Damping unit with torque limiter arranged between spring damper and centrifugal pendulum

A technology of torque limiter and spring shock absorber, applied in the direction of spring/shock absorber, rotational vibration suppression, vibration suppression adjustment, etc., can solve the problem of large design size of vibration damping unit, and achieve the effect of solid design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

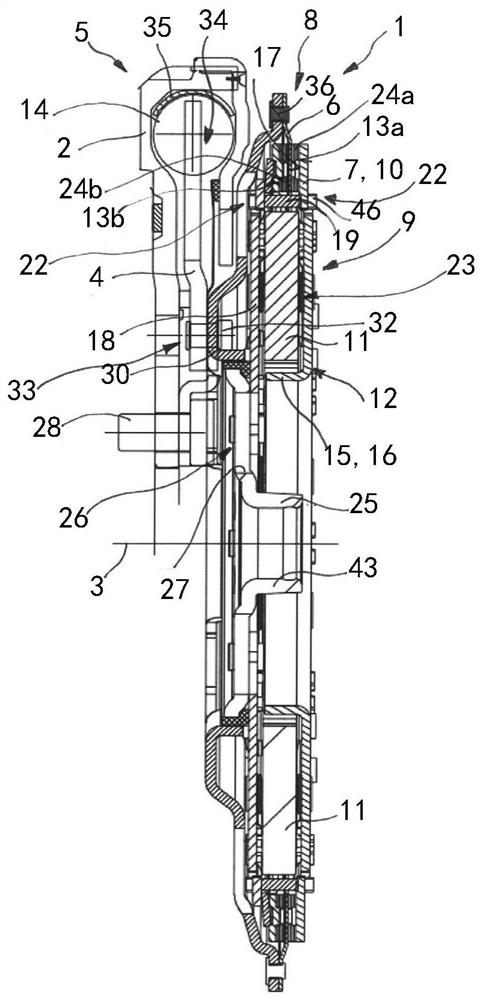

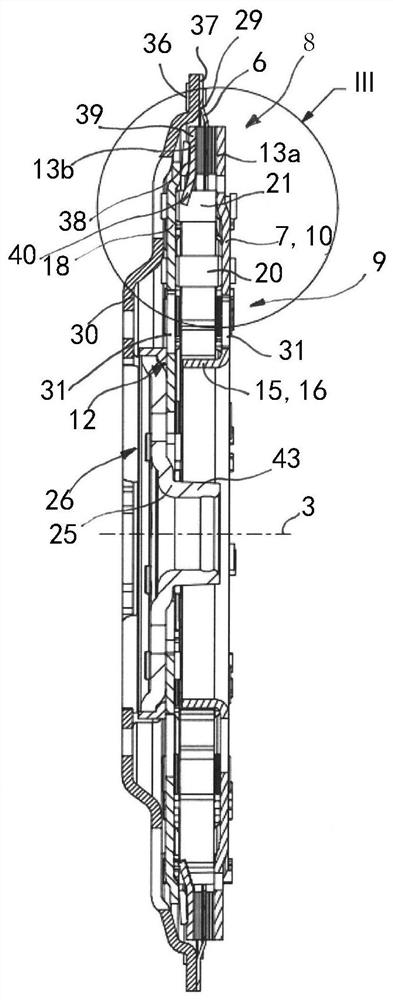

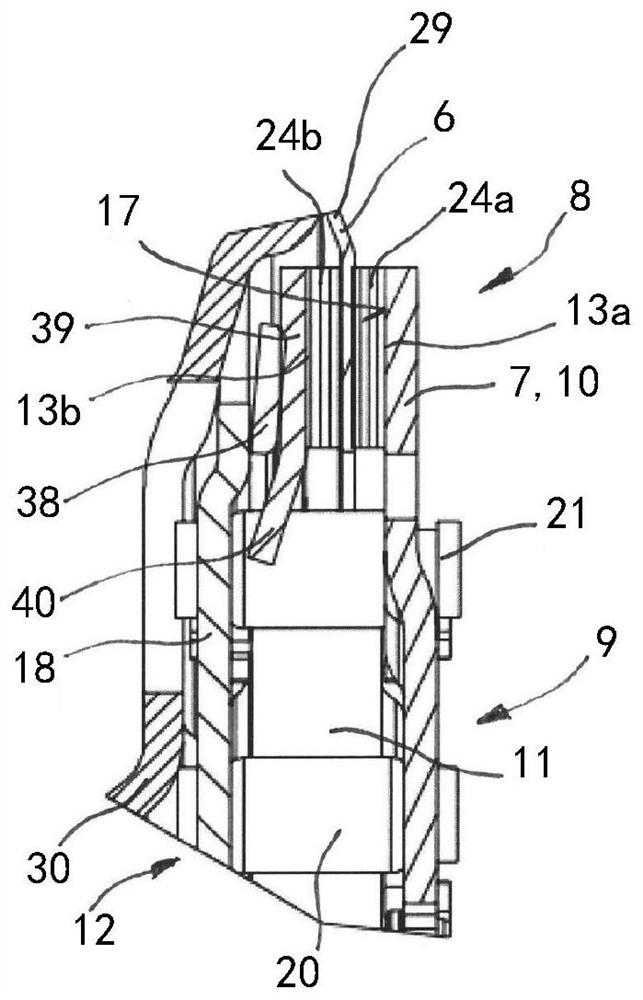

[0037] with the help of figure 1 The vibration-damping unit 1 according to the invention which corresponds to the preferred embodiment in its construction is clearly shown. The damping unit 1 is designed for a hybrid motor vehicle drivetrain. The damping unit 1 is therefore used for damping torsional vibrations that occur during operation of the motor vehicle drivetrain. Viewed along the torque transmission path, the damping unit 1 is usually installed between the crankshaft of the internal combustion engine and the transmission of the powertrain. The damping unit 1 basically has three components. A first component is realized in the form of a spring damper 5 , a second component is realized in the form of a torque limiter 8 and a third component is realized in the form of a centrifugal pendulum 9 . These three components 5, 8, 9 are arranged in series / tandem along the torque transmission path.

[0038] Regarding the spring damper 5, in figure 1 It can also be seen in FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com