Method and structure for annealing giant magnetoresistance sensor

A resistance and magnetic field technology, applied in the field of magnetoresistive sensors, can solve the problems of low precision and low efficiency, and achieve the effect of overcoming low precision and realizing industrial mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

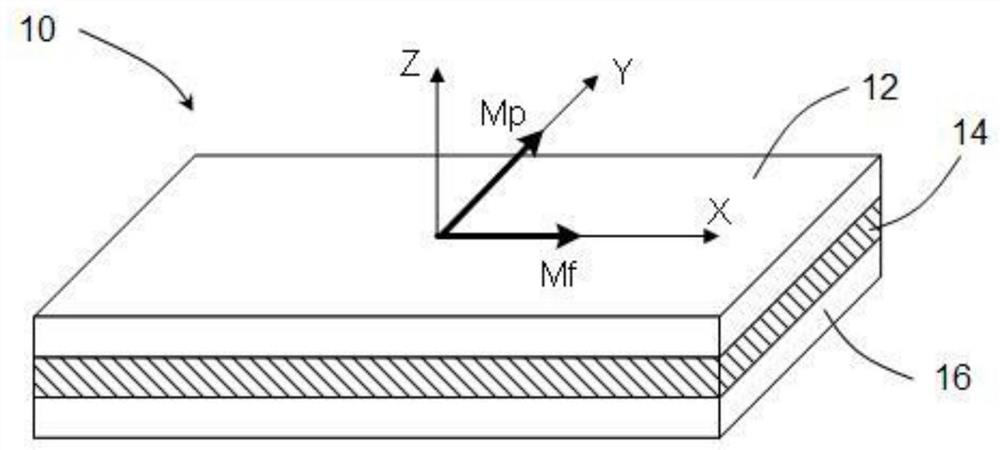

[0058] The invention discloses an annealing method and mechanism for making the pinned layer of the MR resistor in the MR resistor have different magnetization directions. In particular, the pinned layers of adjacent MR resistors have completely opposite magnetization directions. In one example, the annealed MR resistors can be assembled into a Wheatstone full bridge. This MR resistance structure can be applied in any magnetoresistance, such as GMR (giant magnetoresistance) and TMR (tunneling magnetoresistance).

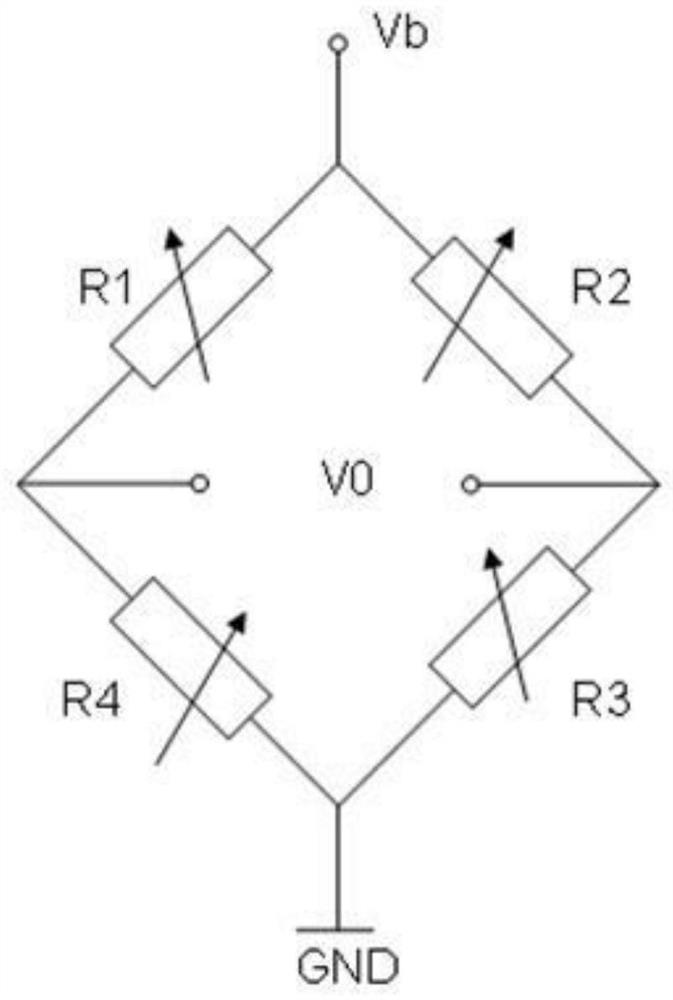

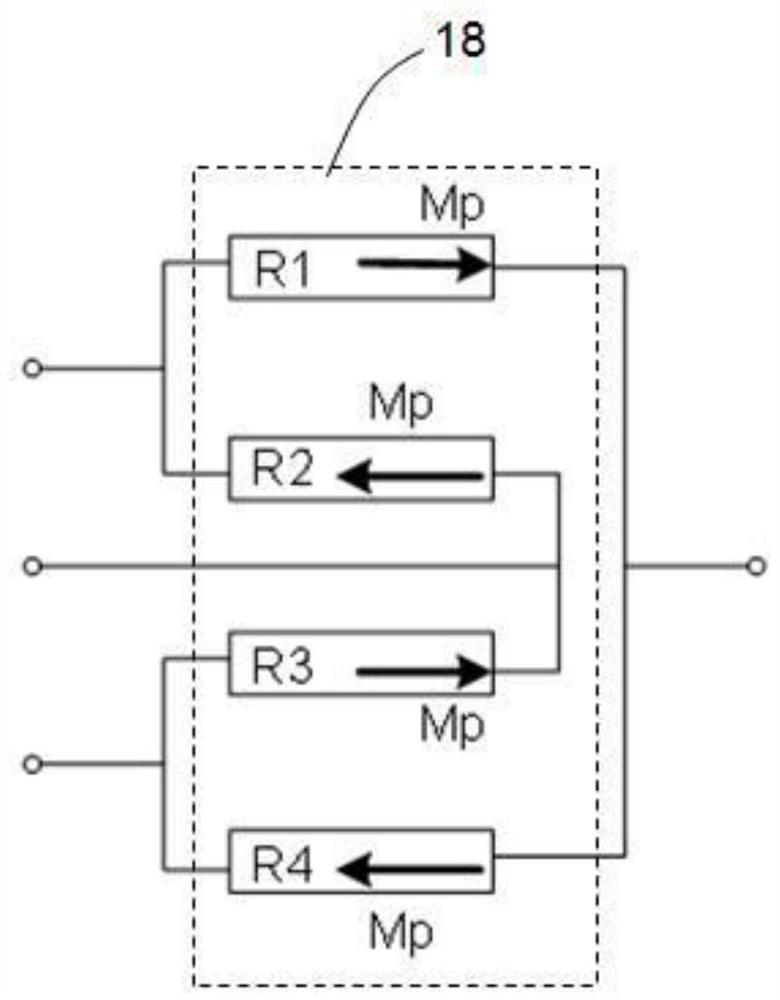

[0059] as above reference image 3 As described in , an MR Wheatstone full-bridge sensor usually requires four MR resistive structures, where each MR structure behaves as a magnetoresistance, such as GMR or TMR. Each MR magnetoresistor in a Wheatstone full bridge is capable of varying with the magnetic field being measured (the magnetic field has been sensed or tested). Adjacent magnetoresistors have opposite M p direction. Many times, MR sensors are fabricated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com