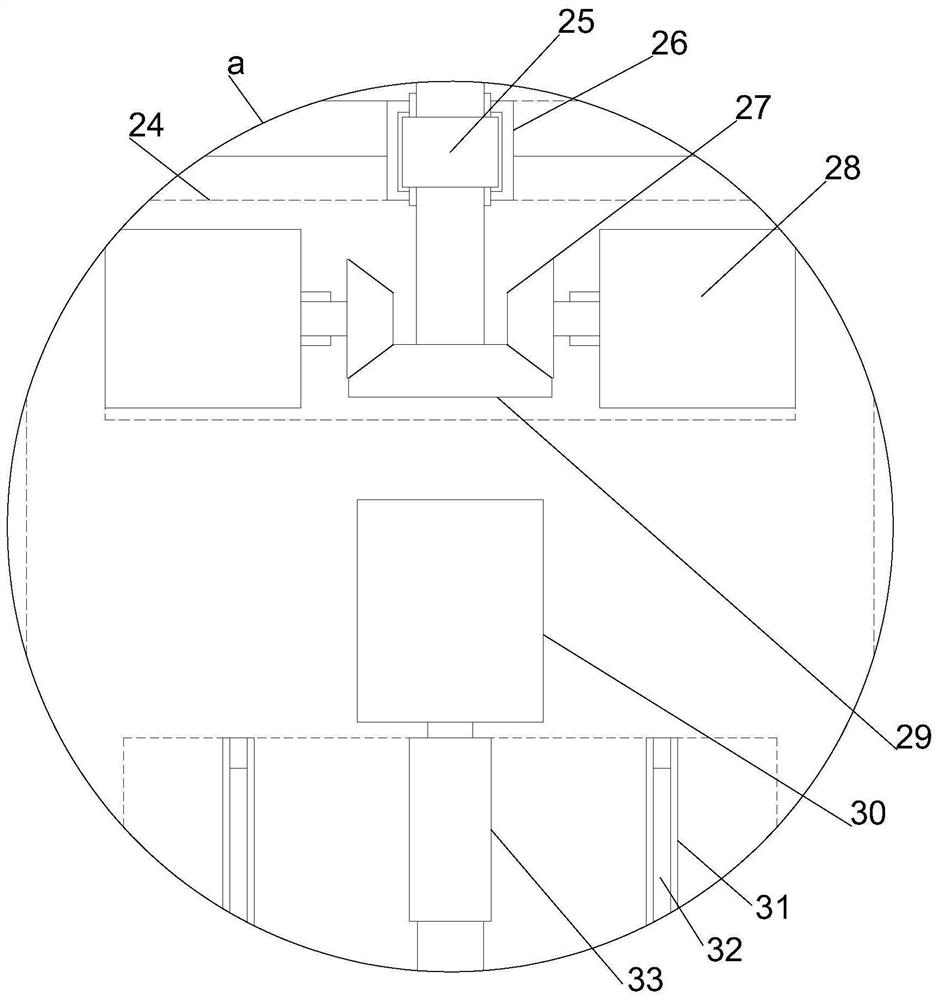

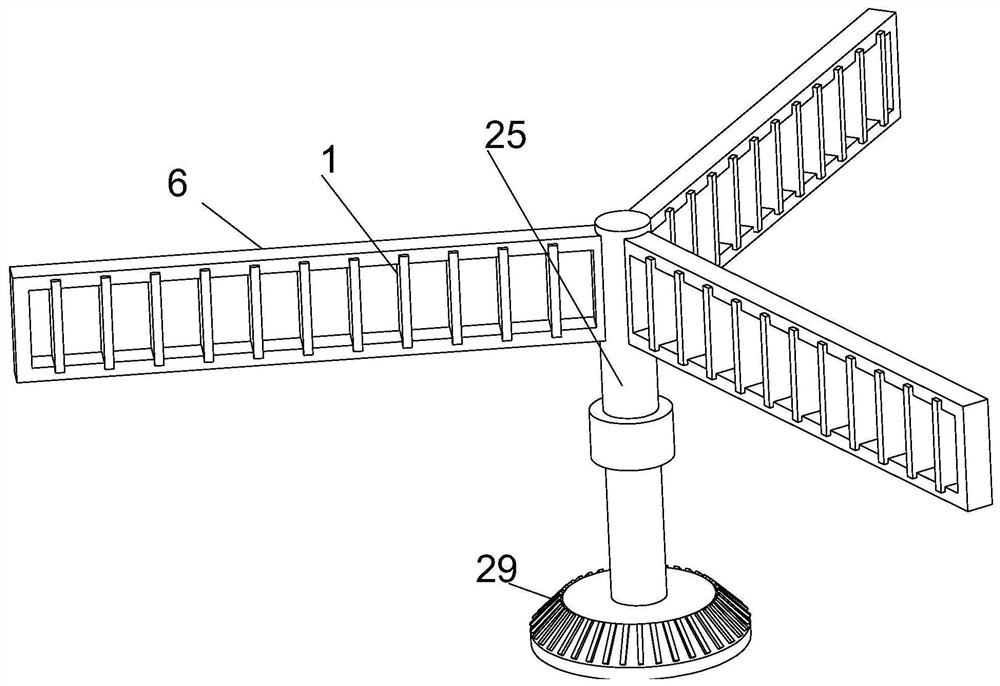

[0021] see Figure 1~3 , in an embodiment of the present invention, a multi-cavity diversion type non-foam architectural paint stirring device includes a vertically arranged support installation cylinder 12, a fixed installation plate 7 is symmetrically arranged on the outer side of the upper half of the support installation cylinder 12, and the support installation cylinder The upper end of 12 is horizontally provided with a stirring installation cylinder 5, and the upper end of the agitation installation cylinder 5 is equiangularly provided with several feeding installation cylinders 3, and the upper end of the feeding installation cylinder 3 is provided with a feeding cover plate 2 through a rotating shaft, and the feeding The lower end of the installation cylinder 3 is communicated with the stirring installation cylinder 5 through the feed electromagnetic valve 4, and the middle position of the upper half of the support installation cylinder 12 is horizontally provided with...

Embodiment 2

[0024] On the basis of Embodiment 1, through the cooperation of the lifting guide column 32 and the lifting guide cylinder 31, the stable lifting of the active piston 15 is realized, and the stability of the guide material is improved. The material is exported, which is convenient for the next continuation of the operation. The external thread connecting cylinder 21 is connected with the external conduit, so that the device can carry out multiple groups of material guiding operations, and the efficiency of the device can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com