A magnetic suspension motor with high reliability vibration compensation

A vibration compensation and reliability technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of reduced motor reliability, excessive rotor axial force, mechanical wear, etc., to reduce unreliability, breathing resistance, etc. Small, eliminate the effect of beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

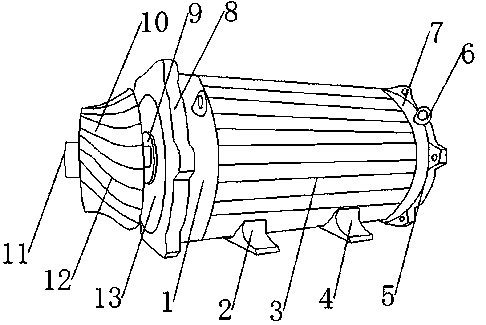

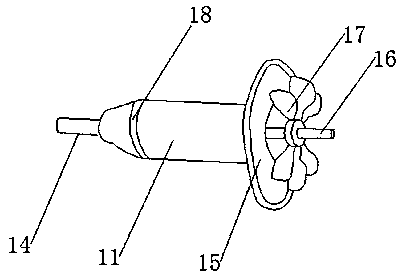

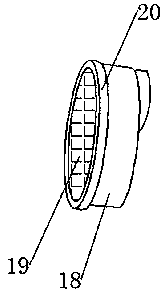

[0022] Example 1: See Figure 1-3 , the present invention provides a technical solution: a magnetic levitation motor with high reliability vibration compensation, including a motor body 1, a first leg 2, a heat dissipation rib 3, a second leg 4, a bearing cover 5, a suspension ring 6, an end cover 7, Rotor sleeve 8, position sensor 9, impeller 10, rotor 11, boundary line 12, limit ring 13, installation shaft 14, axial buffer mechanism 15, iron core 16, impeller blade 17, electrostatic precipitator 18, filter screen 19 and sealing cover 20, the bottom side of the motor body 1 is provided with a first leg 2, one side of the first leg 2 is provided with a second leg 4, one side of the motor body 1 is provided with a rotor sleeve 8, and the motor body 1 is provided with a rotor sleeve 8. The other side is provided with an end cover 7, the side end of the rotor sleeve 8 is provided with a limit ring 13, the middle part of the limit ring 13 is provided with a position sensor 9, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com