Optical fiber ring implementation method of a small-caliber cylindrical high-precision optical fiber gyroscope

A technology of fiber optic gyroscope and implementation method, which is applied in Sagnac effect gyroscopes, gyroscope/steering sensing equipment, measuring devices, etc., to achieve the effect of improving output accuracy and realizing high-precision performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly illustrate the present invention, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings. Those skilled in the art understand that the following content does not limit the protection scope of the present invention, and any improvements and changes made on the basis of the present invention are within the protection scope of the present invention.

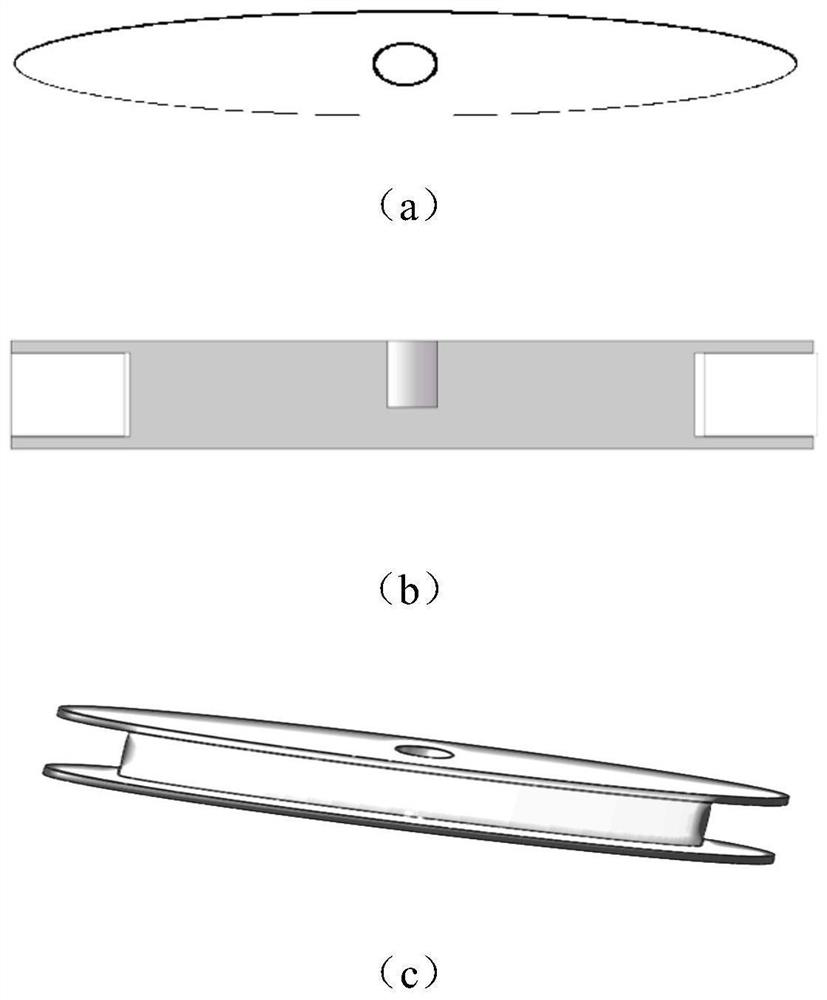

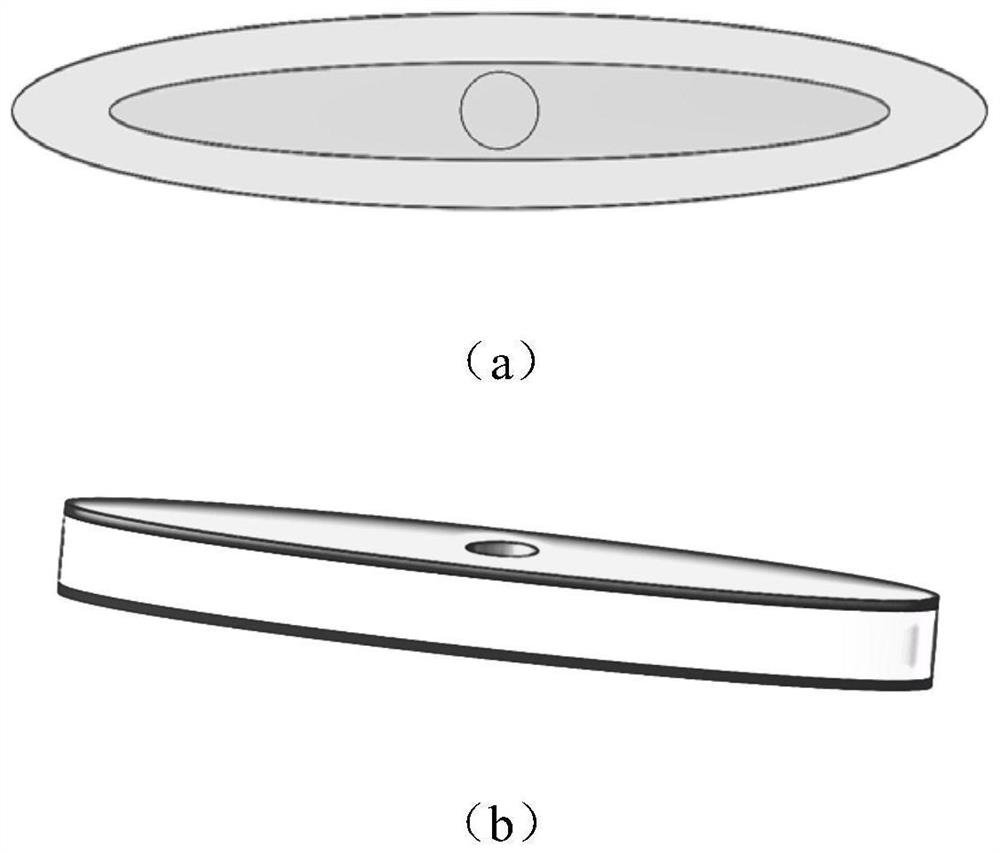

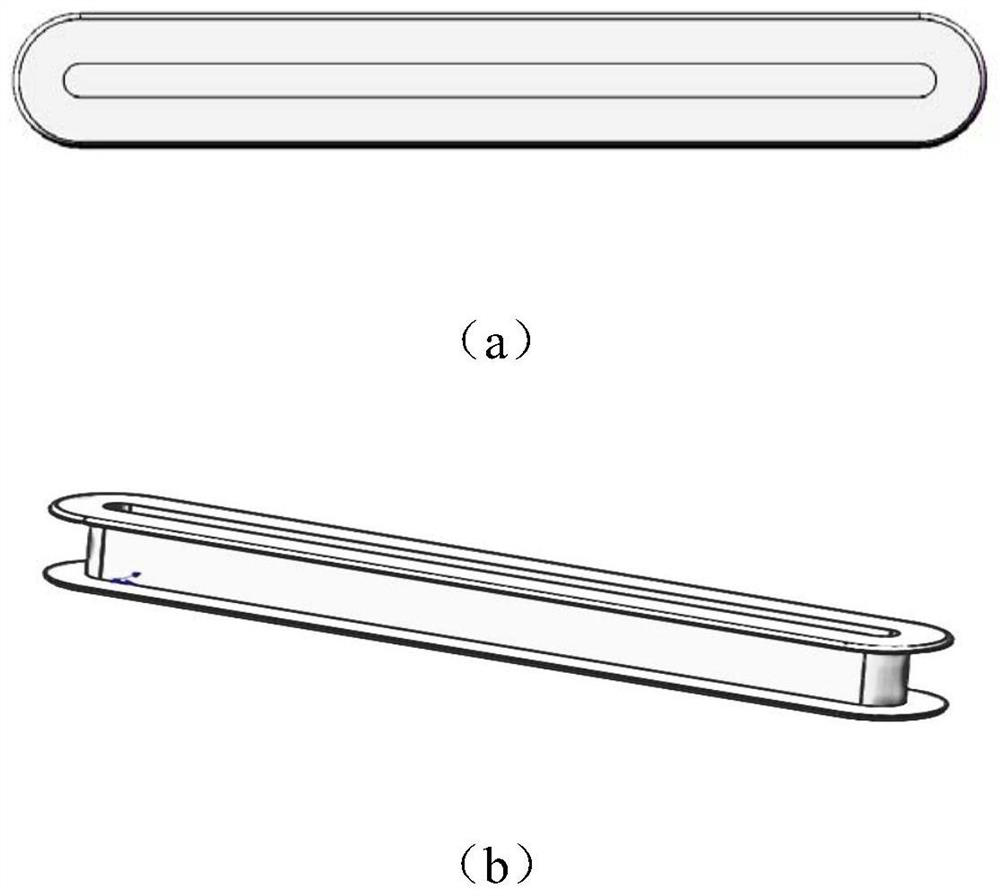

[0026] The invention adopts the design of a plurality of small cylindrical optical fiber rings to ensure the winding length of the optical fiber under the condition of limited diameter. In order to improve the heterogeneity of the connection methods of multiple cylindrical fiber rings, and to offset the asymmetric stress generated in the winding process between multiple fiber rings, two connection methods between cylindrical fiber rings were designed, and a targeted proposal was made. Technical requirements for optical fiber surround sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com