Self-cleaning purification device for ventilation system

A technology of fresh air system and purification device, applied in air conditioning system, application, household heating and other directions, can solve the problems of high labor intensity and troublesome operation, and achieve the effect of avoiding disassembly and cleaning, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

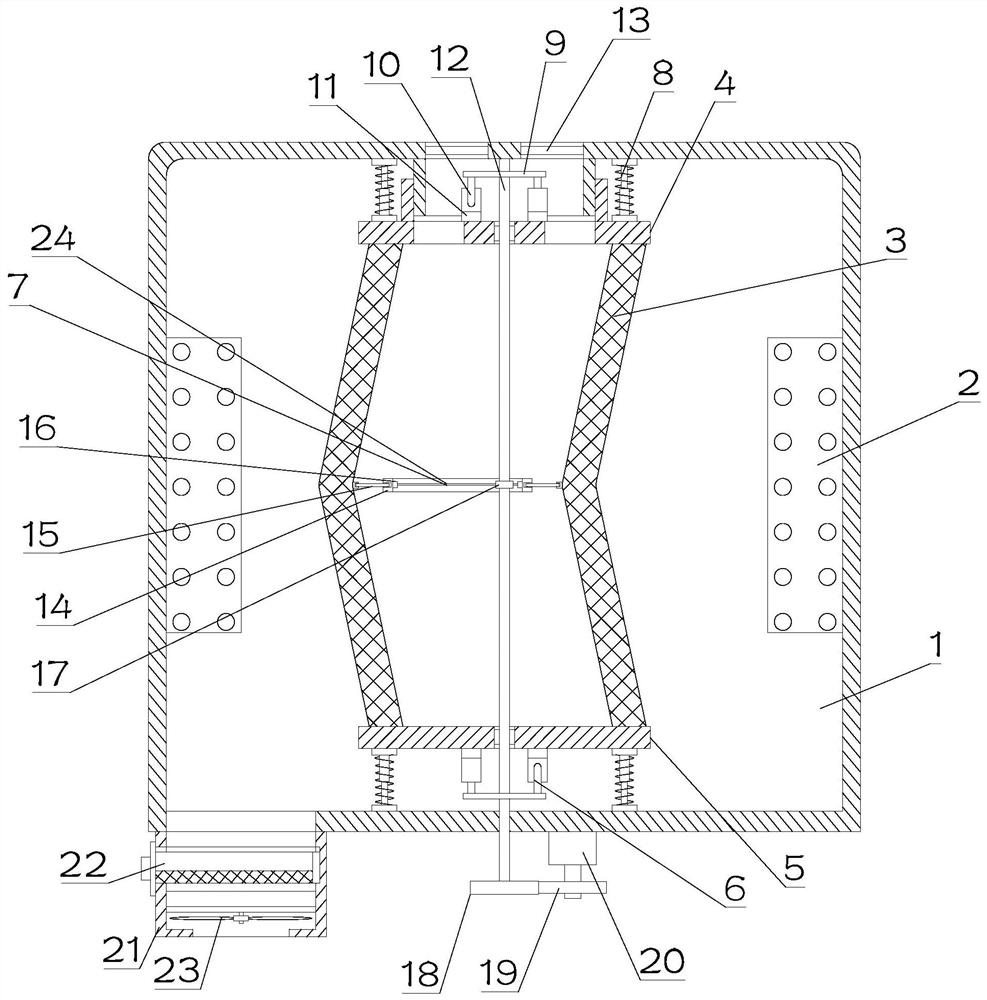

[0027] see Figure 1~3 , in Embodiment 1 of the present invention, it is a structural diagram of a self-cleaning purification device for a fresh air system provided by the embodiment of the present invention, including: a device main body 1, which is hollow inside;

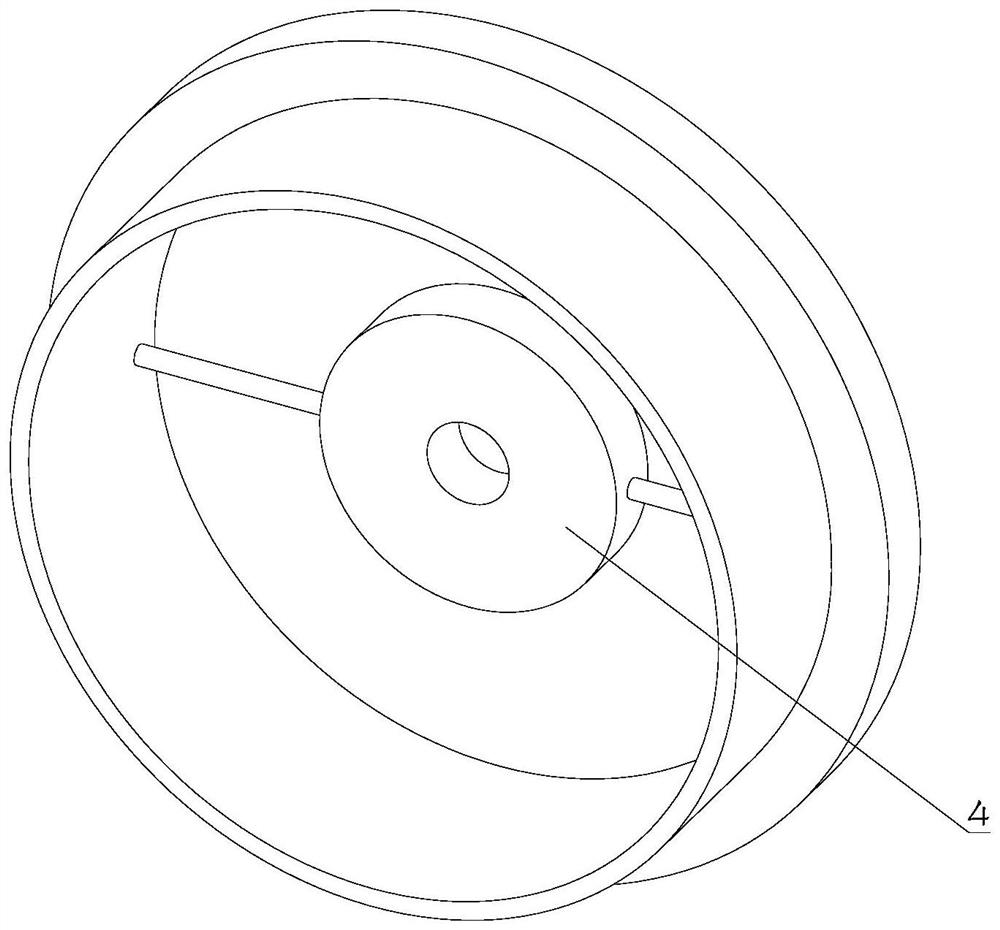

[0028] The flexible filter cartridge 3 is arranged in the middle of the device main body 1, and its upper and lower ends are installed on the upper connecting ring 4 and the lower sealing ring 5 respectively, and the flexible filter cartridge 3 is used to filter the air entering the device main body 1;

[0029] Two groups of reciprocating vibration components 6 respectively drive the upper connecting ring 4 and the lower sealing ring 5 to reciprocate up and down;

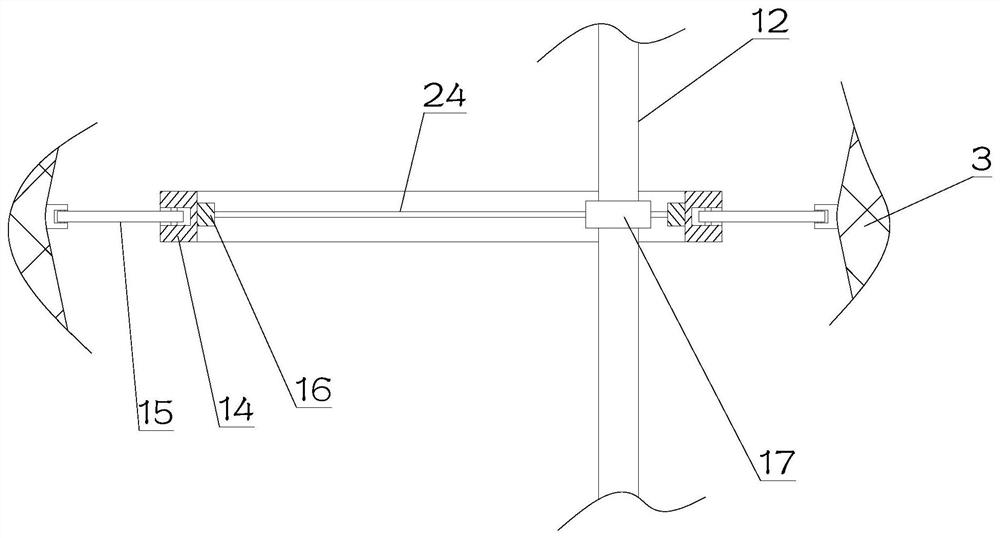

[0030] The swing assembly 7 is arranged in the middle position inside the flexible filter cartridge 3;

[0031] The rotating shaft 12 is arranged inside the flexible filter cartridge 3 for self-rotation, and the rotating shaft 12 installed on the devic...

Embodiment 2

[0035] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that the inside of the device main body 1 is cylindrical, and the outer side of the device main body 1 is provided with a plurality of air inlets 2 in an array, and the plurality of air inlets 2 and the device body 1 The communication port is tangent to the inner wall of the device main body 1, and the upper part of the device main body 1 is provided with an air outlet 13, and the air outlet 13 communicates with the inside of the flexible filter cartridge 3 through the upper connecting ring 4, and this setting further allows the air to rotate into the device main body 1, so that the air rotates through the flexible filter cartridge 3 to filter, so that part of the dust in the air falls under the action of centrifugal force, improving the filtering effect.

[0036] The reciprocating vibration assembly 6 includes a driving rod 10 symmetrically installed on both sides of the rotating shaft 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com