Patents

Literature

37results about How to "Export implementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

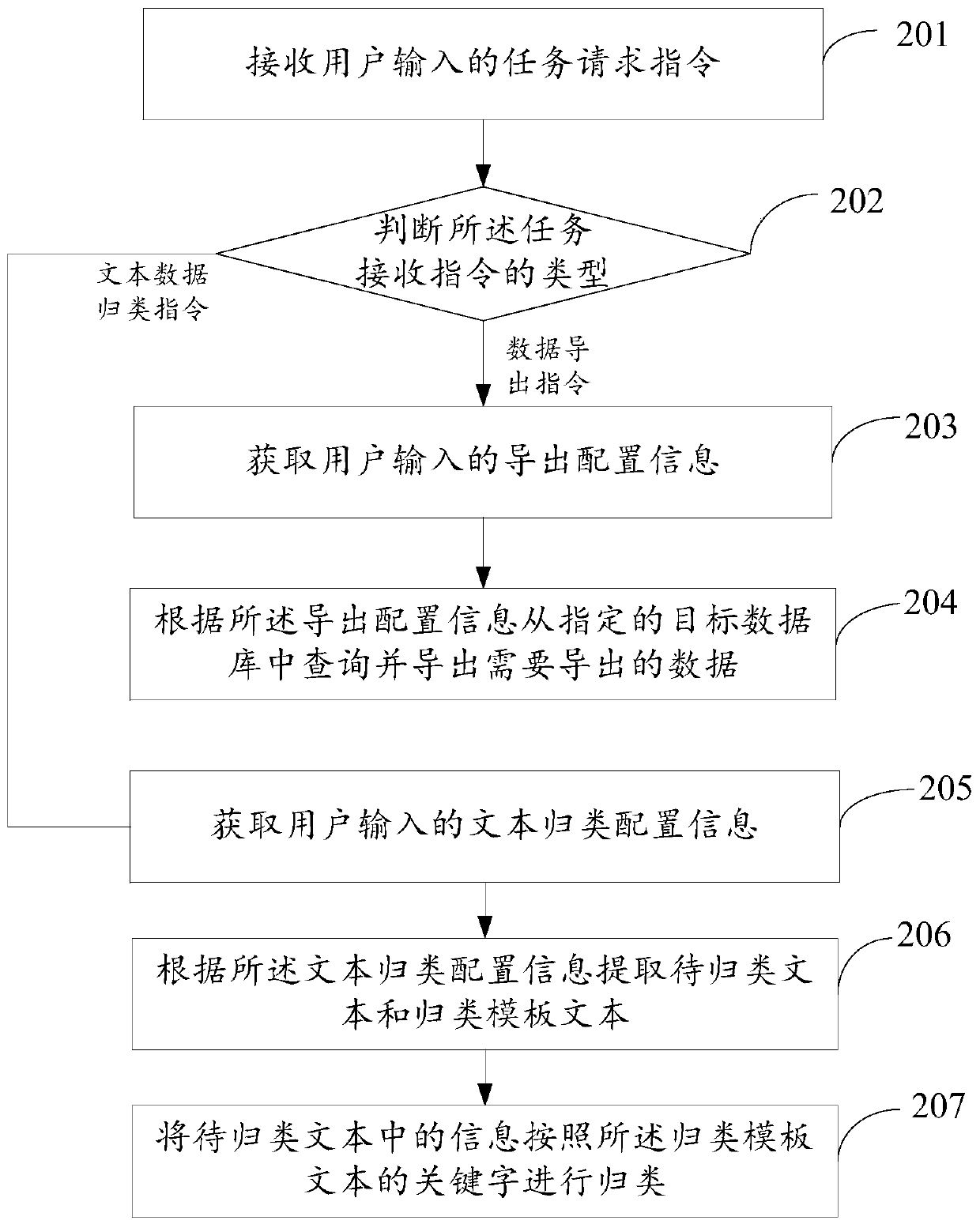

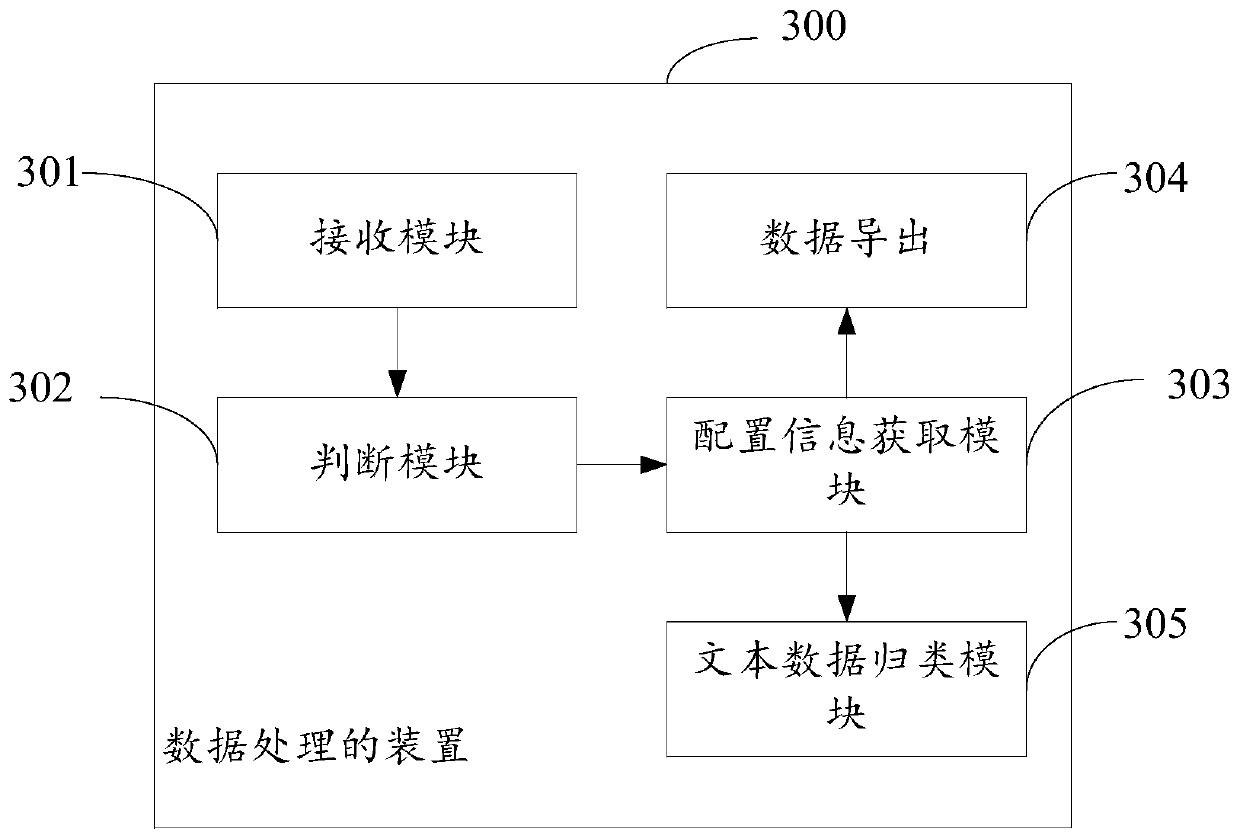

Multi-database data processing method and device, computer equipment and storage medium

PendingCN109947789AExport implementationDatabase management systemsSpecial data processing applicationsData exportComputer equipment

The embodiment of the invention belongs to the technical field of artificial intelligence, and relates to a multi-database data processing method, which comprises the steps of receiving a task requestinstruction input by a user; judging the type of the task receiving instruction; if the type of the task request instruction is a data export instruction type, obtaining export configuration information input by a user; and querying and exporting data required to be exported from a specified target database according to the exporting configuration information. The invention further provides a multi-database data processing device, computer equipment and a storage medium. When data exporting is carried out, different databases are connected according to exporting configuration information fordata exporting, and dependence of different databases on different clients is replaced.

Owner:PING AN TECH (SHENZHEN) CO LTD

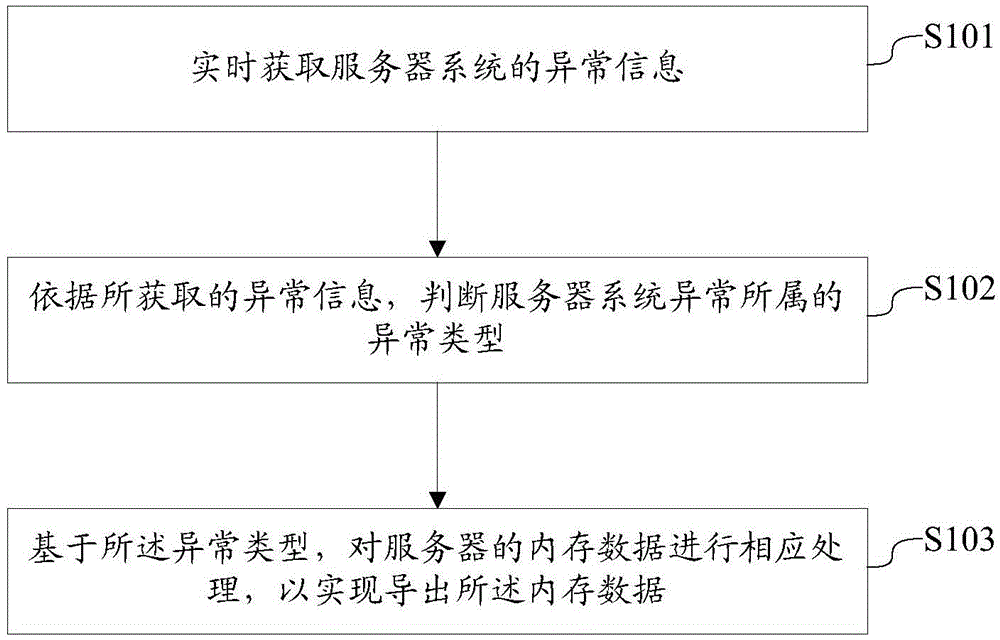

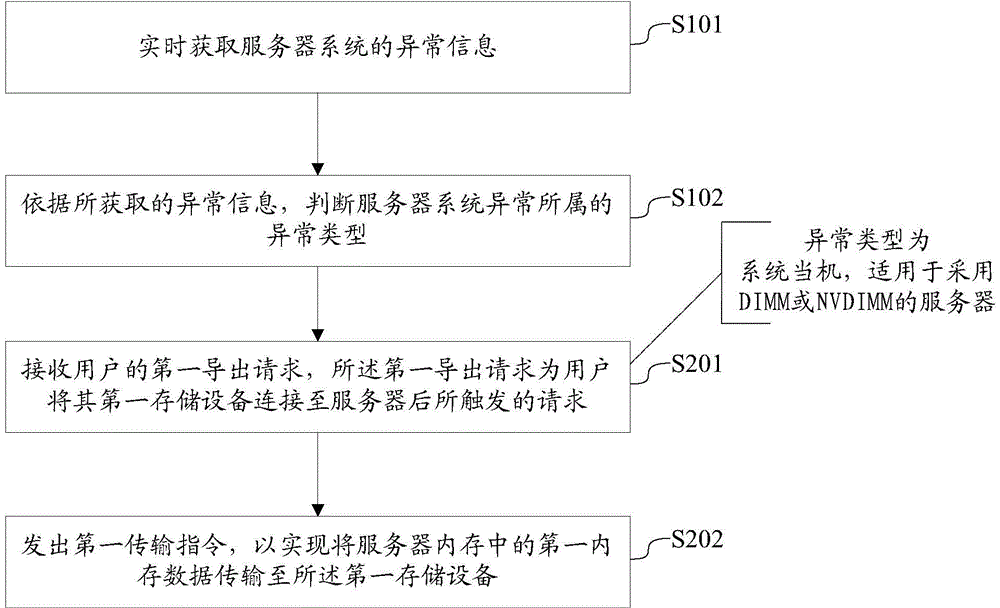

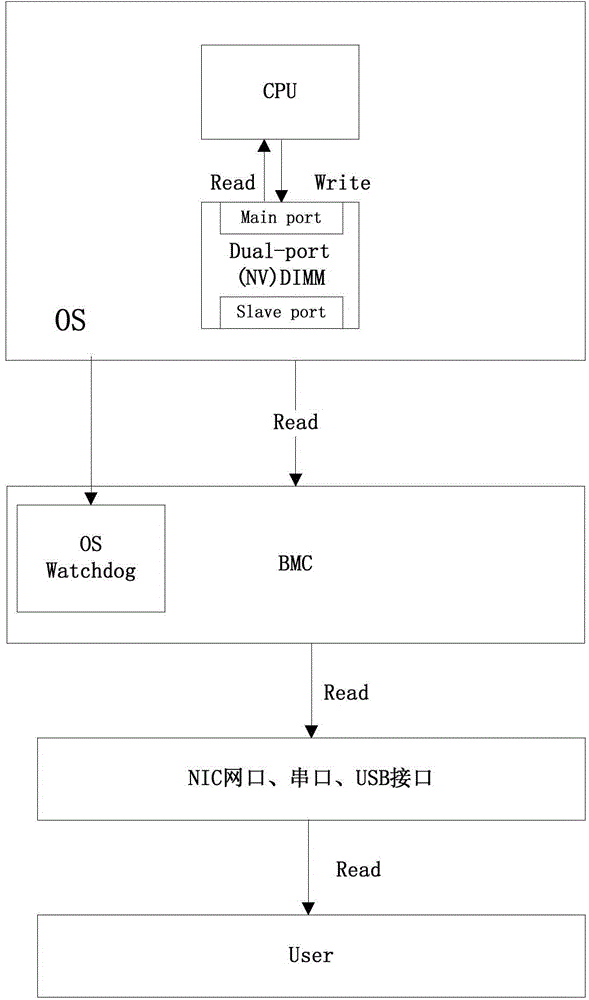

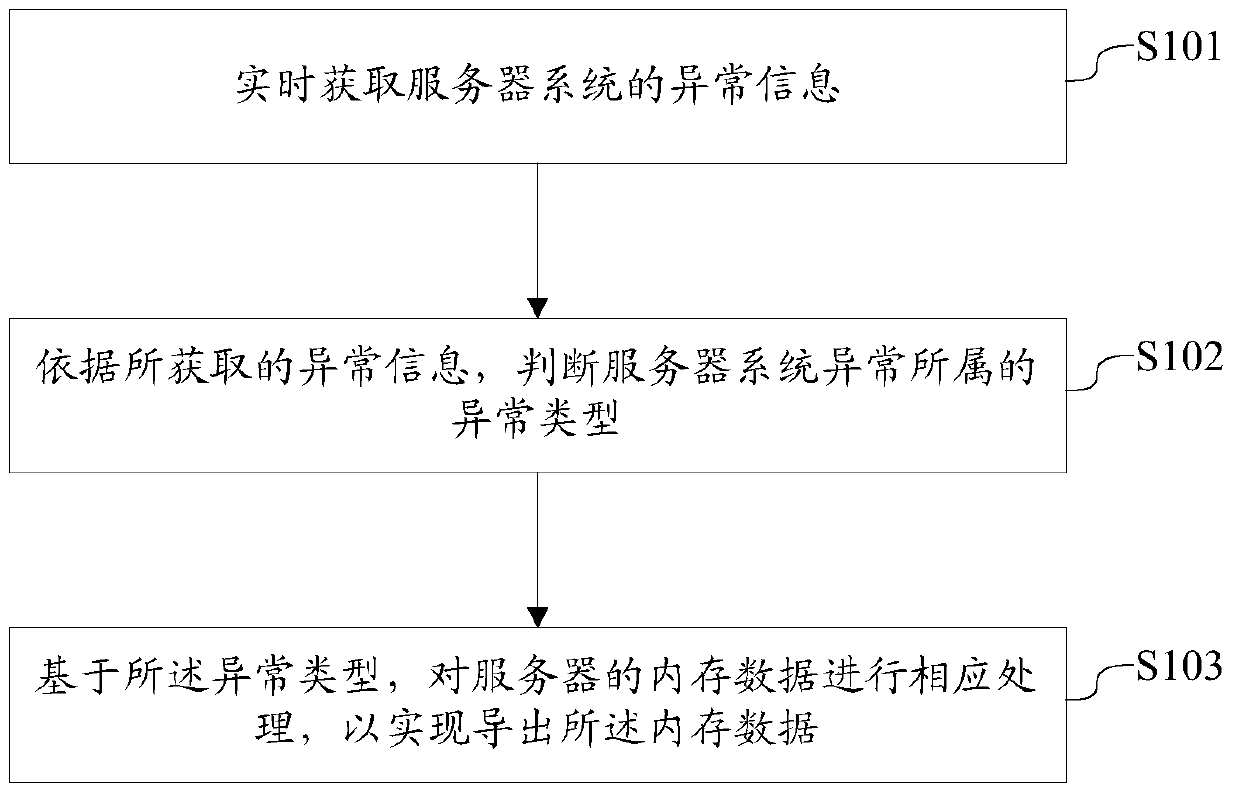

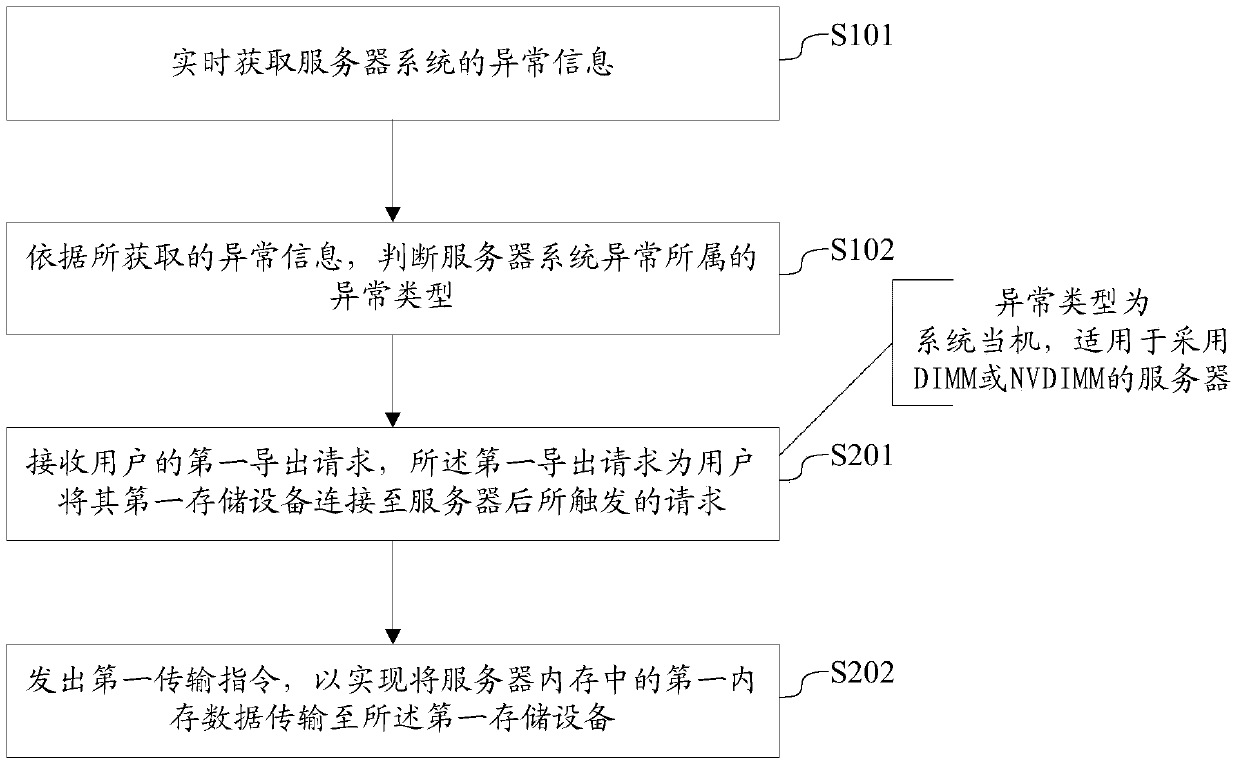

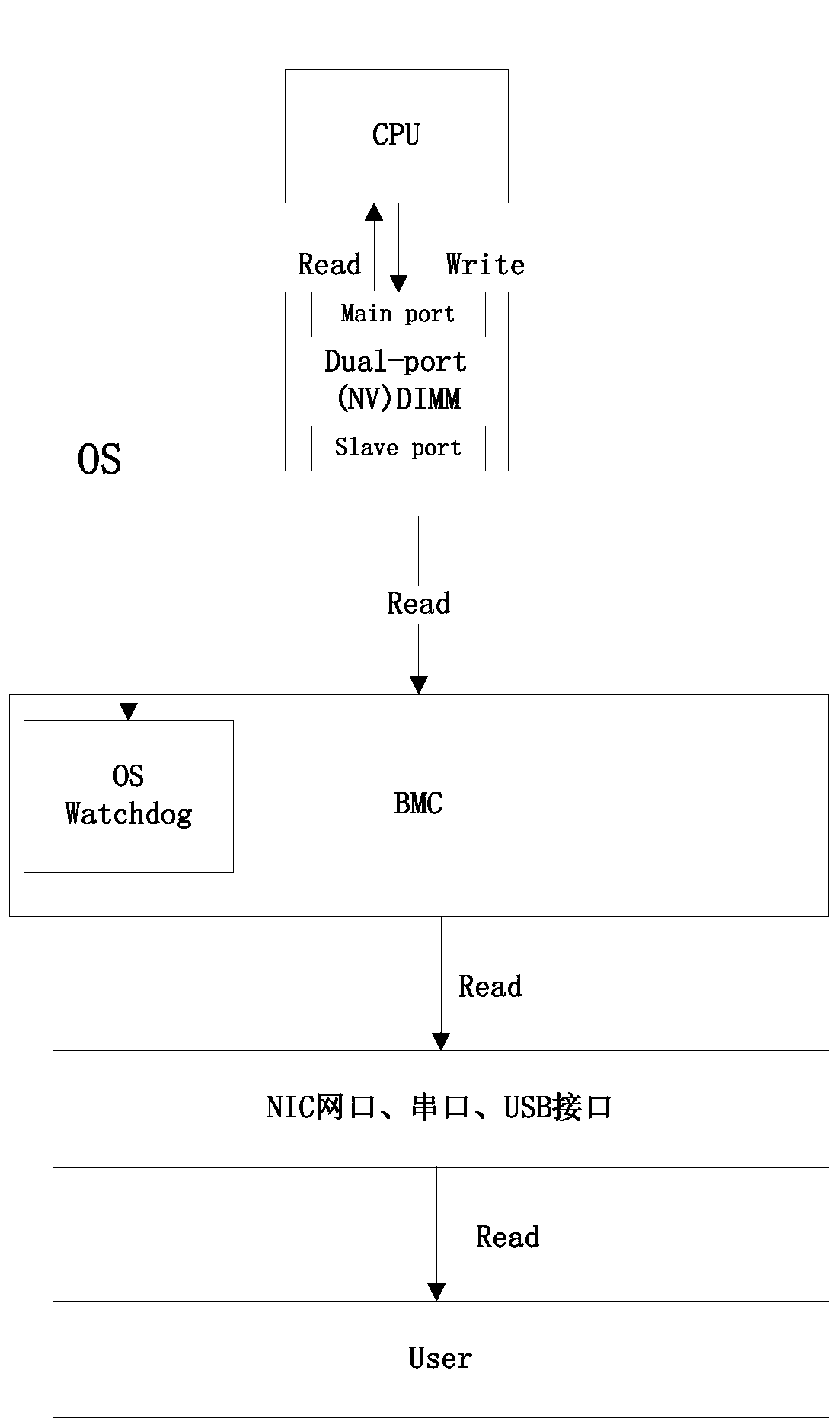

Exporting method and system for memory data

ActiveCN105760241AImprove maintainabilityExport implementationFault responseMaintainabilityField data

The invention discloses an exporting method and system for memory data.A server system is detected in real time, when abnormal phenomena, such as crashes and accidental restart, occur to the server system, abnormal information of the server system is acquired, and the abnormality type to which the abnormality of the server system belongs is judged according to the abnormal information; on the basis, the server memory data is subjected to the processing process corresponding to the abnormality type, the server memory data is exported.Thus, when the abnormality occurs to the server system, field data of a server memory is effectively exported, support can be provided for following analysis of server abnormality reasons, and the maintainability of a server is improved.

Owner:LENOVO (BEIJING) LTD

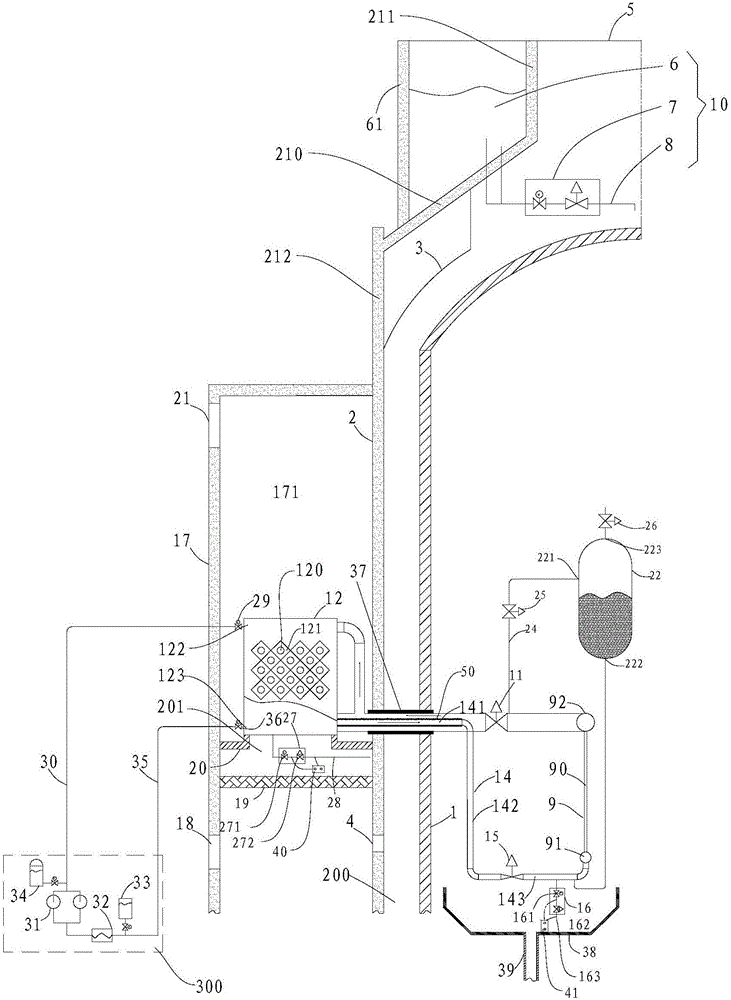

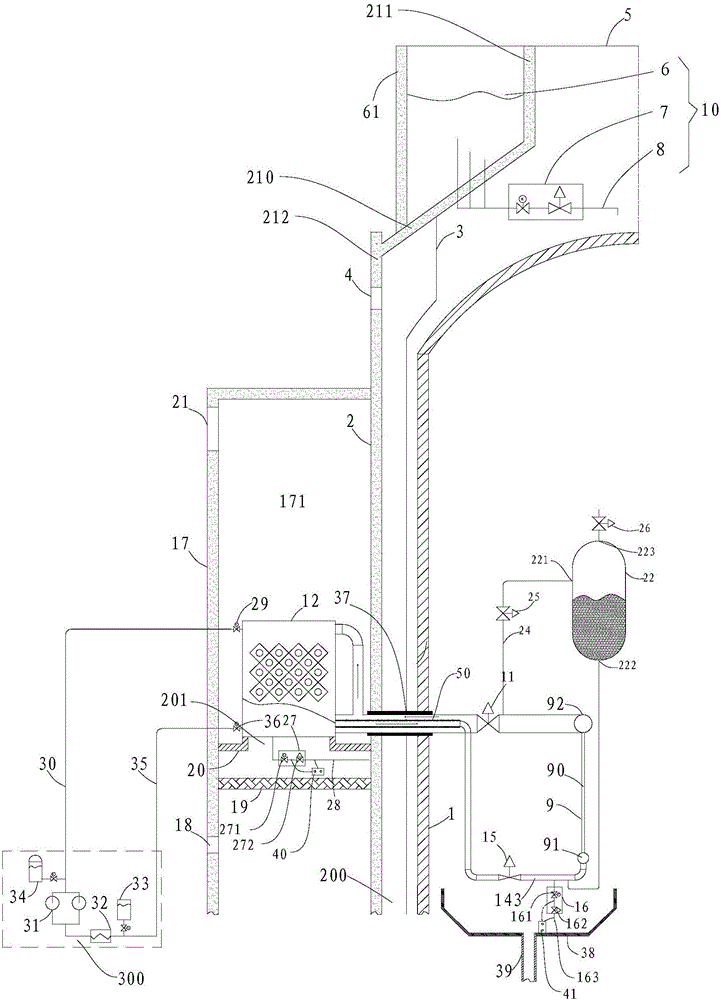

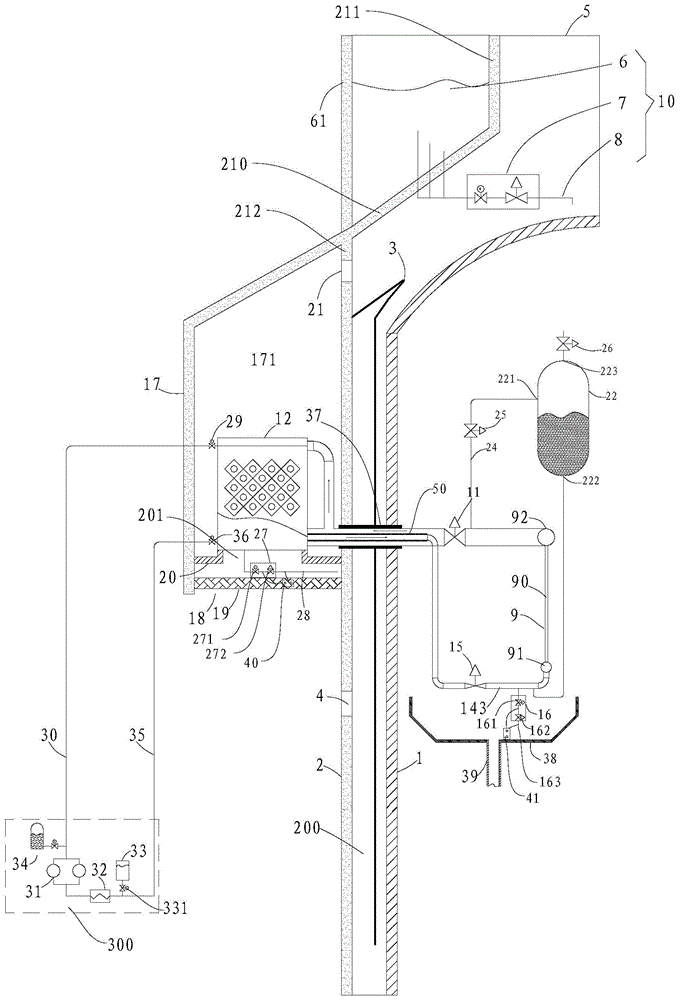

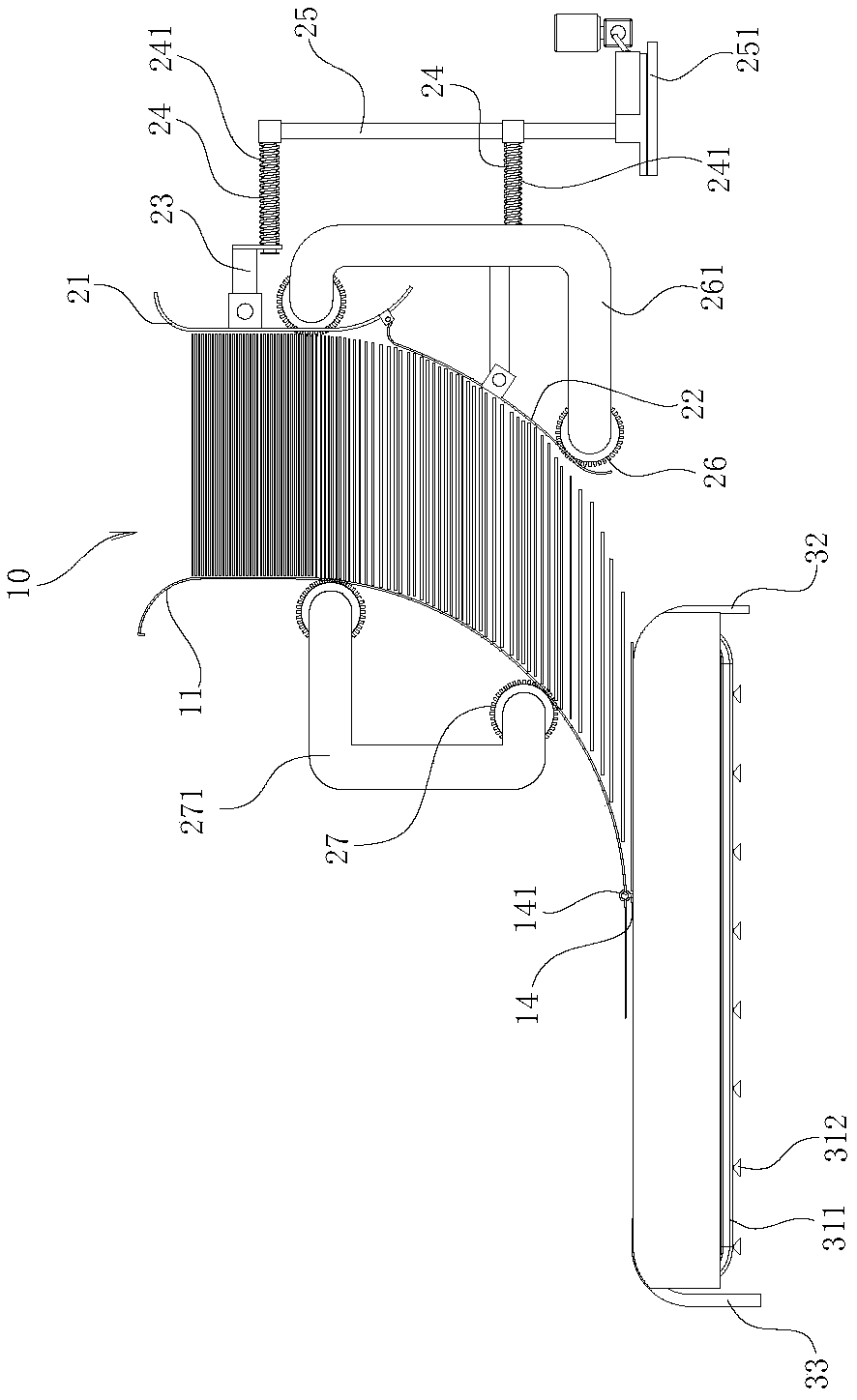

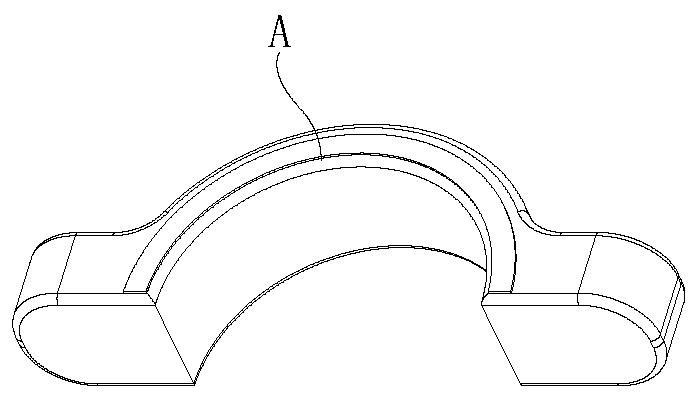

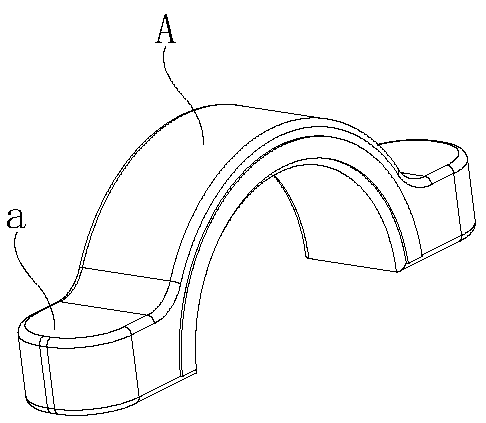

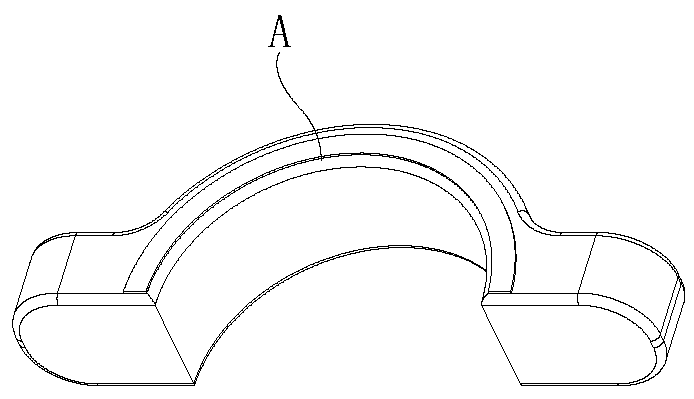

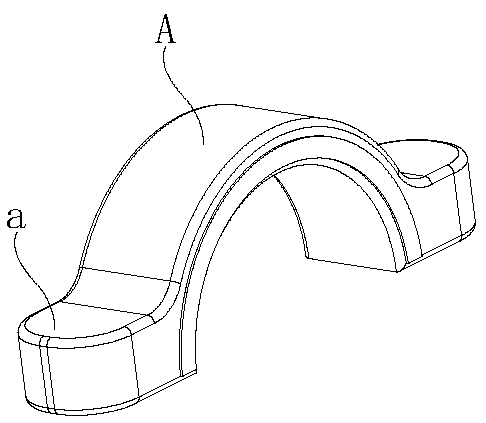

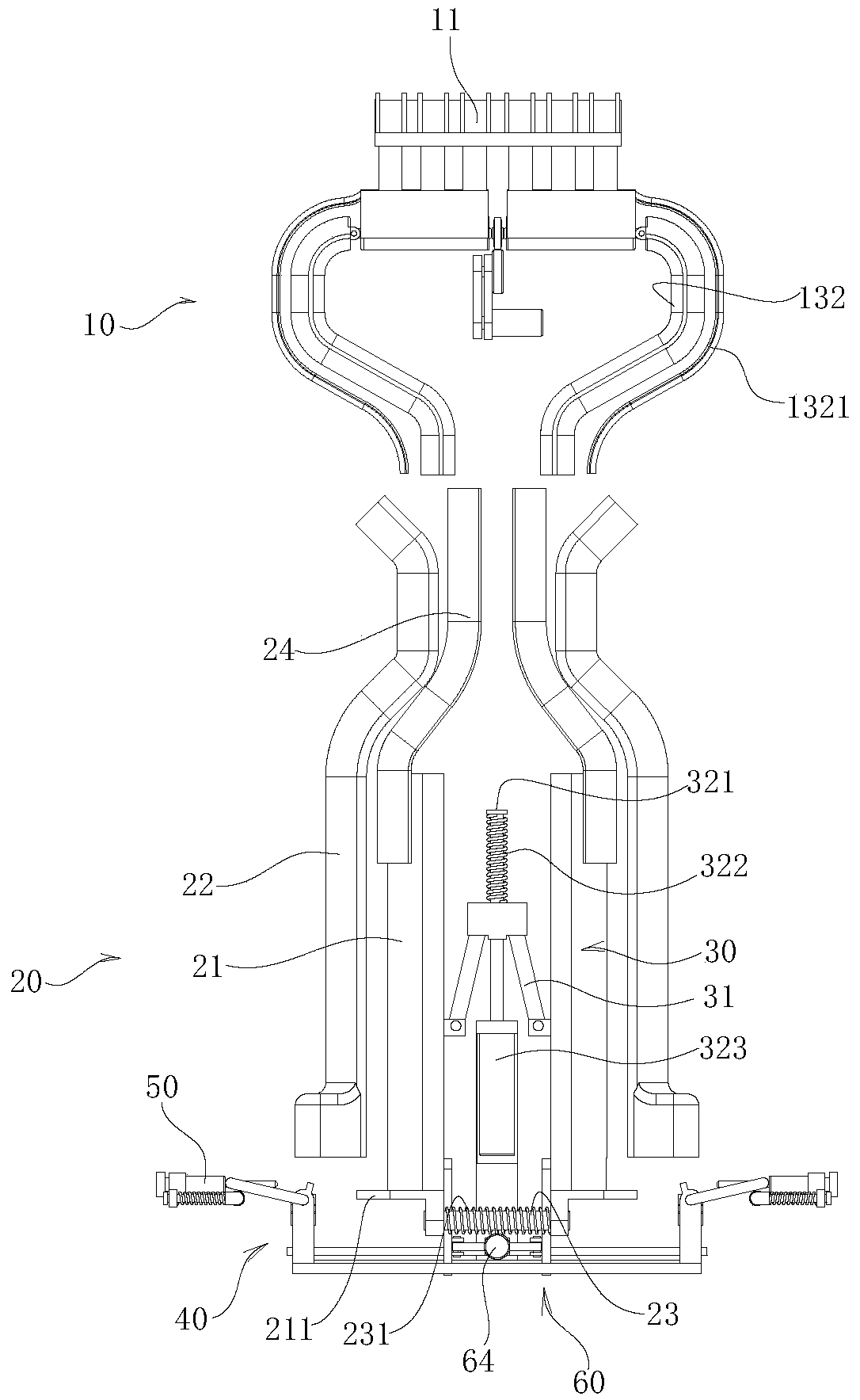

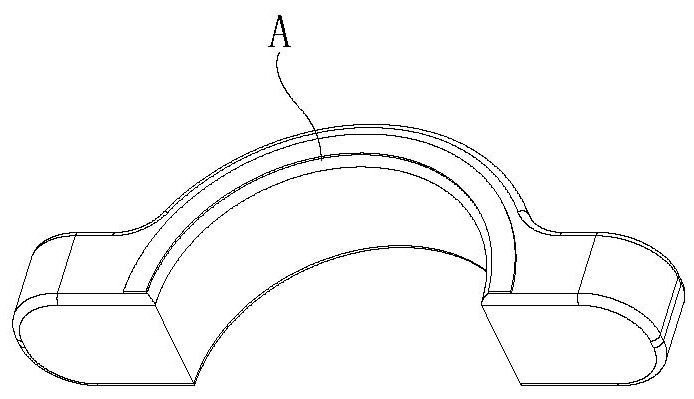

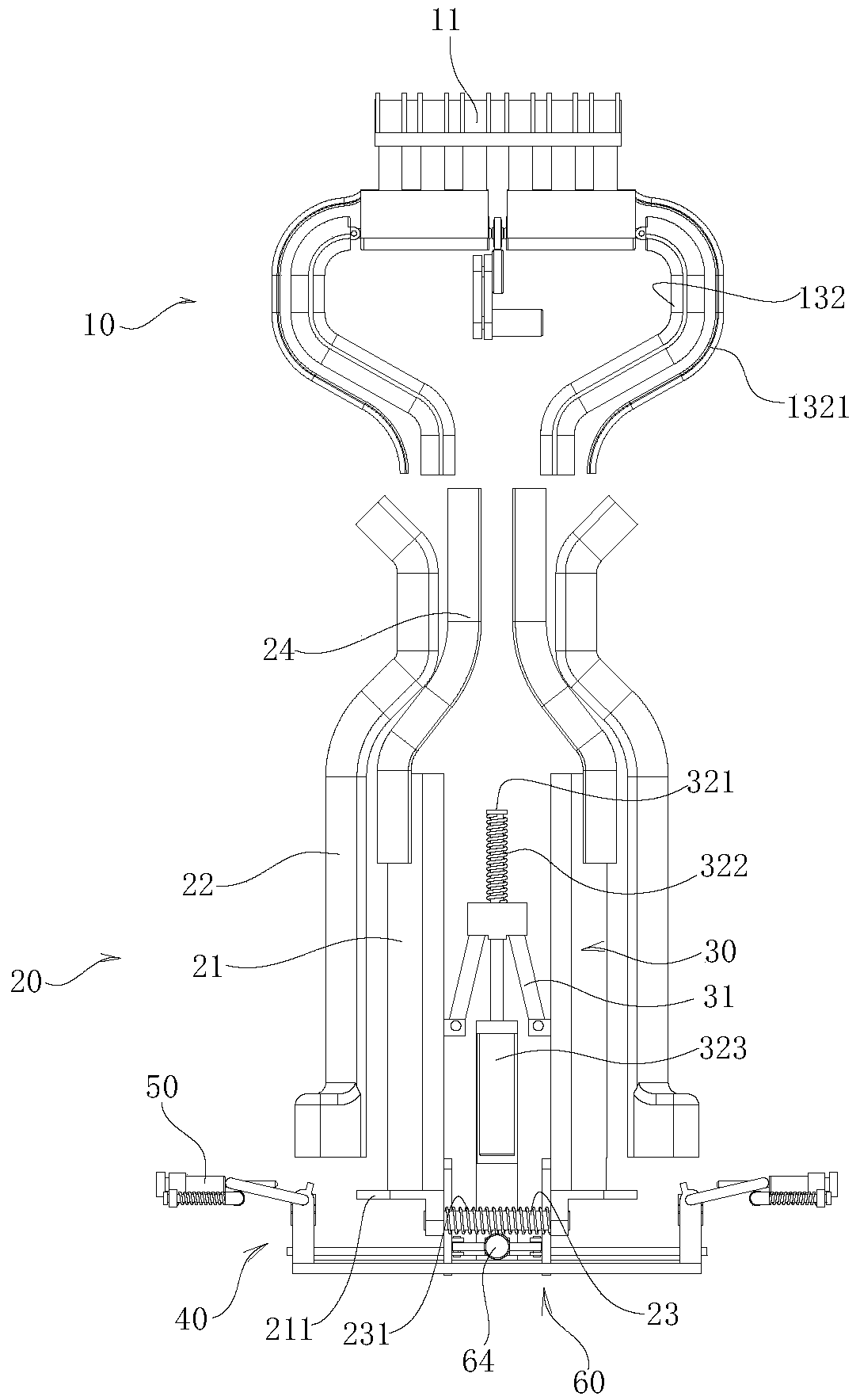

Passive containment heat removing-out system and pressurized water reactor

ActiveCN105047234AReduce water sprayExtend the spray timeNuclear energy generationEmergency protection arrangementsPressurized water reactorCooling channel

A passive containment heat removal system, control method thereof and pressurized water reactor; the passive containment heat removal system comprises an outer containment (2), an inner containment (1), an air duct (200) defined between the inner containment (1) and the outer containment (2) having an air inlet (4) and an air outlet (5), a spraying assembly (10) disposed outside the inner containment (1), a built-in heat exchanger (9) disposed in the inner containment (1), an air cooling channel (171) located outside the outer containment (2) having an air inlet (18) and air outlet (21) of an air cooling channel (171), and an external air cooler (12) disposed in the air cooling channel (171); the inlet of the external air cooler (12) is connected to the outlet of the built-in heat exchanger (9) via a first communication pipe (13), and the outlet of the external air cooler (12) is connected to the inlet of the built-in heat exchanger (9) via a second communication pipe (14).

Owner:STATE POWER INVESTMENT CORP RES INST +1

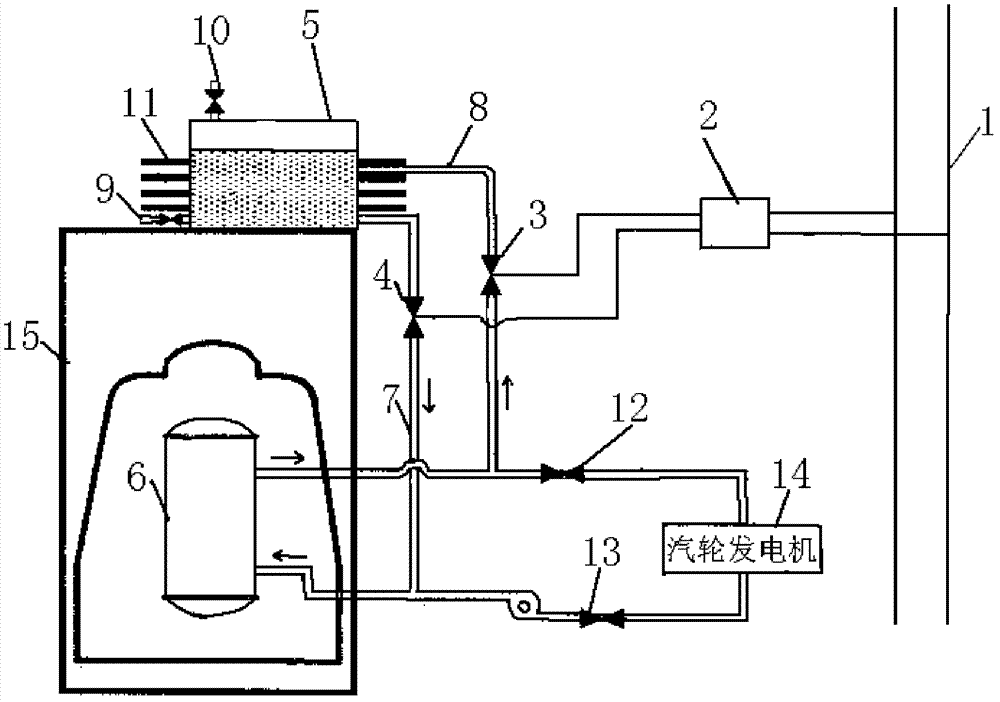

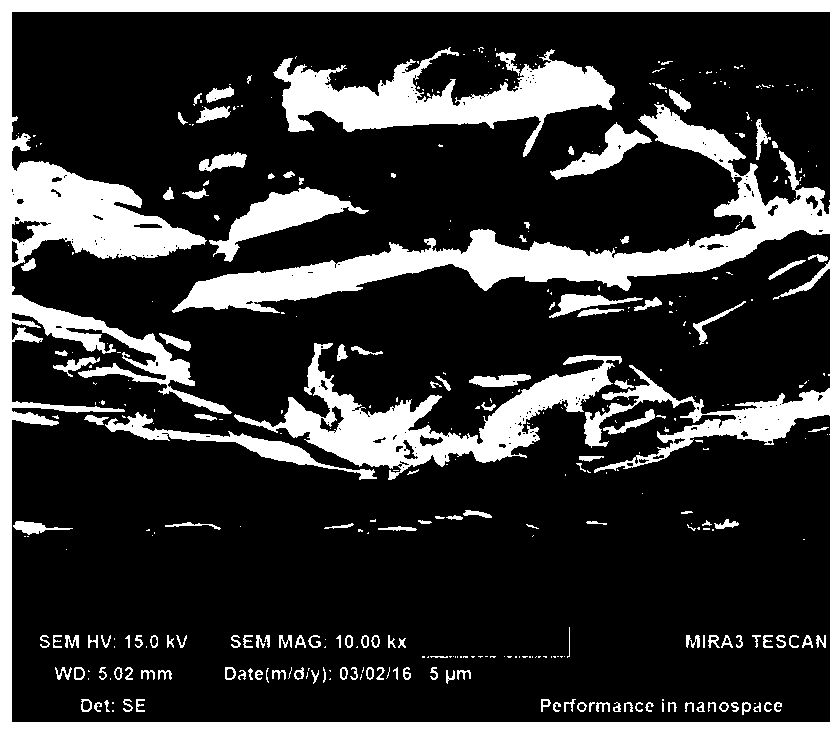

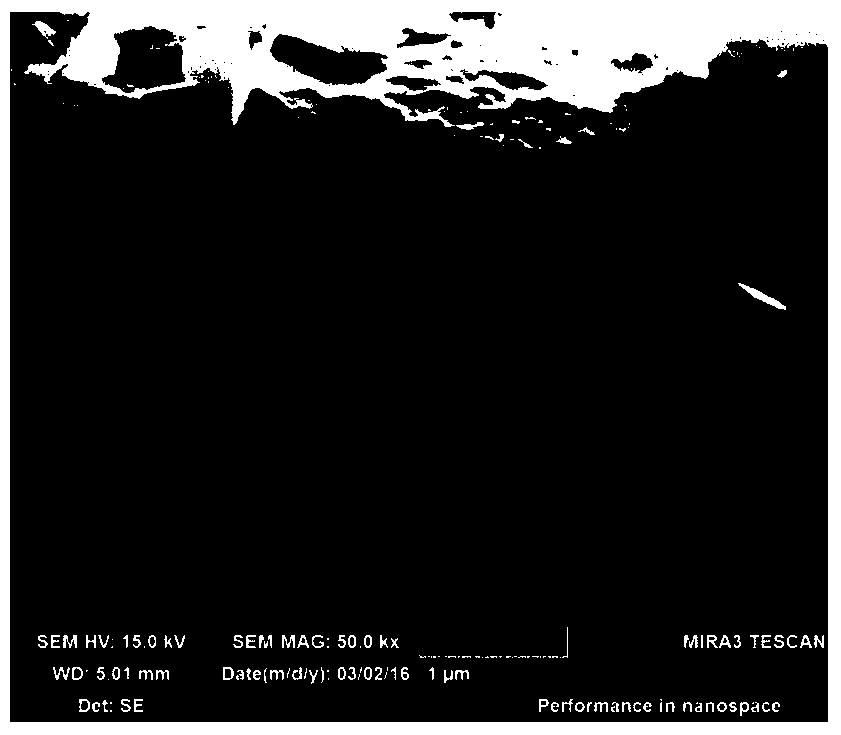

Passive residual heat removal system under accident of boiling-water reactor based on characteristics of nanometer fluid

InactiveCN102243897BExport implementationPassiveNuclear energy generationCooling arrangementRadioactive agentNuclear engineering

The invention discloses a passive heat removal system of a boiling-water reactor based on the characteristics of a nanometer fluid and belongs to the technical field of equipment and safety of nuclear power stations. The system consists of a valve controller, a water tank, a circulating pipeline, a valve and the like. In the case of unavailability of a station power supply, the quick removal of heat in the boiling-water reactor is realized by using the higher heat transfer characteristic and lower viscosity coefficients of the nanometer fluid and higher natural circulation capacity. The aims of preventing radioactive materials from being discharged and protecting the public and environments are fulfilled. When a severe accident occurs, a safety assurance function is executed and realized. The system is good in backup safety, simple in flow, stable in performance, high in reliability, convenient for implementation and simple to control.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

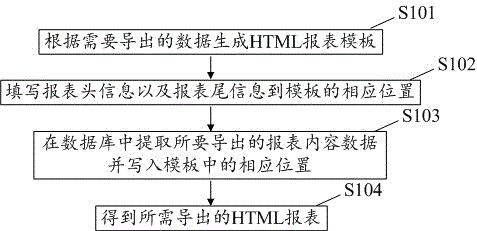

Exporting method and system of database hierarchical HTML (Hypertext Markup Language) statement

InactiveCN105718495AExport implementationImprove export efficiencySpecial data processing applicationsData informationHTML

The invention provides an exporting method and system of a database hierarchical HTML (Hypertext Markup Language) statement. A logic relationship between business and a database is extracted and is enabled to be configurable; and according to different contents and forms of data imported under different business scenes, the statement can be automatically exported, and data is extracted on the basis of configuration in a process that the statement is automatically exported, and is filled into a HTML template to form a final HTML report. The exporting method and system makes up the deficiency of poor strain capacity capability of a traditional data exporting technology, realizes the automatic exporting of the data according to different requirements, effectively improves data exporting efficiency, and guarantees the integrity and the instantaneity of data information.

Owner:HARBIN ANTIY TECH

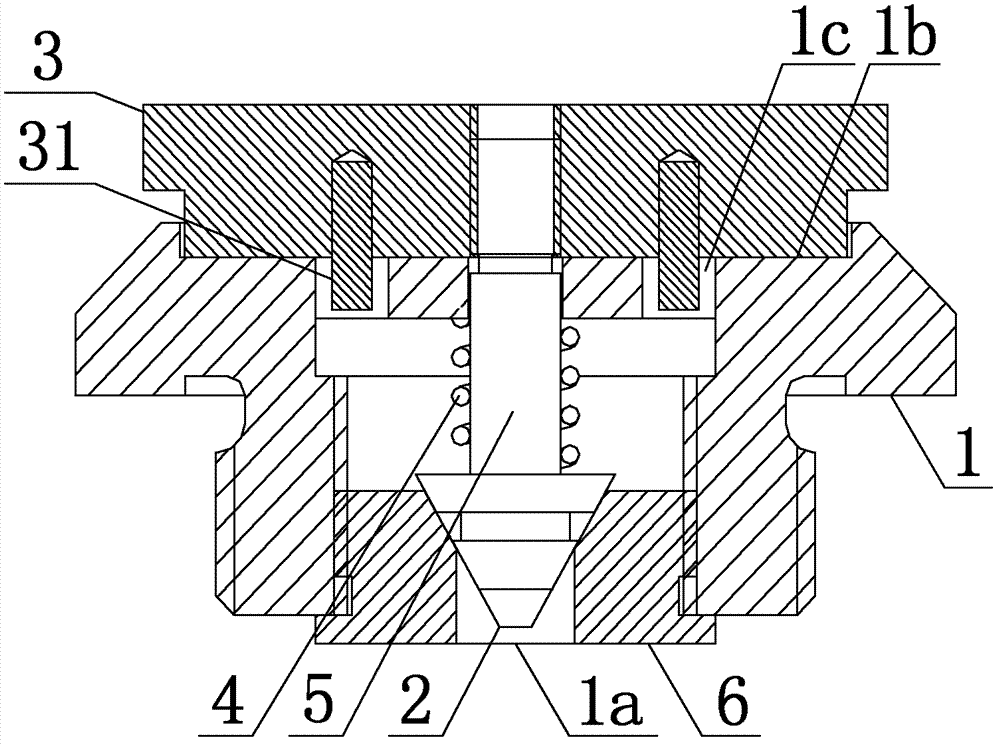

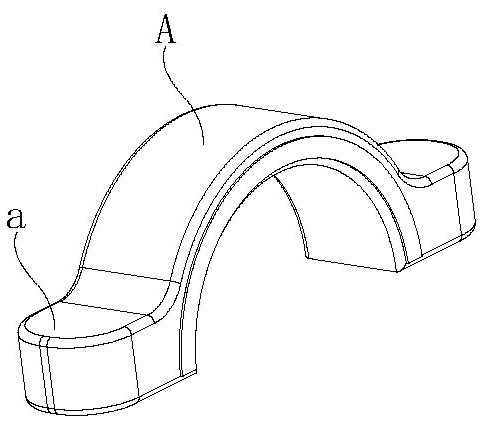

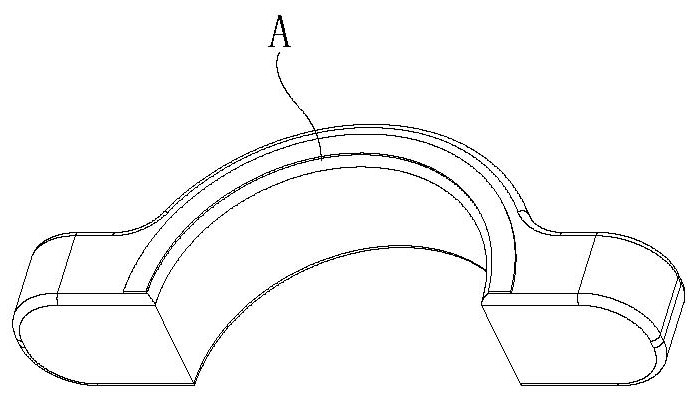

Vent cap

ActiveCN103244657AAchieving stress reduction goalsExport implementationEqualizing valvesSafety valvesInternal pressureProduct gas

The invention discloses a vent cap which comprises a vent cap main body, a first plugging piece, a second plugging piece and a resetting component. An air inlet and an air outlet which are communicated with each other are arranged on the vent cap main body, the air inlet is communicated with a vent of a reducer, the first plugging piece seals the air inlet, the second plugging piece seals the air outlet, and the resetting component is connected with the first plugging piece. The resetting component can provide resetting force for the first plugging piece, when the pressure in the reducer exceeds force exerted on the first plugging piece by the resetting component, the first plugging piece is ejected, and air in the reducer is guided out. When the pressure in the reducer is reduced, the first plugging piece and the second plugging piece are reset to seal the air inlet and the air outlet again. By means of the structural design, the vent cap can conduct pressure adjustment on the reducer, and a purpose of solving the problem that the vent cap is easy to damage in severe working condition environment is achieved.

Owner:WORLD TRANSMISSION TECH TIANJIN SHARE LTD

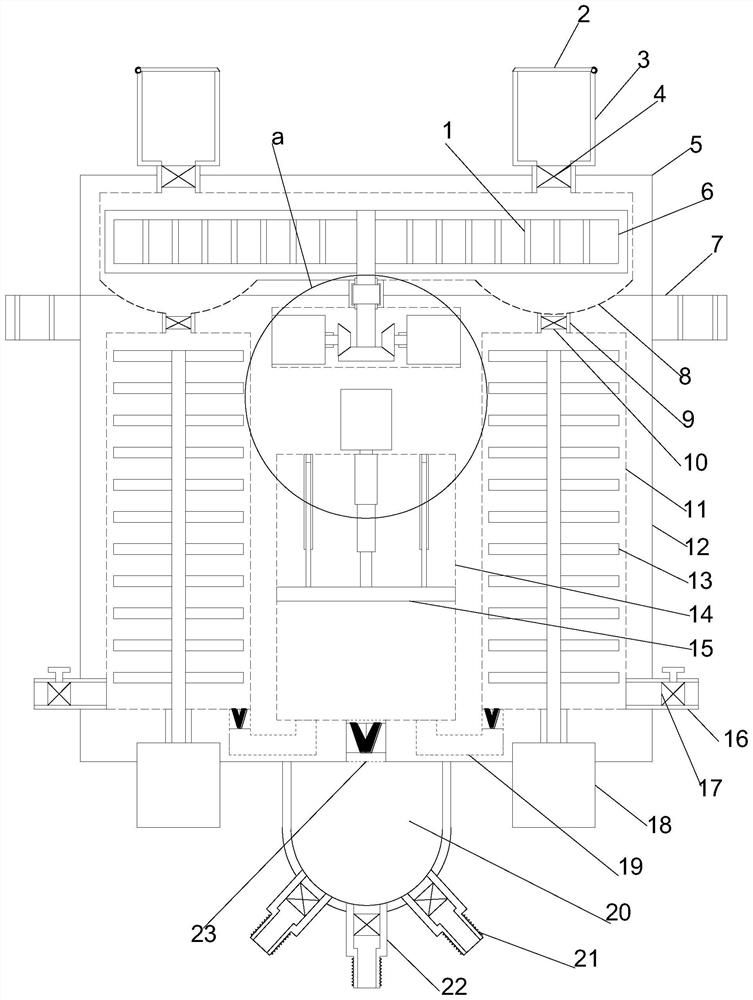

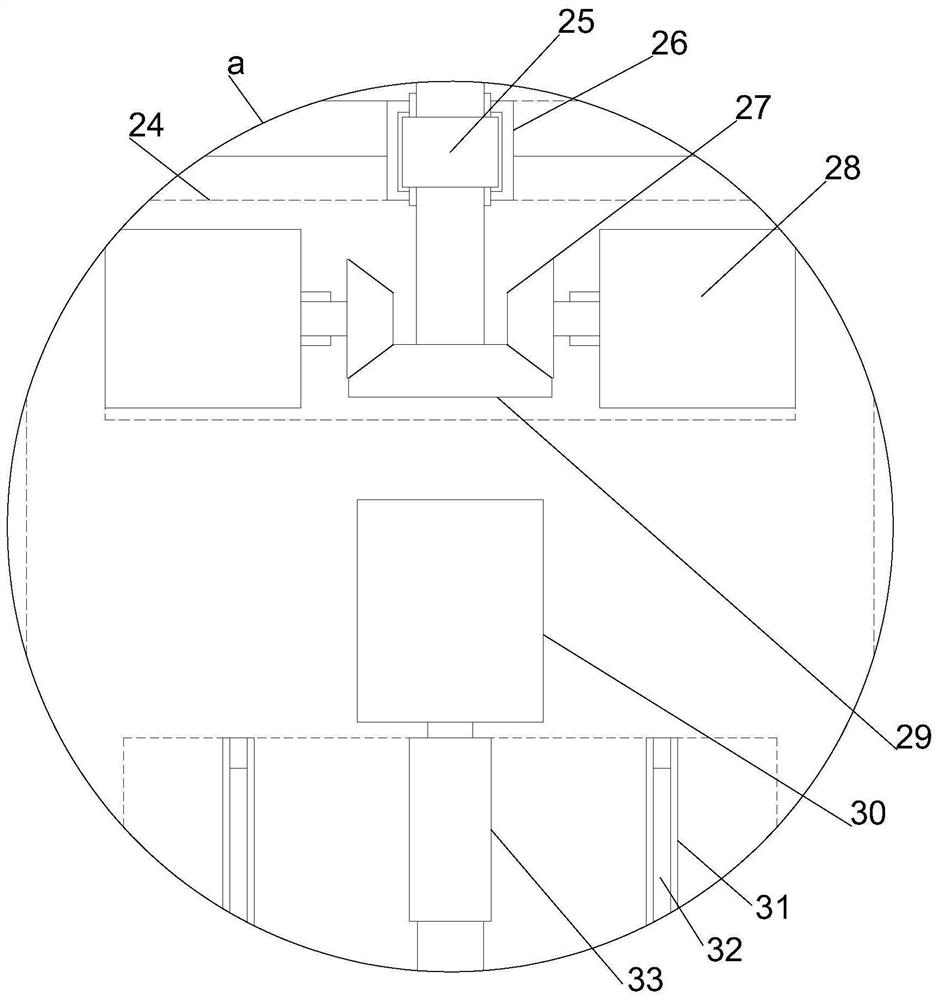

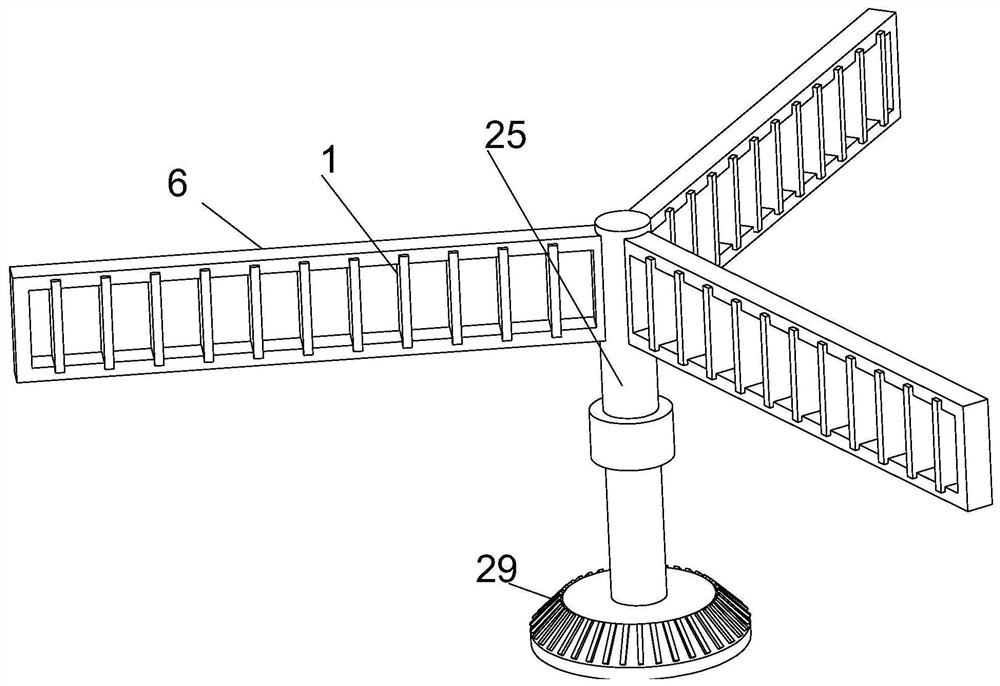

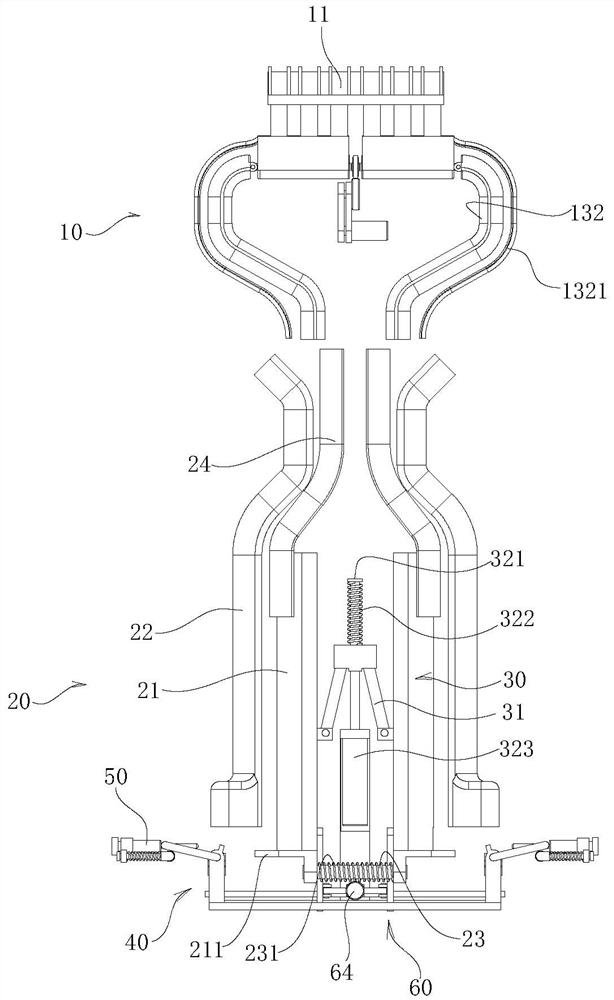

Multi-cavity flow guide type foam-free building coating stirring device

InactiveCN112295483AImprove output efficiency and qualityExport implementationTransportation and packagingRotary stirring mixersStructural engineeringElectromagnetic valve

The invention relates to the field of building equipment, in particular to a multi-cavity flow guide type foam-free building coating stirring device which comprises a vertically-arranged supporting mounting cylinder, fixed mounting plates are symmetrically arranged on the outer side of the upper half section of the supporting mounting cylinder, and a stirring mounting cylinder is horizontally arranged at the upper end of the supporting mounting cylinder. A plurality of feeding mounting cylinders are arranged at the upper end of the stirring mounting cylinder at equal angles, feeding cover plates are arranged at the upper ends of the feeding mounting cylinders through rotating shafts, the lower ends of the feeding mounting cylinders communicate with the stirring mounting cylinder through feeding electromagnetic valves, and a transmission mounting cavity is horizontally formed in the middle of the upper half section of the supporting mounting cylinder. The device supports simultaneous feeding of multiple building coatings, preliminary mixing and split-flow feeding into multiple cavities for vertical stirring, so that bubbles are always located at the top, bottom material pumping andleading-out are conducted in cooperation with the injection principle, continuous foam-free coating leading-out is achieved, the coating quality and the output efficiency are remarkably improved, multiple sets of synchronous material guiding are achieved, and the efficiency of the device is further improved.

Owner:王光远

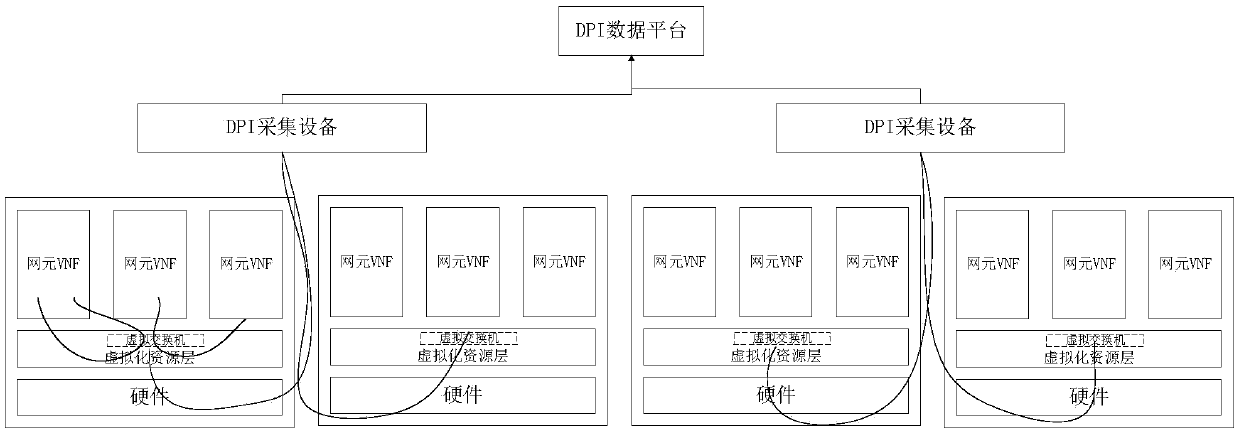

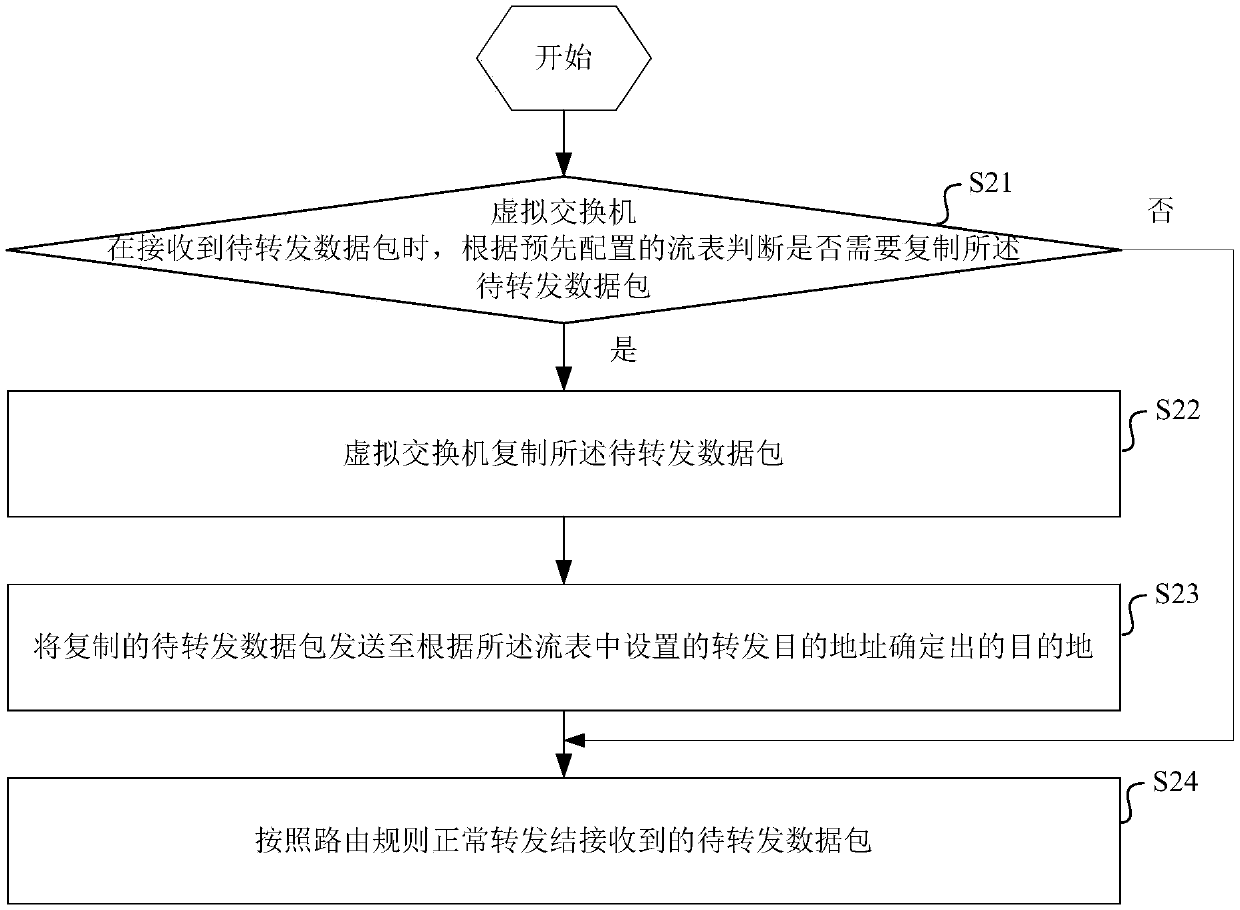

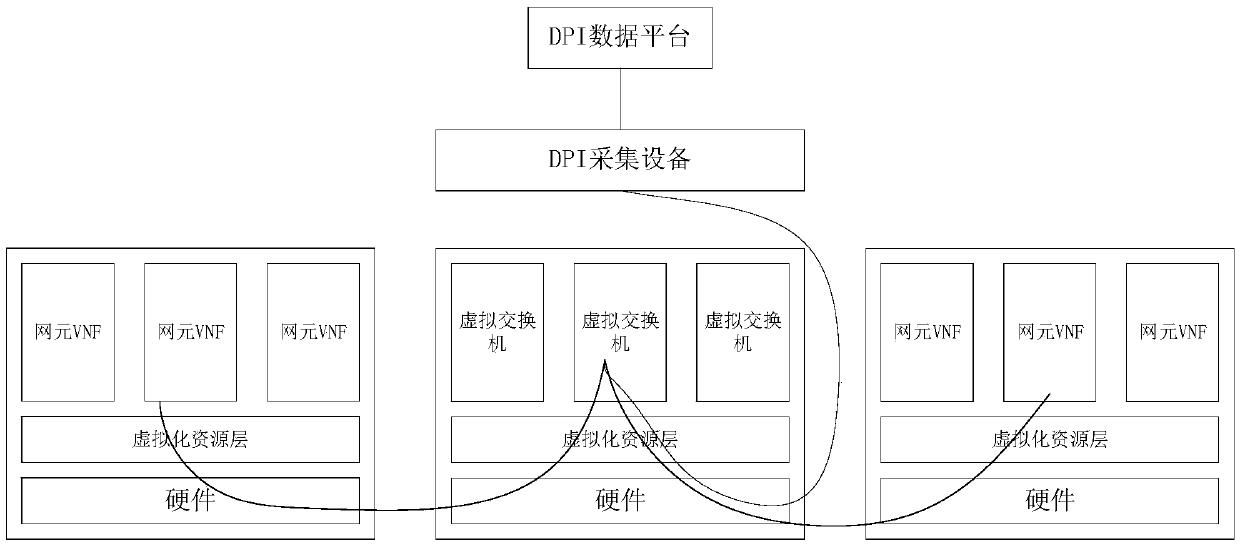

Virtualized network element data traffic exporting method and device and storage medium

ActiveCN111405590AExport implementationData switching networksWireless communicationData packVirtualization

The invention discloses a virtualized network element data traffic exporting method and device and a storage medium, which are used for realizing the exporting of virtualized network element data traffic. A virtual switch is deployed in a network function virtualization environment. The virtual switch is used for connecting a virtual network card and a physical network card, and pre-configurationis performed to route data traffic of a virtual network element needing to export the traffic to the virtual switch. Also disclosed is a method, comprising: when the virtual switch receives a to-be-forwarded data packet, judging whether the to-be-forwarded data packet needs to be copied or not according to a pre-configured flow table; when the judgment result is yes, the virtual switch copying heto-be-forwarded data packet; and sending the copied to-be-forwarded data packet to a forwarding destination address set in the flow table.

Owner:CHINA MOBILE COMM LTD RES INST +1

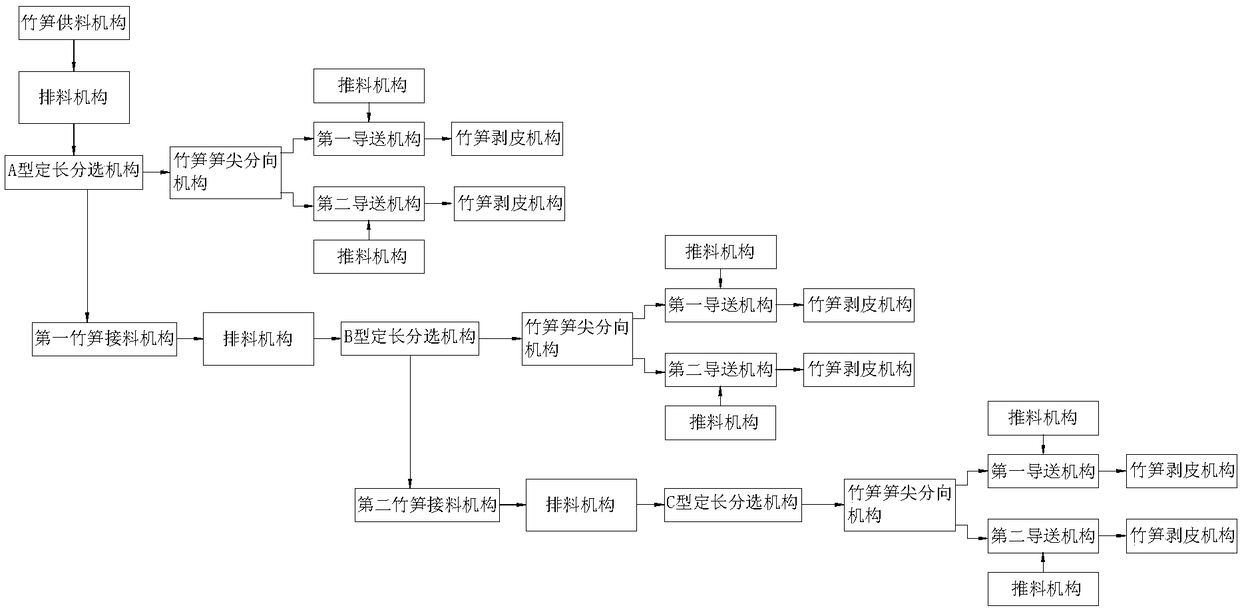

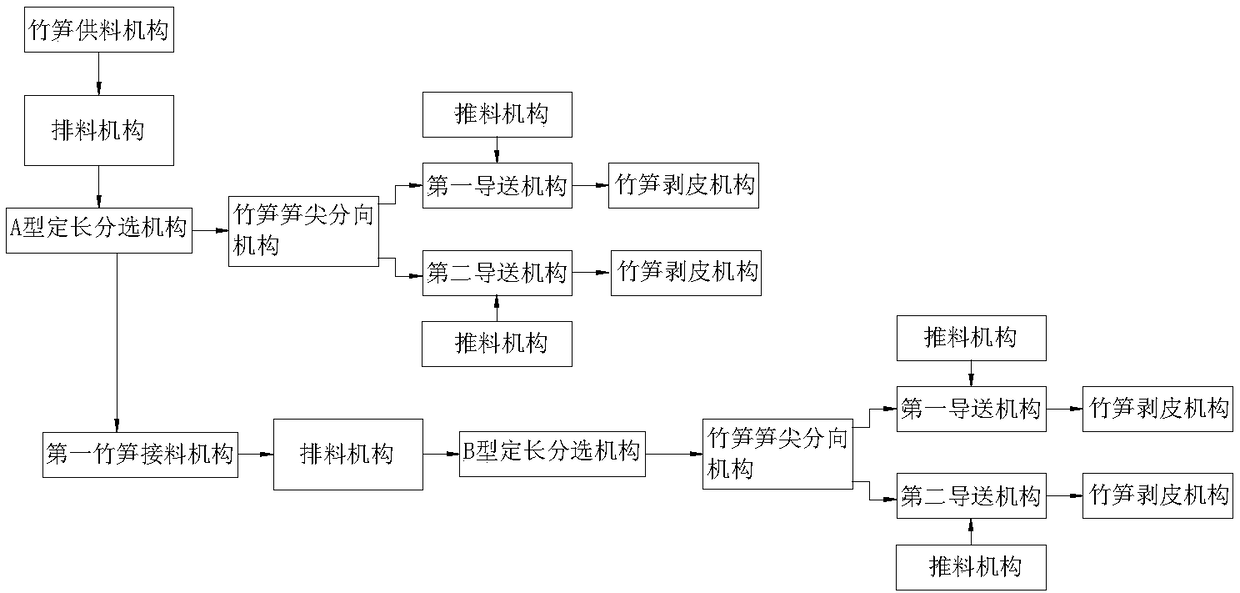

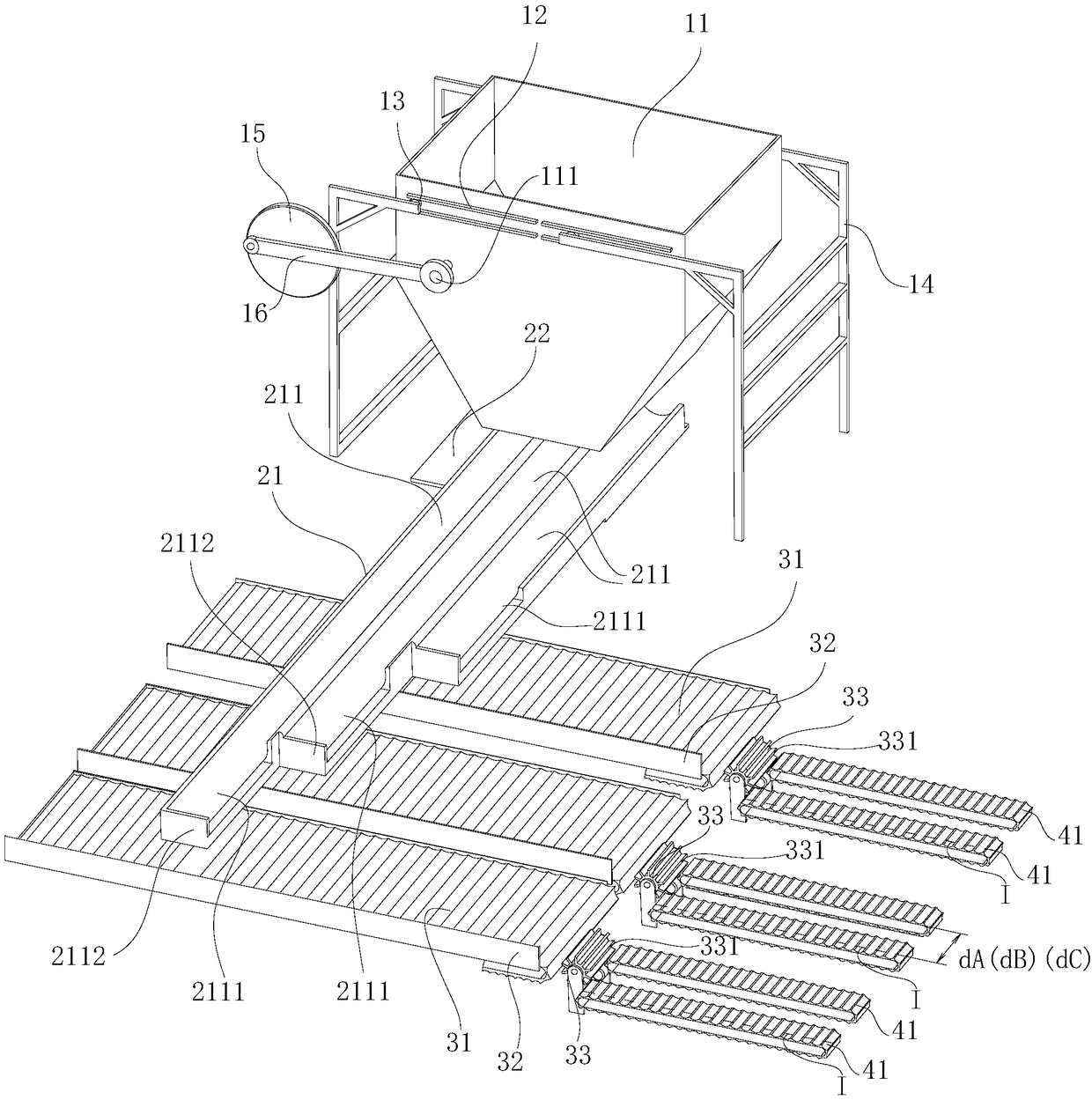

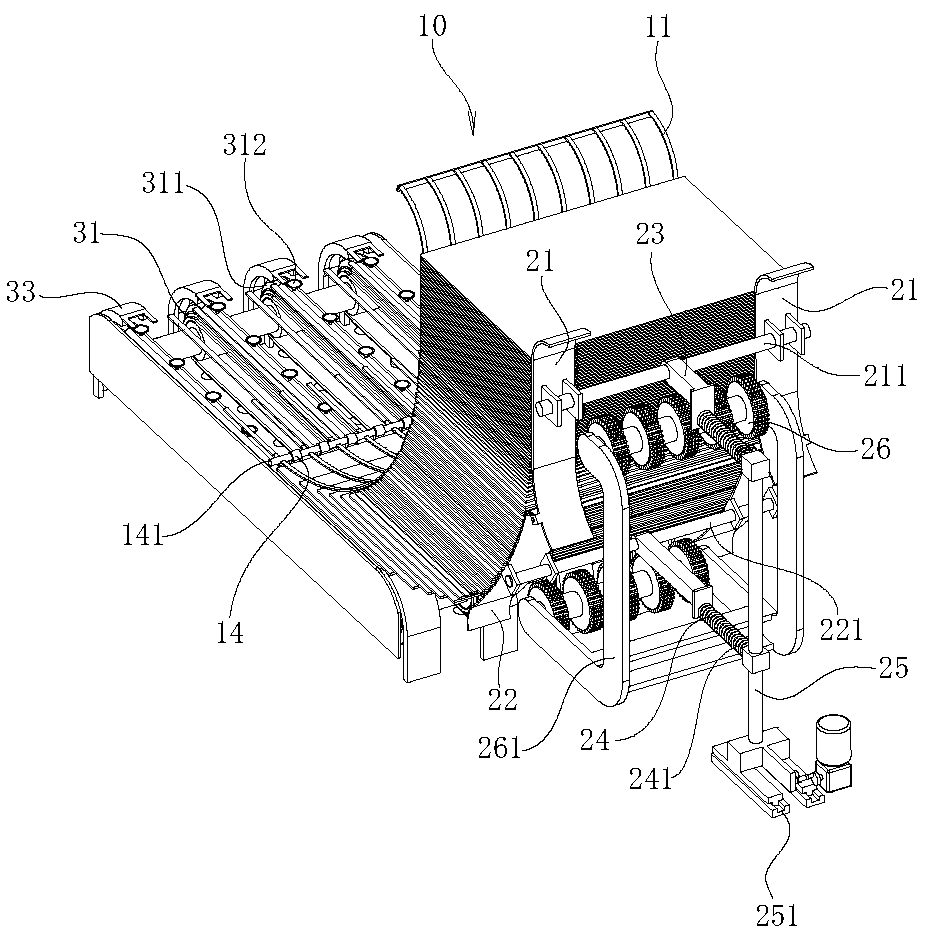

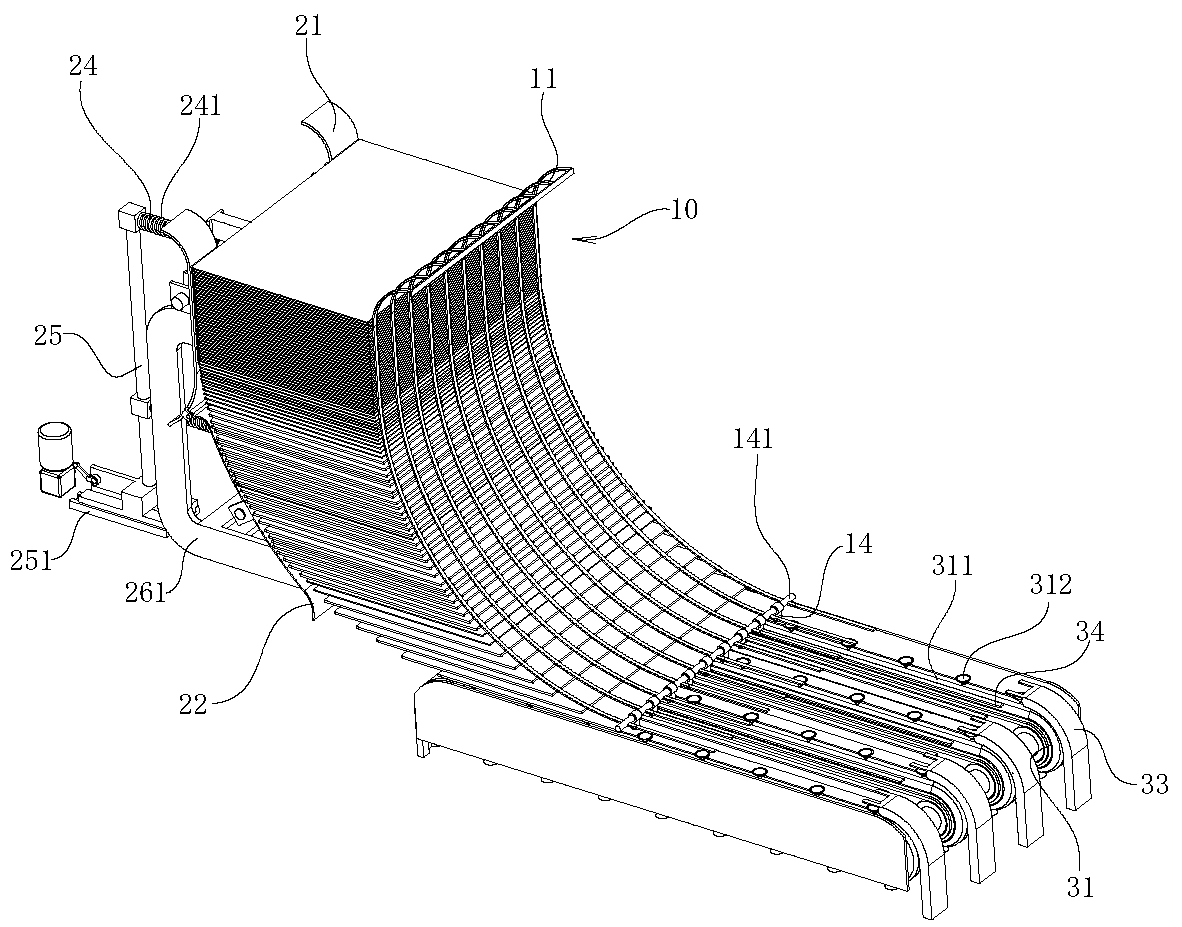

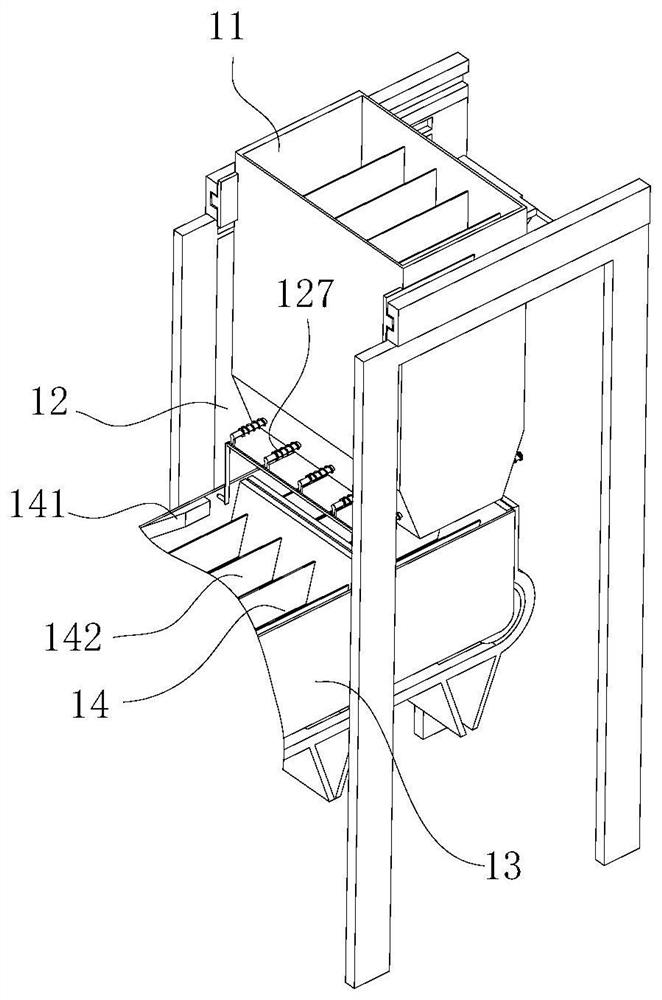

Bamboo shoot tip direction sorting mechanism

ActiveCN108745910AExport ensuresExport implementationVegetable peelingConveyor partsShootBamboo shoot

Owner:岳西神农氏农业科技有限公司

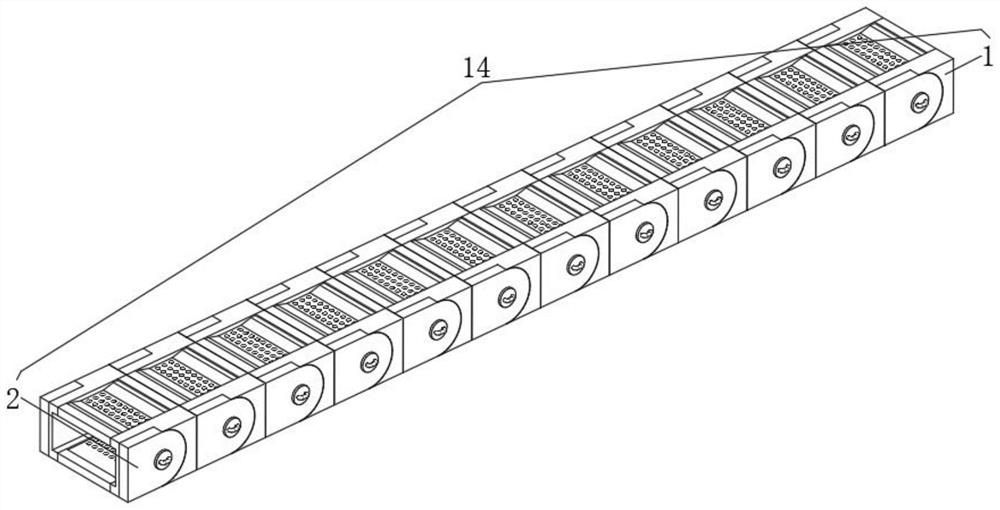

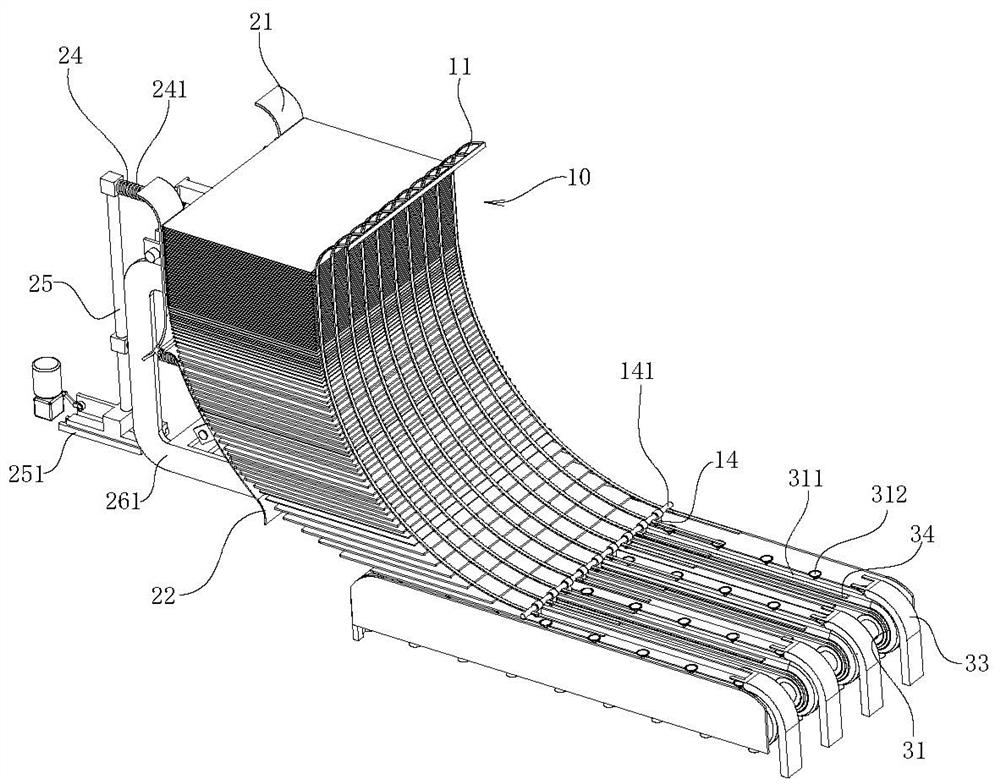

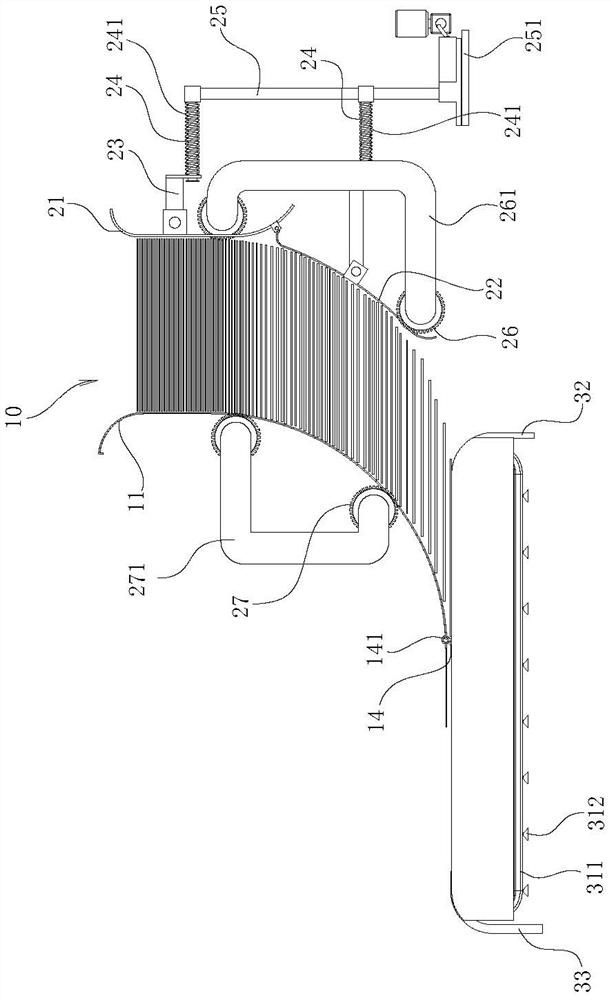

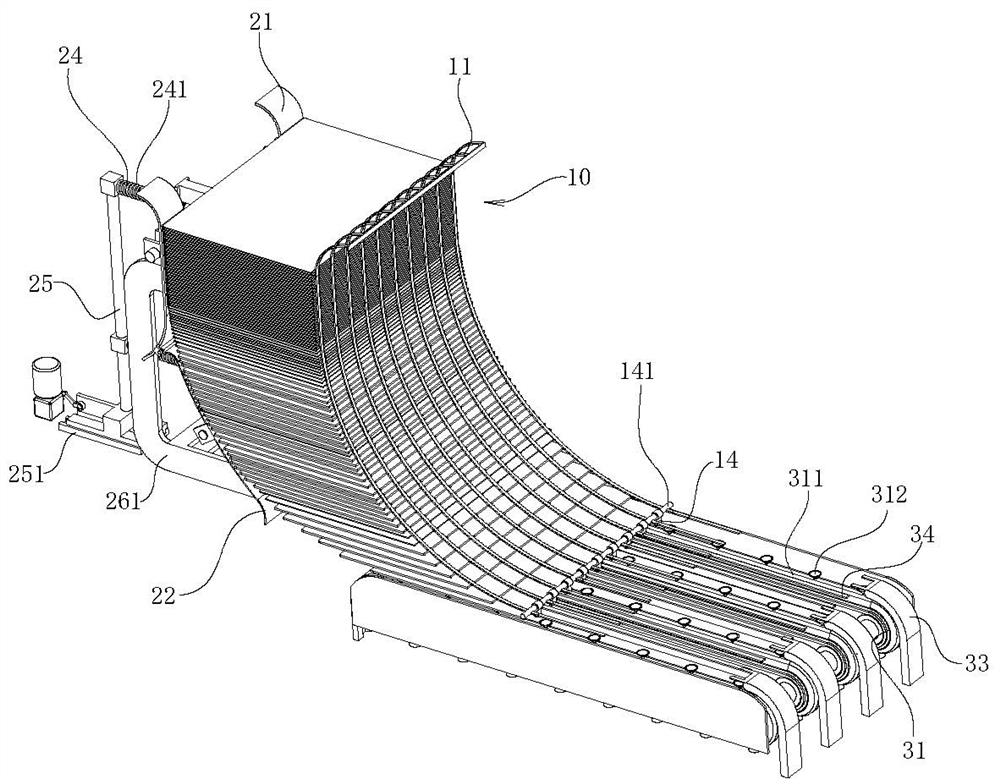

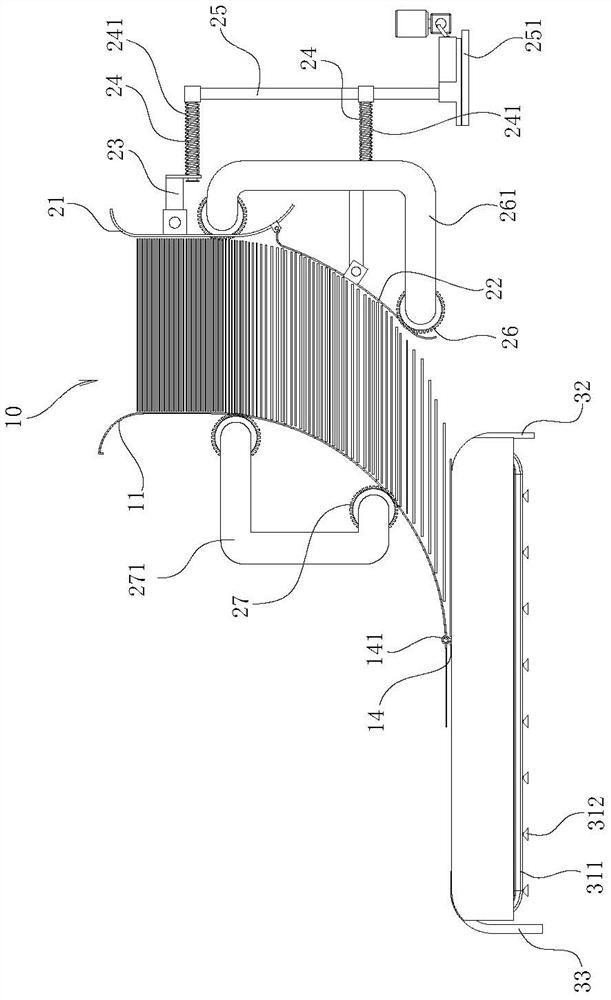

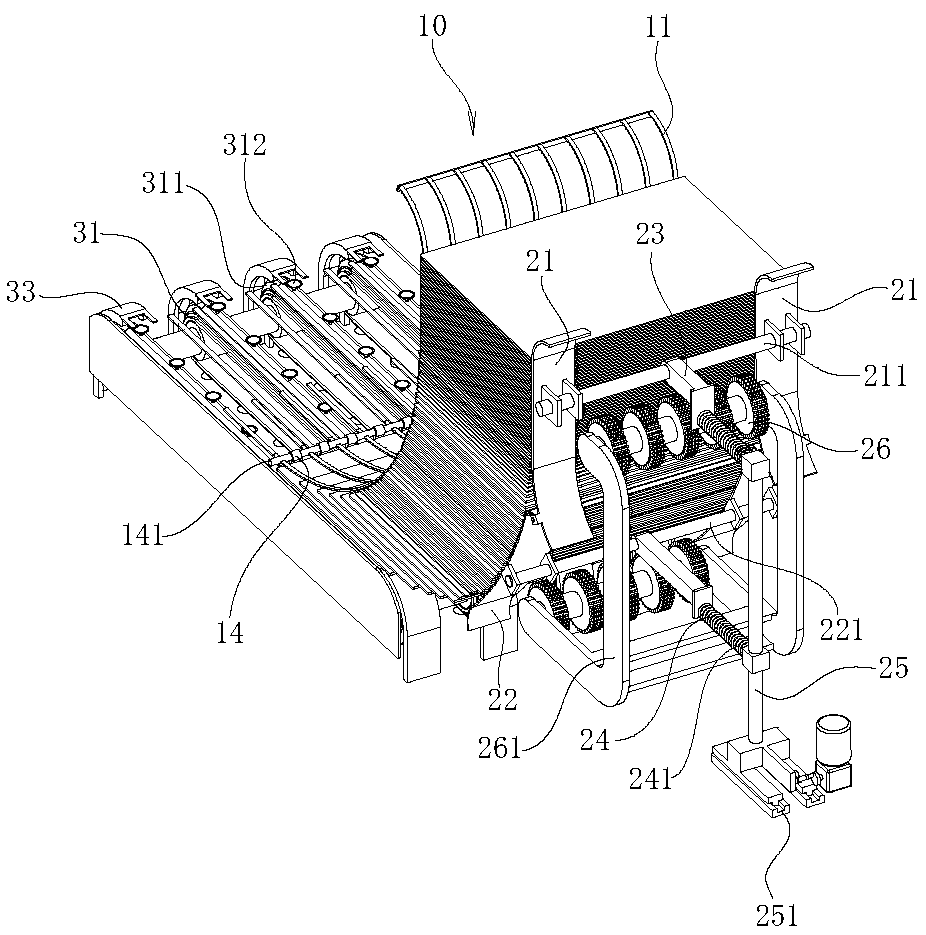

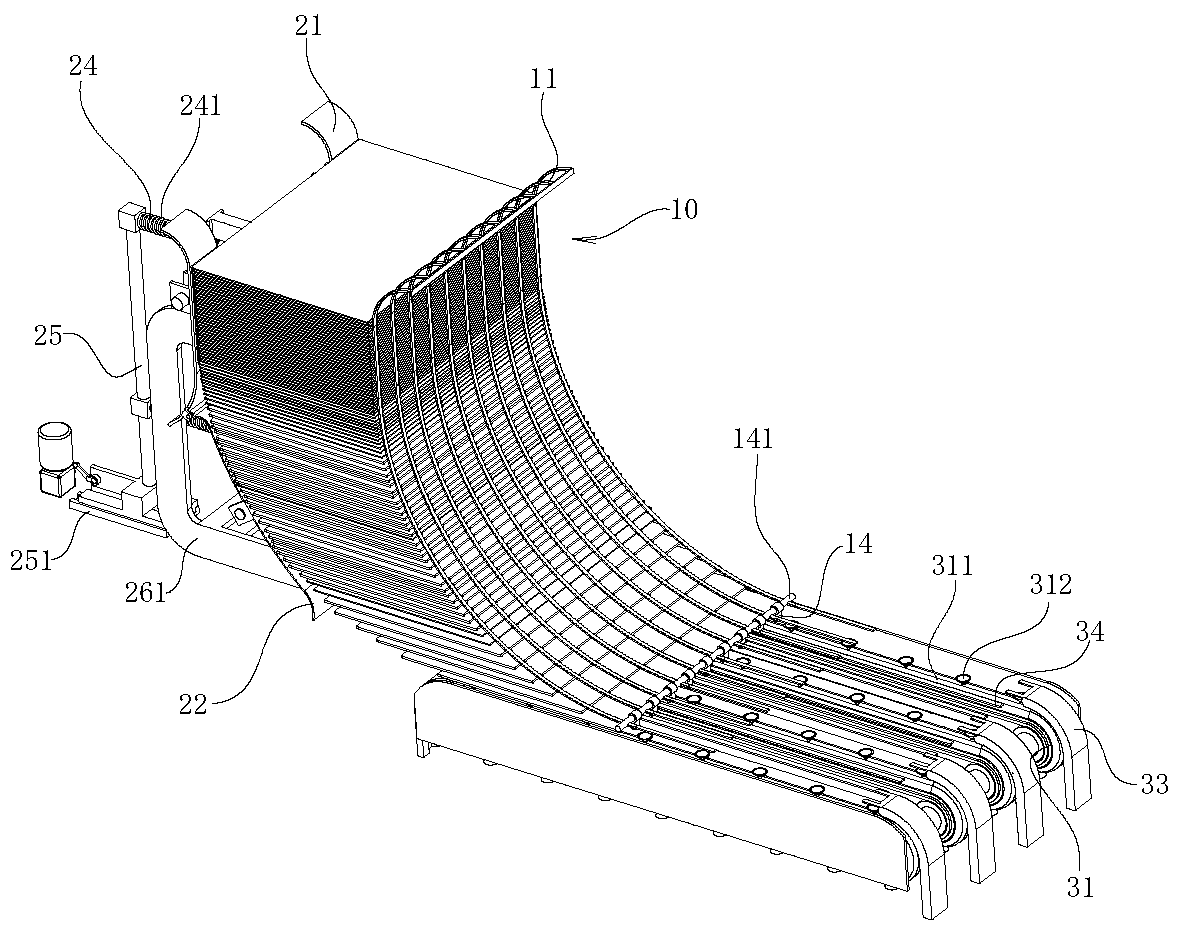

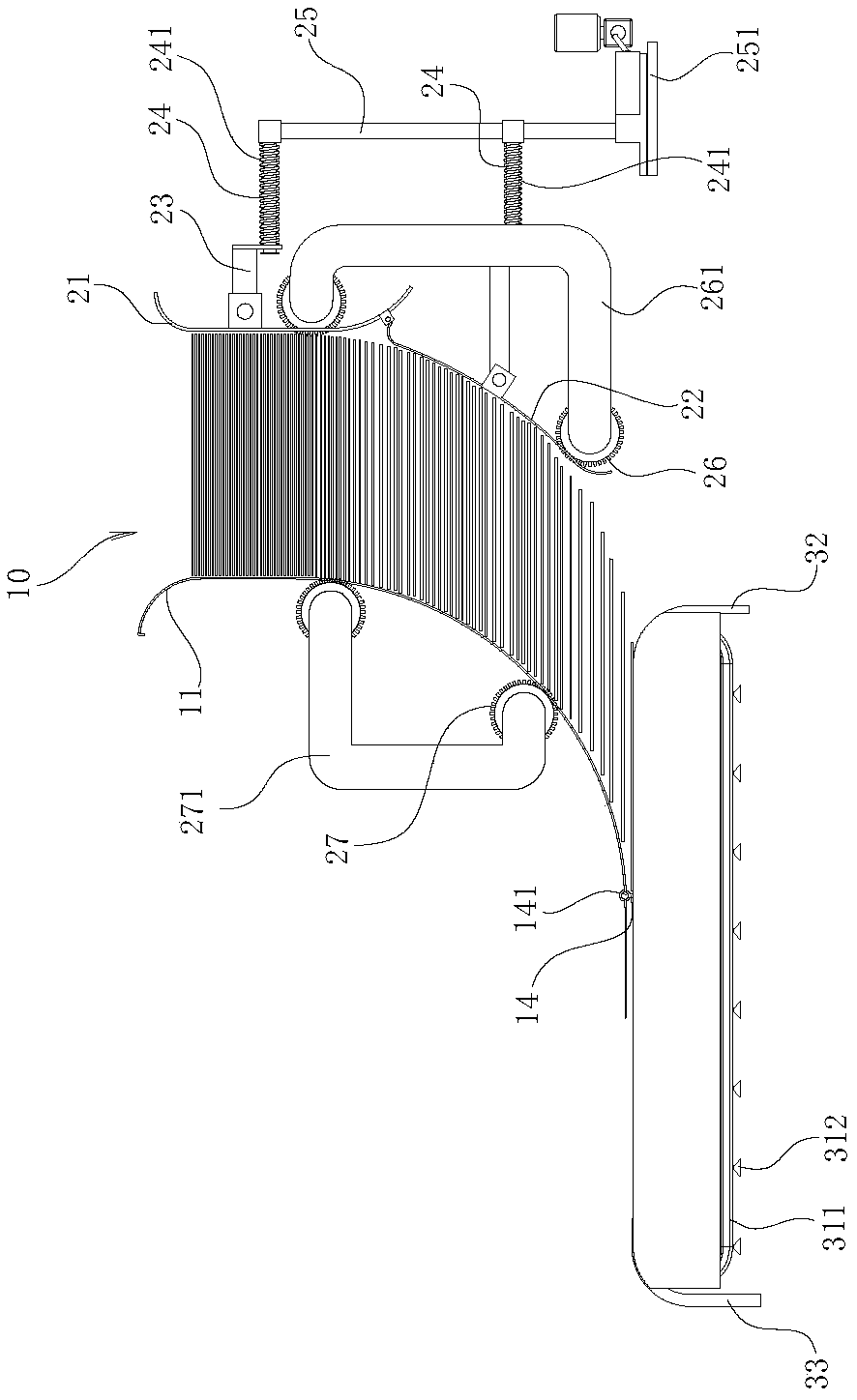

Guiding-out method for single paper board

ActiveCN110202828AGuaranteed production efficiencyExport implementationPaper-makingBox making operationsCardboardPulp and paper industry

The invention relates to a guiding-out method for a single paper board. The paper boards to be processed are stacked in order and are arranged in an inlet in the upper end of a paper guide rail; a pushing and twisting mechanism is started, so that one ends of the paper boards which are stacked in order are smoothly arranged along grid strips of the paper guide rail; a material spreading crawler belt of a paper spreading mechanism is started, and the paper boards in the paper guide rail are independently guided out from the outlet position; and the single paper board is guided out to a materialreceiving crawler belt, the guiding and paving operation of the single paper board is carried out by utilizing the material receiving crawler belt, and the paper board is guided out to other equipment of the system for further processing; and the paper boards which are stacked in order are hoisted into the paper guide rail through a lifting mechanism, and timely paper feeding operation is carriedout, so that the paper board with sufficient internal storage oil of the paper guide rail can be ensured, and the production efficiency of a packaging box can be ensured.

Owner:安徽世品佳工业产品设计有限公司

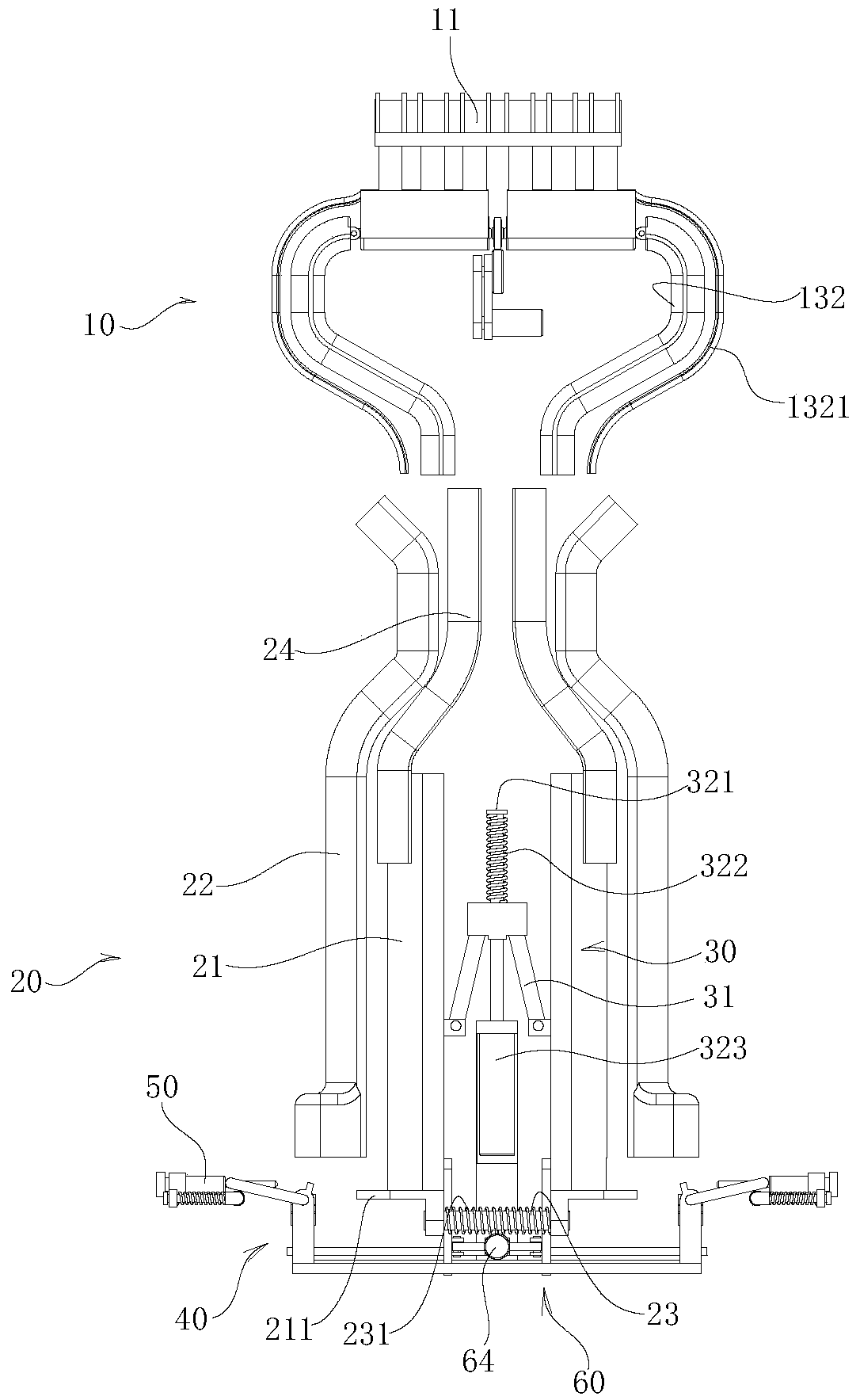

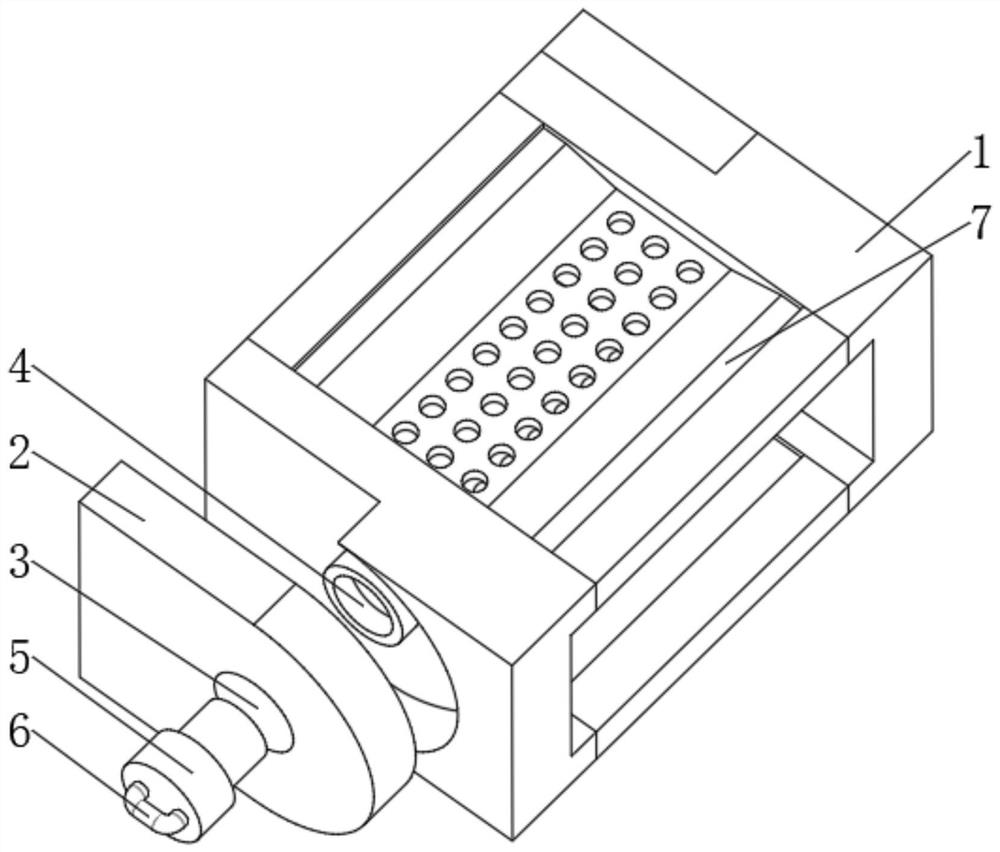

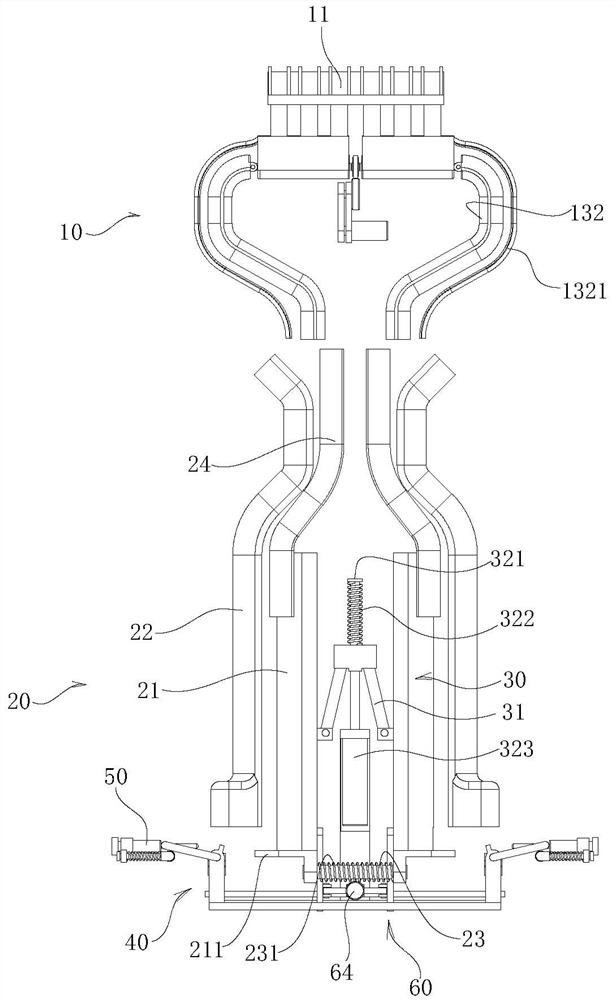

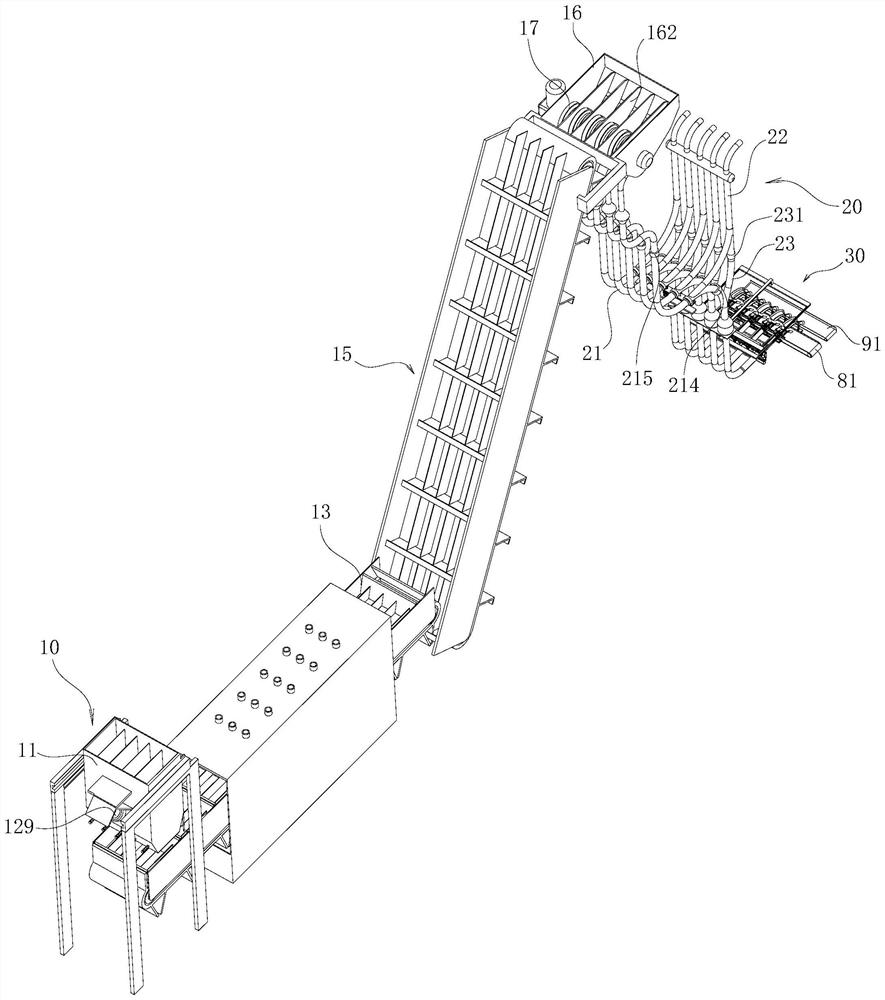

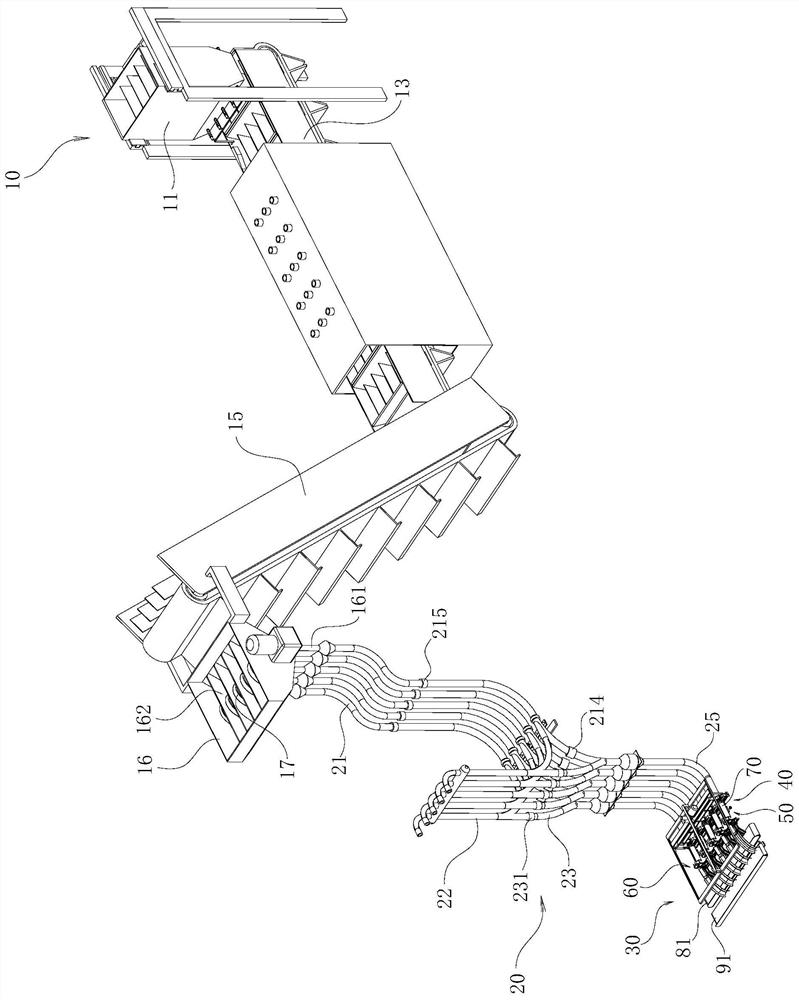

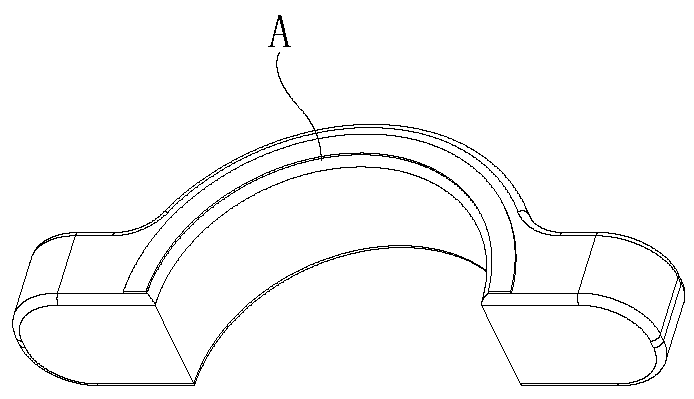

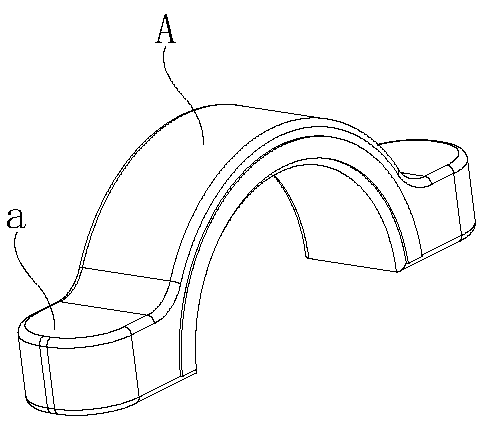

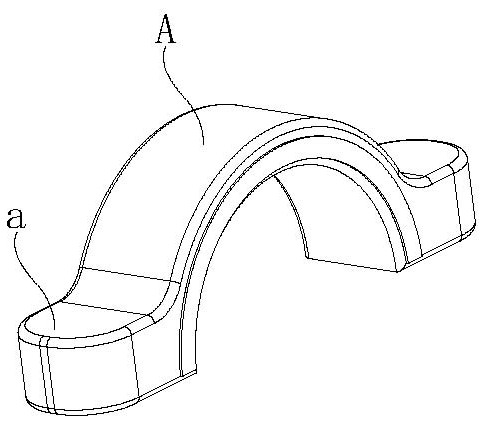

Perforating device for mounting surfaces of bearing blanks

ActiveCN111299654ARealize the drilling operationIncrease productivityStacking articlesMetal working apparatusClassical mechanicsEngineering

The invention relates to a perforating device for mounting surfaces of bearing blanks. The perforating device comprises a blank stacking mechanism used for stacking the blanks in order. A core positioning mechanism is arranged at an outlet of the blank stacking mechanism and used for core positioning of the blanks stacked in order. A clamping mechanism is arranged beside the outlet of the blank stacking mechanism and used for clamping the mounting surfaces of the two ends of the blanks. Drill bits are arranged on the lateral sides of the clamping mechanism and vertically move along the mounting surfaces of the two ends of the blanks to conduct drilling. A discharging mechanism is arranged beside the blank stacking mechanism and used for discharging perforated bearings. By the adoption of the perforating device, the blanks can be automatically fed to realize automatic drilling of bearing seats, and the production efficiency and quality of the bearing seats are improved.

Owner:岳西县顺达机械有限公司

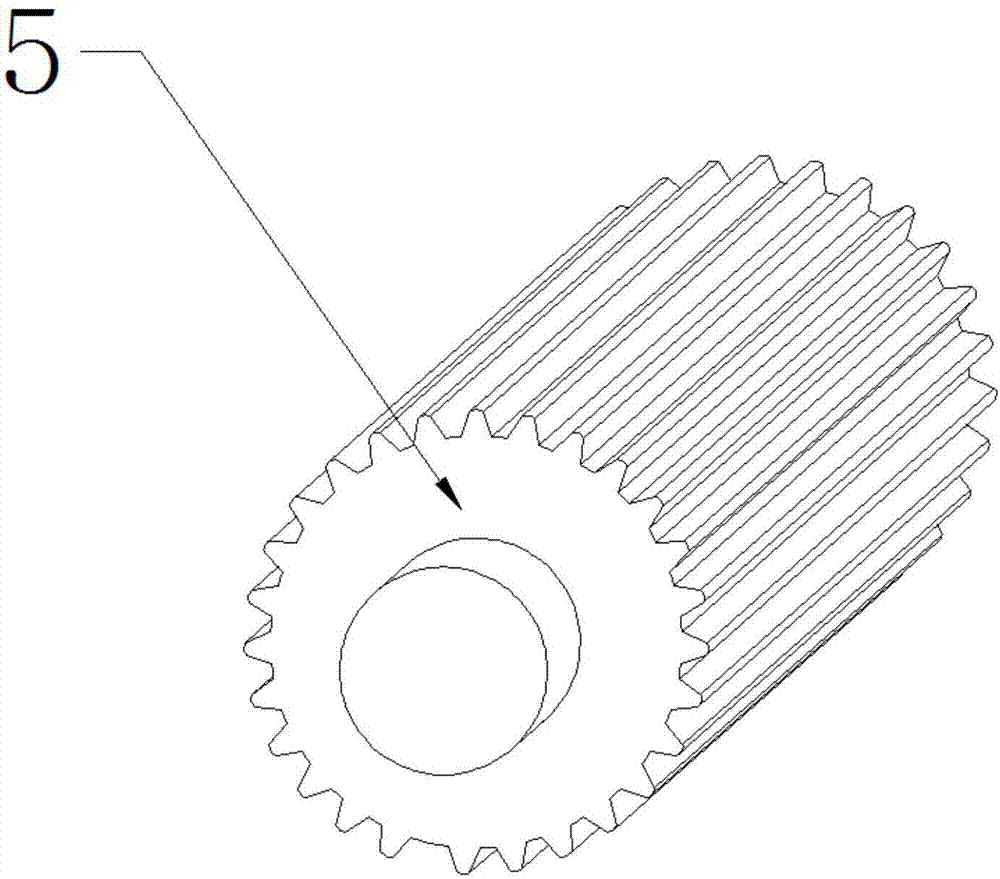

Ball mill convenient to clean for coating production

InactiveCN107971086AImprove practicalityIncrease flexibilityGrain treatmentsTemperature controlAgricultural engineering

The invention discloses a ball mill convenient to clean for coating production. The ball mill comprises a main body and a ball milling cylinder, wherein a base is fixed at the lower end of the main body, a speed reducer assembly is fixedly arranged in the middle position of the upper surface of the base, and the left side of the upper end of the speed reducer assembly is sleeved with a fluted disc. The upper end of the fluted disc is meshed with a toothed ring, the two sides of the speed reducer assembly are provided with guide wheel assemblies respectively, the upper ends of the guide wheel assemblies are connected with guide wheels, guide bearings are embedded in the middle positions of the two sides of the ball milling cylinder, the guide bearing on the right side of the ball milling cylinder is connected with an impact column mounting bearing, and a driving motor is fixedly installed on the right side surface of the impact column mounting bearing. According to the ball mill for coating production, in the ball milling process, temperature control can be carried out on the outer surface of an impact column through cold and hot wind provided by a temperature control tube, so thatthe working quality and flexibility is improved. The ball mill is suitable for production and use of ball mills for coating production, and has a good development prospect.

Owner:江西景新漆业股份有限公司

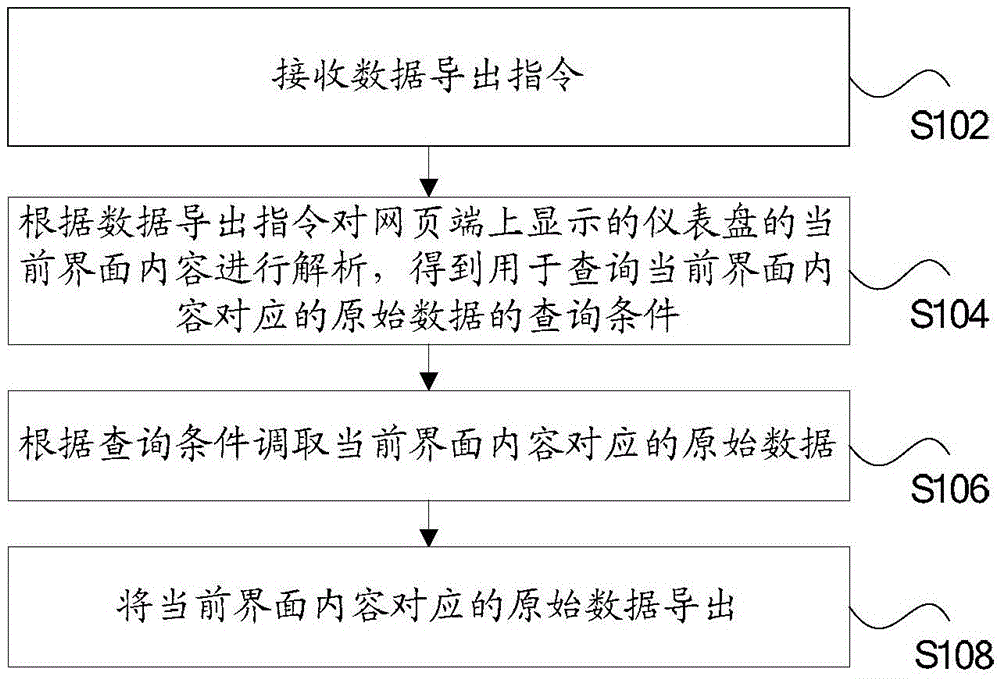

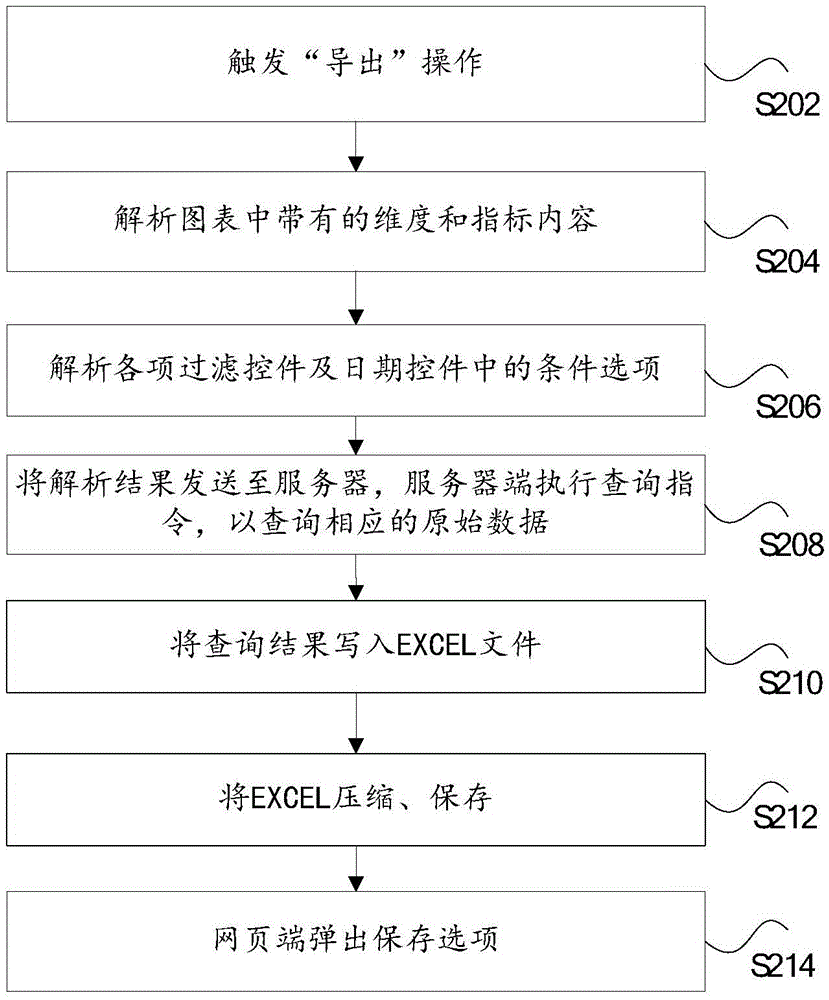

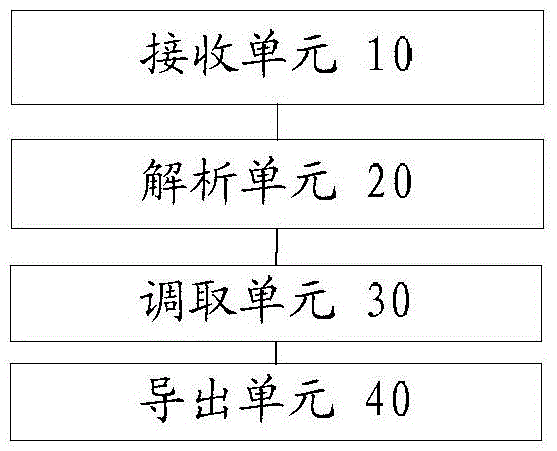

Data processing method and device

InactiveCN106708877AExport implementationSolve technical problemsSpecial data processing applicationsOriginal dataData mining

The invention discloses a data processing method and a data processing device, wherein the method comprises the steps of receiving a data export command; parsing a current interface content of a dash board displayed on a webpage end according to the data export command to obtain a query condition for inquiring original data corresponding to the current interface content; acquiring the original data corresponding to the current interface content according to the query condition; and exporting the original data corresponding to the current interface content. According to the data processing method and the data processing device, the technical problem that the data on a dash board interface cannot be exported is solved.

Owner:BEIJING GRIDSUM TECH CO LTD

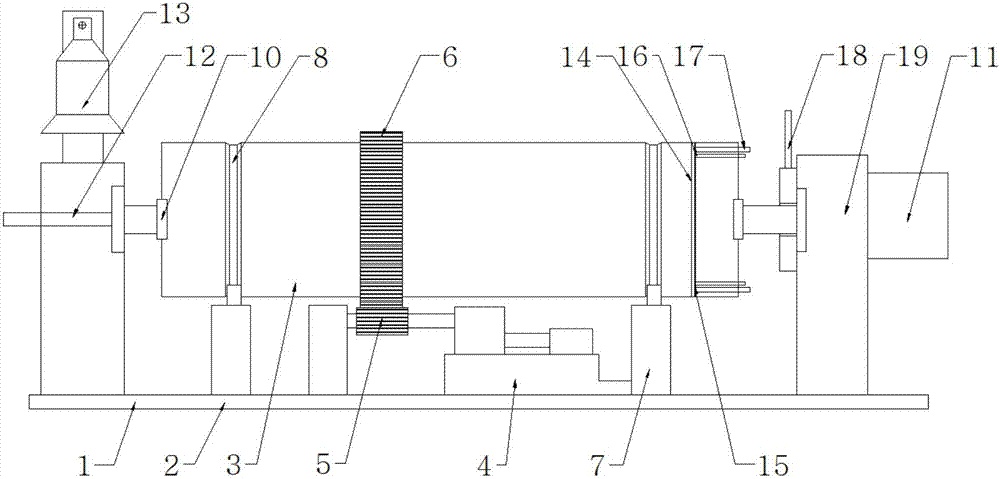

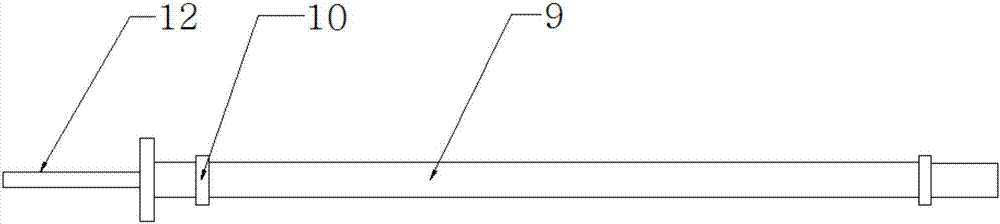

Bearing pedestal machining system

ActiveCN111299653ARealize the drilling operationIncrease productivityStacking articlesPositioning apparatusStructural engineeringMachining system

The invention relates to a bearing pedestal machining system. The system comprises a bearing blank mechanism, an outlet of a blank feeding mechanism is connected with a feeding port of a blank stacking mechanism, the blank stacking mechanism is used for neatly stacking blanks, a core setting mechanism is arranged at the outlet of the blank stacking mechanism, and the core setting mechanism is usedfor core-setting the neatly stacked blanks; a clamping mechanism is arranged beside the outlet of the blank stacking mechanism and used for clamping installation faces at the two ends of a blank; a drill bit is arranged beside the clamping mechanism, and the drill bit moves in the vertical direction of the installation faces at the two ends of the blank and conducts drilling operation. The systemcan automatically realize the introduction of the blanks, thereby realizing automatic drilling operation on the bearing pedestal, and improving the production efficiency and quality of the bearing pedestal.

Owner:岳西县顺达机械有限公司

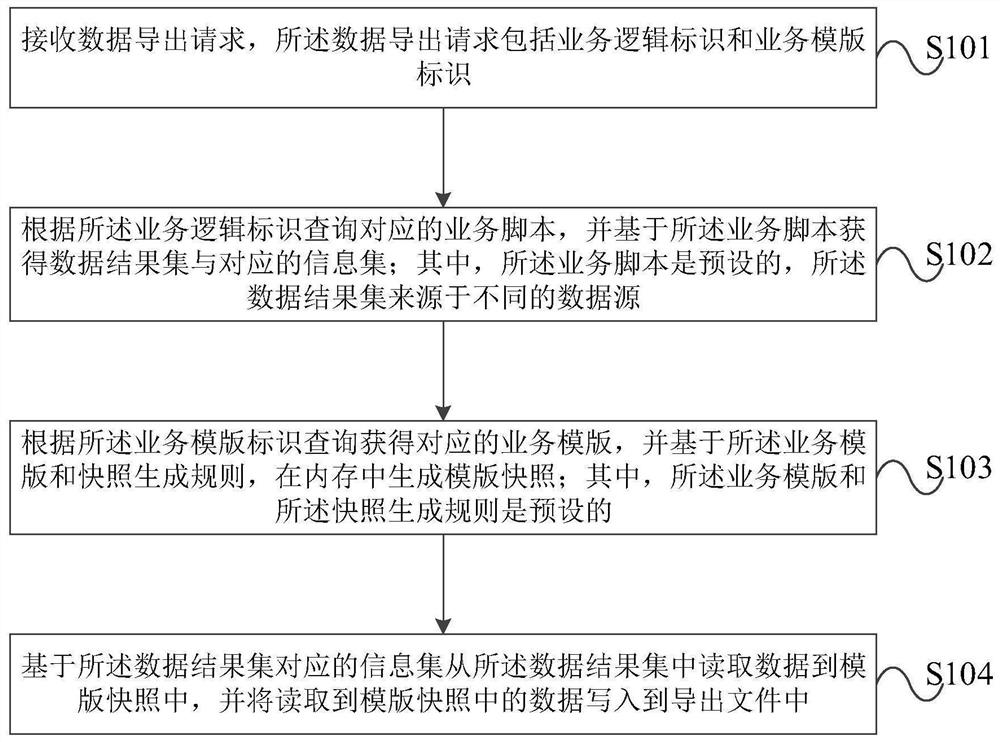

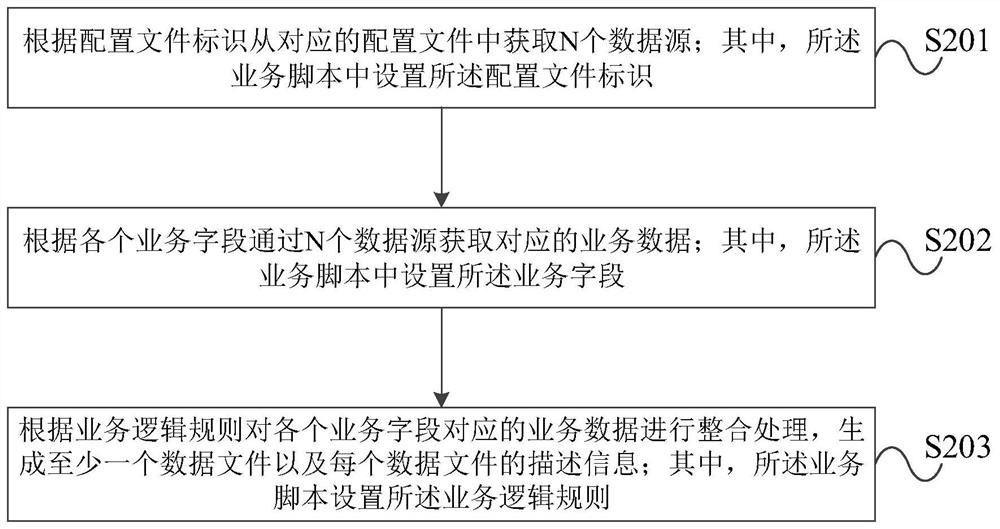

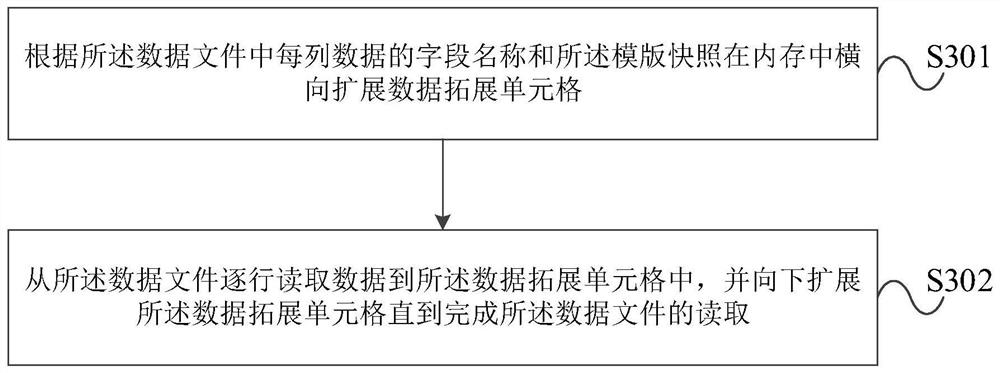

Data export method and device for different data sources

PendingCN113177021AExport implementationImprove export efficiencyNatural language data processingFile system administrationData sourceEngineering

The invention provides a data export method and device for different data sources, which can be used in the financial field or other technical fields. The method comprises the following steps: receiving a data export request, wherein the data export request comprises a service logic identifier and a service template identifier; querying a corresponding service script according to the service logic identifier, and obtaining a data result set and a corresponding information set based on the service script, wherein the data result set is from different data sources; querying according to the service template identifier to obtain a corresponding service template, and generating a template snapshot in a memory based on the service template and snapshot generation rules; reading data from the data result set into a template snapshot based on the information set corresponding to the data result set, and writing the data read into the template snapshot into an export file. The device is used for executing the method. According to the data export method and device for different data sources provided by the embodiment of the invention, the data export efficiency is improved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

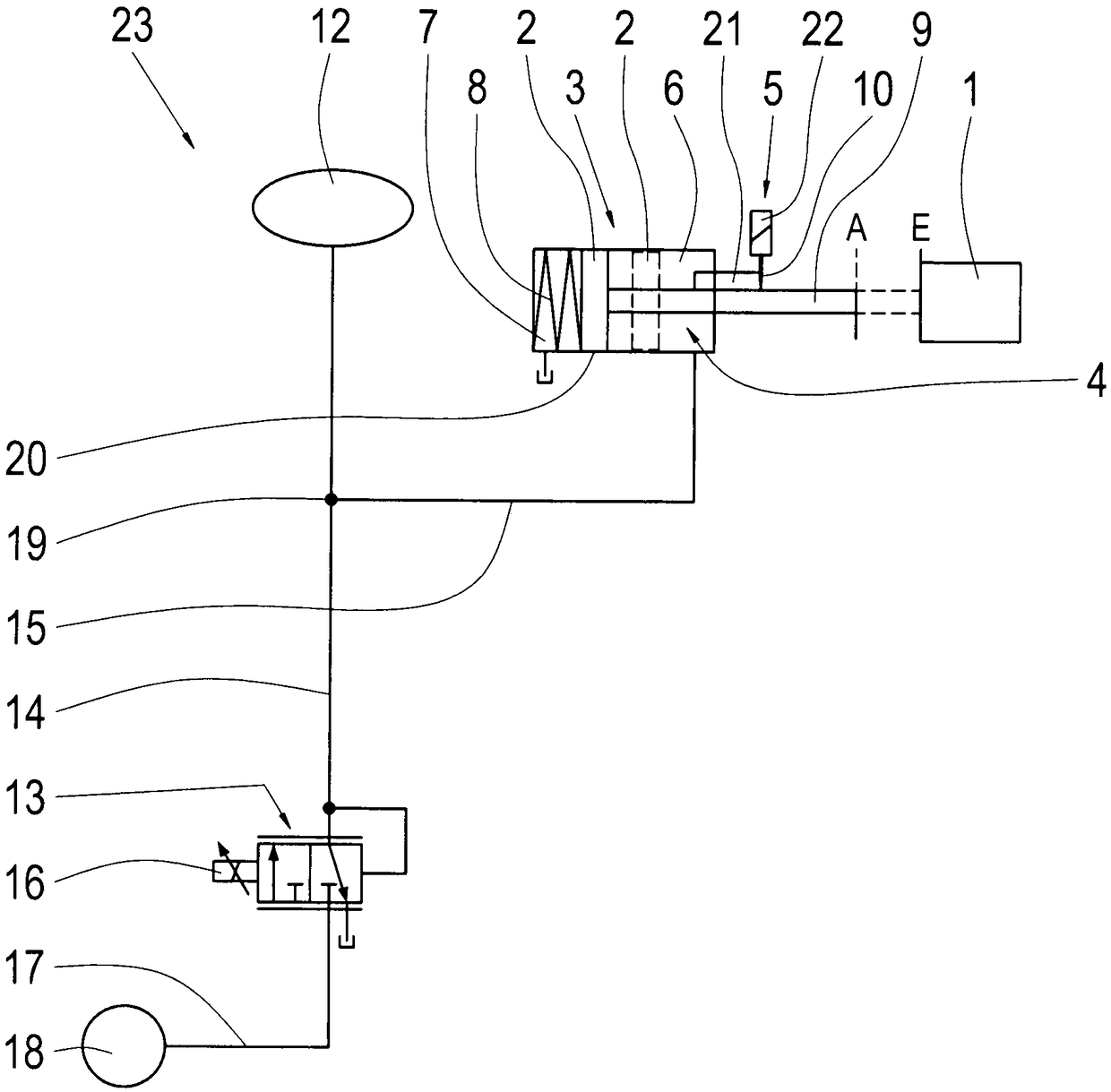

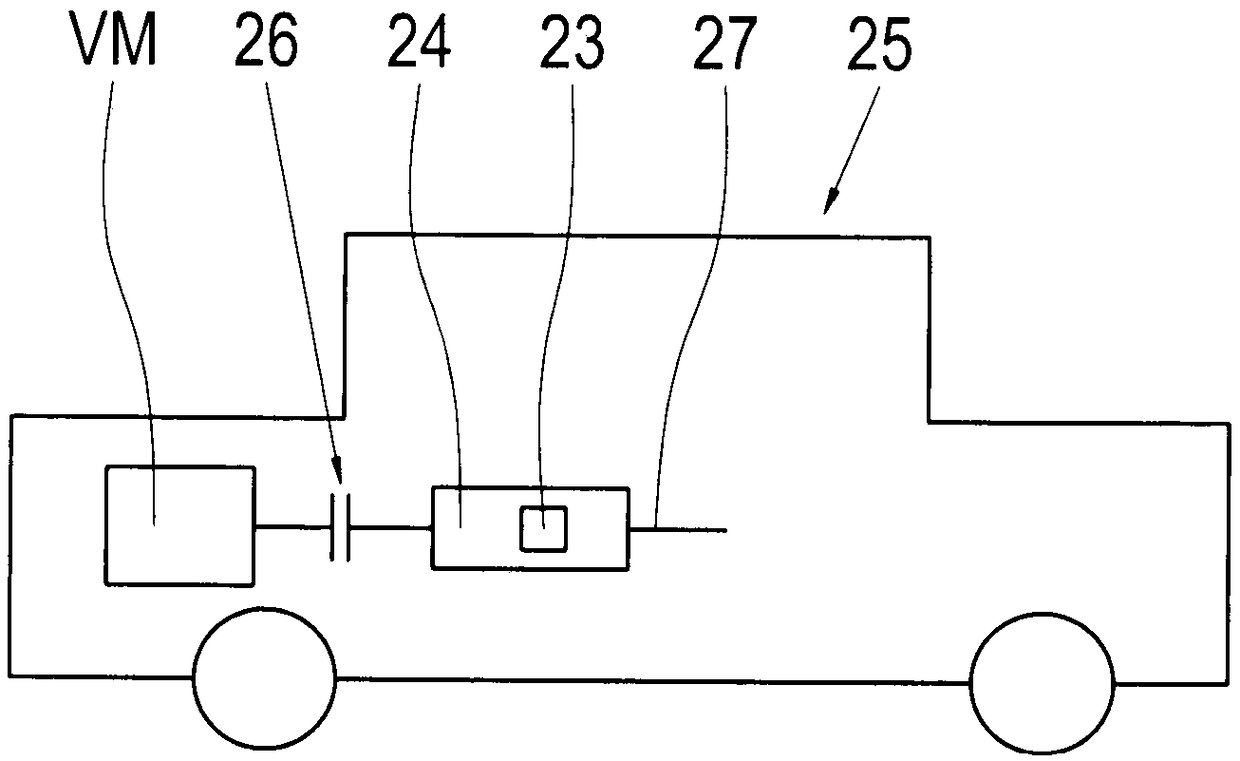

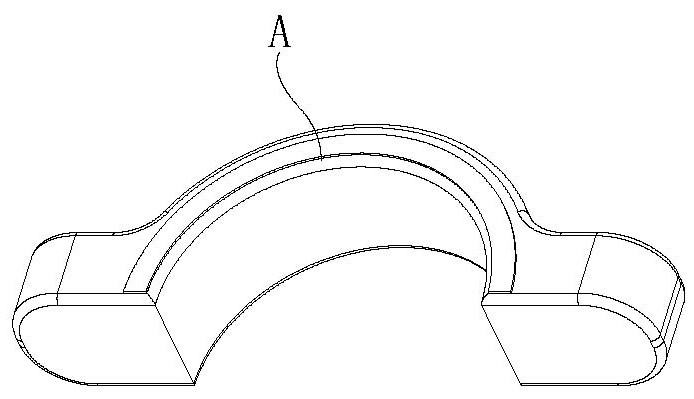

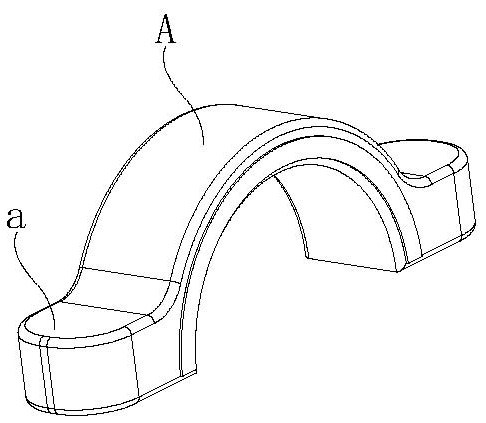

Actuation arrangement system

ActiveCN109210191ASimple structureUnintentional motion blockingGearing controlMechanical engineeringPiston

The invention relates to an actuation arrangement system including an actuating device for actuating a transmission parking locking device. The actuating device has a piston movable into an engaged position and into a disengaged position. The actuating device further has a cylinder including a cavity and a locking unit. The actuation arrangement system further includes a transmission shift element; a valve; a first line fluidically connecting the transmission shift element and the valve to each other, wherein valve has a first valve position, when the valve is in the first valve position, transmission oil is supplied to the transmission shift element through a first line to actuate the transmission shift element; and a second line which is fluidically connected to the first line and by which the transmission oil is suppliable into the cavity. The actuation arrangement system is characterized in that the actuation of the transmission parking locking device by the operating device can becontrolled or regulated by means of the valve, when the valve is in the first valve position, the actuating device operates the transmission parking locking device.

Owner:ZF FRIEDRICHSHAFEN AG

Bearing processing system

ActiveCN111299653BRealize the drilling operationIncrease productivityStacking articlesMetal working apparatusStructural engineeringMachining system

The invention relates to a bearing pedestal machining system. The system comprises a bearing blank mechanism, an outlet of a blank feeding mechanism is connected with a feeding port of a blank stacking mechanism, the blank stacking mechanism is used for neatly stacking blanks, a core setting mechanism is arranged at the outlet of the blank stacking mechanism, and the core setting mechanism is usedfor core-setting the neatly stacked blanks; a clamping mechanism is arranged beside the outlet of the blank stacking mechanism and used for clamping installation faces at the two ends of a blank; a drill bit is arranged beside the clamping mechanism, and the drill bit moves in the vertical direction of the installation faces at the two ends of the blank and conducts drilling operation. The systemcan automatically realize the introduction of the blanks, thereby realizing automatic drilling operation on the bearing pedestal, and improving the production efficiency and quality of the bearing pedestal.

Owner:岳西县顺达机械有限公司

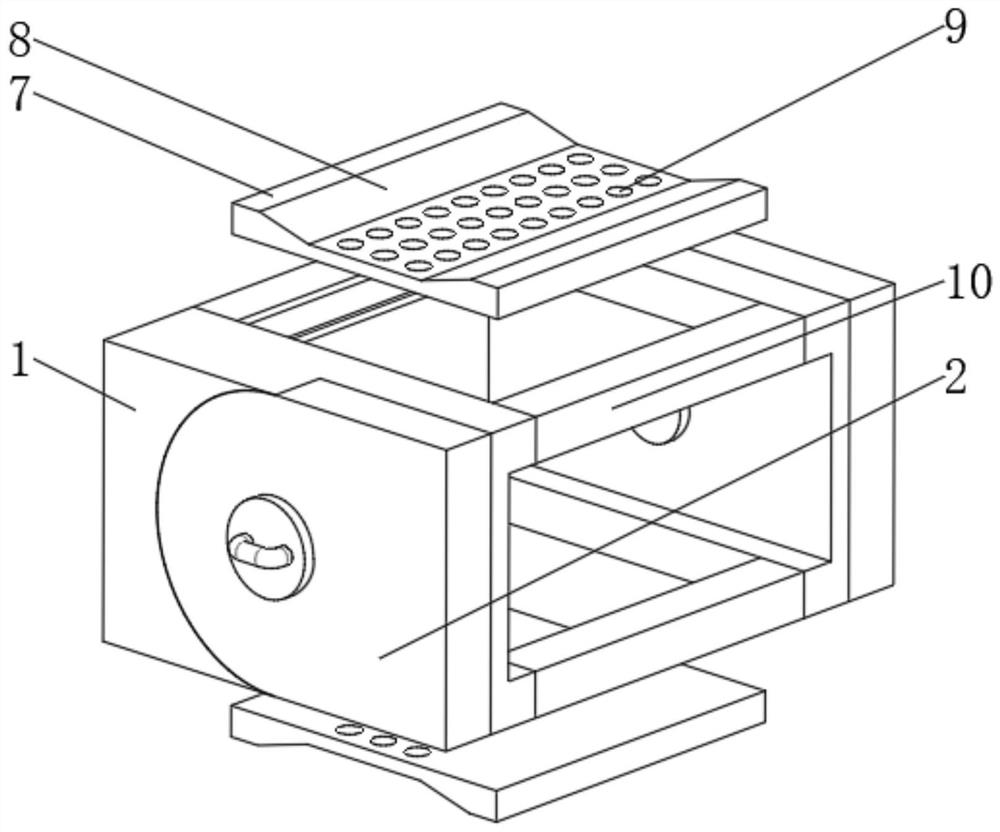

Nylon drag chain for numerical control tool bit movement

InactiveCN112081873AEasy to disassembleReduce wearHauling chainsHoisting chainsNumerical controlClassical mechanics

The invention relates to the technical field of numerical control accessories, and discloses a nylon drag chain for numerical control tool bit movement. The nylon drag chain for numerical control toolbit movement comprises a drag chain body composed of a plurality of drag chain female seats and a plurality of drag chain male seats, wherein female seat heads are fixedly installed in the middles ofthe left and right sides of the drag chain female seats; completely-through movable holes are formed in the front surfaces of the drag chain male seats; and the drag chain male seats are movably clamped with the female seat heads through the movable holes. According to the nylon drag chain for numerical control tool bit movement, the female seat heads are installed at the left ends and the rightends of the drag chain female seats, the drag chain male seats are movably clamped with the female seat heads through the movable holes in the drag chain male seats, the drag chain male seats are movably clamped with the female seat heads through magnetic blocks, and when the drag chain female seats and the drag chain male seats need to be disassembled, baffles can be disassembled firstly, and handles are pulled to drive the magnetic blocks to move relative to the movable holes so as to disassemble the magnetic blocks, so that tools are not needed for disassembly, magnetic adsorption is adopted for reducing abrasion, and the advantage that fixing pieces can be conveniently disassembled is achieved.

Owner:广州云弈科技有限公司

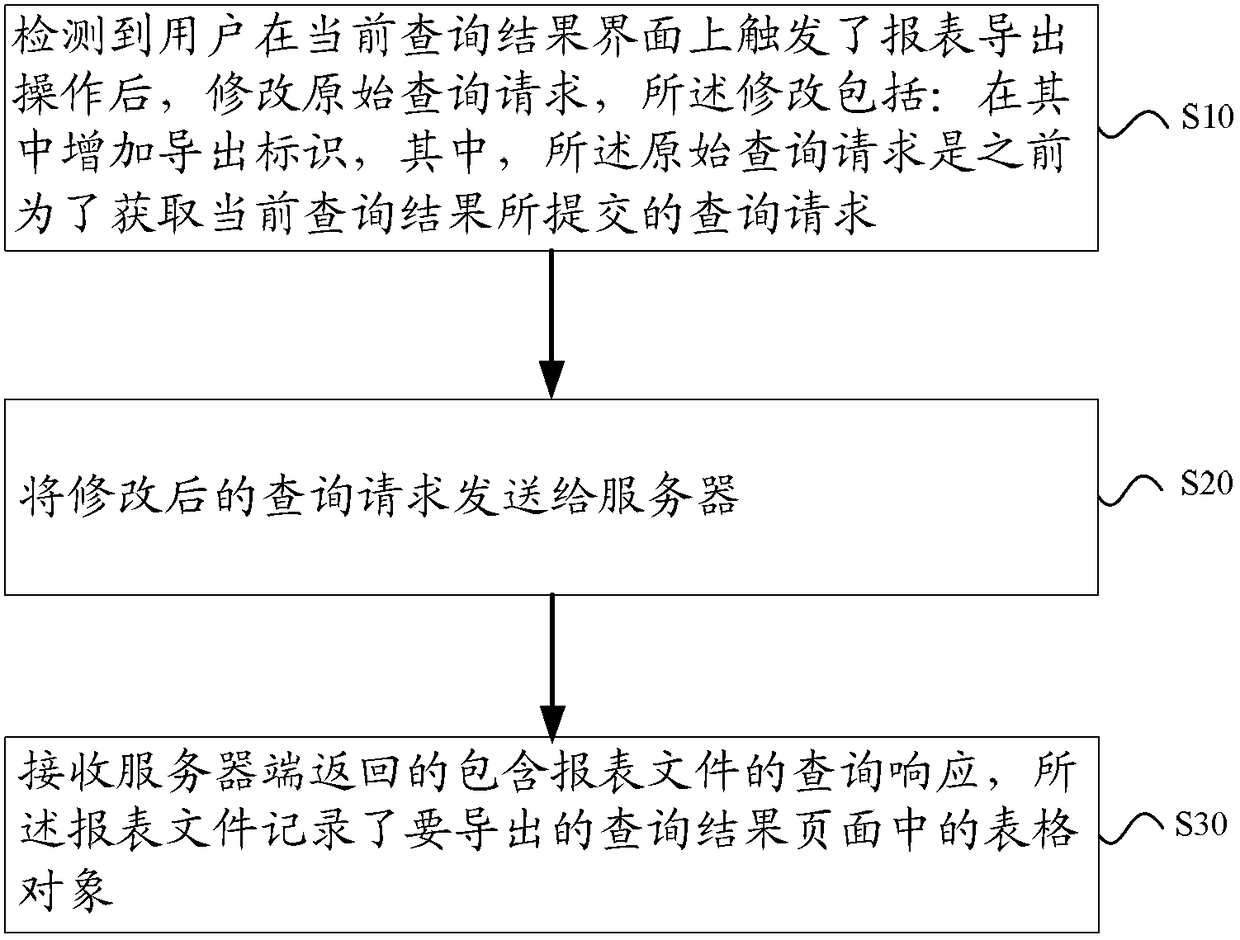

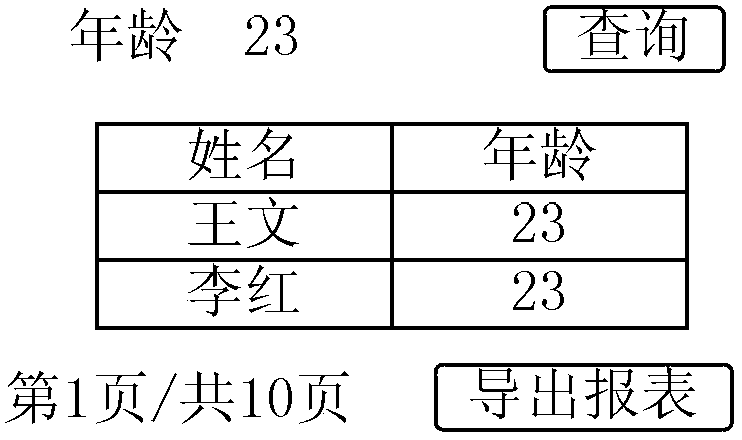

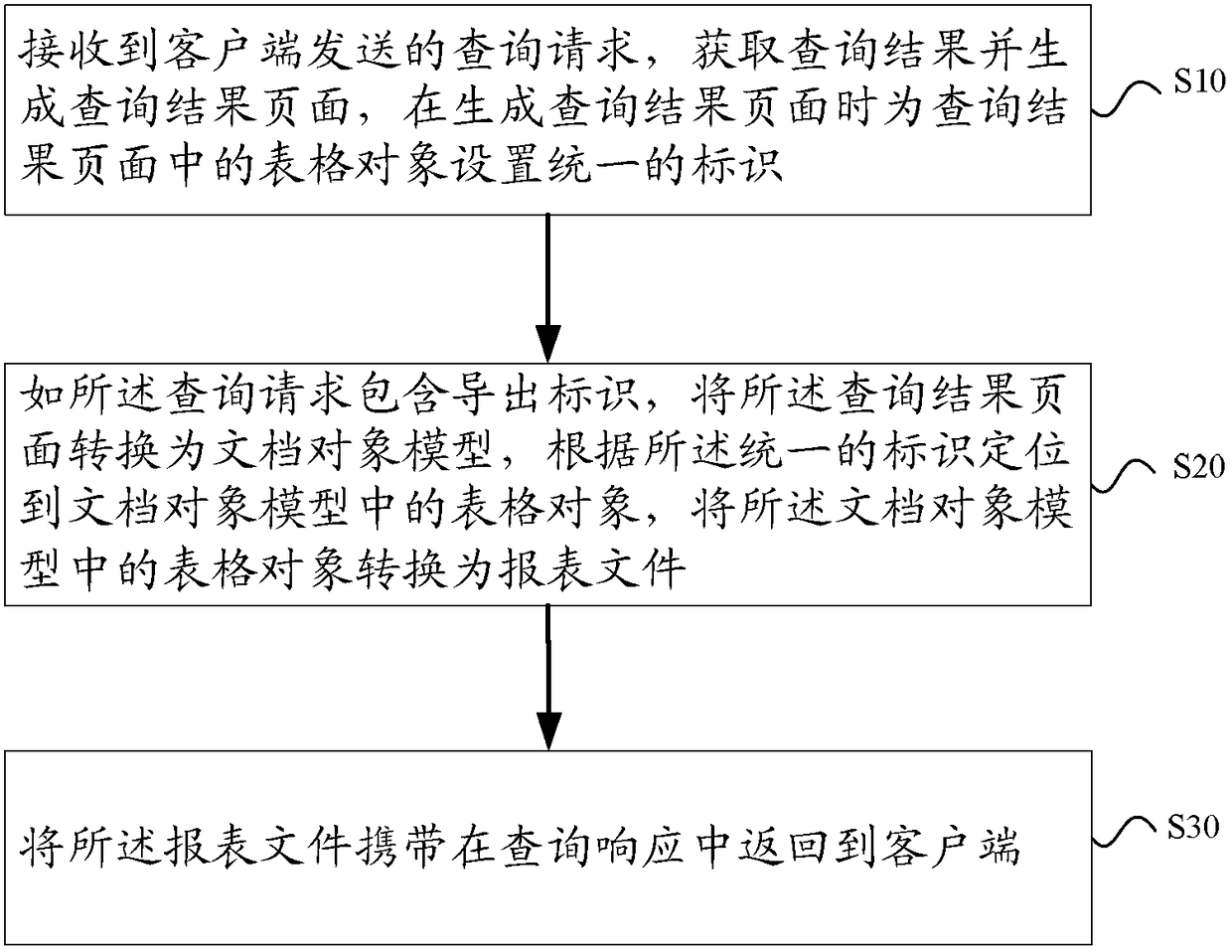

A method, device and system for exporting reports from a web query system

ActiveCN103473234BImprove development efficiencyImprove maintenance efficiencySpecial data processing applicationsClient-sideDocument Object Model

The invention discloses a method for exporting a report from a web query system, which is applied to a client, comprising: modifying an original query request after detecting that a user triggers a report export operation on a current query result interface, adding an export identifier and sending it to a server , to receive the response containing the report file returned by the server. A corresponding method applied to the server is also disclosed, including: receiving a query request sent by a client and generating a query result page, setting a uniform identifier for the table object in the query result page, if the query request includes an export identifier, and converting the query result The page is converted into the document object model, and the table object in the document object model is located according to the identifier, and the table object in the document object model is converted into a report file, which is carried in the response and returned to the client. The invention can achieve no intrusion to the server-side query program, realize the export of the WYSIWYG report file, and improve the efficiency of system development and maintenance.

Owner:ZTE CORP

Drilling device for mounting surface of bearing blank

ActiveCN111299654BIncrease productivityImprove product qualityStacking articlesMetal working apparatusStructural engineeringMechanics

The invention relates to a perforating device for mounting surfaces of bearing blanks. The perforating device comprises a blank stacking mechanism used for stacking the blanks in order. A core positioning mechanism is arranged at an outlet of the blank stacking mechanism and used for core positioning of the blanks stacked in order. A clamping mechanism is arranged beside the outlet of the blank stacking mechanism and used for clamping the mounting surfaces of the two ends of the blanks. Drill bits are arranged on the lateral sides of the clamping mechanism and vertically move along the mounting surfaces of the two ends of the blanks to conduct drilling. A discharging mechanism is arranged beside the blank stacking mechanism and used for discharging perforated bearings. By the adoption of the perforating device, the blanks can be automatically fed to realize automatic drilling of bearing seats, and the production efficiency and quality of the bearing seats are improved.

Owner:岳西县顺达机械有限公司

Reversing mechanism

ActiveCN109329363BExport implementationThe deboning operation went wellFish filletingFish arrangingControl engineeringControl cell

The invention relates to a reversing mechanism. The reversing mechanism comprises a main pipe, the main pipe is bent to extend downwards, a reversing pipe is arranged on a pipe body of the main pipe,the reversing pipe extends upwards and communicates with a suction port of a suction unit, a material guide pipe is arranged on a pipe body of the reversing pipe, the material guide pipe extends vertically downwards and communicates with the main pipe, a recognition unit is arranged in a position where the reversing pipe and the main pipe communicates, the recognition unit is used for recognizingthe tail and head of eel guided to the position, the recognition unit is connected with a control unit, and the control unit is used for controlling start and stop of the suction unit. The reversing mechanism can guide out the head of the eel in a set manner and ensure that the whole eel deboning operation is carried out smoothly.

Owner:苏州果汁网信息科技有限公司

Method for removing black edge of electronic scanning image of paper document

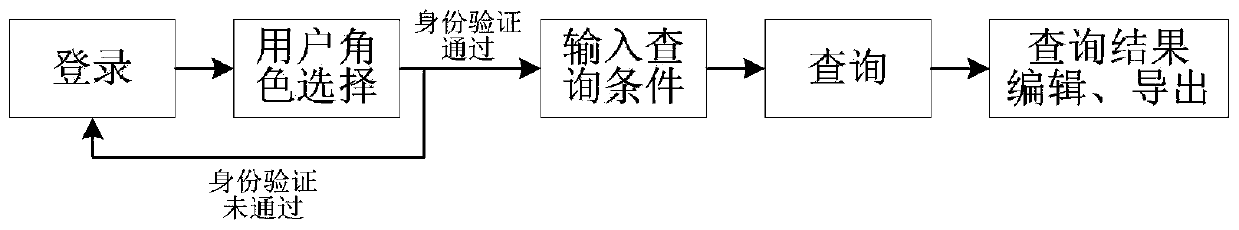

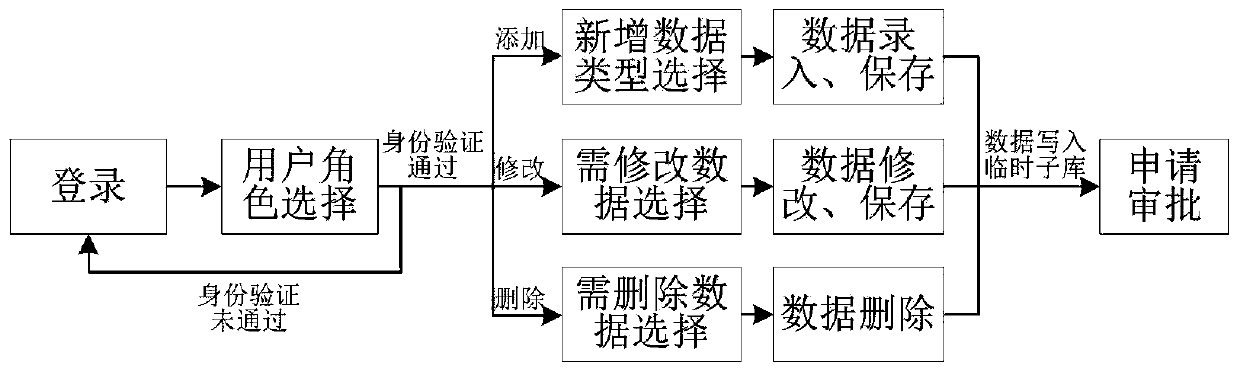

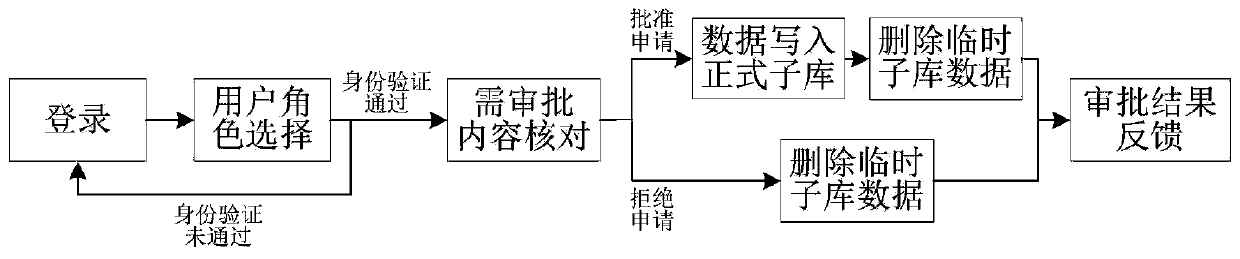

PendingCN111563485ARealize structured managementImprove securityImage enhancementCharacter and pattern recognitionSystems managementElectronic form

The invention relates to a method for removing black edges of an electronic scanning image, and specifically relates to a method for removing black edges of an electronic scanning image of paper document. The system comprises a system login module, a system management module, an employee management module, an approval management module and a policy regulation management module. Aiming at the requirements of generating and exporting various spreadsheets in an employee management process, information query, salary calculation and document exporting method researches are carried out, and exporting of multi-condition query results and exporting of editable contents in the aspect of document contents are realized, a fixed template format document is exported and a user-defined format document in the aspect of document format is exported. Through deployment and use of the system, on the basis that original employee archive management depends on a manual recording mode and only one paper original part exists, database management and electronic archive backup of employee information are achieved, the working efficiency is greatly improved, and the safety of employee archive data is ensured. Work requirements of users are met, and employee archive management problems are solved.

Owner:63653 FORCES PLA

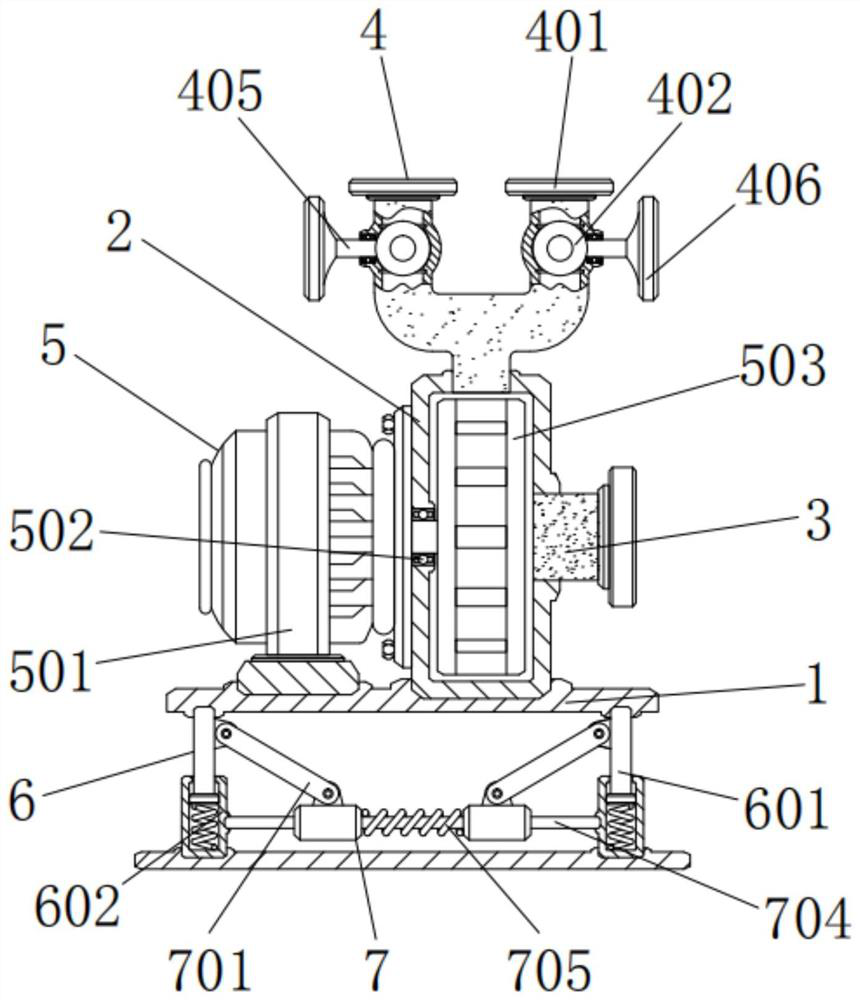

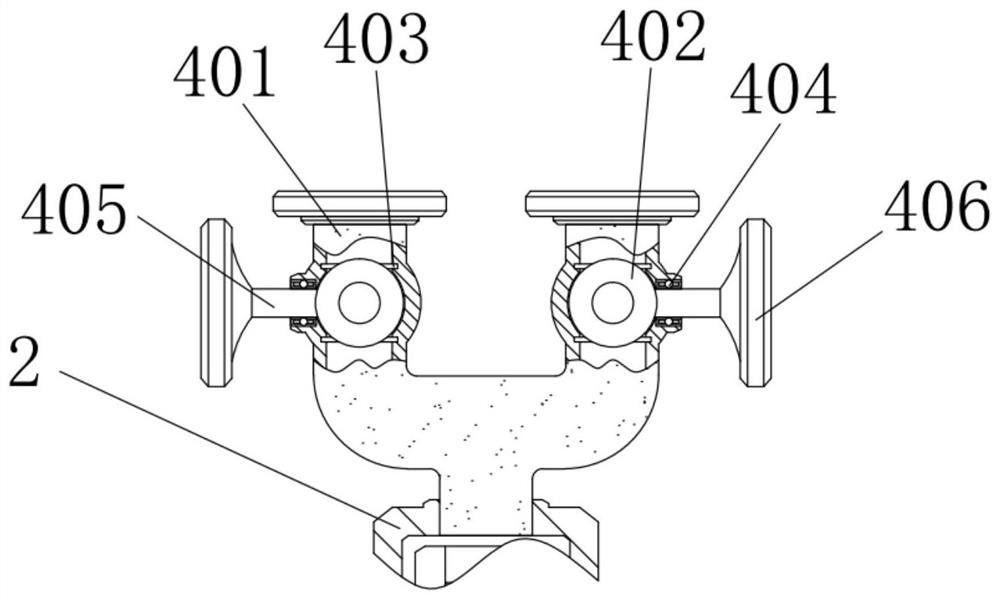

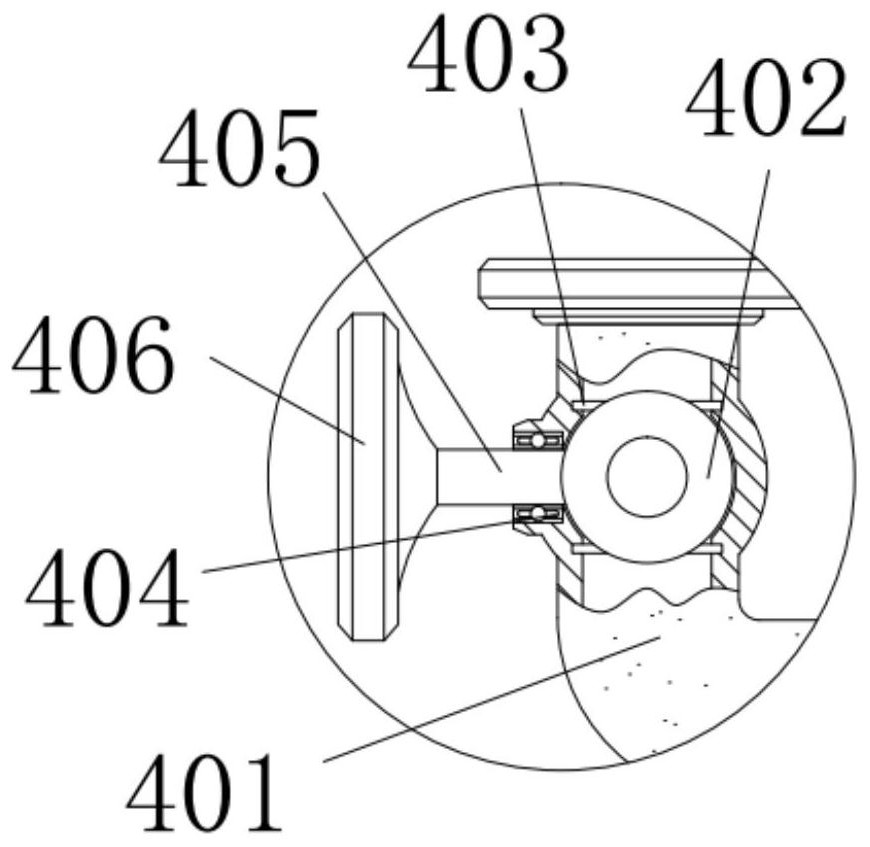

Multi-waterway intelligent output water pump

InactiveCN111622956AScientific and reasonable structureEasy to usePump componentsPump controlInterference fitMarine engineering

The invention discloses a multi-waterway intelligent output water pump. The water pump comprises a first transverse plate, a box body is fixedly connected to the top of the first transverse plate, a Y-shaped pipe communicates with the top of the box body, ball valves are in clearance fit with the inner walls of pipelines on the left side and the right side of the top of the Y-shaped pipe correspondingly, sealing rings are in interference fit with the tops and the bottoms of the ball valves, two round rods are rotationally connected with the inner walls of the pipelines on the left side and theright side of the top of the Y-shaped pipe through first sealing bearings correspondingly, and rotating discs are fixedly connected to the outer sides of the two round rods correspondingly. Accordingto the multi-waterway intelligent output water pump, the Y-shaped pipe can be connected with two pipelines, so that the conveying efficiency of the water pump is improved; the single-pipeline connection or double-pipeline connection can be conducted through the ball valves according to the requirements of a user; and buffering can be conducted through elastic deformation of a first spring and a second spring, so that the situation that when the water pump works, the vibration is generated, and a connecting pipe is driven to vibrate synchronously, so that the connection between the connectingpipe and the water pump is possibly loosened is avoided.

Owner:汪长霞

Cardboard Twisting Mechanism

Owner:安徽世品佳工业产品设计有限公司

Bearing pedestal machining method

ActiveCN111299655ARealize the drilling operationIncrease productivityStacking articlesPositioning apparatusStructural engineeringMachining

The invention relates to a bearing pedestal machining method. The method comprises the step of supplying bearing blanks, wherein an outlet of a blank supplying mechanism is linked to a feeding port ofa blank stacking mechanism, the blank stacking mechanism orderly stacks the blanks, a core fixing mechanism is arranged at an outlet of the blank stacking mechanism and conducts core fixing on the blanks which are orderly stacked, a clamping mechanism is arranged beside the outlet of the blank stacking mechanism, and is used for clamping mounting faces at the two ends of each blank, and a drill is arranged beside the clamping mechanism, and moves in the direction perpendicular to the mounting faces of the two ends of each blank and conducts drilling. By means of the bearing pedestal machiningmethod, the blanks can be automatically imported to achieve automatic drilling on bearing pedestals, and the production efficiency and quality of the bearing pedestals are improved.

Owner:岳西县顺达机械有限公司

Method and system for exporting memory data

ActiveCN105760241BImprove maintainabilityExport implementationFault responseMaintainabilityField data

The invention discloses an exporting method and system for memory data.A server system is detected in real time, when abnormal phenomena, such as crashes and accidental restart, occur to the server system, abnormal information of the server system is acquired, and the abnormality type to which the abnormality of the server system belongs is judged according to the abnormal information; on the basis, the server memory data is subjected to the processing process corresponding to the abnormality type, the server memory data is exported.Thus, when the abnormality occurs to the server system, field data of a server memory is effectively exported, support can be provided for following analysis of server abnormality reasons, and the maintainability of a server is improved.

Owner:LENOVO (BEIJING) LTD

Processing method of bearing seat

ActiveCN111299655BIncrease productivityImprove product qualityStacking articlesMetal working apparatusStructural engineeringMachining

The invention relates to a bearing pedestal machining method. The method comprises the step of supplying bearing blanks, wherein an outlet of a blank supplying mechanism is linked to a feeding port ofa blank stacking mechanism, the blank stacking mechanism orderly stacks the blanks, a core fixing mechanism is arranged at an outlet of the blank stacking mechanism and conducts core fixing on the blanks which are orderly stacked, a clamping mechanism is arranged beside the outlet of the blank stacking mechanism, and is used for clamping mounting faces at the two ends of each blank, and a drill is arranged beside the clamping mechanism, and moves in the direction perpendicular to the mounting faces of the two ends of each blank and conducts drilling. By means of the bearing pedestal machiningmethod, the blanks can be automatically imported to achieve automatic drilling on bearing pedestals, and the production efficiency and quality of the bearing pedestals are improved.

Owner:岳西县顺达机械有限公司

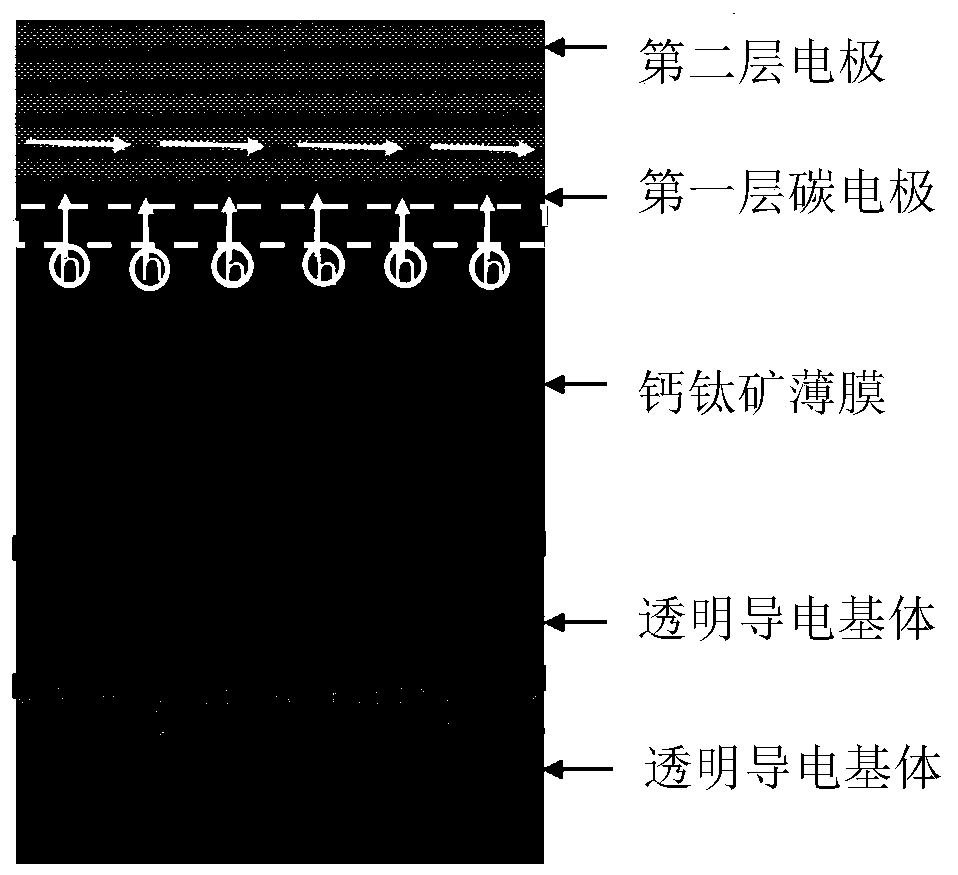

A kind of double-layer electrode perovskite solar cell and preparation method thereof

ActiveCN107910445BImprove performanceIncrease contactFinal product manufactureSolid-state devicesPerovskite solar cellElectrical battery

Owner:咸阳瞪羚谷新材料科技有限公司

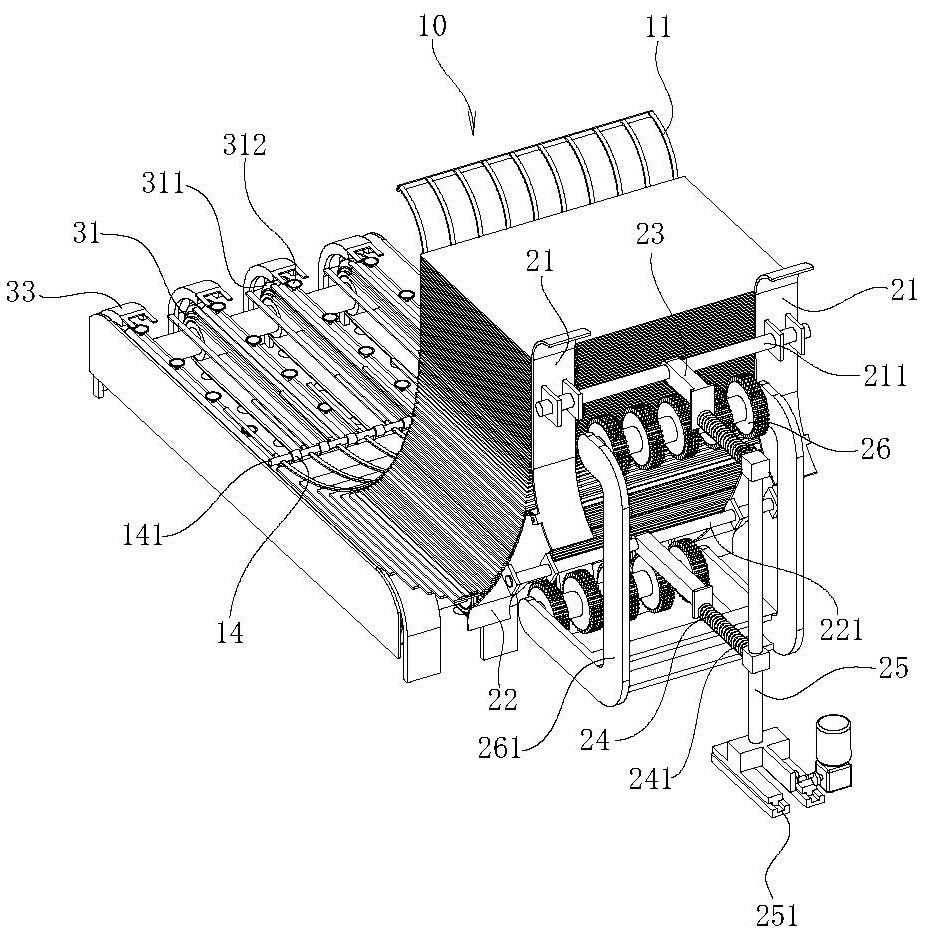

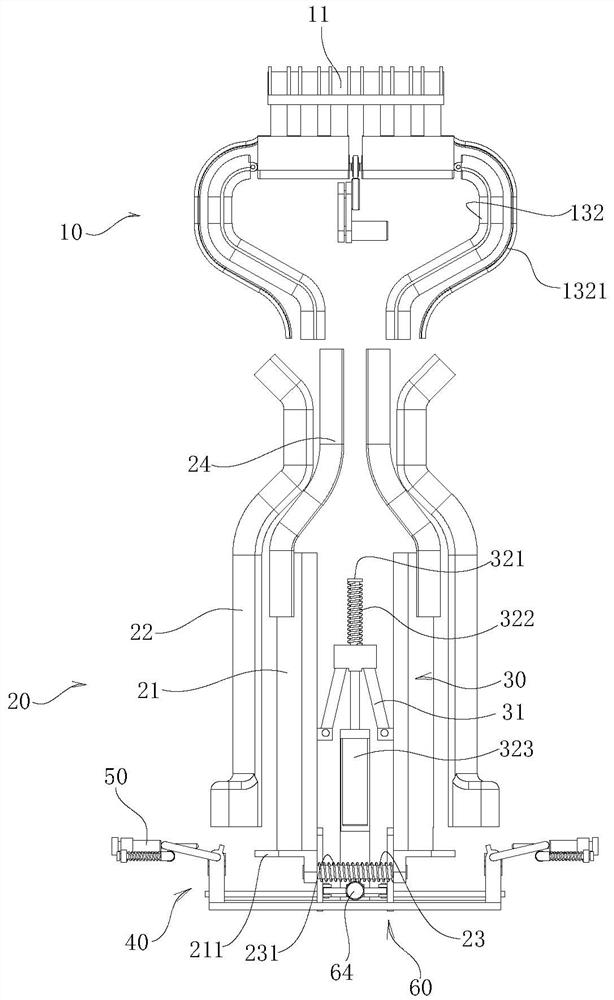

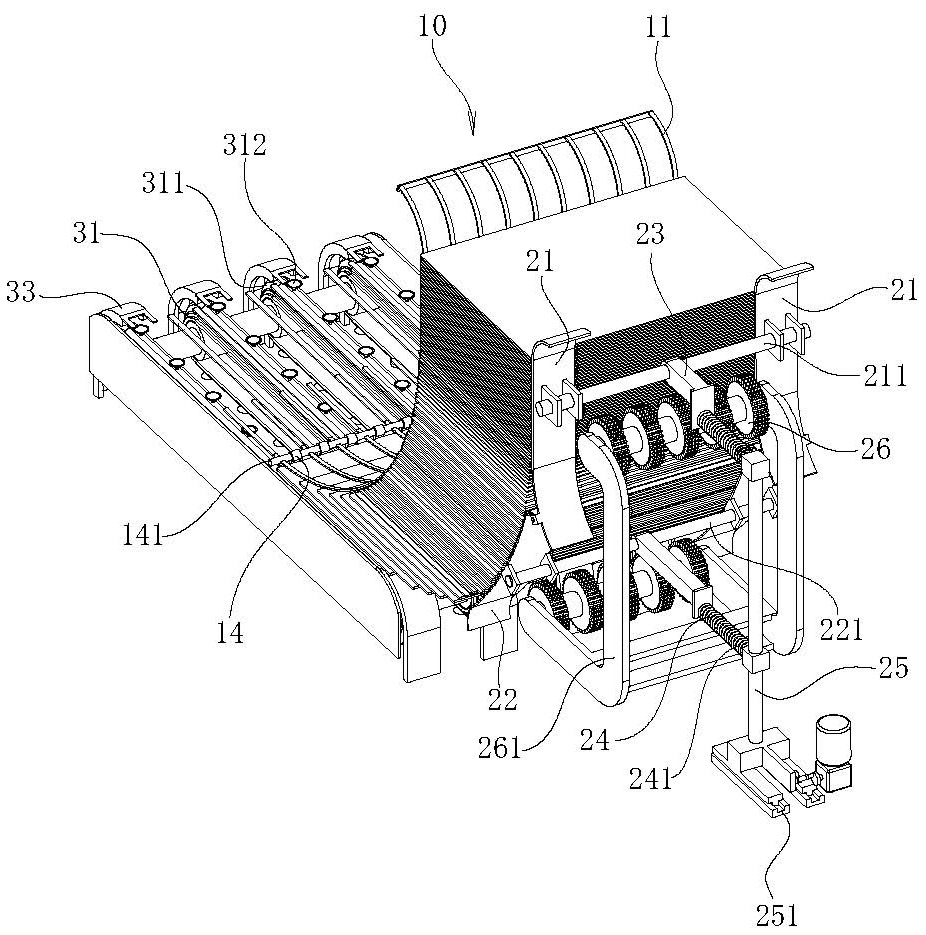

Cardboard export device

ActiveCN110143013BGuaranteed production efficiencyExport implementationPaper-makingBox making operationsPaperboardProcess engineering

The invention discloses a paperboard guide-out device. The paperboard guide-out device comprises a paper guide fence, wherein paperboards are stacked in the paper guide fence; an outlet is formed in the lower portion of the paper guide fence; one side of the paper guide fence is equipped with a pushing mechanism which is used for dispersing stacked paperboards, and pushing the paperboards to the outlet position of the fence; a paper spreading mechanism is arranged on the outlet position of the paper guide fence; the paper spreading mechanism is used for guiding out single paperboard from the outlet of the paper guide fence; when raw material paperboards of a packaging box are practically guided out, the raw material paperboards are stacked in the paper guide fence; and the pushing mechanism is utilized for pushing out the raw material paperboards and dispersing the stacked paperboards, and then, single paperboard is guided out by the paper spreading mechanism at the outlet position ofthe paper guide fence, so that raw material paperboards of the packaging box are guided out into follow-up production equipment one by one for production, and therefore, the paperboard guide-out device can ensure production efficiency of the packaging box.

Owner:安徽世品佳工业产品设计有限公司

Paperboard pushing mechanism

ActiveCN110253939AExport implementationBox making operationsPaper-makingPaperboardPulp and paper industry

The invention relates to a paperboard pushing mechanism comprising a paper guiding fence. Paperboards are stacked in the paper guiding fence, an outlet is formed below the paper guiding fence, a pushing mechanism is arranged on one side of the paper guiding fence, the paper guiding fence comprises a side surrounding plate formed by grating strips, the grating strips downwards extend in an arc shape, the extending end is horizontal, the pushing mechanism is arranged on one sides of the grating strips, the pushing direction is horizontal, and the pushing mechanism pushes the paperboards to abut against the grating strips; under the pushing action of the pushing mechanism, one side ends of the paperboards abut against one sides of the grating strips, so that the stacked paperboards are sequentially arranged along the grating strips, and one sides of the stacked paperboards are staggered; and under the pushing effect of the pushing mechanism, the paperboards are guided out from the horizontal extending sides of the grating strips, the staggered sides of the paperboards are guided out from one sides of the horizontal sections of the grating strips, and guide-out operation of the paperboards is further completed.

Owner:安徽世品佳工业产品设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com