Cutting-off device for water soluble chitosan textile processing

A technology of water-soluble chitosan and cutting device, which is applied in textiles and papermaking, textile material cutting, fabric surface trimming, etc. It can solve the inconvenience of cutting, the lack of fabric wrinkle removal, low degree of compression and straightening, etc. problem, to achieve the effect of improving the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

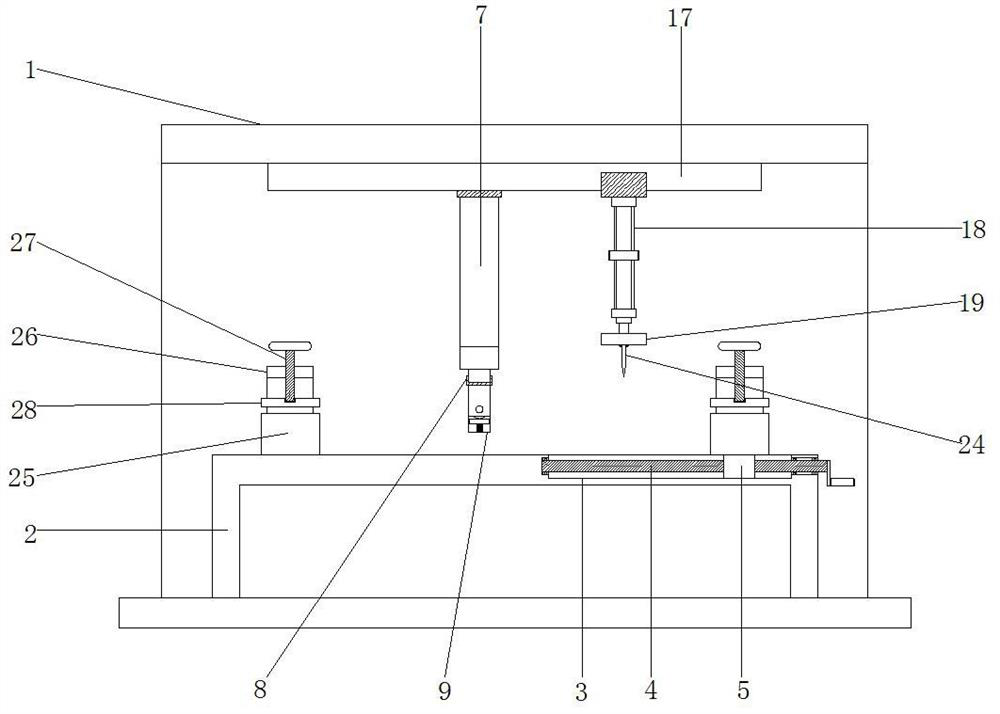

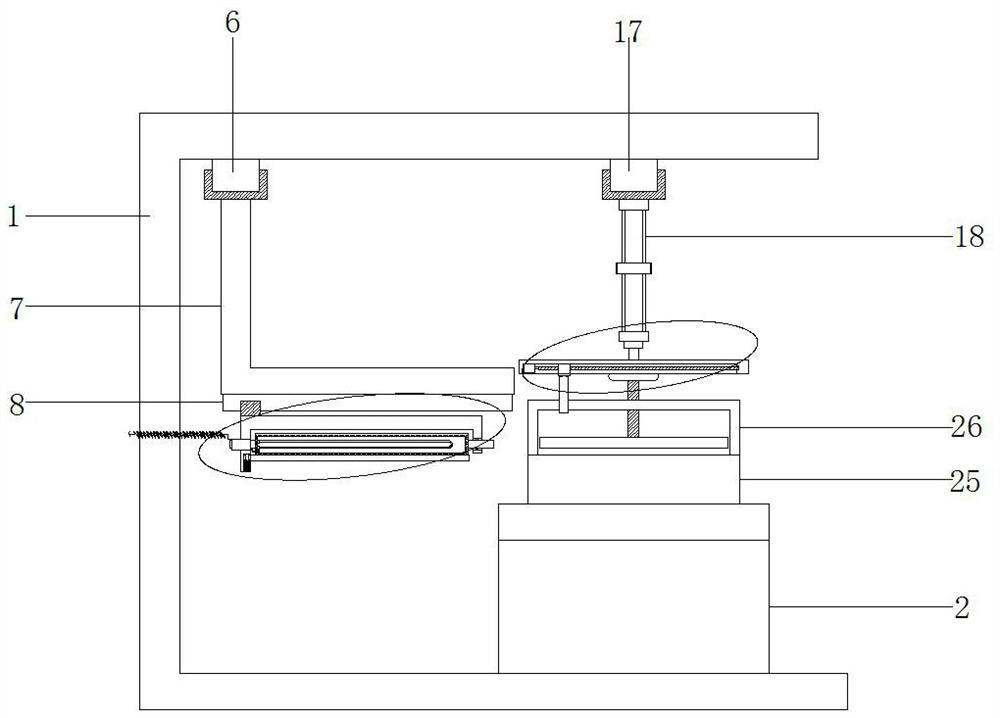

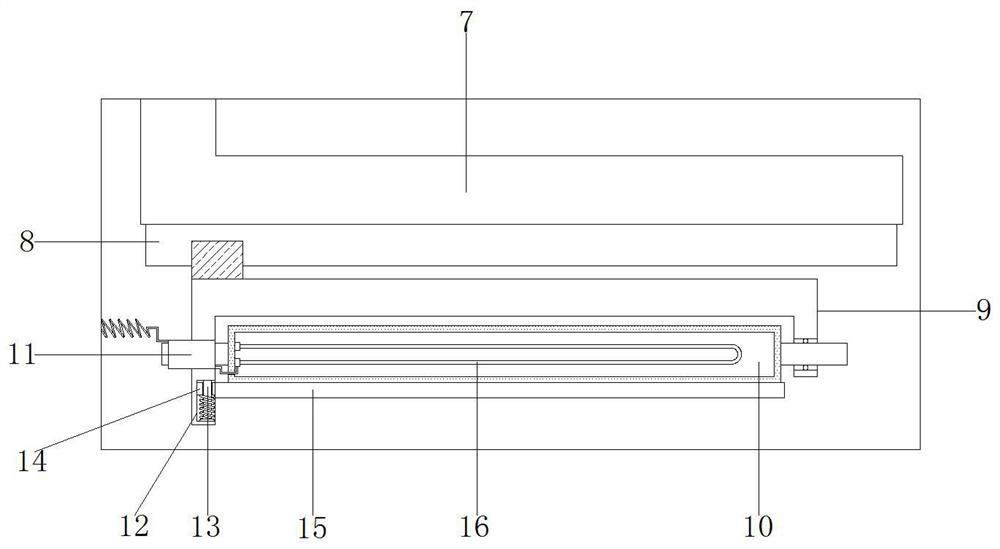

[0021] Embodiment 1, with reference to Figure 1-4 , a cutting device for water-soluble chitosan textile processing, including a mounting frame 1, the mounting frame 1 is a "C"-shaped structure, and the bottom of the mounting frame 1 is fixed to the ground by bolts, and a fixing platform is welded on the inner wall of the bottom of the mounting frame 1 2. There is a chute 3 at one end of the top of the fixed table 2, and a threaded rod 4 is arranged in the chute 3, and one end of the threaded rod 4 is connected with the inner wall of one side of the chute 3 through a bearing, and the other end of the threaded rod 4 is fixed with a bearing through a bearing. The outer wall on one side of the platform 2 is connected, and the threaded rod 4 is screwed with a slider 5 and the top is welded with a first fixing mechanism, and the top of the fixed platform 2 is welded with a second fixing mechanism at one end away from the first fixing mechanism. The two fixing mechanisms all include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com